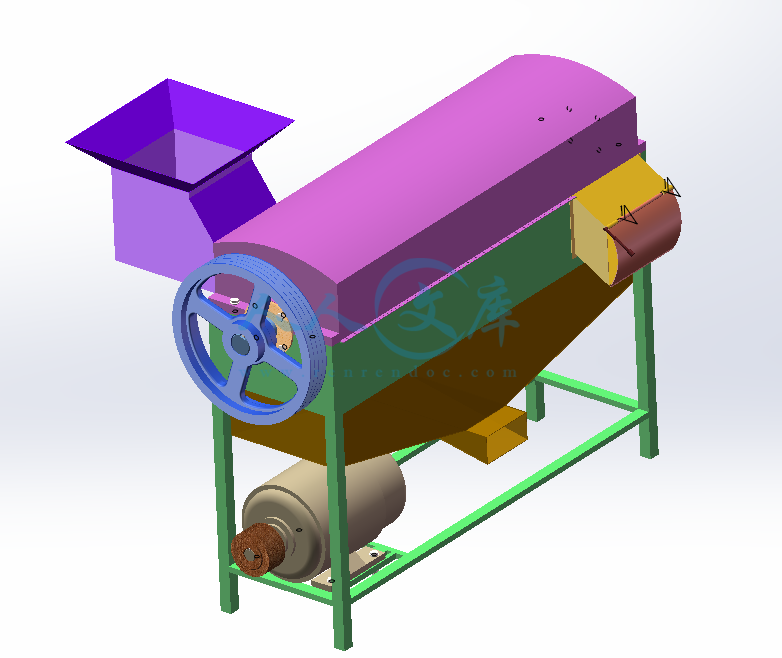

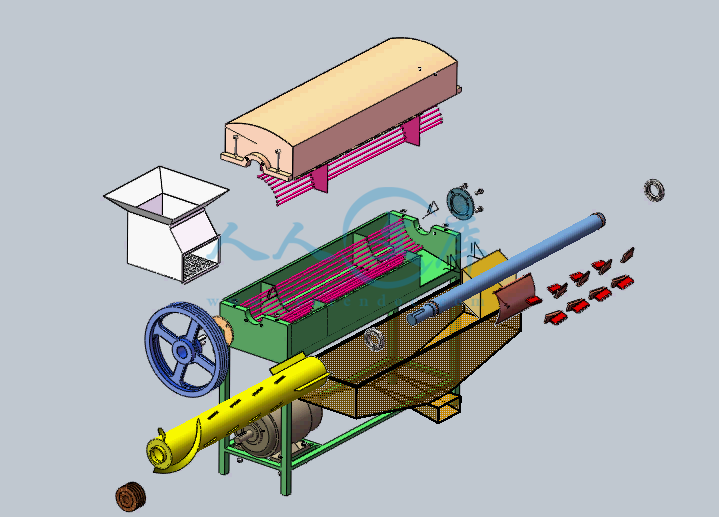

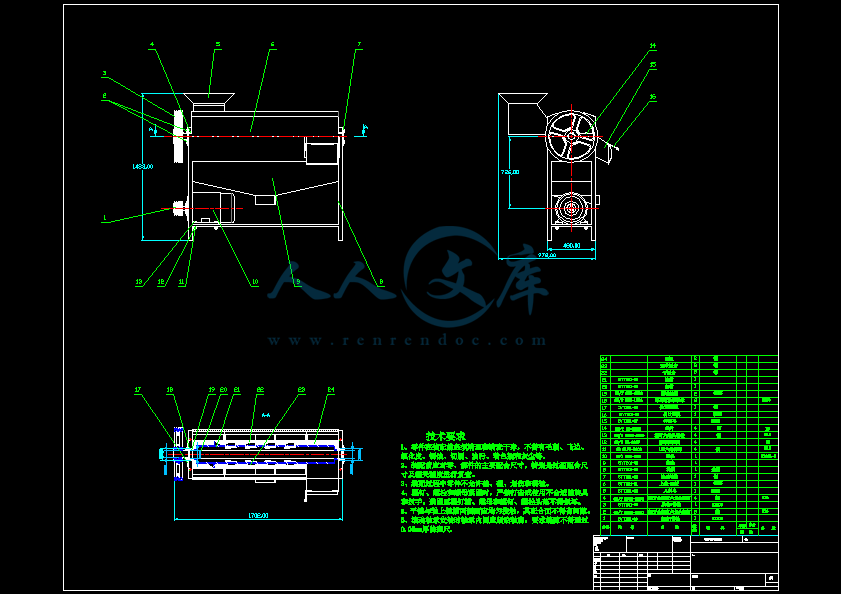

玉米脱粒机工作过程分析及优化设计【含CAD图纸、SW三维模型】

收藏

资源目录

压缩包内文档预览:(预览前20页/共23页)

编号:17619365

类型:共享资源

大小:30.69MB

格式:ZIP

上传时间:2019-04-12

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

100

积分

- 关 键 词:

-

含CAD图纸、SW三维模型

sw三维模型

设计cad图纸

设计【含SW三维

CAD图纸】

三维建模设计

CAD图纸

sw三维模型

【含SW三维

- 资源描述:

-

- 内容简介:

