摘 要

自古以来小麦是我国人民的重要的粮食作物,对保障我国粮食生产安全有重要的意义。要实现作物高产的目标,必须重视农机与农艺相结合。合理而精量的播种能够为小麦提供良好的生长条件并能提高小麦对土壤营养、水分和阳光的利用效率,协调小麦个体与群体关系,使小麦成穗率高,粒多、饱满,实现小麦的优质高产。因此小麦精密播种机的性能关系着农业生产成本和产量,但现有播种机并不能很好的满足小麦的生产要求。因此有专家提出了一种加行不加量的播种方法,即将行距减小到10cm,但播量不变,即行距减小一半,每行的播量减小一半但总播量不变,此播种方法可使小麦播种均匀,且播深一致,从而达到高产目的。河北省是中国第三小麦生产大省。本课题设计制造了适合河北省应用的小麦10cm行距播种机。

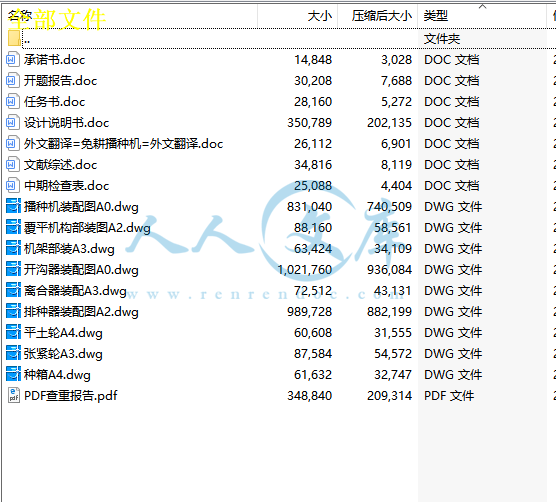

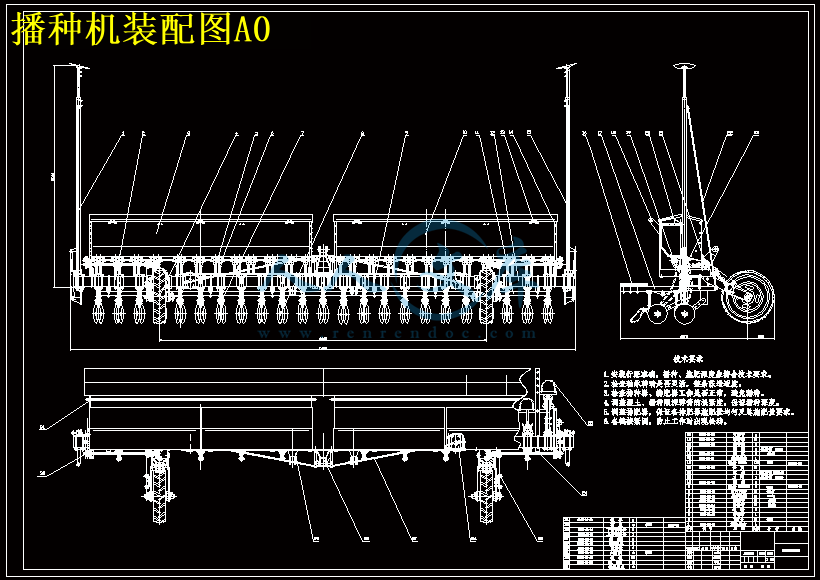

在设计小麦10cm行距播种机的过程中,对现有小麦播种机进行调查了解,又对10cm行距小麦播种机进行详细的研究分析,为所设计的播种机选择了合适动力的拖拉机,依据所选拖拉机确定了播种机的工作幅宽和悬挂方式。在整机的设计过程中分析选择了适宜的开沟器与种管,设计了机架结构、种箱和传动系统,并通过播量实验设计了调节播量的变速器。论文设计的充种沟式精密排种器使小麦播种更均匀,合理布置的开沟器使播种机有较好的通过性能,设计的小麦10cm行距播种机工作稳定,试验表明此播种机播种的小麦有效分桑多,苗壮,达到了小麦增产的目的。

