【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

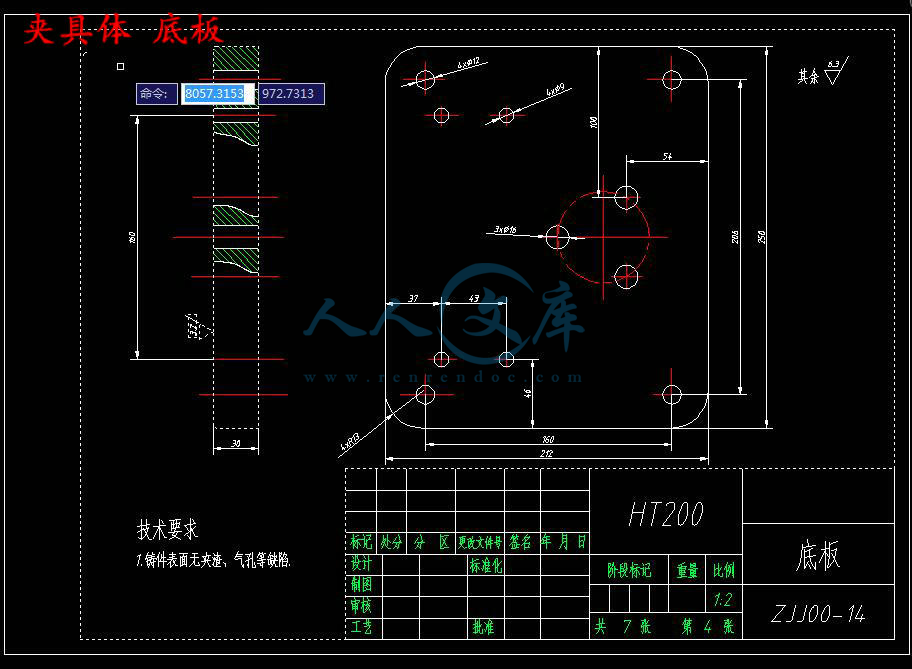

双联齿轮零件机械加工工艺及其典型夹具设计

摘 要

通过对零件的分析,制定一套合理的工艺方案,并设计出可行的夹具。本文主要是围绕双联齿轮零件的机械加工工艺以及对其中两道工序的夹具设计来展开的。其主要内容有:首先分析了零件图,确定生产类型和毛坯,确定加工设备,确定加工方案及装夹方案,刀具的选择,切削用量的选择与计算,数据处理等。本次设计主要是对钻28的孔和滚齿进行夹具设计,对夹具设计方案进行分析和选择。选定方案后,通过查阅相关夹具设计书籍和相关图例,最终完成钻孔和滚齿的夹具设计。试图找出一种简单、实用的加工方法,以提高劳动生产率和降低成本。

关键词:双联齿轮;工艺分析;工艺规程设计;夹具设计

The machining process and fixture design of the Dual gear

Abstract

Part of the analysis,to develop a reasonable process scheme, and design a feasible fixture.This paper is mainly about the Dual gear machining process and fixture design for the two processes to start. Its main contents are: the first analysis of the parts diagram, determine the production type and blank, determine the processing equipment, determine the processing scheme and clamping scheme, tool selection, selection and calculation of cutting parameters, data processing etc.. This design is mainly to drill 28 holes and hobbing fixture design, analysis and selection of design scheme of fixture. The selected solution, by consulting the related jia design books and related legend, fixture design finished drilling and hobbing. Trying to find a processing method of simple, practical, to improve labor productivity and reduce the cost.

Key words:Dual gear; Process analysis; Process design; fixture design

目 录

1 绪论 1

1.1设计内容及意义 1

1.2国内外相关研究情况 1

1.3课题背景知识 2

1.4夹具设计 5

2 工艺规程设计 7

2.1工艺分析 7

2.1.1零件的作用 7

2.1.2零件工艺分析 7

2.1.3生产纲领计算 8

2.2毛坯选择 8

2.2.1选择毛坯种类 8

2.2.2确定毛坯尺寸及机械加工总余量 9

2.2.3 绘制毛坯图 10

2.3制定工艺路线 10

2.3.1定位基准选择 10

2.3.2加工阶段划分 11

2.3.3工序的集中与分散 13

2.3.4工序顺序的安排 13

2.3.5工艺路线拟定 13

2.3.6 加工设备及工艺装备选择 15

2.3.7工序尺寸确定 16

2.3.8切削用量及基本工时 17

3 滚齿夹具设计 26

3.1问题的提出 26

3.2确定定位方案 26

3. 3确定夹紧机构 26

3. 4确定其他装置 26

3. 5绘制夹具总图 27

3. 6夹具简要说明 28

4 钻夹具设计 29

4.1问题的提出 29

4.2定位基准的选择 29

4.3确定夹紧机构 29

4.4绘制夹具装配图 29

4.5切削力和夹紧力计算 30

4.6定位误差分析 31

4.7夹具简要说明 31

5 结论 32

参考文献 33

致谢 34

毕业设计(论文)知识产权声明 35

毕业设计(论文)独创性声明 36

1 绪论

1.1设计内容及意义

本次设计是在我们学完了大学的全部基础课,技术基础课以及专业课之后而进行的。此次的设计是对大学期间所学各课程及相关的应用绘图软件的一次深入的综合性的总复习,也是一次理论联系实际的训练。其目的在于:

a.巩固我们在大学里所学的知识,也是对以前所学知识的综合性的检验;

b.加强我们查阅资料的能力,熟悉有关资料;

c.树立正确的设计思想,掌握设计方法,培养我们的实际工作能力;

d.通过对双联齿轮零件的机械制造工艺设计,使我们在机械制造工艺规程设计,工艺方案论证,机械加工余量计算,工艺尺寸的确定,编写技术文件及查阅技术文献等各个方面受到一次综合性的训练。初步具备设计一个中等复杂程度零件的工艺规程的能力。

e. 能根据被加工零件的技术要求,运用夹具设计的基本原理和方法,学会拟定夹具设计方案,完成夹具结构设计,初步具备设计出高效,省力,经济合理并能保证加工质量的专用夹具的能力。

f.通过零件图,装配图绘制,使我们对于AutoCAD绘图软件的使用能得到进一步的提高[1]。

川公网安备: 51019002004831号

川公网安备: 51019002004831号