-

毕 业 设 计(论 文)任 务 书设计(论文)题目:玉米脱粒机工作过程分析及优化设计 学生姓名:学号:专业:机械设计制造及其自动化 所在学院:机电工程学院 指导教师:职称:发任务书日期:年月日 任务书填写要求1毕业设计(论文)任务书由指导教师根据各课题的具体情况填写,经学生所在专业的负责人审查、系(院)领导签字后生效。此任务书应在毕业设计(论文)开始前一周内填好并发给学生。2任务书内容必须用黑墨水笔工整书写,不得涂改或潦草书写;或者按教务处统一设计的电子文档标准格式(可从教务处网页上下载)打印,要求正文小4号宋体,1.5倍行距,禁止打印在其它纸上剪贴。3任务书内填写的内容,必须和学生毕业设计(论文)完成的情况相一致,若有变更,应当经过所在专业及系(院)主管领导审批后方可重新填写。4任务书内有关“学院”、“专业”等名称的填写,应写中文全称,不能写数字代码。学生的“学号”要写全号,不能只写最后2位或1位数字。 5任务书内“主要参考文献”的填写,应按照金陵科技学院本科毕业设计(论文)撰写规范的要求书写。6有关年月日等日期的填写,应当按照国标GB/T 740894数据元和交换格式、信息交换、日期和时间表示法规定的要求,一律用阿拉伯数字书写。如“2002年4月2日”或“2002-04-02”。毕 业 设 计(论 文)任 务 书1本毕业设计(论文)课题应达到的目的: 通过进行本次毕业设计,全面系统地对学生进行设计方法和研究方法的基本训练,培养学生综合运用所学基础理论、专业知识和各项技能,培养学生综合运用所学知识,结合具体的科学问题而独立解决问题的能力,进而总结、归纳和获得合理结论,进行较为系统的工程训练,初步锻炼科研能力,提高论文撰写和技术表述能力,为实际工作奠定基础,达到人才培养的目的和要求。着重地培养以下几方面能力:1调查研究、中外文献检索、阅读与翻译的能力;2综合运用基础理论、专业理论和知识分析解决实际问题的能力;3查阅和使用专业设计手册的能力;4设计、计算与绘图的能力,包括使用计算机进行绘图的能力;5撰写设计说明书(论文)的能力。2本毕业设计(论文)课题任务的内容和要求(包括原始数据、技术要求、工作要求等): 1.分析玉米脱粒机用途、工作原理并制定主体结构设计方案。2.根据结构方案图,在图纸上拟定传动构件及执行构件。3.提交装配图、零件图、设计说明书等相关设计。4.提出初步的控制策略与设计。 毕 业 设 计(论 文)任 务 书3对本毕业设计(论文)课题成果的要求包括图表、实物等硬件要求: 1、根据课题收集资料,书写开题报告。 2、毕业设计说明书 3、相关装配图及其主要零件图一套 4、与指导老师交流,进行数据分析总结 4主要参考文献: 1贺俊林,佟金.我国玉米收获机械的现状及其发展J.农机化研究,2006(2):29-362郝付平,陈志.国内外玉米收获机械研究现状及思考J.农机化研究,2007(10):206-2083章惠全,李伟红,谢琼,慕美霞.5TN-1型玉米对生种子脱粒机的设计J.农业科技与装备,2009,10(5):40-414李波.湘西地区小型玉米脱粒机的应用与推广D.湖南;湖南农业大学,20125毛江峰.小型电动玉米脱粒机的设计J.机械工程师,2012(11):1556周志伟.一种锤头式玉米脱粒机Z.实用型专利说明书,20097杨玉芬,张永丽,张本华,佟玲,高连兴.典型玉米种子籽粒的静压破损试验研究J.农机化研究,2008(7):149-1518李清龙.打击式玉米脱粒机脱粒过程实验研究及仿真分析D.吉林;吉林大学.20149李心平,张伏,高连兴.玉米种子脱粒装置的结构技术剖析J.农机化研究,2008(6):24-26 毕 业 设 计(论 文)任 务 书5本毕业设计(论文)课题工作进度计划:2015.12.132016.03.09 毕业设计调研;开题报告;英文翻译;2016.03.102016.04.06 毕业设计查阅;收集资料;论文提纲;2016.04.072016.05.04 毕业设计实验方案程序设计与优化;2016.05.052016.05.11 毕业设计全套材料;2016.05.122016.05.17毕业设计论文预审;毕业设计答辩; 所在专业审查意见:通过负责人: 2016 年 1 月18 日 毕 业 设 计(论 文)开 题 报 告设计(论文)题目:玉米脱粒机工作过程分析及优化设计 学生姓名:学号:专业:机械设计制造及其自动化 所在学院:机电工程学院 指导教师:职称:年 月日 开题报告填写要求1开题报告(含“文献综述”)作为毕业设计(论文)答辩委员会对学生答辩资格审查的依据材料之一。此报告应在指导教师指导下,由学生在毕业设计(论文)工作前期内完成,经指导教师签署意见及所在专业审查后生效;2开题报告内容必须用黑墨水笔工整书写或按教务处统一设计的电子文档标准格式打印,禁止打印在其它纸上后剪贴,完成后应及时交给指导教师签署意见;3“文献综述”应按论文的框架成文,并直接书写(或打印)在本开题报告第一栏目内,学生写文献综述的参考文献应不少于15篇(不包括辞典、手册);4有关年月日等日期的填写,应当按照国标GB/T 740894数据元和交换格式、信息交换、日期和时间表示法规定的要求,一律用阿拉伯数字书写。如“2004年4月26日”或“2004-04-26”。5、开题报告(文献综述)字体请按宋体、小四号书写,行间距1.5倍。毕 业 设 计(论文) 开 题 报 告 1结合毕业设计(论文)课题情况,根据所查阅的文献资料,每人撰写不少于1000字左右的文献综述: 1 研究背景及意义玉米是世界上重要的谷物之一,它可以作为食品和饲料,也是重要的工业原料i 贺俊林, 佟金. 我国玉米收获机械的现状及其发展J. 农机化研究, 2006(2):29-36i。全世界每年种植玉米超过1.3亿公顷,主要分布在美国、中国、巴西和阿根廷ii 郝付平, 陈志. 国内外玉米收获机械研究现状及思考J. 农机化研究, 2007(10):206-208ii。世界玉米种植面积增长迅速。玉米遍及世界各地,除了南极洲之外,各大洲均有种植。伴随着全球气候变暖和科学技术的进步,玉米的种植地域不断地向北、向南延伸。种植玉米的北界已经达到18N,青饲玉米可达到60N;南界达到40Siii 路立平, 赵化春, 赵娜, 刘志全, 沈海波. 世界玉米产业现状及发展前景 J. 玉米科学, 2016, (5):149-151iii。玉米是我国第二大农作物全国种植面积约0.27亿公顷iv 章惠全, 李伟红, 谢琼, 慕美霞. 5TN-1型玉米对生种子脱粒机的设计J. 农业科技与装备, 2009,10(5):40-41iv,仅次于美国。我国是人口大国,农业是国民经济的基础,粮食生产是发展农业的基础。党和政府强农惠农政策的进一步落实,农业发展方式的进一步转变,对玉米产业发展提出了更高要求,玉米产业科技支撑能力必须得到进一步强化,玉米脱粒学科必须奋起直追,敢于迎接新挑战,在服务玉米产业发展中获得更广、更好的发展v 王启现. 我国玉米产业形势分析与栽培学科前景展望J. 玉米科学, 2008(4):35-38v。随着我国玉米消费供需的不断增加供求关系正在发生巨大的转变有数据表明十五期间我国的玉米消费年增长率已经达到2.7%,到了十一五玉米需求得到进一步增长玉米的产由2003年1258亿kg提为2006年的1440亿kg较好地满足了国内的玉米消费需求vi 李波. 湘西地区小型玉米脱粒机的应用与推广D. 湖南; 湖南农业大学, 2012vi。玉米脱粒质量对其产量有着重要的影响,其中机械脱粒产生的冲击、压缩和剪切等作用造成玉米种子损伤问题,严重地影响了玉米的质量vii 杨玉芬, 张永丽, 张本华, 佟玲, 高连兴. 典型玉米种子籽粒的静压破损 试验研究J. 农机化研究, 2008(7):149-151vii。近10年来,国家利用世界银行贷款和国债建设资金,为新(扩)建国家粮库招标采购了大批玉米仓储设施和干燥设备,这对促进科学保粮、提高机械化程度和降低工人劳动强度起了巨大的推动作用viii 周云, 曹毅, 郑刚, 王德华. 东北地区玉米破碎原因及解决措施J. 粮油 食品科技, 2007(6):20-21viii。中国幅员辽阔,自然资源丰富,农作物产量位于世界前列。有些地方采用落后的脱粒技术:如连盖打、竹片撬、木棒打、胶鞋搓、两个玉米棒相互搓、螺丝刀脱粒以及一些老式手摇脱粒机脱粒等,这些落后的脱粒方式还沿用至今,严重制约着玉米生产的效率,让农民的劳动更加繁重不堪。个别地方采用较先进的脱粒技术如利用各种大、中型脱粒机设备脱粒。这种方式脱粒,容易将玉米粒以及玉米芯打碎,影响玉米的质量。在玉米的脱粒过程中,往往一次脱不干净,需要第二次脱粒。同时,购置大、中型的脱粒机费用较贵(少则几千,多则上万或几万),制约着农民朋友的购买热情,若请专门脱粒玉米的商家脱粒,则要收取不少的费用,严重影响着玉米生产农户的收入ix 毛江峰. 小型电动玉米脱粒机的设计J. 机械工程师, 2012(11):155ix。目前的玉米脱粒机有手动和机械电动式两种,手摇脱粒机仅适用于小批量的玉米脱粒费力又费时,而机械式脱粒机效率不高,脱净率差,而且脱后的棒芯破坏严重。玉米粒容易破碎,碎棒和玉米粒不容易分开,影响质量,而且结构复杂,制造成木高x 周志伟. 一种锤头式玉米脱粒机Z, 实用型专利说明书, 2009x。目前,全国的玉米脱粒机使用率率不足2%,主要集中在鲁、冀、京、津等发达地区及少数大型农场。因此,玉米脱粒环节已经成为我国主要粮食作物机械化生产的瓶颈xi 闫洪余, 陈晓光, 吴文福. 玉米收获机械分类解析J. 农机化研究, 2007(10):154-156xi。玉米是世界第三大粮食作物,也是我国三大粮食作物之一。玉米不仅是粮食,更是重要的饲料和工业原料,其生产水平对我国乃至世界粮食生产、畜牧业发展和粮食安全等问题有着至关重要的作用xii 陈立东, 马淑英, 石磊, 冯利臻. 小型揉搓式玉米脱粒机的设计J. 农 机化研究, 2009(1):154-155xii。玉米脱粒机用于对晾干后的玉米果穗进行脱粒。我国玉米加工工艺流程与国外存在差异,国外大田玉米果穗收获后水分一般为35%,经过烘干室果穗烘干后使果穗水分达到12.5%,然后进行脱粒。而国内种子公司规模一般比较小,没有足够的资金建立果穗烘干室,基本上没有果穗烘干工艺过程。国内种子公司通常采用的办法是将玉米果穗场上晾干后,使水分降至18%,然后进行脱粒,再使用烘干塔对玉米籽粒烘干,使玉米籽粒水分降到13%xiii 赵克明. 关于我国玉米生产发展问题的看法J. 玉米科学, 2003(专刊): 60-61 xiii。由于国内玉米果穗脱粒时水分较高,籽粒与芯轴联结强度大,致使脱粒质量下降,脱粒损失提高xiv 赵武云, 吴劲锋, 张锋伟, 杨术明. 玉米轴流脱粒机研究现状分析Z. 机械研究与应用. 2009:9-13xiv。