摘 要

数控卧式机床的发展与应用,大大降低了零件的加工辅助时间,提高了生产效率。随着数控机床的普及应用,机械加工的自动化程度大大提高,数控机床发展成了当今普遍应用的一种更新、更先进的制造设备。加工中心带有刀库和自动换刀装置,可以实现按照预定程序对工件进行多工序加工。

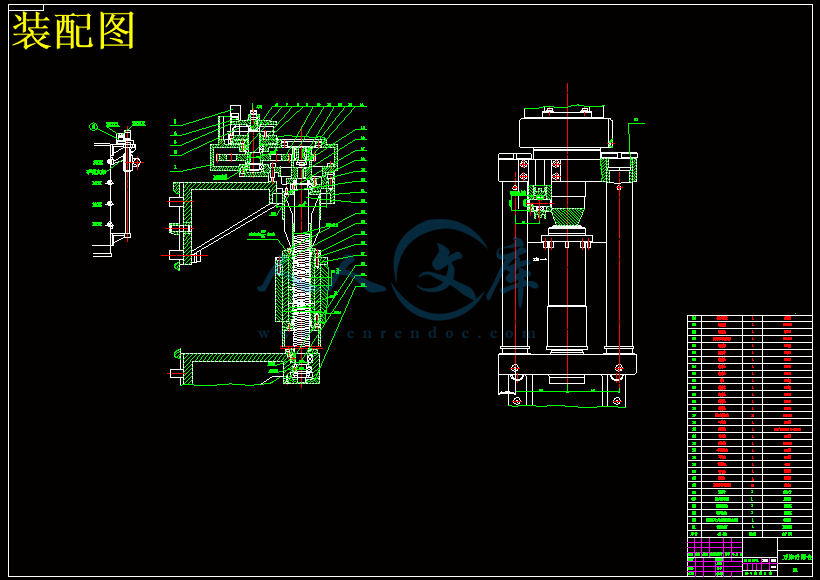

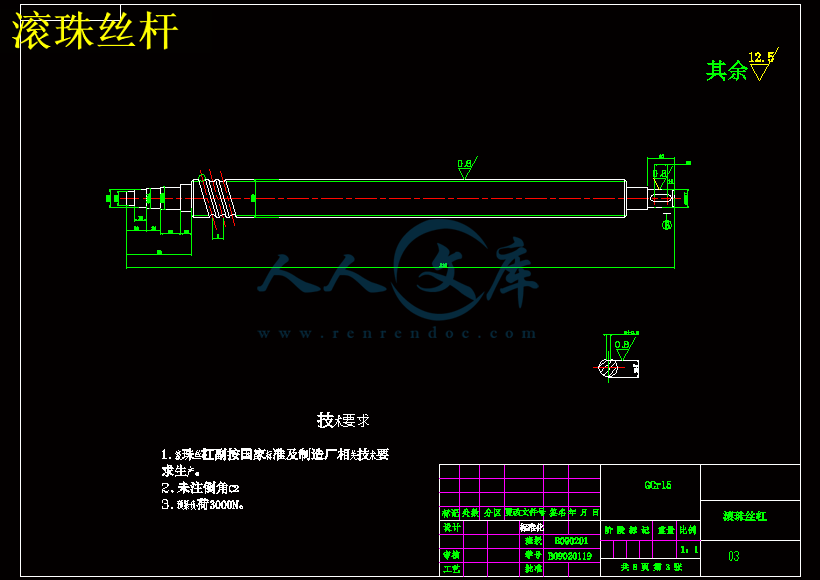

数控卧式镗铣床是一种具有自动换刀装置和任意分度数控转台的数字控制机床,工件在一次装夹后能自动完成几个侧面的的多种工序的加工。数控卧式镗铣床刀库机械手升降机构由液动机、滚珠丝杠副、减速齿轮、摩擦片式电磁离合器等构成。了解刀库机械手升降机构的性能要求;了解刀库机械手升降机构的工作原理,进行结构设计和计算分析;液动机带动滚珠丝杠转动,带动手架运动,通过减速和离合器吸合,丝杠制动,使手架准确停在换刀位置,良好的结构设计能够实现刀库中刀具的快速更换,提高机床的加工效率。

