集装箱龙门起重机起升机构传动装置设计【含6张CAD图纸、说明书】

收藏

资源目录

压缩包内文档预览:

编号:17286899

类型:共享资源

大小:899.43KB

格式:ZIP

上传时间:2019-04-03

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

100

积分

- 关 键 词:

-

含6张CAD图纸、说明书

集装箱龙门起重机起升机构传动装置设计【

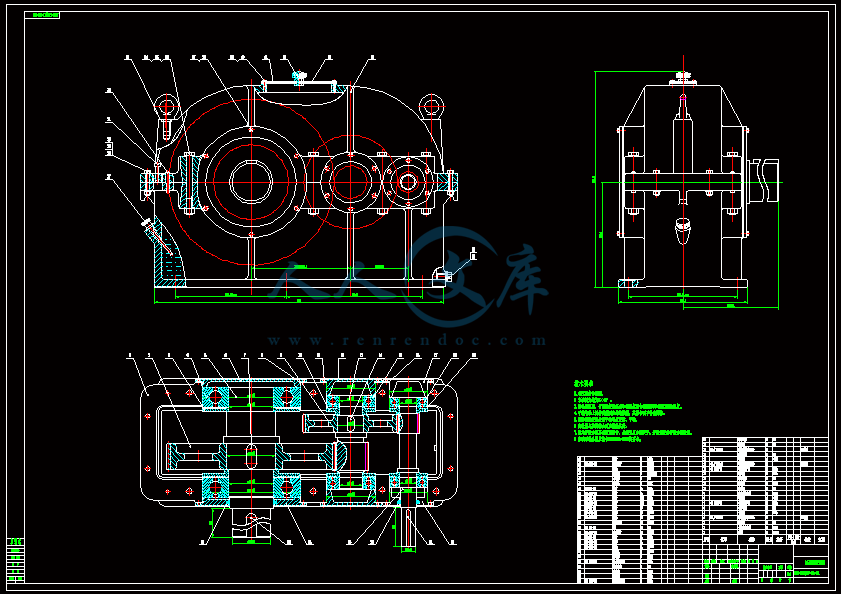

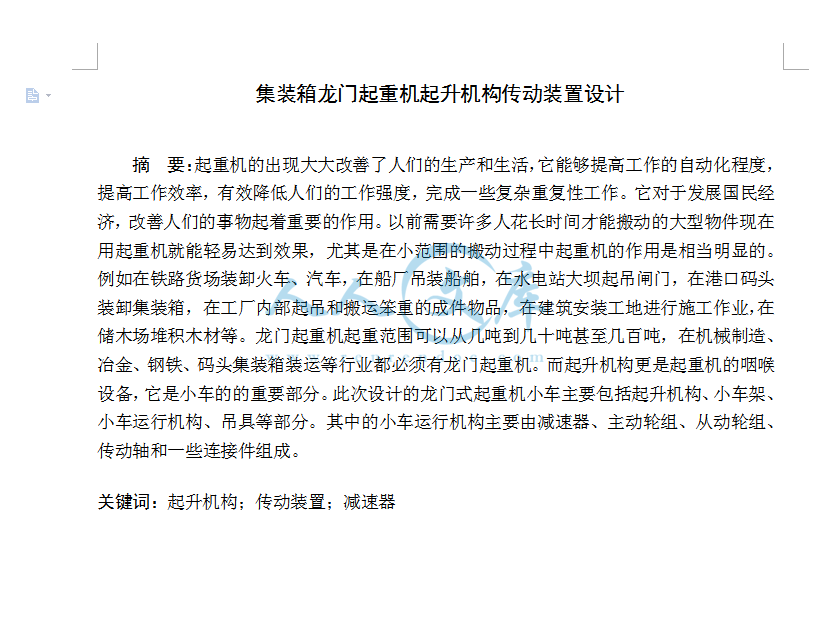

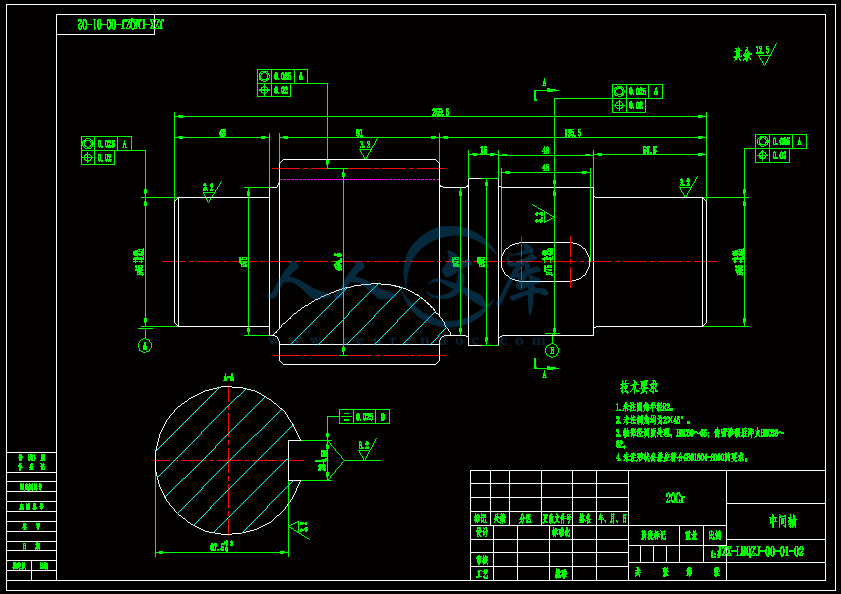

集装箱龙门起重机起升机构传动装置设计

6张CAD图纸

起升机构设计

集装箱龙门起重机设计

张CAD图纸

- 资源描述:

-

- 内容简介:

-

附录A:Hoist crane metal structureFlows -like in the hoist crane, the majority of tire hoist crane, the crawler crane as well as the partial autohoist and special-purpose flows -like the hoist crane, all installs has clothes rack the bracket arm, and through lifts using its peak block and tackle installs changes lifts the steel wire position, thus realization heavy item fluctuation; Again changes its height of lift and the working radius through the change clothes rack bracket arm length and the angle of tilt. Therefore, maintenance clothes rack bracket arm incompleteness is extremely important. Because the hoist crane rises and falls the heavy item work content the multiplicity and all kinds of work environment, as well as the hoist crane pilot operational level high low status reason (has also contrary operation), these can create clothes rack the bracket arm varying degree damage, even folds the arm or the personnel casualtyOn clothes rack the bracket arm steel pipe is specially in the welding place, very easy to appear the crack; This must examine carefully, when necessity applies the magnifying glass careful observation. According to we many year experiences, is very small when the crater place crack, must carry on the regular track inspection, gazes at the crack closely the development change, in order to take the measure promptly. When crack width as big as 1mm above, should the prompt patching. The concrete method is, carries on first to the crack place original crater polishes, removes how many to regard the special details to decide; Then carries on the patching; Finally renovates well then.When the pit depth achieved the steel pipe the arm thick size, also the pit distortion diameter achieves when 25mm (diameter for 25mm) and a straightedge, if the pit position in clothes rack on the bracket arm steel pipe surface, then defers to the method which shown in Figure 1 to determine the pit the depth, soon chooses the good steel ball to put in the pit, if the steel ball apex up just could with right angle under along the contact, we be possible to regard the steel ball by now the diameter for the pit depth. If the pit position in the steel pipe side or under, after may use the butter to stick to first the steel ball carries on again the survey. To this kind of maintenance damage, the available general material quality and the original steel pipe same steel pipe welding reinforcement, namely takes section of steel pipes to divide into along the middle line two half, builds its nose the incline, has exempted the crater to be vertical to clothes rack the bracket arm steel pipe length direction. Must treat in front of welding the original clothes rack bracket arm steel pipe above welds place paints polishes cleanly front, prepares for welds When clothes rack the bracket arm simple root steel pipe surface damage quite is serious, should adopt its damage serious section of steel pipes removes, welds section of steel pipes the method to carry on processing, but must add on a section inside the steel pipe to strengthen the steel pipe. Front in order to cause to weld strengthens the steel pipe to be able the smooth insertion to remove in a section of clothes rack bracket arm steel pipe, strengthens the steel pipe to be supposed to make the similarly long two sections, and uses the thread successively and welds two ways to carry on the connection. Strengthens steel pipe L1 and L2s length must a section of short 20mm which removes compared to clothes rack the bracket arm steel pipe, also its outer