传统玉米脱粒机在作业环节中的破碎率平均在3%5%之间,最高的可达到8%以上,直接造成了产量降低的问题。因此,结合我国国情,研制出满足我国市场需要的高脱净率、低破碎率玉米脱粒机具有重要的实际意义xv 邓小红. YT-1.5型小型玉米脱粒机设计Z. 郴州; 郴州职业技术学院北 院, 2009:10-13xv。 毕 业 设 计(论文) 开 题 报 告 2本课题要研究或解决的问题和拟采用的研究手段(途径): 2 研究内容2.1 目前脱粒机的主要种类打击式玉米脱粒装置(1)工作原理:通过钉齿打击玉米果穗,使玉米籽粒产生振动和惯性力而破坏它与穗轴间的连接;在钉齿滚筒的转动下,齿侧面间和钉齿顶部与凹板弧面上的搓擦作用使玉米穗与穗间、穗与凹板间产生搓擦,从而实现脱粒 (2)结构特点:钉齿式脱粒机主要由钉齿滚筒和凹板组成。钉齿滚筒上的钉齿通常按螺旋线排列,成排地固定在滚筒上。钉齿形状有方形倾斜齿、圆柱形倾斜齿和球顶方根齿等几种。滚筒外缘线的速度一般为610m/s,滚筒直径一般为200500mm。凹板有冲孔式和栅格式两种,凹板包角一般为120180,通常在凹板上装有导向板。 (3)工作过程:玉米穗由喂入斗切向进入,被钉齿抓取进入脱粒间隙,受到钉齿的打击、齿侧面间和钉齿顶部与凹板间搓擦,实现脱粒;通过凹板筛分离出玉米和小杂,玉米芯由轴向排出。碾压式玉米脱粒装置碾压原理的玉米脱粒机,由气胎主辊、气胎定位辊和橡胶条凹板组成,其脱粒原件对玉米果穗进行碾压,在碾压过程中会使玉米籽粒和玉米芯之间产生横向相对位移,从而破坏其连接力使玉米籽粒掉落,该原理的脱粒机对玉米籽粒伤害很小,但生产效率不高。挤搓式玉米脱粒装置(1)工作原理:板齿式脱粒方式模仿人工用手搓玉米的动作。在脱粒区内,由于板齿与滚筒轴之间有一定的夹角,玉米果穗既向前运动,又做向上、向下运动,在运动过程中与两侧和底部的栅格进行揉搓,从而实现脱粒i 柳建安, 李伟杰. 螺旋挤搓式玉米脱粒机的设计J. 农机化研究, 2010(8):82-84i。(2)结构特点:板齿式脱粒机主要由板齿滚筒和栅格凹板组成。板齿宽而高,与滚筒轴向成一定的夹角。板齿有平板齿和冠状板齿两种,在滚筒上按一定方式排列,滚筒外缘线速度m/s;凹板为栅格式圆钢,分布于左、右、下3个方向,包角为90,既起搓板作用,又起筛板作用。(3)工作过程:玉米果穗由喂入斗切向进入,滚筒对应进料处的结构为短螺旋搅龙,搅龙转动将果穗送入脱粒区;在脱粒区内,果穗沿轴向做螺旋滚动与滑动,在此过程中,板齿与果穗之间、果穗与果穗之间、果穗与栅格凹板之间进行揉搓;被脱下的籽粒穿过栅格凹板排出,玉米芯被推送到排芯区排出。 (4)特点:板齿式脱粒机由于具有高脱净率、低破碎率和低功耗等优点。结合挤搓式脱粒工艺、仿生技术及组合式轴流脱粒滚筒脱粒性能柔和、脱粒效果好的特点ii 何晓鹏, 刘春和, 师建芳, 王广万. 挤搓式玉米脱粒机的研制J. 农业 工程学报, 2003,19(2):105-107ii。差速式玉米脱粒装置 差速式原理设计的脱粒机,一般有一个螺旋辊和一个直辊,这两个辊的旋转方向相同,但旋转速度不同,彼此形成差速旋转,玉米果穗与这两个辊接触并实现脱粒。如图1。4所示,是一台差速式脱粒机结构简图,玉米果穗进入脱粒区后,再螺旋辊的作用下向排芯口方向运动,同时在螺旋辊和直辊的差速作用下实现脱粒,特点这类脱粒机具有玉米芯完整、破碎率低、脱净率高及适应性强等特点。但生产效率低,仅适用于单个玉米果穗种子的脱粒iii 李心平, 高连兴. 差速式玉米种子脱粒机的性能试验J. 农业工程学报, 2009(12):102-106iii。 搓擦式玉米脱粒装置 采用搓擦式原理设计的脱粒机,是利用玉米穗与脱粒元件之间的摩擦以及果穗之间的相互摩擦进行脱粒的。例如图1。5所示的立式玉米脱粒机,其工作原理主要靠脱粒滚筒上焊接的脱粒条与玉米果穗之间的搓擦实现脱粒,脱粒条按螺旋线布置在滚筒表面上,对玉米果穗具有轴向的推力。滚筒侧边安装有下料筒,下料筒与机架相连接,它的锥度直接影响脱粒性能,锥度的大小可以通过弹性元件来进行调节。一般来说,对于不同品种的玉米穗,由于其尺寸不同,正式脱粒前需要进行试机,以此来获得合适的下料筒锥度。2.2 脱粒机种类分析 现将常用的脱粒机进行对比,选出合适的脱粒机进行研究。碾压式玉米脱粒装置对玉米籽粒伤害很小,但生产效率不高。传统钉齿玉米脱粒机易造成籽粒表皮的伤害;对水分较高(19%以上)的果穗,不仅脱净率会降低,而且个别籽粒表皮损伤严重,导致总损失率增高;一般来说,传统脱粒方式总损失率要超过2%。差速式玉米脱粒装置具有玉米芯完整、破碎率低、脱净率高及适应性强等特点。但生产效率低,仅适用于单个玉米果穗种子的脱粒。搓擦式玉米脱粒装置能在脱粒的同时进行谷粒分离,脱净率高而又破碎率低。轴流脱粒结构是这种类型脱粒机的核心部分,它不仅在很大程度上决定机器的脱粒质量和生产率,而且对分离和清选也有很大影响。目前国内外很多新型玉米脱粒机采用轴流式。挤搓式玉米脱粒装置脱粒机性能更好,脱净率高、籽粒破碎率低且功耗低。结合板齿式脱粒工艺、仿生技术及组合式轴流脱粒滚筒脱粒性能柔和、脱粒效果好的特点。与传统钉齿使脱粒机作比较,由于钉齿式的滚筒线速度为7.39.4m/s,超过了4m/s这个限值,故产生的破碎率要高于板齿挤搓式脱粒机的破碎率。当玉米含水率在13%20%范围内时,两种机型的技术性能指标比较稳定;当玉米含水率高于20%时,钉齿式脱粒机的脱净率和破碎率指标明显下,板齿挤搓式脱粒机的脱净率和破碎率稍有下降。板齿挤搓式脱粒机的单位功率生产率要高于钉齿式脱粒机。综上所述板齿挤搓式玉米脱粒机性能好、对不同类型种子玉米的适应性强、效率高、脱净率高、种子破碎率相对较小iv 吴多峰, 许峰, 袁长胜. 板齿式与钉齿式玉米脱粒机的性能比较J. 农 机化研究, 2006(10):78-79iv。目前发达国家如美国已将以打击原理为主的玉米脱粒机淘汰,用挤搓式板齿脱粒机取代,并已得到推广应用v 周旭, 李心平, 高连兴, 刘明国. 两种脱粒滚筒的玉米籽粒损伤试验研究 J. 沈阳农业大学学报, 2005,36(6):756-758v。这种技术符合脱净率高、破碎率低的要求。因此本可以主要研究板齿挤搓式脱粒机。2.3 研究重点与难点玉米在脱粒机中的运动是十分复杂的。为了可以将玉米的脱粒过程从更直观的角度进行研究,参考吉林大学生物与农业工程学院数字化实验室提出的离散元法对玉米的运动分析。设计一台玉米脱粒机,找出可改进的方面。运用可以模拟分析的软件进行运动分析。根据实验结果,试探性修改脱粒部件的结构及尺寸,再对修改后的脱粒机进行脱粒仿真实验,直到获得满意的性能为止,以此来实现脱粒机中玉米脱粒过程的分析以及优化。3 研究方法我国市面上用的最多的脱粒机为钉齿滚筒式脱粒机。这种脱粒机采用打击式原理将玉米粒从玉米果穗上脱落。这种脱粒方式虽然脱粒效率以及脱净率比较高,但是对玉米籽粒的损伤较大。挤搓原理的脱粒机如今在美国等的发达国家已经得到广泛的推广应用并取代了打击原理的脱粒机。挤搓原理脱粒机全面克服了钉齿式玉米脱粒机的缺点,不仅脱净率高而且破碎率低,它的损失率比打击式玉米脱粒机至少下降了0.5%30,适合种子玉米以及普通玉米的脱粒。因此本文主要设计一款运用挤搓原理的板齿式玉米脱粒机。在计算机上进行仿真,根据仿真结果修改设计尺寸与结构,然后再对修改后的脱粒机进行仿真分析,直到得出符合要求的分析结果,从而实现对玉米脱粒机的优化设计。这可以削减研发成本。本文先绘制二维CAD草图,建立PRO/E三维模型。然后对自行设计的板齿玉米脱粒机进行仿真。通过改变滚筒转速以及喂入量等变量,考察玉米脱粒机的脱粒效果。探究所设计的脱粒机的脱粒情况并进行优化。 毕 业 设 计(论文) 开 题 报 告 指导教师意见:1对“文献综述”的评语:文献检索充分。 2对本课题的深度、广度及工作量的意见和对设计(论文)结果的预测:同意继续课题研究。 3.是否同意开题: 同意 不同意 指导教师: 2016 年 03 月 17 日所在专业审查意见:同意 负责人: 2016 年 03 月 28 日毕 业 设 计(论 文)外 文 参 考 资 料 及 译 文 译文题目:Investigation of the maize ear threshing process玉米脱粒过程的研究 学生姓名: 学号: 专业: 机械设计制造及其自动化 所在学院: 机电工程学院 指导教师: 职 称: 年 3月 3日Investigation of the maize ear threshing processS. Petkevichiusa ,L.Shpokas ,H.-D.KutzbachbWet maize ears of the Benicia variety with a moisture content of 32.5% and medium dry maize ears of Attribut variety with a moisture content of 18.5% were fed in parallel and perpendicular to the drum shaft of a conventional threshing drum. Maize ears fed in parallel with the drum shaft in the concave clearance moved twice as fast (45 m s1),received twice as few (57) rasp bar impacts, and 1020% of the threshed grain passed through the concave when compared to threshing with the maize ears fed perpendicular to the drum shaft.Threshing losses of wet Benicia maize ears did not exceed the permissible range of0.5% when drum rasp bars moved at the speed of 16 m/s and the concave clearance was in the front 21 mm and at the end 6 mm (216 mm). When medium dry Attribut maize ears were threshed, the concave clearance was in the front 27 mm and at the end 15 mm. When maize ears were fed perpendicular to the drum shaft, the clearance