摘要

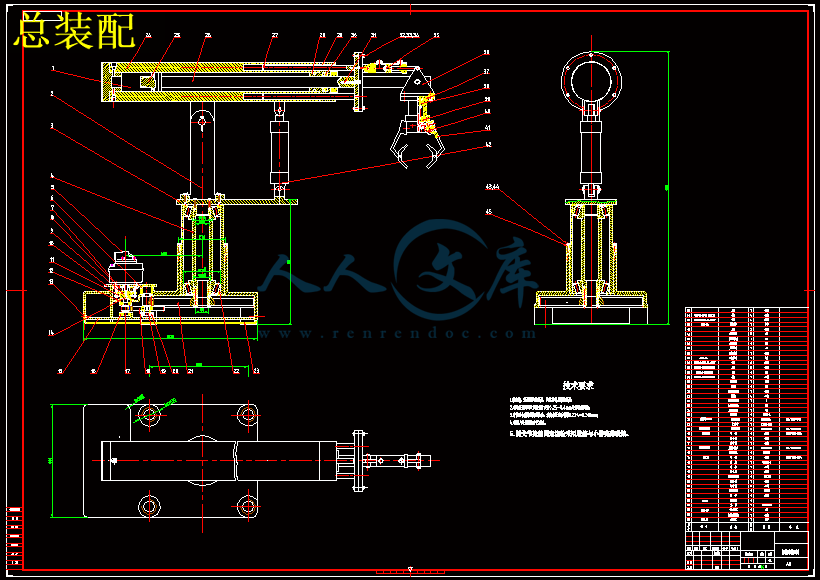

随着现代科学技术的发展,机器人技术越来越受到广泛关注,在工业生产日益现代化的今天,机器人的使用变得越来越普及。因此,对于机器人技术的研究也变得越来越迫切,尤其是工业机器人方面。本论文作者针对这一领域,设计了一款液压机械机械手,该机器人拥有五个自由度。首先,作者针对该机器人的设计要求,对结构设计选择了一个最优方案,对关键零件设计并进行校核。

本课题是一个机械、液压紧密的实用性项目,文中对机械手机械结构的设计、液压系统的设计讨。最后,总结了全文,指出了机械手的改进措施、应用前景和发展方向。

关键字:机械手,液压系统,五个自由度

Abstract

With the development of modern science and technology, the robot technology has been paid more and more attention, in an increasingly modernized industrial production, the use of robots is becoming more and more popular. Therefore, the research of robot technology becomes more and more urgent, especially industrial robots. The author of this thesis in this field, design of a hydraulic mechanical manipulator, the robot has five degrees of freedom. First of all, the author according to the requirement of the design of this robot, an optimal scheme of the structure design of the selection, the design of key parts and checked.

This topic is a mechanical, hydraulic close practical project, design of mechanical design, mechanical structure of the hydraulic system of the mobile phone in. Finally, summarized the full text, points out the improvement measures, manipulator application prospect and development direction.

