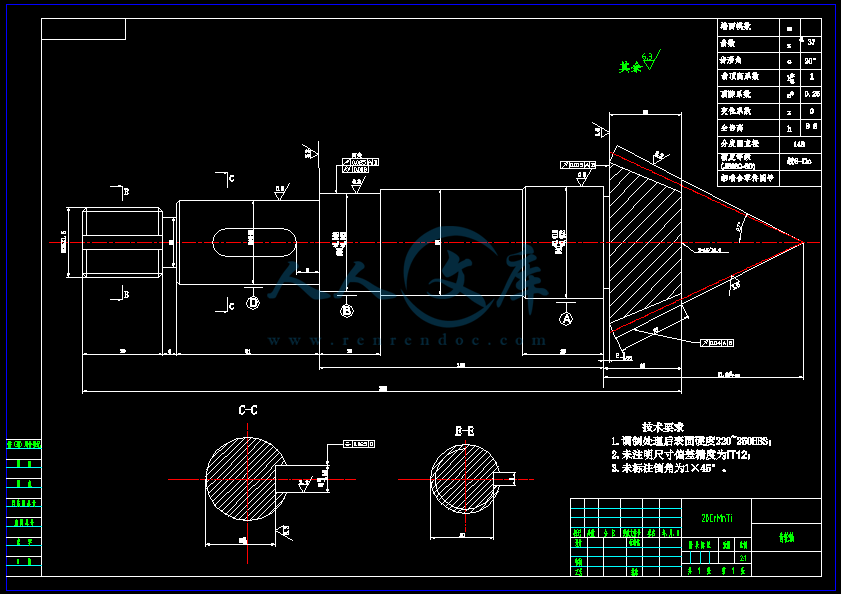

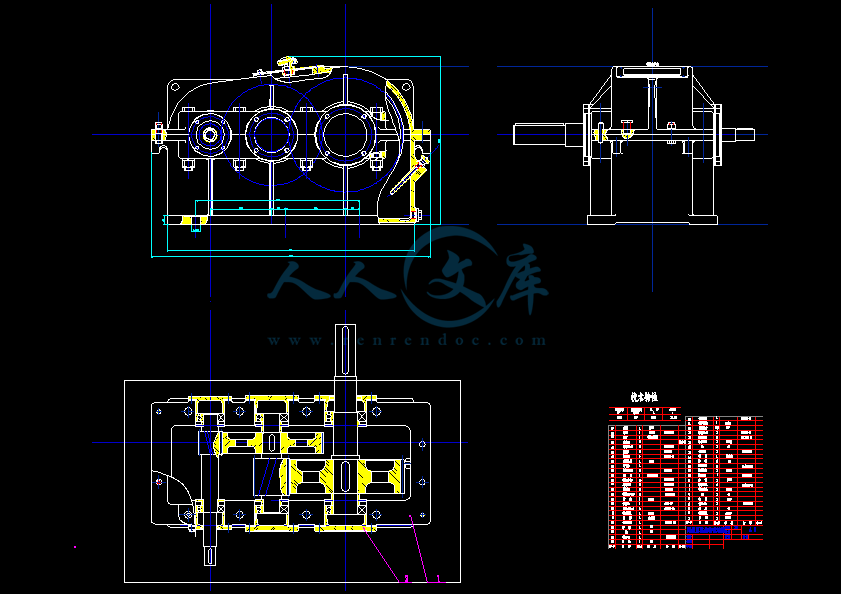

内齿轮铣齿机铣削动力头的设计【含CAD图纸+文档资料】

收藏

资源目录

压缩包内文档预览:

编号:17992892

类型:共享资源

大小:1.18MB

格式:ZIP

上传时间:2019-04-21

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

含CAD图纸+文档资料

内齿轮铣齿机铣削动力头的设计【含

CAD图纸】

内齿轮铣齿机的铣削动力头设计

含CAD图纸

内齿轮铣齿机铣削动力头的设计

内齿轮铣齿机的

内齿轮铣齿机铣削动力头

计算机辅助设计

- 资源描述:

-

- 内容简介:

-

附录英文翻译The CAD application of the curve awl wheel gearAuthor:johnThe curve awl wheel gear movement system greatly applys in professions such as aviation, car and tool machine etc., but so far the curve awl wheel gear movement system design still stay around tradition from now on.But this kind of method is not only time-consuming, and the accuracy is low.In the usage process , using this kind of method design process of awl wheel gear, sometimes hard to satisfy process request.Many researcher research for long times in the curve awl wheel gear movement system to carry on a thorough, make clear of the merger principle,process principle and the contact analysis method.For the sake of research result have application spread to move at the curve awl wheel gear of design, manufacturing and examination,so we develop this curve awl wheel gear to movement of CAD system.This system first according to design request, establishment the curve awl wheel gear spread to move excellent turn design model, and adoption mixture punish a function method to carry on solve, acquire the best design project;Then carry on gnashing teeth with hatred to adjust a calculation, is processed the gear awl wheel gear opportune moment bed of adjust parameter value.With number control instruction to combine, then can at number control tool machine to process a curve awl wheel gear.In addition, this system return and can spread to move to carry on an assistance examination to the Hu wheel gear, with assurance eat noodles contact area of directions and size, and acquire sport characteristic curve, lend this can evaluation spread move of quality;Combining can use a limited dollar a method analysis awl wheel gear to spread to move to carry a lotus with should dint, with assurance awl wheel gear of structure size, and can draw a limited dollar mesh model and awl wheel gear work diagram.The curve live wheel gear to spread to move of calculator assistance designExcellent turn a design with limited dollar analysis is the main contents that the curve awl wheel gear spread to move CAD.The gear awl wheel gear spread to move excellent turn design is at thorough analysis research design request, usage request and craft request etc. foundation up, establishment reasonable of excellent turn design model.The design change quantity fixed position sell awl wheel gear is few Zts, big carry mold few Mts, gear breadth B, gear breadth middle point spiral Cape(drive he), pressure Cape( method)s etc. five parameter, but will become the X1, X2, X3 of a coefficient, X4 conduct and actions two excellent turn to change quantity.After win an election to settle design to change quantity value, their value is pass two excellent turn assurance.In consideration of design of concrete circumstance, target function fixed position 2 kind:1 kind is to give settle power bottom smallest turn awl wheel gear to spread move of total accumulate;2 kinds are to give to settle size bottom biggest turn awl wheel gear to spread move of power.Controling the condition is a strength, craft and assemble etc. request.The end pass a sorting, the gear awl wheel gear be excellent to turn design model and can write for .This isnt 1 line programming problem, and is long-lost to change quantity with continuous change quantity mixture of circumstance, choose to use to punish a function method(SUMT) to solve.For the sake of the in general use of the increment software, it is still excellent to turn procedure to have a school to calculate to awl wheel gear is several what size etc. function.Usage is hand over with persons machine with each other a way importation customer each item request, past very convenience.Excellent turn strength within design calculation to press simplification formula to carry on, cant control the whole wheel gear structure in should distribute of dint circumstance and variety circumstance.Several parameter with gnash teeth with hatred adjustment parameter assurance after, spread to move to carry on a limited dollar analysis to the gear awl wheel gear, with assurance reasonable reasonable structure parameter.The limited dollar model take the awl which constitute for two awl wheel gear previous three gear a piece.Matching principle according to the space, establish the tooth face of the gear awl wheel gear a square a distance, solve to produce dentition but node to sit a mark, then formation round the limited dollar of the model.Make use of soft degree matrix analysis carry a lotus at the churs to the allotment of and round gear surface node with distribute regulation, ask for help of a tooth face contact analysis(TCA) technique assurance moment contact line directions.For overcoming tiny machine memory small weakness, the adoption sub- structure and method technique before the wave.Make use of this limited dollar analysis software, not only can acquire a Chi top each a piece noodles last moment etc. should dint curve, and basis carry a lotus table, can analysis the match to move inside period should dint, for credibility analysis provide basis.The calculator assistance of 3 gear awl wheel gear designThe gear awl wheel gear is at