could be increased by 2 mm as the maize ears moved through the concave at an approximately 1.8 m/s slower speed, and received 8 additional rasp bar impacts. During the threshing of wet Benicia maize ears the threshing damage was 30% greater as compared with the threshing damage of medium dry maize ears of Attribut variety. Wet maize should be immediately crushed and preserved as silage.1. IntroductionMaize production is increasing in Europe as maize crops are grown not only for a silage and grain but also for biogas production. Since 2000, maize varieties with shorter vegetation periods have been grown in Lithuania. In good weather conditions the grains in ears mature to 35% moisture content after which they are harvested during the second half of October (Bulgakov et al., 2006). However, it is not economic to dry such grains to a14%moisture content. Thus, a new wet maize processing technology was tested (Shpokas & Petke-vichius, 2005). When the maize moisture reached 35%, the ears were harvested using the corn head, maize grains wereCrushed on-site, and the silage was kept in a trench. However, the threshing process of the wet maize ears was not investigated and the optimum parameters for the threshing apparatus were not determined.The most important quality indices for maize ears threshing are grain loss, damage, concave separation, and the degree of the ear length reduction. The threshing process depends on the maize variety characteristics, the design and structure of the threshing apparatus, and its adjustment.Kravchenko and Kuceev (1979) determined that adhesion between a grain and the maize cob depends on the grain moisture content and its location on the ear. At the ear base kernel attachment is the strongest and at the top it is the weakest. As grains dry, their adhesion to the cob increases. In order to detach grains from the cob some force should be applied longitudinal or perpendicular to the ear axis (Kravchenko & Kurasov, 1988; Danilevich, 1961). When threshing the ears approximately 66% of power is used to overcome the friction forces between the grains and only 34% of power is used for the ear deformation (Kelemen, 1967; Kurasov & Kuceev , 1999). The main influences on maize threshing are the gap between drum rasp bars and the concave and the drum peripheral velocity. Rudakov (1962) established that the ear diameter decreases during the threshing; thus, the clearance at the concave end should be less than that at the concave front. He also stated that the speed of the threshing drum rasp bar of (7 m/s) was not sufficient to separate grain from the ear .Kravchenko and Kuceev (1987) found that the optimum speed of the threshing drum rasp bar was 11 m/s. This was about 2.5times less than the movement speed of the rasp bars when the grain crops were being threshed ( Gasparetto et al., 1977).Most investigations of the threshing of ears with a medium moisture content concentrate on grain damage. Wacker (2005) found that the least maize grain damage (11%) occurred when the moisture content was 28% wet basis. On threshing of maize grains on a41% moisture wet basis, grain damage increased to 33%.Wacker (1987) also stated that grain damage from an axial threshing machine is less that of a tangential machine. Data obtained by Vindizhev and Blaev (1983)showed that maize grain damage occurred when the drum rasp bars operated at a rate of 7 m/s and their impact direction coincided with the longitudinal axis of a grain .When the impact direction is at an angle with the grain longitudinal axis, the damage appears at rasp bar speeds of15 m/s. During the harvesting of maize the number of ears fed to the threshing drum varies considerably. It has been shown (Jakumenkov, 1965) that the grains damage increases with an increase of ears feed rate .Kustermann (1987)states that during the first impact of the rasp bar the greatest number of grain are threshed. The degree of grain threshing depends on the ear orientation with respect to the drum shaft position (Kuceev, 2000). When the ear axis is parallel to the drum shaft grain threshing losses are 2.3 times lower than in case of threshing the ears fed perpendicular to the drum shaft.Most research into maize threshing has evaluated the ear threshing process with respect to grain damage and grain loss during threshing. However, the reasons for grain damage or loss during the threshing do not often evaluate the movement of ears in the threshing apparatus. Crop movement in the threshing apparatus was investigated by Gasparetto et