Keywords: manipulator, hydraulic system, five degrees of freedom

目录

摘要 I

Abstract II

第1章 绪论 1

1.1 选题背景及其意义 1

1.2 国内外研究现状与发展趋势 1

1.3 本设计主要研究的内容 3

第2章 机械手的总体设计 4

2.1 机械手的组成及各部分关系概述 4

2.2 机械手的设计分析 4

2.2.1 设计要求 4

2.2.2 总体设计任务分析 4

2.2.3 总体方案拟定 6

第3章 机械手结构的设计分析 8

3.1 末端操作器的设计分析 8

3.2 手腕的设计分析 8

3.3 手臂的设计分析 8

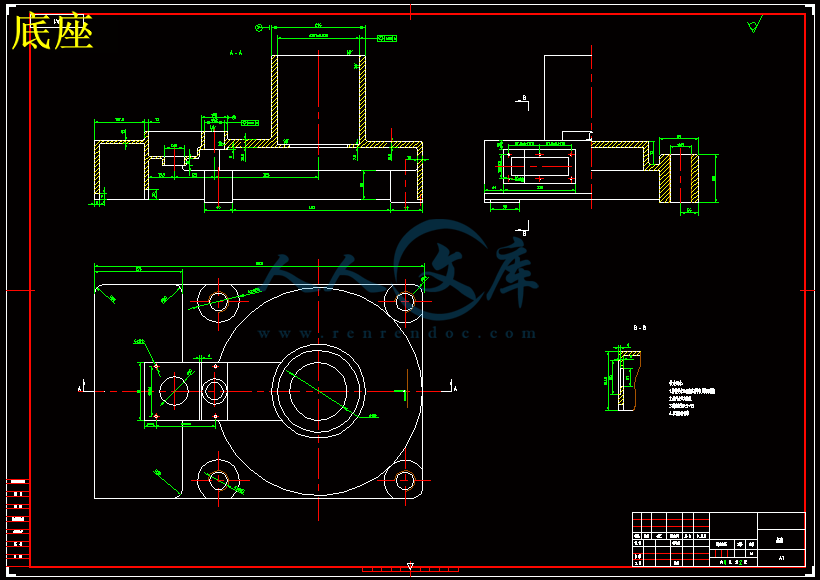

3.4 机身和机座的设计分析 9

第4章 机械手各部件的载荷计算 11

4.1 设计要求分析 11

4.2 手指夹紧机构的设计 11

4.3 手臂伸缩机构载荷的计算 12

4.4 手臂俯仰机构载荷的计算 13

4.5 机身摆动机构载荷力矩的计算 13

4.6 初选系统工作压力 14

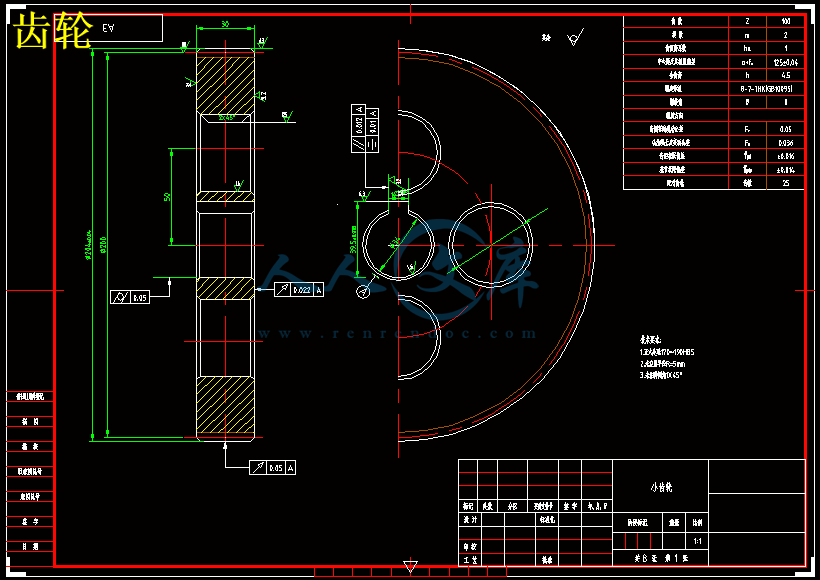

第5章 机械手各部件结构尺寸计算及校核 16

5.1 手腕油缸尺寸的确定 16

5.2 手臂伸缩机构结构尺寸的确定 19

5.3 手臂俯仰机构结构尺寸的确定 19

5.4 机身摆动机构的确定 19

5.5 强度校核 19

5.6 弯曲稳定性校核 20

第6章 液压系统的设计 22

6.1 制定基本方案 22

6.1.1 基本回路的选择 22

6.2 液压元件的选择 22

6.2.1 液压泵的选择 22

6.2.2 液压泵所需电机功率的确定 24

6.2.3 液压阀的选择 24

6.2.4 液压辅助元件的选择原则 25

6.2.5 油箱容量的确定 26

6.2.6 液压原理图 27

结论 29

参考文献 30

第1章 绪论

1.1 选题背景及其意义

随着工业自动化程度的提高,工业现场的很多易燃、易爆等高危及重体力劳动场合必将由机器人所代替。这一方面可以减轻工人的劳动强度,另一方面可以大大提高劳动生产率。

通过本课题,让学生在毕业设计过程中综合大学所学基础课程及专业课程,培养学生综合应用所学知识和技能去分析和解决一般工程技术问题的能力;进一步培养学生分析问题、创造性地解决实际问题的能力。

本课题中多自由度机械手系统主要采用液压驱动。

1.2 国内外研究现状与发展趋势

(1)国内的研究现状

工业机械手最早应用在汽车制造工业,常用于焊接、喷漆、上下料和搬运。工业机械手延伸和扩大了人的 手足和大脑功能,它可替代人从事危险、有害、有毒、低温和高温等恶劣环境中工作:代替人完成繁重、单调重复劳动,提高劳动生产率,保证产品质量。目前主要应用与制造业中,特别是电器制造、汽车制造、塑料加工、通用机械制造及金属加工等工业。工业机械手与数控加工中心,自动搬运小车与自动检测系统可组成柔性制造系统和计算机集成制造系统,实现生产自动化。随着生产的发展,功能和性能的不断改善和提高,机械手的应用领域日益扩大。

我国工业机械手的研究与开发始于20世纪70年代。1972年我国第一台机械手开发于上海,随之全国各省都开始研制和应用机械手。从第七个五年计划(1986-1990)开始,我国政府将工业机器人的发展列入其中,并且为此项目投入大量的资金,研究开发并且制造了一系列的工业机器人,有由北京机械自动化研究所设计制造的喷涂机器人,广州机床研究所和北京机床研究所合作设计制造的点焊机器人,大连机床研究所设计制造的氩弧焊机器人,沈阳工业大学设计制造的装卸载机器人等等。这些机器人的控制器,都是由中国科学院沈阳自动化研究所和北京科技大学机器人研究所开发的,同时一系列的机器人关键部件也被开发出来,如机器人专用轴承,减震齿轮,直流伺服电机,编码器,DC——PWM等等。

我国的工业机械手发展主要是逐步扩大其应用范围。在应用专业机械手的同时,相应的发展通用机械手,研制出示教式机械手、计算机控制机械手和组合式机械手等。可以将机械手各运动构件,如伸缩、摆动、升降、横移、俯仰等机构,设计成典型的通用机构,以便根据不同的作业要求,选用不用的典型机构,组装成各种用途的机械手,即便于设计制造,又便于跟换工件,扩大了应用范围。目前国内机械手主要用于机床加工、锻造。热处理等方面,数量、品种、性能方面都不能满足工业生产发展的需要。所以,在国内主要是逐步扩大应用范围,重点发展铸造、热处理方面的机械手,以减轻劳动强度,改善作业条件,在应用专业机械手的同时,相应的发展通用机械手,有条件的要研制示教式机械手、计算机控制机械手和组合机械手等。同时要提高速度,减少冲击,正确定位,以便更好的发挥机械手的作用。此外还应大力研究伺服型、记忆再现型,以及具有触觉、视觉等性能的机械手,并考虑与计算机连用,逐步成为整个机械制造系统中的一个基本单元。

川公网安备: 51019002004831号

川公网安备: 51019002004831号