quasi- double curved face Xian the Chi be on board to process, it according to the principle design ofappearance even crest wheel gear, in order to processing the stalk line which produce a form round of the even crest of big awl wheel gear with process small awl wheel gear of even crest the spade form axle line gravamen line, so get of big, small round Chi surface.Say from the theories that isnt a real total track noodles.On the other hand, in actually the usage, assurance the gear awl wheel gear tooth face is total track noodles combine has no occasion for, because wheel gear of manufacturing, assemble error margin with is carry to transform will make work appearance with process appearance inconformity but break wheel gear of normal the Nie match a condition.Therefore, the gear awl wheel gear be actually a part to look like a total track. all ssurance currently two tooth face part total track arrive two rank.The process of the research gear awl wheel gear is to want research at dissimilarity of gnash teeth with hatred under the condition how adjust tool machine, change knife the parameter of the dish, make to process to get of the awl wheel gear tooth face satisfy part look like total track condition, and have the best tooth face contact area.Before process awl wheel gear, according to technique request, gnash teeth with hatred principle and gnash teeth with hatred a method to carry on to gnash teeth with hatred to adjust calculation.Often adoption of gnash teeth with hatred to adjust calculation method to have 4 kinds:line error margin compensate method, close throw a thing noodles method, have already controled contact calculation method and contact analysis method.The purpose which gnash teeth with hatred to adjust calculation be assurance process to get of the awl wheel gear satisfy part look like total track.This system aim at simple two-sided gnash teeth with hatred a method, use a calculator assistance completion to gnash teeth with hatred to adjust calculation.This kind of method process a big round to slice with the two-sided knife dishing, cave and convex slice noodles to be cut off in the meantime, but the small round then use one side knife dish to slice to make convex noodles with cave side respectively.For make small round of convex noodles and cave side respectively orientation rightness should of big round total 1,2 rank differential calculus realm characteristic of track tooth face, adoption close throw thing noodles a method to carry on to gnash teeth with hatred adjust calculation, adjust the slice a small round of five craft parameter, namely the knife blade Chi form Cape, knife dish formation radius, the path is to the knife, knife dish pole Cape with roll to slice ratio.Calculation result can pass conversion to connect and number control the instruction database of tool machine direct connect with each other, and with control the instruction for exercise of tool machine and work piece combine together, direct completion process of awl wheel gear manufacturing.The curve awl wheel gear spread to move of calculator assistance examinationIn order to gnashing teeth with hatred a calculation is according to part point contact look like total track theories, so according to calculation acquire of adjust parameter, process to get of the gear awl wheel gear, at work uncertain have the best of contact area shape and sport characteristic.In addition processing an error margin, installing an error margin is in additioncarry to transform etc. all would influence the spread of the gear awl wheel gear move quality.Therefore spread to move to all want to carry on examination and V-H of the tooth face contact examination to the gear awl wheel gear.The method of normal regulations is after process a finished product, is at laurel east the examination be on board to carry on examination, be unqualified, afresh adjust tool machine parameter, again process, again examination, this kind of method, not only period long, and very uneconomical, in addition adjust tool machine parameter, also have certain of blindness.With the calculator carry on gear to make track for a round to spread move of assistance examination, not request process a finished product, but after gnashing teeth with hatred to adjust calculation, reasonable according to the space theory and process of concrete condition, in the calculator formation all of the wheel gear of tooth face square distance, then according to part total the track theories carry on a tooth face contact analysis and V-H analysis, assurance contact area of directions and size, moment spread to move ratio of variety curve with spread to move the sensitive degree to the error margin.According to calculation result, then can carry on evaluation towards spreading to move.When think not reasonable, then carry on parameter to adjust.Because of already establishment the function of each parameter of tool machine and tooth face shape relation, so adjust have certain of theories foundation, and also can acquire the best adjust parameter.When think everyones noodles all reasonable after, can process awl wheel gear on the tool machine.Such