al. (1989) and ear movement by Rudakov (1962), who found that the threshed dry ear in the concave moved 4 times slower than the threshing drum rasp bars and that the threshed grains moved in several directions in the threshing apparatus .The threshing of ears with a moisture content greater than30% has not been fully investigated because grain moisture should be less than 30% when maize ears are harvested for storage. The objectives of this research were to determine the influence of the drum peripheral velocity and concave clearance on the ear feed rate through the concave, the number of rasp bar impacts, grain damage, separation, the degree of the cob crumble, and to determine the optimum adjustments of the threshing apparatus.2. Material and methodsBiometric indices of maize ears were determined by measuring the length and diameter of 100 ears of different varieties (measurement accuracy of 0.1 mm) and counting the number of vertical and horizontal grain rows. The mass of the grains, ears, and 1000 grain mass (measurement accuracy of 0.1 g) was evaluated at 14% moisture content.The aerodynamic properties of the grain were determined the using a test rig for determining terminal velocity which varied air-flow from 5 to 20 m/s. Grain samples of 500g were replicated three times and divided into five groups. The variation of grain terminal velocity was calculated and an integral curve of grain dispersion constructed.The moisture of grains (U1) and cobs (U2) has been determined during drying. Five samples of grain and cob pieces were heated in the drying oven for 24 h at 1051C.The process of maize threshing was tested in Hohenheim University (Germany) using a test rig (Fig. 1), that consisted of a six-rasp-bar threshing drum (2), whose diameter was 0.45m and width was 0.5 m. The concave (8) surrounded the drum at an angle of 951. It consisted of a metal sheet with 10perpendicular rows of holes; the length of the rows was40 mm and the width was 19 mm. There were transverse bars welded between the rows of holes and the width and the height of the bars was 10 mm. The concave was divided into five equal parts the area of each was 0.047 m2. The threshed materials passing through different parts of the concave were collected into separate trays (1014), weighed, and then cleaned. The grain was weighed (measurement accuracy of 0.1 g) and the grain separation through the first part (0.141 m2) and the second part (0.094m2) of the concave was calculated.The average cob length was calculated from the measurements of 50 maize cobs thrown from the concave (measurement accuracy of 0.1 mm). Five grain samples of 50g screened through the concave were taken, the damaged grains were separated, and the average grain damage was estimated.Ears of Benicia and Attribut maize varieties were threshed. The threshing drum peripheral velocity (Vb), the concave clearance (a), and the ear position with reference to the drum shaft were varied during the tests. The ears were fed into the threshing apparatus either parallel or perpendicular to the threshing drum shaft (Fig. 1). When placed on the guideboard they were pushed until the drum rasp bar touched the ear. The ear threshing process, the passing of the ear through the concave surface, grain separation, and movement in the threshing clearance were recorded using a high-speed 4500 frames s) camera and images were analysed with a Kodak Ektapro HS 4540mx motion analyser. This enabled the ear and grain behavior during its movement through the concave, the average velocity of the ear movement, and the number of impacts of the rasp bars to be determined.The permissible range of threshing loss (0.5%) and the grain fraction thrown from concave to the straw walkers (20%)determine the main parameters of the threshing apparatus .Grain damage was not as important since wet maize should be immediately crushed and preserved as silage.Statistical tests were carried out using Analysis of Variance and significance tests. Confidence intervals for mean values were calculated using 0.95probability. 3. Results3.1. Biometrical indices of maize earsThe biometric indices of ears of maize varieties Benicia andAttribut grown in Germany, and maize variety G12 grown in Lithuania, are shown in Table 1.The most important biometric indices are the diameter of the maize ear and its cob. This is because at the front part of the concave the clearance must be less than the ear diameter and at the end of the concave this clearance must be less than the cob diameter. The average diameter of the ears and cobs from Germany and Lithuania varied approximately by 3 mm. Ear length has little influence on the threshing process. Thus, he results of investigations of ear threshing in Germany could be used in Lithuania for preparing the combine-harvesters for the maize ear harvesting.