【温馨提示】 购买原稿文件请充值后自助下载。

以下预览截图到的都有源文件,图纸是CAD,文档是WORD,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

滚动轴承普遍应用于航空、军工、汽车、机械等工业中,它作为各种机械装备十分重要的基础件是一种精密的机械元件,而球轴承作为滚动轴承家族中重要的一员其应用尤为广泛。

钢球加工质量的优劣是制约精密机械装备发展的重要原因,因为钢球的制造精度在球轴承里的影响能很大成程度上决定球轴承的质量,钢球是球轴承里最关键的零件。目前,国内普遍采用的钢球生产工艺为:备料、冷镦压、光球、热处理、硬磨、表面强化处理、精研、光电外观检查和尺寸分组、清洗、涂油包装入库。通过现场勘察,发现光球工序加工质量很差余量较大,对后面的工序造成的影响很大。

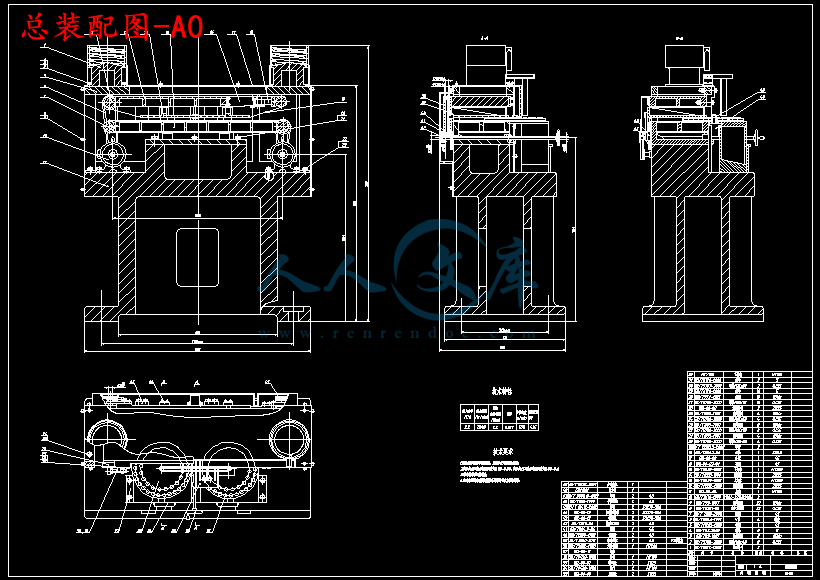

为了到达提高光磨工序的质量,降低后续工序加工余量这个目的,本课题旨在研究钢球生产中用于去除冷镦球坯缺陷并可以替代原有光球工序的新工艺,并对其相关工艺、设备进行改进。研究的主要内容有研究现有光球工艺机理,分析存在的缺点和造成缺点的原因,提出创造使用新工艺的重要性;提出利用砂带磨削钢球的新工艺及具体方案,分析不同该方案的好坏,选取最佳工艺参数;通过实验验证砂带磨削钢球的表面质量优于现有光球工艺所加工的钢球,如此加工效率便得到提高;参考现有磨削机床,完成钢球砂带磨床的设计。

为了实现了新技术的实际方面的应用,在加工设备方面,本课题围绕有关现有光球机的几大技术上的缺点,设计了节能减排、清洁生产需求的全新砂带磨床。该机床采用新的机械式进给系统,并将阻尼板以模块化机构的形式安装到新型机床中。

为了可普遍应用于实际钢球生产中,开始了新型光球工艺与设备的研究,它将对传统的光球加工工艺产生非常大的影响。在经过实践检验与工艺参数改进后,能实现自动化控制和流水线生产,市场应用前景广阔。

关键词:光球,砂带磨床,工艺,磨削

目 录

摘 要 I

目 录 i

第1章 绪论 1

1.1课题来源 1

1.2课题的科学依据 1

1.2.1课题的科学意义 1

1.2.2国内外研究状况及其应用前景 2

1.3课题的指导思想及研究内容 3

1.3.1课题指导思想 3

1.3.2课题研究内容 3

第2章 总体方案设计 5

2.1拟采取研究方法、技术路线、实验方案的提出及可行性分析 5

2.1.1研究方法和技术路线 5

2.2研究方案的确定 7

2.2.1动力及传动系统的确定 7

2.2.2进料系统的确定 7

2.2.3压模板升降系统的确定 8

2.2.4砂带磨头结构的确定 9

2.2.5机床总体布局的确定 9

第3章 钢球的运动机理研究 10

3.1刚体动力学基础 10

3.1.1刚体一般运动的描述 10

3.1.2刚体一般运动的微分方程 11

3.2钢球动力学分析 13

3.2.1磨削模型的建立 13

3.2.2钢球受力分析 13

3.2.3钢球运动微分方程 18

3.3钢球表面磨削迹线 19

第4章机床部件的设计及其校核 21

4.1电机的选择 21

4.2 V带的选择计算及其校核 21

4.3张紧机构中弹簧的选择及其校核 24

第5章 结论与展望 27

5.1课题总结 27

5.2课题不足之处 27

5.3课题未来展望 27

参考文献 29

致谢 30

附录A:砂带磨削的组成及其特点 31

第1章 绪论

1.1课题来源

滚动轴承普遍应用于航空、军工、汽车、机械等工业中,它作为各种机械装备十分重要的基础件是一种精密的机械元件,而球轴承作为滚动轴承家族中重要的一员其应用尤为广泛。

钢球加工质量的优劣是制约精密机械装备发展的重要原因,因为钢球的制造精度在球轴承里的影响能很大成程度上决定球轴承的质量,钢球是球轴承里最关键的零件。目前,国内普遍采用的钢球生产工艺为:备料、冷镦压、光球、热处理、硬磨、表面强化处理、精研、光电外观检查和尺寸分组、清洗、涂油包装入库,各个过程产生的球的外表如图1-1所示,其实从冷镦件到光球这一工序很重要,很大程度上决定了生产出钢球的质量。通过到无锡钢球厂进行现场勘察,发现光球工序加工质量很糟糕,留下的余量很大,对后道工序的加工造成了较大的困难。

根据工件的形状,选择相应的接触方式,在一定的压力作用之下,使得高速运动的砂带与工件相接触产生摩擦,将工件表面上的余量渐渐地磨除或者抛磨光滑的这种方式就是砂带磨削,而利用砂带对工件进行加工的技术在国内为日趋成熟。六十年代以来,砂带磨削在国外发展的十分迅速,应用的范围也在逐渐扩大。五十年代末我国开始是用砂带磨削这一方法,然而当前的技术水平与国外工业发达的国家相差很大。纵观国内外,当前很少有将砂带磨削这一方式应用于钢球的磨削,因此本课题在市场的前景十分广阔。

因此本课题目的是寻找新的工艺

川公网安备: 51019002004831号

川公网安备: 51019002004831号