diameter should compared to clothes rack bracket arm steel pipe inside diameter small 2040 m, cause to strengthen the steel pipe both to be possible to move in clothes rack the bracket arm steel pipe and no longer becomes less crowded. Will strengthen steel pipe L1 and L2 first inserts clothes rack in separately the bracket arm steel pipe, and will use them the screw joint not to be able to get up, then will screw tight causes two shoulders to depend on strictly, will hold looks strengthens the steel pipe after the position, after will occupy separately its screwtop the position, separately and two will weld its screwtop place the jail already to be possible. Clothes rack the bracket arm steel pipe crater must make the incline, when the steel pipe spool thread perpendicular line included angle for 1030 between, like the damage is the multi-root steel pipe, should choose 10. Here, again earnestly surveys clothes rack the bracket arm steel tube welding good after actual gap size, and refers to the shape which shown in Figure 2, the next section of steel tubing material, the both sides make 30 inclines, cuts open the welding along among in clothes rack in the bracket arm steel pipe gap; Finishing touch, paints then This time, 4 steel pipes all must weld, therefore should defer to Figure 4 requests the vehicle to make 4 inside diameters to strengthen the tube, after the inside diameter strengthens wall thickness which the tube turning remains to be supposed not to be bigger than clothes rack the bracket arm steel pipe thickness, the middle crater slope must be able to satisfy the strength of a weld the need. At the same time, the entire clothes rack bracket arm 4 steel pipe welding position must stagger, cannot in the identical lateral section, also each steel pipe crater in its spool thread perpendicular line included angle should be 10.Welds repairs time must pay attention: Chooses the appropriate welding rod and the material quality reasonable strengthens the steel pipe; Also must pay attention to the ambient temperature in the fall winter season and weld the explanation labor embryo clamping apparatus and so on to entire to weld repairs the quality the influence, as well as the welding circumference welded joint do not have to be vertical with the original steel pipe length direction.The weak clothes rack bracket arm goes against the sheave pintle the wearing capacity to surpass the full size time 5%, namely should replace. When examination, clothes rack the bracket arm will place in a bearing point, will cause to lift the steel wire to relax, the hand will push the pulley if will rock the quantity to be very big, will have to dismantle with the ruler surveys, otherwise added an oil to be possible.To connects the crown arm festival (lift hook block and tackle), the middle arm festival (expands and contracts cylinder fixedly), the foundation arm festival (with turnplate, amplitude cylinder, keeps off cord pulley axis) and so on place to sell the axis also to have to inspect frequently. When its wearing capacity achieved when full size 5%, must replace promptly. When inspection, also is places clothes rack the bracket arm in a bearing point, dismantles one, inspects one, again installs one, by root inspection, until checkoff.Inspects the lift hook the mark and guards against escapes installs whether conforms to the requirement, flaws and so on lift hook whether there is crack, stripping; The lift hook cross section wears, the aperture increase, the torsional deflection, whether exceeds the