表.13.2. Maize grain aerodynamic characteristicsWhen the threshing drum rotates the rasp bars and the coverings cause an air-flow. To avoid grain being blown onto the straw walkers this air-flow should be less than the terminal velocity of the grain. The tests showed that roughly10% of threshed grains had a terminal velocity less than11 m/s (Fig. 2).3.3. Investigation of the maize ear threshing processWet Benicia ears (moisture contentU132.5%) and mediumdry Attribut ears (U118.5%) were threshed whilst being fed in parallel with the drum shaft of the threshing drum. The rasp bar movement speed was varied from 12 to 20 ms.When the threshing drum rasp bars moved 12 m/s (Fig. 3a), the threshing losses of the wet Benicia ears as the threshed grains passed through the concave were 27% and 42%. When the rasp bar speed was increased to 20 m/s, threshing losses of the grain were decreased to 5%, but this exceeds the permissible 0.5% rate. The grain separation through the concave increased to 71% and grain damage increased from10% up to 23% (Fig. 4).When drum rasp bars moved at 12 m/s, at the concave front (gap of 29 mm) the ear rolled to the third transverse bar before threshing started. After rasp bars had pushed the ear further behind the sixth transverse bar (gap of 22 mm), grain was being threshed intensively, but 58% of the threshed grain was unable to pass through the concave (Fig. 3a). The cob was thrown out from the concave after five impacts of the rasp bar (Fig. 5b). The ear moved at an average speed of 4.5 m/s through the threshing zone (Fig. 5a).When the drum rasp bar speed was increased to 20 m/s, the speed of the ear through the concave increased up to6.3 m/s (Fig. 5a). Most of the grains were threshed between the third and seventh transverse bars of the concave; thus, only about 30% of threshed grains did not pass through the concave. Grain threshing losses were minimised to 5% (Fig. 3a). When the wet ears were threshed the clearance between the drum and the concave should be reduced to allow the threshed grains to pass through the concave and as a result less than 20% of threshed grains would be thrown onto the straw walkers. When the medium dry Attribut ears (Fig. 3b) were fed parallel to the drum shaft, drum rasp bars moved at 12 m/s, more grains were threshed at the concave front compared with the threshing of Benicia ears. After every impact of the rasp bar the ear rose up from the concave to the drum between rasp coverings. Grain was most intensively threshed when the ear moved between the third and the fifth transverse bars of the concave. Threshing losses, the part of grain that passes through the concave, and damaged grains were 1.5%, 76% and 4%, respectively (Fig. 4). Grain threshing losses of ears of the Attribut variety did not exceed the permissible rate when the rasp bars moved 15 m/s, but more than 20% of the threshed grains were thrown on to the straw walkers (Fig. 3b). Also 78% of the threshed grains passed through the concave and 7% of the grain was damaged (Fig. 4).The average movement speed of the ear through the concave was about 4 m/s. The optimum speed of the drum rasp bars was 16 m/s because at that speed less than 20% of the threshed grains were thrown from the concave.Following analysis of test results the conclusion was drawn that a drum rasp bar speed of 16 m/s is too high for threshing medium dry grains of Attribut ears fed in parallel to the drum shaft when the concave clearance was 2918 mm. The impact of drum rasp bars moving20 m/s was insufficient to thresh grains of wet Benicia ears. As a result the concave clearance had to be reduced to produce acceptable threshing at the front of the concave.When wet and dry ears were threshed and drum peripheral velocity was varied, threshed grains in the concave moved in several directions, changing direction after striking the concave, the drum rasp bars, or the coverings. The air-flow caused by drum rotation was sufficient to keep some part of the grains suspended in the air and even to be blown from the concave.When Benicia ears were fed perpendicular to the drum shaft (vb20 m/s ; a298 mm) at the front of the concave they remained on the two parallel bars or the tops of the ears caught on the third transverse bar. The drum