关键词:播种机;小麦;10cm行距;充种沟式精密排种器

ABSTRACT

Wheat is one of the major staple food for our people. It has a great significance in the grain production. Our country has realized the sowing mechanized. To achieve the goal of high yield of wheat crop, it must pay great attention to combine agricultural machinery and agriculture. The agronomic requirements of wheat crop all row spacing, planting distance and sowing depth all need to be accurate in order to sow the wheat reasonably, which will save seed, make full use of land, sunlight and wind. It is that row spacing decreases to 10cm and sowing is the quantity of 15cm spaces. The seeding method can make more uniform distribution of wheat and sow depth consistent. It can be reached the goal of high yield. Due to the uniform distribution of wheat, it is up to the ecological effect of water retention. In different regions,natural environment, soil conditions, wheat varieties and so on, the Structure of seeding machine is different. The subject design and manufacture of the 10cmrow seeder for wheat applied in Hebei Province.

In the process of designing and manufacturing the 10cm row seeder for wheat, this paper investigated the existing wheat seeder, analyzed the 10cm row wheat seeder detaily, and selected appropriate power tractors for sowing machine. According to the selected tractor,it determined seeding machine working width, selected the way of suspension, chewed feasible furrow opener, designed the structure of frame, box, and transmission system,chewed the pipe through sowing experiment, and designed the transmission for regulate seeding rate. The filling groove precision metering device makes planting more uniform.Reasonable arrangement of the opener makes the machine has good through performance.The10cm row seeder for wheat works stable. Effective tillers of wheat in planter are more. It achieved the purpose of wheat production.

Key words: Seeding machine; Wheat; 10cm row spacing; Ditch filling-type precision seed-metering device

目 录

1引言 1

1.1课题研究意义及必要性 1

1.2国内外现状 1

1.2.1国外小麦播种机现状 1

1.2.2国内小麦播种机现状 2

1.3课题的研究 2

2小麦播种机总体结构设计 2

2.1小麦播种机的工作原理 2

2.2整体总体设计方案 2

2.2.1播种机主要参数...................................................................................................................................3

2.2.2播种机结构简图...................................................................................................................................3