as have necessity, rightness positive article can also again carry on a set examination.The calculator assistance of the curve awl wheel gearAt the limited dollar carried on the gear awl wheel gear to spread to move analysis, is examination model of accuracy, can draw limited dollar model.This system pursue an unit to carry on while drawing a limited dollar model.The adoption is 3D 20 node etc. unit.Draw an establishment a connection matrix, matrix of line and row respectively is 20, rightness should 20 node.If at two some painting line, rightness should matrix chemical element is 1, otherwise is 0.While draw from node 1 beginning, first painting low noodles side line, again painting a side transform, end painting Leng side line, all unit press position emissions together and then formation wheel gear limited dollar model.Because each painting over an unit can pause, past customer can pursue the unit carry on check, can convenience of know the accuracy of model. After the completion awl wheel gear structure design, then can design draw awl wheel gear work diagram.For the purpose of backup or process awl wheel gear to use.Draw the procedure of the awl wheel gear work diagram from draw a gear, round good luck, round Fu, round and mark sub- function procedures, such as size and business trip.etc. to constitute.Each sub- function procedure is the size and position which employ parameter to come to control son diagram.The painting of this system software all should with painting database document connect with each other. Application example The some aviation launch a machine lord to spread to move the gear awl wheel gear, in the usage the process once occurrence several times split trouble, result in graveness loss.Should spread for the exaltation move of credibility, use to develop of as to its does the CAD system carry on an improvement design. Turn a design towards spreading to move to carry on excellently first, the result list on form 1.Has been turned a design excellently, spread to move of total accumulated to descend 21.2%.Then carry on gnashing teeth with hatred to lift to adjust a calculation, acquire each adjust parameter value, see form 2.Secondly spread to move to carry on tooth face contact analysis to the gear awl wheel gear of design and V-H analysis, and make exchange the whole parameter to carry on an optimization.Should the contact area directions and size of the gear awl wheel gear window hole, sport the characteristic curve show at the diagram 5.In addition spread to move to carry on a limited dollar analysis to the awl wheel gear, among them, one round the limited dollar model of the gear see diagram 6.Diagram 7 is small round round the gear follow gear breadth some piece noodles of moment etc. should dint line diagram.End can the manifestation draw awl wheel gear work diagram, and process manufacturing finished product. Conclusion This CAD systems turn to spread in using of carrying on to the curve awl wheel gear excellent turning design, limited dollar analysis, gnashing teeth with hatred to adjust calculation, tooth face contact analysis, V-H analysis calculation and the sketch drawing, to shorten the gear awl wheel gear of design period, exaltation design quality, lower design to make to add expenses to all have certain meaning.This system application spread at the aviation awl wheel gear move of design, acquire to have most excellent design project and adjust parameter value, and carry on dint analysis. passing with light play experiment and the set experiment result compare, both be basic to fit together, elucidation origin the software system be very valid. From: Machine Design Fundamentals 中文对照弧齿锥齿轮传动系统的CAD应用作者:约翰弧齿锥齿轮传动广泛应用于航空,汽车和铣齿机等行业中,但到目前为止弧齿锥齿轮传动的设计还停留在传统方式下进行.但是这种方法不但费时,而且精度低.使用过程中发现,用这种方法设计加工的锥齿轮,有时难以满足加工要求.长期以来许多研究人员对弧齿锥齿轮的传动进行了深入的研究,搞清楚了它的啮合原理,加工原理以及它的接触分析方法. 为了将一以有的科研成果应用于弧齿锥齿轮传动的设计,制造和检验中,我们研制出了这套弧齿锥齿轮传动的CAD系统.该系统首先根据了设计要求,建立弧齿锥齿轮传动优化设计模型,并采用混合罚函数法进行求解,获得最佳设计方案;然后进行切齿调整计算,获得加工弧齿锥齿轮时铣齿机的调整参数值.与数控指令结合,便可在数控铣齿机加工出弧齿锥齿轮.此外,本系统还可对弧齿轮传动进行辅助检验,以确定吃面接触区的方位及大小,并获得运动特性曲线,借此可评价传动的质量;并可用有限元法分析锥齿轮传动载荷和应力,以确定锥齿轮的结构尺寸,并可绘制有限元网格模型和锥齿轮工作图.弧齿住齿轮传动的计算机辅助设计优化设计和有限元分析是弧齿锥齿轮传动CAD的主要内容.弧齿锥齿轮传动优化设计是在深入分析研究设计要求,使用要求和工艺要求等基础上,建立合理的优化设计模型.设计变量定位销锥齿轮齿数Zt,大端模数Mt,齿宽B,齿宽中点螺旋角(被他),压力角(阿法)等五个参数,而将变位系数X1,X2,X3,X4作为二次优化变量.当选定设计变量值后,它们的值是通过二次优化确定的.考虑到设计时的具体情况,目标函数定位两种:第一种是给定功率下极小化锥齿轮传动的总体积;第二种是给定尺寸下极大化锥齿轮传动的功率.约束条件是强度,工艺,装配等方面要求.最后通过整理,弧齿锥齿轮优化设计模型可书写为.这是一个非线性规划问题,而且是离散变量与连续变量混合的情况,选用罚函数法(SUMT)求解.为了增加软件的通用性,优化程序还具有校核计算锥齿轮几何尺寸等功能.使用时以人机交互方式输入用户各项要求,故十分方便.优化设计中的强度计算是按简化公式进行的,无法掌握整个齿轮结构中应力的分布情况和变化情况.在几何参数和切齿调整参数确定之后,对弧齿锥齿轮传动进行有限元分析,以确定合理合理结构参数.有限元模型取为两锥齿轮上三轮齿组成的锥扇块.根据空间啮合原理,成立弧齿锥齿轮的齿面方程,求解产生齿而节点坐标,进而形成轮齿的有限元模型.利用柔度矩阵分析载荷在齿对间以及轮齿表面节点上的分配和分布规律,借助齿面接触分析(TCA)技术确定瞬时接触线方位.为了克服微机内存小的缺点,采用子结构和波前法技术.利用这套有限元分析软件,不但可获得轮齿上每一截面上瞬时等应力曲线,而且依据载荷谱,可分析啮合周期内动应力,为可靠性分析提供依据.弧齿锥齿轮的计算机辅助设计弧齿锥齿轮是在准双曲面铣齿机上加工的,它是根据”假象平顶齿轮”原理设计时,由于加工大锥齿轮的平顶产形轮的轴线与加工小锥齿轮的平顶铲形轮轴线不平行,这样得到的大,小轮齿表面.从理论上说不是真正的共轨面.另一方面,在实际使用中,保证弧齿锥齿轮齿面为共轨面并无必要,因为齿轮的制造,装配误差和受载变形都将使工作状态与加工状态不一致而破坏齿轮的正常啮合条件.因此,弧齿锥齿轮实际上是局部近似共轨.目前,都是保证两齿面局部共轨到二阶.研究弧齿锥齿轮的加工就是要研究在不同的切齿条件下如何调整铣齿机,改

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号