rasp bars bent the ear, some grains were threshed, but the ear did not move forward. After six rasp bar impacts, when some of the grain had been threshed, the ear started to be pushed forward. The ear was broken into two pieces and these parts moved forward chaotically, changing directions. After twelve impacts of rasp bars (Fig. 5b) cob pieces of approximately 65 mm were thrown from the concave.Grain threshing losses were reduced to 3% (Fig. 6a), but exceeded the permissible rate by 0.5%, the grain separation through the concave was 83%, and more than 40% of the grain was damaged (Fig. 4). The ear moved in the concave at approximately 4 m/s.Twelve impacts of rasp bars moving at a speed of 20 m/s were insufficient to thresh wet Benicia ears. When wet ears were threshed the clearance at the concave front had to be reduced in order to thresh more grains.Attribut variety ears fed perpendicular to the drum shaft(Fig. 6b) were threshed after thirteen impacts of rasp bars moving at 15 m/s (concave clearance 2918 mm). The ear moved in the concave at 2.2 m/s (Fig. 5a). Grain losses during threshing did not exceed the permissible rate, 84% of grains passed through the concave, cobs were not broken, and their average length did not exceed 160 mm. Thus, when the clearance between the drum and the concave was 2918mm the optimum speed of the drum rasp bars was 15 m/s.Threshing losses of grains, the grain separation through the concave, and grain damage were determined whilst changing the concave clearance from 216 to 3730 mm. When Benicia ear was fed in parallel with the drum shaft (Fig. 7a) and when the gap between rasp bars and the concave was 216 mm, threshing losses of the grain made up 1.4%, 86% of all threshed grain passed through the concave, and 33% of grain was damaged (Fig. 8). Grain losses during the threshing exceeded the permissible level as the ear moved through the concave, rotated about its axis, and jumped, the rasp bars broke it into two pieces, and thus their average length was96 mm. The average speed of the ear through the concave was 4.5 m/s, and it received five impacts from the rasp bars (Fig. 9). The drum rasp bars had to move at the speed of18 m/s in order not to exceed the permissible grain loss during threshing and less than 20% of the threshed grains were thrown onto the straw walkers.When medium dry Attribut ears were fed in parallel with the drum shaft, the optimum concave clearance was2715 mm, because after seven impacts of rasp bars the threshing losses of grains were less than the permissible rate,80% of threshed grains passed through the concave (Fig. 7b),and 8% of the grains were damaged (Fig. 8). The average speed of the ear through the concave was 4.6 m/s (Fig. 9a).When Benicia ears were fed perpendicular to the drum shaft with the concave clearance set at 238 mm (Fig. 10a),88% of grains passed through the concave, but 37% of threshed grains were damaged because the ear moved through the concave at a speed of 2.8 m/s, and they received eight impacts from the rasp bars. The greatest number of rasp bar impacts (from five to eight) occurred at the front part of the concave and it pushed the ear forward. Concave clearance must be such that after the impact of the rasp bar the ear rises from the concave and the next rasp bar pushes it forward. When medium dry Attribut ears were fed perpendicular to the drum shaft and the concave clearance was 2918 mm, the threshing grain losses did not exceed the permissible rate, 84% of grain passed through the concave (Fig. 10), 7% of grain was damaged, the ear moved through the concave at 2.2 m/s (Fig. 9), and it received 13 impacts of the rasp bars. The drum rasp bars bent the ear whilst moving it along its axis and slowly threshing grains. After a significant part of the grains was threshed, and the cob rose from the concave it was hit with a rasp bar and the next rasp bar began to push it forward. When the ear moved through the concave, it was rarely broken into two pieces; thus, the average length of cob thrown from the concave was 150 mm. 4. ConclusionsThe analysis of wet Benicia and medium dry Attribut ears showed that the grain moisture content, the position of the threshed ear with reference to the drum shaft, the drum peripheral velocity, and the concave clearance influenced the threshing losses of grains, their separation through the concave, and grain damage.In order to thresh wet Benicia ears with losses less than0.5% and less than 20% of threshed grains thrown from the concave, drum rasp bars should move