关键词: 升降机构;JCS-013数控镗铣床;液动机;滚珠丝杠;手架;离合器;

CNC horizontal boring and milling machine tool storage manipulator lifting mechanism design and analysis

Abstract

With the development of NC,the automatic tool changer system is more and more important in the modern advanced manufacture,because the ATC can shorten the cycle time of product manufacturing,improve the precision of product machining.The latest requirements of machine tool user comprise of diversification of control object,complexity of process,flexible of application and high reliability.The function of tool magazine is that stores the tool and moves the tool

which will be used in the next manufacturing process to the right changeover position and robot will finish the change over tool.

CNC horizontal boring and milling machine is a automatic tool change device and arbitrary indexing of digital control machine tool nc rotary table, After a clamping workpiece can automatically complete several profiles of a variety of machining process. CNC horizontal boring and milling machine tool storage manipulator lifting mechanism by the Liquid motive, The ball screw vice, Reduction ear, Friction plate electromagnetic clutch, etc. Understanding of knife library manipulator lifting mechanism performance requirements ,The understanding of the principle of operation of knife library manipulator lifting mechanism, Structure design and calculation analysis, Liquid motivation drives the ball screw rotation, lead frame hand movement, By slowing down and clutch and screw brake, make hand aircraft parked in knife position accurately,

Good design can bring about quick replacement knife tool in library, improve the processing efficiency of machine tool.

Key words: Lifting mechanism; CNC horizontal boring and milling machine ;Liquid motive ;Ball screw;Hand; Clutch;

目录

1 绪论 1

1.1数控镗铣床的结构组成 1

1.2国内外数控机床的发展 2

1.2.1国内外数控卧式镗铣床的现状 2

1.3数控机床的发展趋势 5

1.3.1高速化、高精度化、高可靠性 5

1.3.2复合化 6

1.3.3智能化 6

1.3.4柔性化、集成化 6

2数控卧式镗铣床刀库机械手升降机构设计 7

2.1 设计目的 7

2.2 设计内容 7

2.3升降机构的组成和运动 7

2.3.1升降机构的组成 7

2.3.2 手架升降机构的运动 8

3 升降机构驱动电机 9

3.1 升降电机的选择 9

3.1.1 升降电机的理论分析 9

3.1.2升降电机的选择 10

3.2 电机调速 11

3.2.1 变频调速原理 12

3.2.2变频器选型时要确定以下几点 12

4摩擦片式电磁离合器的选用 13

4.1转矩特性 13

4.2动作特性 14

4.3散热特性与寿命 14

4.4摩擦片式电磁离合器的测试方法 14

4.4.1静力矩的测定 14

4.4.2动力矩的测定 14

4.4.3空转力矩的测定 15

4.4.4残留力矩及力矩消灭时间的测定 15

4.5选用电磁离合器的注意事项 16

5 滚珠丝杠副的选用 17

5.1滚珠丝杠副的工作原理 17

5.2滚珠丝杠副的类型 18

5.2.1外循环 18

5.2.2 内循环 18

5.3滚珠丝杠副的传动特点 19

5.4滚珠丝杠的选用指标 19

5.5滚珠丝杠副的设计计算 20

5.6滚珠丝杠的保护 24

6 控制系统 25

6.1模拟式 25

6.2数字式 25

6.2.1行程开关 25

6.2.2接近开关 26

总 结 27

参 考 文 献 28

致 谢 29

毕业设计(论文)知识产权声明 30

毕业设计(论文)独创性声明 31

1 绪论

在车床、镗床、铣床、插、拉床、磨床、数控加工中心、齿轮加工中心、切断机床、特种加工机床、组合机床、柔性制造系统等众多机械加工设备中,镗铣床加工特点:加工过程中工件不动,让刀具移动,并使刀具转动(主运动),在实践中具有“万能机床”的称号。

镗铣床主要是刀具在工件上加工已有预制孔的机床。通常,刀具旋转为主运动,刀具或工件的移动为进给运动。它主要是用来加工高精度孔或一次定位完成多个孔的精加工,此外还可以从事与孔精加工有关的其他加工面的加工。

川公网安备: 51019002004831号

川公网安备: 51019002004831号