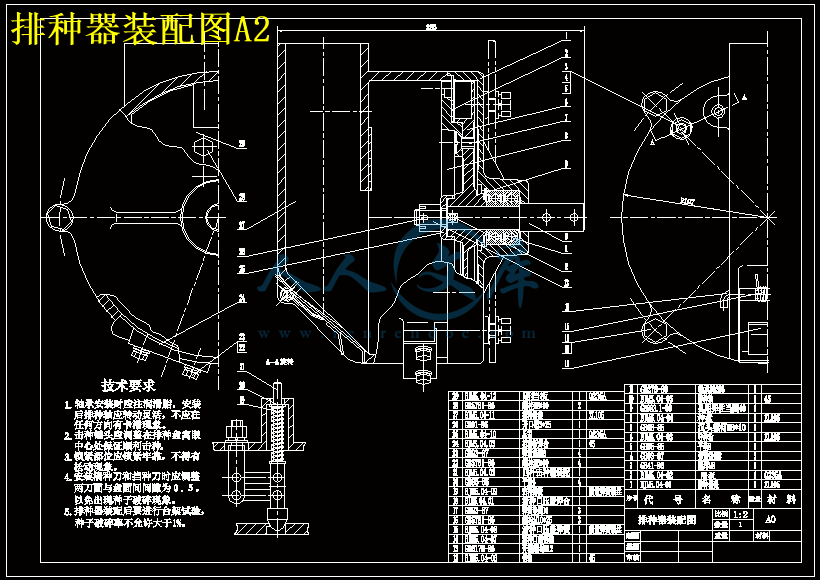

3排种器的设计 4

3.1技术要求 4

3.1.1技术要求分析 4

3.1.2技术要求 4

3.2方案分析 4

3.2.1现有小麦排种器分析 4

3.2.2新型小麦排种器的设计方案的探索 4

3.3结构与工作原理 6

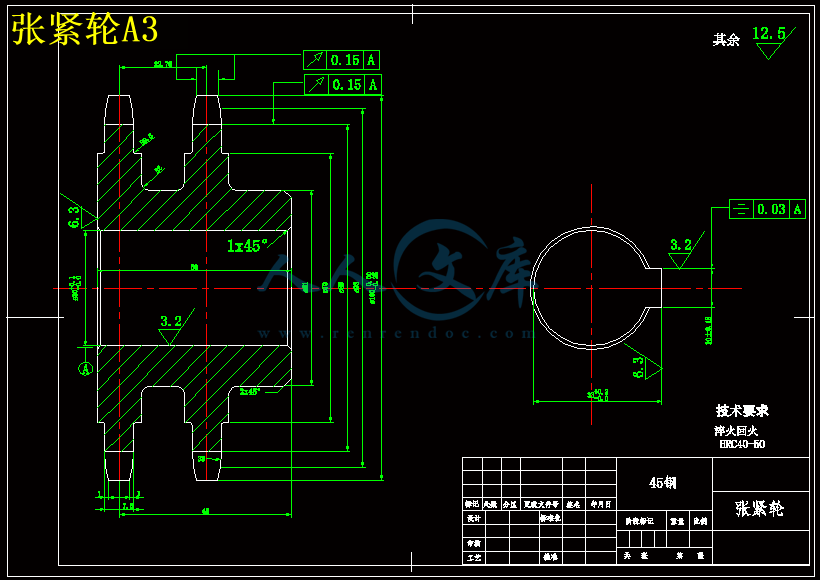

3.3.1充种沟式精密排种器的结构 6

3.3.2充种沟式精密排种器的工作原理 6

3.3.3充种方式分析 7

3.4关键部件设计 7

3.4.1排种轮直径、宽度与充种槽个数的设计 7

3.4.2种盒的设计 8

3.4.3清种缝隙与清种片的设计 8

3.4.4导种槽的设计 8

3.4.5排种轴的设计 8

4播种机其它部件设计 8

4.1拖拉机的选择及工作幅宽、播种行数的确定 8

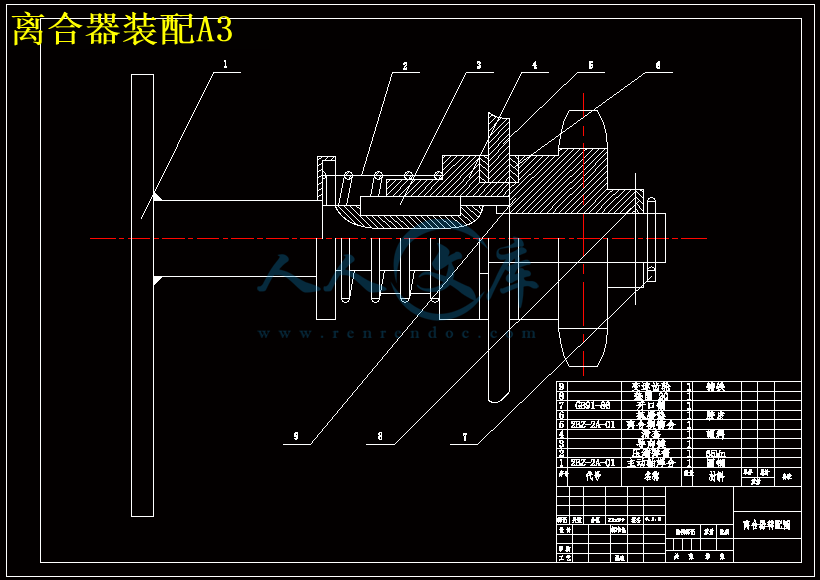

4.2悬挂装置的选择 9

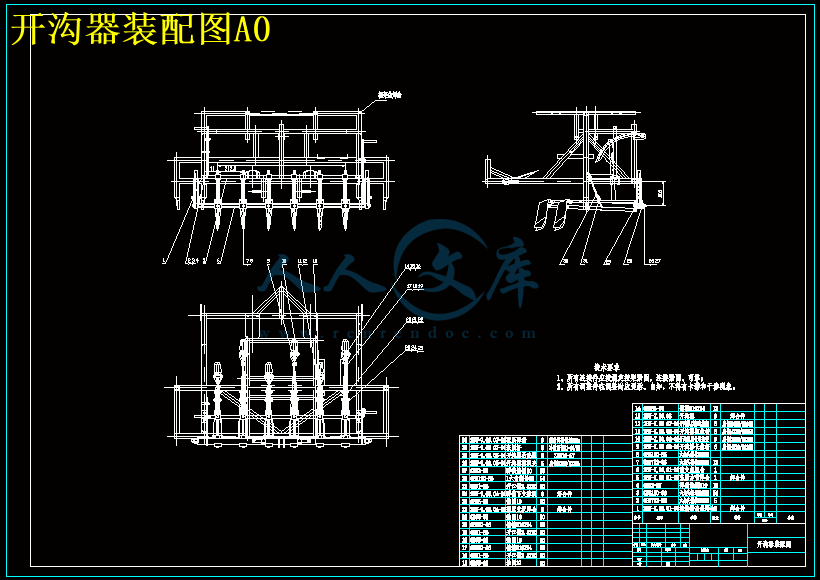

4.3开沟器的设计 9

4.3.1开沟器的选择 9

4.3.2开沟器的布置 9