at 18 m/s, the clearance at the front of the concave should be equal to the cob average diameter (21 mm), and the clearance at the end should be about 6 mm.Wet Benicia ears fed perpendicular to the drum shaft were threshed more intensively at the front part of the concave compared with ears fed parallel because they received twice as many rasp bar impacts (12) because they moved through the concave at half the speed. For threshing of the wetBenicia ears the optimum drum peripheral velocity vbwas16 m/s with the clearance between drum rasp bars and concave transverse barsa238 mm. The reduction of the clearance between the drum and concave had a greater impact on grain loss during the threshing than the increase of the rasp bar movement speed.When wet Benicia ears were threshed 40% of grains were damaged; thus, they should be immediately crushed and silage made. When threshed medium dry Attribut ears were fed in parallel with the drum shaft the optimum speed of drum rasp bars was 16 m/s and the concave clearance was 2715 mm. When ears were fed perpendicular to the drum shaft the clearance was 2918 mm. As the ears moved through the concave at half the speed compared to ears fed parallel with the drum shaft, they received twice the impacts of the rasp bar (13) and 10% more threshed grains passed through the concave. Grain damage was about 19%.The analysis of the threshing process helped to determine that the grains moved longer distances than the ear in the concave clearance. Grains moved in various directions after they hit the drum rasp bars, its coverings, and the concave. Some part of the grains moved in the air-flow produced by the drum or were thrown from the concave. To increase grain separation through the concave, the concave with the greatest active separation area should be used, and the adjustment of threshing apparatus should be changed following estimation of the ear diameter, maturity, and its moisture content.玉米脱粒过程的研究S. Petkevichius ,L. Shpokas ,H.-D. Kutzbach摘要“Benicia”品种的湿玉米果穗含水量为32.5%,“Attribut”品种的中等干度玉米果穗含水量为18.5%。将它们平行或垂直于滚筒轴喂入脱粒机。相比于垂直喂入,玉米穗以平行滚筒轴喂入脱粒机时在凹板间隙移动快了一倍(45米每秒),受到纹杆影响少了一半,且有多于1020%的脱净谷物通过凹板。当滚筒的纹杆以16米/秒的速度转动且凹板间隙为6毫米到16毫米时,“Benicia”品种的湿玉米穗脱粒过程的损失不能超过其允许的范围(0.5%)。“Attribut”品种的中等干度玉米穗在脱粒的时候,凹板间隙在15毫米到27毫米之间。当玉米穗垂直于滚筒轴喂入时,间隙需要增加2毫米,因为玉米穗通过凹板的速度大约下降了1.8毫米/秒。“Benicia”品种的玉米穗的脱粒损失比“Attribut”品种的中等干度玉米穗的脱粒损失多30%。湿玉米需要立即被压碎和保存来作为饲料。1 介绍 玉米作物不止可以作为饲料与粮食还可以作为沼气,因此在欧洲玉米产量增加。在两千年前,立陶宛人就已经种植短植株的玉米。在天气条件良好时,玉米穗成熟时的含水量为35%,一般在下半年十月中旬可以收获。但是,一旦它被干燥到14%时,他就不具有经济性。因此,科学家正在研究一项新的湿玉米加工技术。当玉米的含水率达到35%,玉米穗从顶端开始收获。在种植玉米农场,玉米饲料保存在地窖中。然而湿玉米穗的脱粒过程还没有进行实验,脱粒装置的最优参数还不确定。玉米穗脱粒质量的最重要指标是谷物的损失率、损伤率以及玉米穗长度缩短的程度。脱粒过程依赖于玉米品种特性、脱粒装置的设计和结构。玉米粒与玉米棒之间的附着力主要取决于玉米籽粒的含水率以及玉米籽粒所处于玉米穗的位置决定。处于玉米穗底部的玉米粒的附着力是最强的,顶部则最弱。当对谷物进行干燥后,玉米籽粒的附着力就会降低。为了将玉米籽粒从玉米穗上剥离下来,所施加的力应该是垂直或者平行于玉米穗的。在进行玉米穗脱粒时,约66%的力为与谷物间的摩擦力,约34%的力用来阻碍玉米穗变形。玉米脱粒的主要影响因素是滚筒纹杆与凹板之间的距离以及滚筒的圆周速度。建立玉米穗在脱粒中的模型,在脱粒时玉米穗直径是逐渐减小的,因此凹板末端间隙应小于前端间隙。脱粒时滚筒外围线速度速度(7米/秒)不足以使全部谷粒从玉米穗上脱落。最理想的脱粒滚筒线速度是11米/秒。大多数对于中等水分含量的玉米穗的研究专注于谷粒的损失。研究发现当湿基含水量为28%时,玉米籽粒损伤率最小(11%)。当玉米脱粒时湿基含水量为41%时,谷粒损伤率增加到33%。研究还指出,轴流式脱粒机对谷粒的损伤率小于切流式脱粒机。这些数据由Vindizhev和 Blaev两位学者于1983年发表的论文中获得。谷粒与纹杆以一定的角度进行脱粒,当纹杆速度以15米/秒运行时最容易使谷粒损伤。当收获时玉米穗喂入脱离滚筒的量有很大的变化。科学家Jakumenkov于1965年证明谷粒的损伤率随着玉米穗的喂入速度的增加而增加。科学家Kustermann于1987指出脱离效果的首要影响因素是喂入量。科学家Kuceev于2000指出谷物的脱粒程度取决于玉米穗相对于滚筒轴的位置与方向。当玉米穗平行于脱粒滚筒轴喂入时,其谷粒损失率比垂直喂入低2.3倍。大多数对于玉米脱粒过程的研究是评估玉米脱粒过程的损失以及损伤。然而人们不常研究玉米穗在脱粒装置中的运动状态对谷粒的损伤以及损失的影响。Gasparetto 等学者于1989年对谷粒在脱粒装置中的运动进行研究, Rudakov于1962年对玉米穗的运动进行研究,他们发现干玉米穗在凹板中运动的速度比纹杆的旋转速度低4倍,并且脱落的谷粒在脱粒机中无规则的运动。对于含水率大于30%的玉米穗进行脱粒时的情况并没有进行深入的研究。因为玉米收获后进行存储时,含水率必须低于30%。此次研究的目的是确定脱粒滚筒的圆周速度、玉米穗喂入凹板的速度、纹杆的数量对玉米谷粒损失与损伤的影响,以及调整脱粒装置的最优参数。2 材料与方法玉米穗的生物指标由测量100个不同品种的玉米穗的长度和直径(精确到0.1毫米),并计算横向纵向谷粒的数量来确定。玉米穗的质量和谷粒的质量(精确到0.1克)都是测量自含水率为14%的玉米。通过实验装置测定粮食的空气动力学特性。500克的粮食分成五组,重复测试三次。通过计算末端速度的变化对谷粒分散程度的影响绘制曲线。当谷物晾晒后,谷粒(U1)和玉米棒(U2)的水分含量已经确定。五组实验品在105摄氏度的温度下烘烤24小时。霍恩海姆大学观测玉米的脱粒过程使用了一个实验装置,它由一个直径为0.45米宽0.5米的六纹杆脱粒滚筒组成。凹板围绕在滚筒周围,其角度为95度。它由一个金属薄片组成,上面有10排垂直的孔洞;每排孔长度为40毫米,宽度为19毫米。一根横向的钢筋焊接在孔洞之间,它的高度与宽度都是10毫米。凹板分为五个相同的部分,每个部分的面积为0.047平方米。凹板的五个部分将脱粒后的玉米谷粒收集于单独的托盘上,称重,然后清洗。谷粒的称重精度为0.1克,通过凹板的第一部分(0.141平方米)和第二部分(0.094平方米)进行计算。通过测量50根玉米棒得出其平均长度值(计算精度为0.1毫米)。将被凹板筛选出的五组各50克谷粒样品中的受损谷粒分离出来,计算出平均谷粒损失率。将“Benicia” 和“Attribut”两品种的玉米穗脱粒。脱粒滚筒的圆周速度(vb)、凹板间隙(a)以及相对于滚筒轴的参考位置在测试中都是不同的。将玉米穗以平行或者垂直于脱粒滚筒轴的方向喂入脱粒装置。其落入导板上并被推至与滚筒纹杆相接触。玉米穗的脱粒过程,玉米穗通过凹板表面,经过谷粒分离步骤,谷粒在脱粒的过程都会被一个高速摄像机(4500帧/秒)记录下来并且用柯达运动分析器进行图像分析。这样可以准确测得谷粒在凹板中的运动过程、平均速度、作用中的纹杆数量等参数。3 结果3.1玉米穗的生物统计学指标玉米穗的生物统计学指标。“Benicia”和“Attribut”两种品种的玉米生长在德国,“G12”品种的玉米生长

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号