目 录

第1章 绪论 1

1.1 课题背景 1

1.2 课题研究的目的和意义 1

1.3 现状 2

第2章 总体方案设计 12

2.1 设计的基本要求 12

2.1.1 工艺范围 12

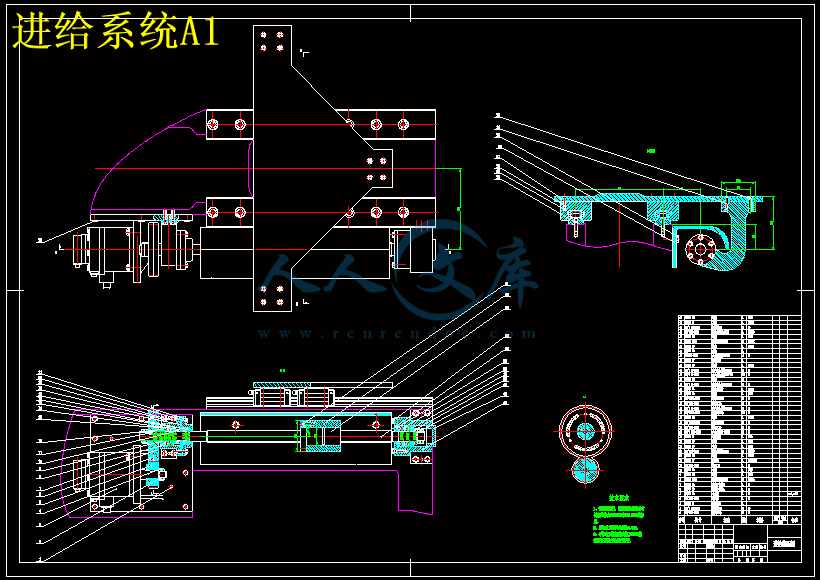

2.1.2 进给方案的选取 12

2.1.3 吸附结构 13

第3章 进给系统设计计算 14

3.1 切削力的计算 14

3.2 丝杠螺母的设计与计算 14

3.2.1 强度验算 14

3.2.2 效率计算 15

3.2.3 刚度验算 15

3.2.4 稳定性验算 16

3.3 电机的选择 17

3.3.1 计算传动比 17

3.3.2 转动惯量计算 18

3.3.3 所需传动力矩计算 18

3.3.4 电机的选择 19

3.4 轴承的选用与校核 20

3.4.1 角接触球轴承的选择 20

3.4.2 深沟球轴承的选择 21

结论 22

致谢 23

参考文献 24

千万不要删除行尾的分节符,此行不会被打印。在目录上点右键“更新域”,然后“更新整个目录”。打印前,不要忘记把上面“Abstract”这一行后加一空行

第1章绪论

1.1课题背景

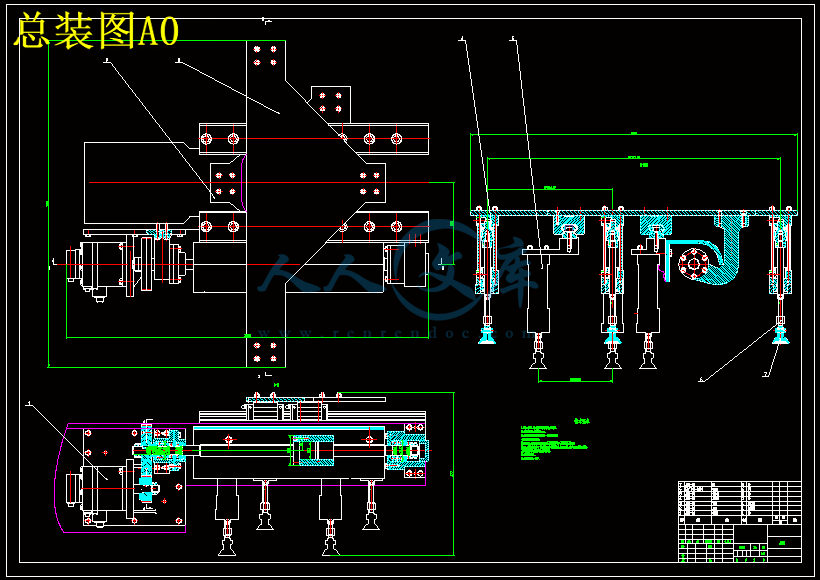

课题来源于常州太烨传感科技有限公司。 船舶在长期的航行中,水下部分的船体表面会附有贝类、藻类生物及生出锈斑,严重影响船舶的航行速度和使用寿命,还增加船舶的燃料消耗,所以定期清洗非常重要,人工清洗人员工作量大、难度大、效率低,目前中国国内对于这方面的研究还很少,对于壁面清洗机器人有一些研究,主要是清洗玻璃、墙壁等,但是对于船舶清洗研究的却是很少,主要是因为船舶清洗是在水下,设计时要考虑水的影响,密封性的要求,水下移动、吸附等问题,增大了设计的难度。因此研制水下清洗机器人成为需要,水下船舶清洗机器人将大大提高船舶清洗的效率,减少工作量,减少工作强度,实现自动化清洗。该机器人的结构主要分成两部分:一部分是移动部分,另一部分是清洗部分。移动部分主要解决的问题是机器人在曲面上的移动,清洗部分的结构设计利用清洗盘的转动来实现清洗。本课题主要内容包括:国内外文献分析,总统方案设计,水下船舶清洗机器人机械结构设计,装配图零件图的设计,结构优化设计。

1.2课题研究的目的和意义

