目录(三号、黑体、居中)

第1章 前言··········································································1

1.1 引言············································································1

1.2 复摆颚式破碎机的特点·······················································1

1.3 国内外颚式破碎机的发展与现状············································2

第2章 总体设计····································································3

2.1 基本结构·······································································3

2.2 工作原理·······································································5

第3章 主要参数的确定··························································5

3.1 已知参数·······································································5

3.2 部分结构参数的选定··························································5

3.3 电动机的选择与确定··························································8

3.4 复摆颚式破碎机生产··························································9

3.5 确定四连杆机构各杆的长度················································10

3.6最大破碎力····································································11

3.7各部件的受力分析····························································11

第4章 传动装置设计···························································13

4.1 带轮的设计···································································13

4.2 偏心轴的设计································································17

4.3 飞轮设计·····································································21

4.4 轴承的校核···································································23

4.5 键的校核·····································································25

第5章 各基本结构的设计······················································26

5.1 动颚的设计···································································26

5.2 尺板的设计···································································30

5.3 推力板的设计································································31

5.4 调整装置的设计·····························································33

5.5 破碎腔型的设计·····························································35

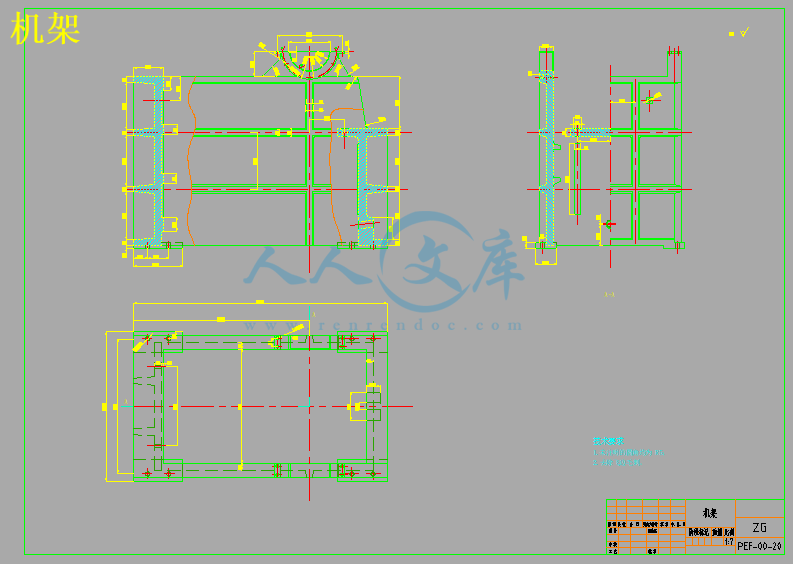

5.6 机架的设计···································································38

第6章 安装维修及改进措施··················································41

6.1 改变飞轮端密封套与锥套螺纹旋向········································41

6.2 修复偏心轴与锥套配合面···················································41

6.3 对颚版材质的选择···························································42

6.4 破碎机出口扬尘的解决·····················································42

6.5 破碎机的噪声危害及防治途径·············································44

第7章 毕业设计小节····························································45

参考文献············································································46

毕业实习报告······································································47

附录或后记·········································································12

附:英文翻译

英文原文

第1章 绪论

1.1 引言

破碎机械和筛分机械这两类机械设备,同属于矿山机械范畴,在各种工业生产线上通常前后工序布置使用,故有密切的关联。破碎机械和筛分机械的联合使用,可以把各种天然的矿物、或者工业生产中间过程物料,通过破碎和筛分,成为最终产品或者进一步深加工原料。因此这两类机械设备在冶金、建材、化工、能源、交通建设、城市建设和环保等诸多领域有广泛的用途。

在改革、开放的国策指引下,我国国民经济的迅速发展,要求各行各业都以先进的机械来装备。在破碎和筛分方面也不例外。这种市场需求促使有关高等院校、科研设计院所和工矿企业对破碎机械和筛分机械做大量的研究工作。近十几年来,这些研究成果的论文纷纷发表在各种出版物上,这些成果表明,当前国内破碎机械和筛分机械的某些方面已经达到国际先进水平。

1.2 复摆颚式破碎机的特点

它们适用于冶金、矿山、建筑、交通、水泥等部门,作为粗碎、中碎抗压强度在300Mpa以下的各种矿石或岩石之用。具有结构简单合理、产量高、破碎比大、齿板寿命长、成品粒度均匀、动力消耗低、维修保养方便等优点,是目前国内最先进的机型。

其具有以下性能特点:

1.破碎腔深而且无死区,提高了进料能力与产量;

2.其破碎比大,产品粒度均匀;

3.垫片式排料口调整装置,可靠方便,调节范围大,增加了设备的灵活性;

4.润滑系统安全可靠,部件更换方便,保养工作量小;

5.结构简单,工作可靠,运营费用低。

6.设备节能:单机节能15%~30%,系统节能一倍以上;

7.排料口调整范围大,可满足不同用户的要求;

8.噪音低,粉尘少。

川公网安备: 51019002004831号

川公网安备: 51019002004831号