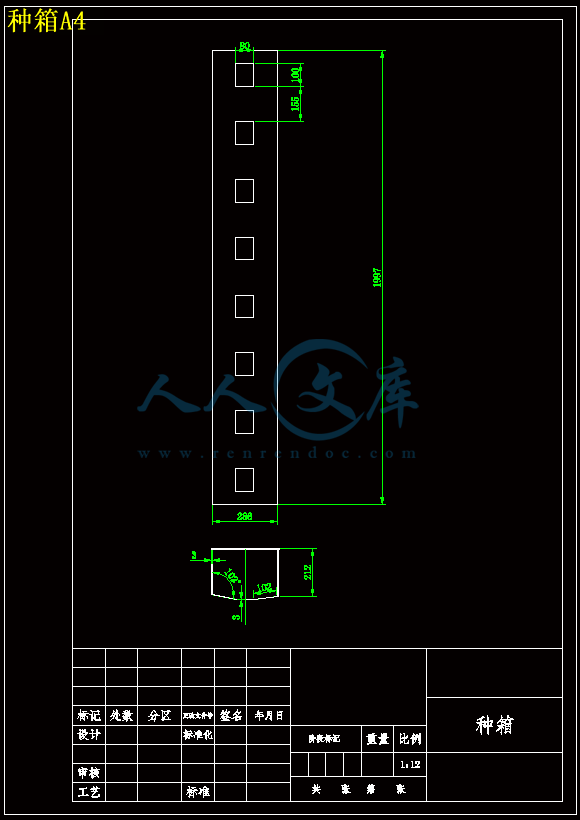

4.4种箱的设计 10

4.4.1种箱的设计 10

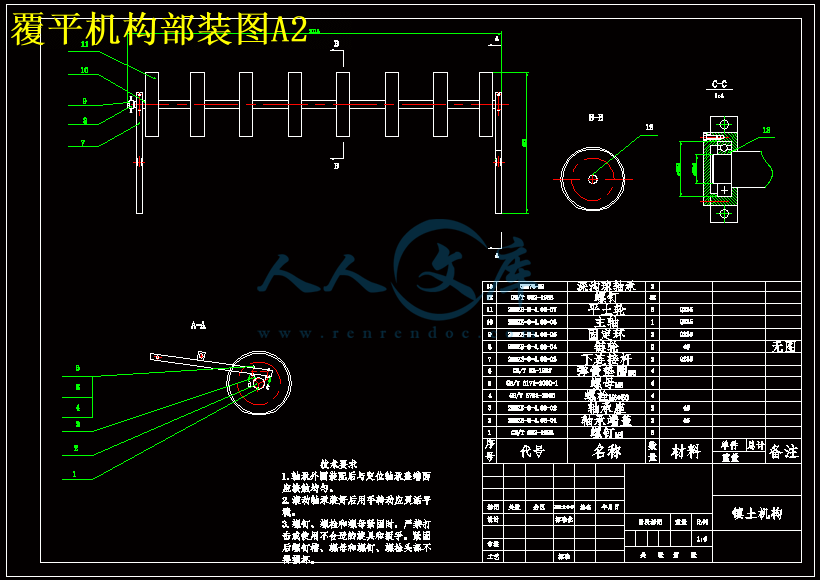

4.5机架设计 10

4.6接种装置设计 10

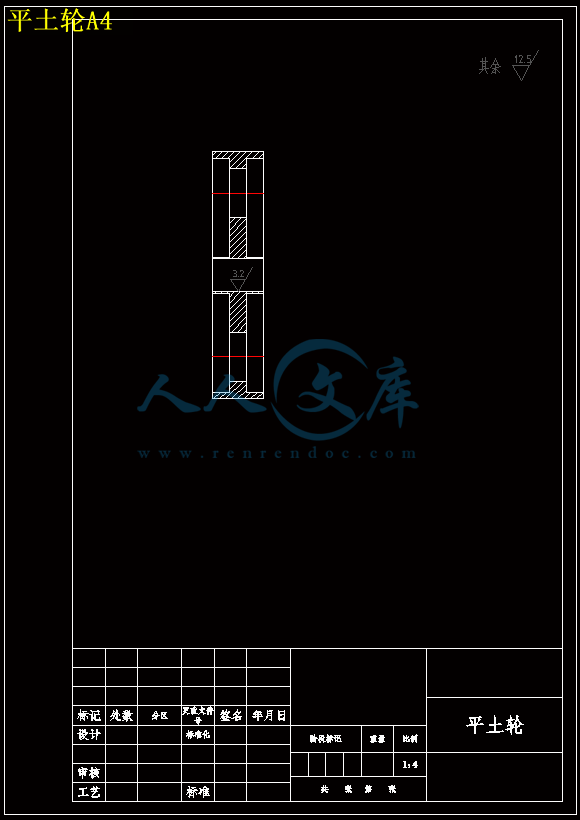

4.7地轮设计 11

4.8变速器选择与传动设计 11

4.8.1变速器的选择 11

4.8.2传动设计 11

4.9其它部件设计 12

5拖拉机牵引功率的校核 12

参考文献 14

致谢 15

1引言

1.1课题研究意义及必要性

我国是一个农业大国,小麦是我国人民的主要粮食来源,也是我国非常重要的商品粮。因此小麦的产量对我国的粮食安全有重要影响,小麦在我国粮食生产上的地位越来越重要。提高小麦产量意义重大,小麦发展的任务非常艰巨。河北省主要种植玉米和小麦,是我国小麦生产第三大省。河北省有丰富的光热资源,肥沃的土壤,适宜的降雨量,适宜优质强面筋小麦的种植。因此,提高河北粮食生产能力的技术与科学研究的进程,对于河北省粮食生产能力的提升和国家粮食安全的保障具有重大意义。