船舶正常工作时总有一部分沉在水下,常年累月,在水下的船体表面会附着一些贝类、藻类等生物,严重影响船舶的航行速度和使用寿命,还增加了船舶的燃料消耗,所以每隔一段时间就要对船舶进行清洗.但传统的清洗方法是工人要潜入水里才能对船舶进行清洗,具有一定的风险性,工作量大,难度大.因此研究水下清洗机器人成为必要.本设计的研究目的就是在于制造出一种在水下可以游动并且可以吸附在船体上的清洗机器人.一方面机器人可以像鱼类一样在水下自由的游动;另一方面该机器人可以通过电磁吸附吸附在船体上并且通过移动装置在船体上爬行,同时进行清洗.因此该机器人代替了人工潜入水下进行清洗,减少了工人的工作量,减轻了工作强度,实现了水下船舶清洗的自动化,同时对于爬行机器人在曲面上的移动提出了一种新的爬行方式,具有重要意义.。

1.3现状

目前中国国内对于这方面的研究还很少,对于壁面清洗机器人有一些研究,主要是清洗玻璃、墙壁等,但是对于船舶清洗研究的却是很少,一方面船舶清洗是在水下,设计时要考虑水的影响,密封性的要求,水下移动、吸附等问题,增大了设计的难度,目前国内有哈尔滨工业大学于 2003 年研制出了一种水下清洗机器人,采用履带式移动方式,吸附在船体上清洗船舶.国外一些国家也开始研究清洗机器人,主要是壁面清洗机器人的研究,都取得一些成绩,但是在实现复杂运动和清洗功能的技术理论和实践上仍需要经历一段成熟期.

对于清洗机器人的研究,尤其是水下清洗机器人,目前仍然是处于开始期,还有很多关键的技术需要解决,并且水下清洗机器人作为一种新的清洗概念和作业方式,还有很长一段路要走,但是随着中国航海事业的发展,船舶的排水量的增加,水下船舶部分的清洗也将是一项很繁重的任务,如果实现自动化清洗,将大大提高效率,减轻工作量,所以水下清洗机器人有着很好的发展前景.

爬行方案

机器人要完成在船体表面的爬行,一方面通过电磁吸附吸附在船体上,同时机器人在船体上要完成移动.

爬行部分主要解决两个问题,一个问题是机器人在曲面的移动,另一个问题是机器人在船体表面的吸附.

爬行方案

对于移动机器人现在的研究主要集中在平面里的移动,例如清洗玻璃的机器人,在玻璃上爬行,清洗管道的机器人等等.下面是现在已经存在的几种机器人及其移动方案:多吸盘真空吸附式壁面清洗机器人系统,该机器人用于清洗高空玻璃,传统的清洗方法是靠升降平台或吊篮承载清洁工进行玻璃幕墙的清洗 ,虽简便易行,但劳动强度大,工作效率又低 ,属于高空极限作业 ,对人身安全及玻璃壁面都有很大的危险性.该机器人可以代替人工清洗.

川公网安备: 51019002004831号

川公网安备: 51019002004831号