allowed figure; The lift hook pate and the superficial whether there is weary distortion, the crack and do the correlation sell the axis, the wrap attrition situation. The inspection steel wire specification, the model and the pulley reel matches whether conforms to the design requirement. Steel wire steel wire attachment systems and so on fixed end clamp, line anchor, agreement block whether conforms to the requirement. The steel wire attrition, breaks the silk, the kinking, compressing, the bend, breaks the stock, the corrosion and so on whether exceeds the allowed figure.Brake establishment, brake pattern whether conforms to the design requirement, brake flaws and so on tension bar, spring whether there is weary distortion, crack; Sells the axis, the spindle, the brake pulley, the brake lining plate whether wears exceeds the allowed figure, hydraulic brake whether oil leak; Applies the brake the gap adjustment, whether brake power conforms to the requirement. The reel body, does the tube reason whether there is fatigue cracking, damage and so on the situations; The rope trough and the tube wall wears whether exceeds the allowed figure; Whether the reel wheel rim highly and does the steel wire twine the layer to match; Guide rope, wireline guide working condition whether conforms to the requirement;Whether the pulley is equipped with guards against escapes the rope trough installment; Pulley rope trough, wheel rim whether has the crack, the ragged edges, the attrition exceeds the allowed figure and so on the conditions, the pulley rotates whether nimbly. The speed reducer moves when whether there is fierce metal fricative, vibration, shell radiation and so on unusual sound; Whether the axial-tab terminal does seal complete, whether the set bolt does have conditions loosely and so on damage; The speed reducer lubricating oil choice, the oil level height, the vertical speed reducer gun movement, opens the type gear drive lubrication and so on whether conforms to the requirement. Wheel roller face, wheel axle whether has the fatigue cracking phenomenon, the wheel roller face wheel axle wears whether exceeds the allowed figure. Whether in the movement appears gnaws the axle phenomenon. Creates gnaws the axle the reason is any. Does the shaft coupling components whether there is damage, the connection become less crowded, movement impact phenomenon. The shaft coupling, sells the axis, the axis cotter hole, the cushion oak rubber or plastic rings wears whether exceeds the allowed figure. The shaft coupling with two parts which connects whether concentric。附录B:起重机金属结构流动式起重机中,大部分轮胎起重机、履带起重机以及部分汽车起重机和专用流动式起重机,都安装有桁架臂,并利用其顶端的滑轮组通过起升装置来改变起升钢丝绳的位置,从而实现重物的升降;再通过改变桁架臂的长度和倾斜角度来改变其提升高度和工作半径。因此,保持桁架臂的完好是非常重要的。因为起重机升降重物作业内容的多样性和各式各样的作业环境,以及起重机驾驶员操作水平的高低等原因(有的还违规操作),这些都会造成桁架臂不同程度的损伤,甚至折臂或人员伤亡。在桁架臂钢管上特别是在焊接处,很容易出现裂纹;这要仔细地查看,必要时应用放大镜仔细观察。根据我们多年的经验,在焊口处的裂纹很小时,就要进行定期跟踪检查,密切注视裂纹的发展变化,以便及时采取措施。当裂纹的宽度大到1mm以上时,就应及时补焊。具体的方法是,先对裂纹处的原焊口进行打磨,去掉多少则视具体情况而定;然后进行补焊;最后整修好即可。当坑的深度达到钢管的臂厚尺寸、且坑的变形直径达到25mm时(直径为25mm)和一把直尺,如果坑的位置在桁架臂钢管的表面上,即可按照图1所示的方法测出坑的深度,即将选好的钢球放入坑中,如果钢球的上顶点刚好能与直角的下边沿接触,这时我们就可以视钢球的直径为坑的深度。如果坑的位置在钢管的侧面或下面,可先用黄油将钢球粘住后再进行测量。对这种维护的损伤,可用一般材质与原钢管相同的钢管焊接加固,即取一段钢管沿中心线分成两半,将其端部修成斜面,已免焊口垂直于桁架臂钢管的长度方向。在焊前须将原桁架臂钢管上面待焊处的涂漆打磨干净,做好焊前准备。当桁架臂单根钢管表面的损伤比较严重时,应该采取将其损伤严重的一段钢管去掉、重新焊上一段钢管的方法进行处理,但在钢管里面必须加上一段加强钢管。为使焊前加强钢管能顺利的插入已去掉一段的桁架臂钢管内,加强钢管应做成同样长的两段,并先后采用螺纹和焊接两种方式进行连接。加强钢管L1和L2的长度须比桁架臂钢管去掉的一段短20mm,且其外径应比桁架臂钢管的内径小2040m,以使加强钢管在桁架臂钢管内既可以移动又不再松动。先将加强钢管L1和L2分别插入桁架臂钢管内,并将它们用螺纹连接起不来,然后拧紧使

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号