但现有小麦精播机的性能还不能达到高产条件。现有小麦精密播种机一般为15cm行距,大多数采用的是外槽轮式排种器。这种排种器的脉动性导致小麦播种机播种不均匀,经常发生幼苗拥挤生长的现象。目前,我国小麦播种过程中缺苗断垄与麦苗拥挤生长的现象较为严重。其原因主要有以下几点:

(1)外槽轮排种器的脉动性,导致排种不均匀;

(2)充种效果不好导致槽轮充不上种,形成漏播;

(3)种子与开沟器发生碰撞或落于开沟器上;

(4)种子在种沟内发生弹跳;

(5)覆土时种子随土壤移动;

(6)作业时播种机的震动使排种时多时少;

(7)地轮打滑或传动轴与排种器间打滑导致传动不均,影响播种均匀性;

因此小麦播种机的性能优劣直接关系到农业生产成本和产量,现代农业越来越需要优秀的小麦精密播种机。

相关专家提出了一种加行不加量的播种方法,即播种行距减小到10cm,播量与15cm行距播量一致,即行距减小一半,每行播量减小一半但总播量不变。此播种方法可使小麦更均匀播种,且播深一致,从而实现高产。由于小麦的均匀分布,还能起到保水的生态效果。现有小麦播种机行距一般调节范围在12cm以上,不能实现10cm行距播种。不同地域的自然环境、土壤条件、小麦品种等的不同,导致不同地域的播种机的构造有所差别。

川公网安备: 51019002004831号

川公网安备: 51019002004831号