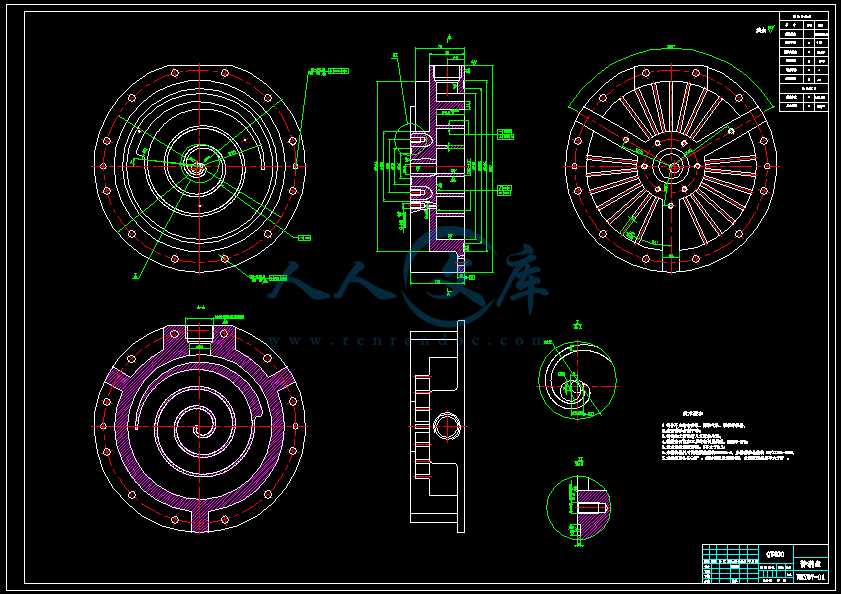

0.8m3-min涡旋式空气压缩机设计资料cad图纸

收藏

资源目录

压缩包内文档预览:

编号:20154712

类型:共享资源

大小:6.37MB

格式:ZIP

上传时间:2019-06-22

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

式空气压缩机

- 资源描述:

-

- 内容简介:

-

三维滚动涡旋压缩机的发展摘要:涡旋压缩机因为其高效率,低振动的优势已被广泛应用于各种场合。为了进一步提高涡旋压缩机性能,作者发展了一个新的三维压缩机制(立体滚动),即通过添加一个轴向压缩,到传统的径向压缩。三维压缩的实现,使得传统压缩机不可能实现的更高效率,更高的可靠性,体积小得以实现。由于立体滚动从滚动顶端到端板有步骤,使得三维压缩效率提高的关键点是要尽量减少气体在端板出的泄漏。通过气缸压力测量及可视化试验,可获得端板泄漏特性,得到了最佳间隙范围。在此基础上,作者开发了高效率,体积小,重量轻的立体滚动商用空调压缩机。所研发的三维滚动与传统的压缩机相比,压缩机体积减小35%,重量减轻26%,效率提高5.5%。关键词:压缩机,设计,制冷,控制,性能,开发,仿真1引言 从环境保护和应对全球变暖的角度出发,节约能源的要求越来越紧迫。由于大多数的制冷和空调电器是由压缩机转化的能源,因此它的效率的提高是节能不可缺少的。同时,这些设备往往在其安装空间受到限制。因此,每个组件,包括压缩机都应小型化,从而提高了安装的灵活性。今天,涡旋压缩机,它具有高效率,低振动的优势,已为各种电器使用,以满足对节约能源的需求和它的更广泛的使用。为了进一步提高涡旋压缩机性能,作者发展了一个新的三维压缩机制(立体滚动),即通过添加一个轴向压缩,到传统的径向压缩。本文介绍了三维滚动的效率改进技术和立体滚动商业空调压缩机的发展。2三维结构涡旋2.1三维滚动的立体特征图1 三维滚动涡旋压缩机 图1展示了商用立体滚动压缩机和其立体滚动涡旋型线。从图中看出气体达到了压缩室正从外侧压缩到内侧。压缩机的制冷剂是从固定涡旋的中心流出。图 2 传统压缩和三维滚动的剖视图 图2从剖视结构揭示了常规压缩和立体滚动的原理。传统涡旋齿的高度在整个压缩过程为常数,压缩制冷剂从外侧到压缩腔内侧数量不断变小。对于立体滚动,相反,在顶端和末端通过安装使得外侧端板比内侧端板高。从而使得三维压缩,即径向和轴向方向成为可能。三维滚动具有以下特点。 1) 通过径向和轴向压缩得到了更高的压缩比。 2)由于降低了内侧齿的重量,涡旋齿的强度得到提高,获得了高的可靠性,这样便减轻了一个沉重的负担。 3)由于增加了外齿的高度,滚动外径没有扩展,使得压缩空间更大,因此三维压缩的积小,重量更轻。2.2压缩机制和立体滚动间隙泄漏 在图3 中展示了三维滚动的压缩机制。从滚动顶端到端板,三维压缩是有步骤进行的。当不符合这些压缩步骤时(见图3(b)到(d)项)切线看,压缩腔具有相同的压力因此,在这一过程中没有泄露。另一方面,当符合这一压缩步骤时(见图3(a)到(c)项),密封线是由两个步骤结合而来的。 图3也显示了第一步的局部放大图和在轨道纵向方向滚动剖面图。每两步的间隙(以下简称步间隙),大致可分为末端间隙和侧面间隙,气体从高压腔到低压腔的泄露是从这些间隙发生的。因此,立体滚动压缩效率提高的关键点是通过优化步间隙来减少气体在步间隙的泄露。图3三维滚动的压缩机制 SPECIAL ISSUE PAPER193Development of a three-dimensional scroll compressorH Sato1,M Fujitani2,H Kobayashi2,H Mizuno2,andT Itoh11Nagoya Research and Development Center, Mitsubishi Heavy Industries, Ltd, Nagoya, Japan2Air-Conditioning and Refrigeration Systems Headquarters, Mitsubishi Heavy Industries, Ltd,3-1 Asahi Nishibiwajima-cho Kiyosu, Aichi 452-8561, JapanThe manuscript was received on 6 December 2007 and was accepted after revision for publication on 16 September 2008.DOI: 10.1243/09544089JPME189Abstract: Scrollcompressorhasbeenemployedinvariousappliancesduetoitsadvantagessuchas high efficiency and low vibration. For the purpose of further performance improvement inscroll compressor, the authors have developed a new conceptual three-dimensional compres-sion mechanism (three-dimensional scroll) by adding an axial compression to the conventionalradial compression. By realizing three-dimensional compression, which has been impossible forthe conventional scroll, higher efficiency, higher reliability, and smaller size are achieved. Sincethe three-dimensional scroll has steps in scroll tip and end plate, the key point of efficiencyimprovementinthethree-dimensionalscrollistominimizethegasleakageinthesteps.Throughcylinder pressure measurements and visualization tests, characteristics of the leakage in thestepsareobtainedandtheoptimumclearancerangesaredetermined.Basedonthis,theauthorshave developed high efficiency, small size, and lightweight three-dimensional scroll compressorfor commercial air-conditioner. The developed three-dimensional scroll compressor archived35 per cent smaller size, 26 per cent lighter weight, and 5.5 per cent improvement of efficiencycompared with the conventional one.Keywords: compressors, design, refrigeration, control, performance, development, simulation1INTRODUCTIONAdemand for saving energy has been extensivelyincreasing from the viewpoint of environmental con-servation against global warming. Since most energyin refrigerating and air-conditioning appliances isconsumed by the compressor, its efficiency improve-ment is indispensable for saving energy. Meanwhile,these appliances are often restricted in their installa-tionspace.Therefore,miniaturizationofeachcompo-nent including the compressor is required to enhancethe flexibility of installation.Today, scroll compressor, which has advantagessuch as high efficiency and low vibration, has beenused for various appliances to meet the demandfor saving energy and its use is expected to spreadincreasingly. For the purpose of further performanceCorrespondingauthor:NagoyaResearchandDevelop-ment Center, Mitsubishi Heavy Industries, Ltd, 1-TakamichiIwatsuka-cho Nakamura-ku, Nagoya 453-8515, Japan. email:hajime_satomhi.co.jpimprovement in scroll compressor, the authors havedeveloped a new conceptual three-dimensional com-pression mechanism (three-dimensional scroll) thatadds an axial compression to the conventional radialcompression.This article describes the efficiency improvementtechnology in the three-dimensional scroll and thedevelopment of the three-dimensional scroll com-pressor for commercial air-conditioner.2STRUCTURE OFTHETHREE-DIMENSIONALSCROLL2.1Features of the three-dimensional scrollFigure1showsthedevelopedthree-dimensionalscrollcompressorforcommercialair-conditionerandapho-tographoftheorbitingscroll.Refrigerantgasflowsintothecompressorthroughthesuctionpipeplacedontheside body. Then, it reaches the compression chambergetting compressed from the outer side to the innerside. The compressed refrigerant is discharged fromthe centre of the fixed scroll.JPME189IMechE 2008Proc. IMechE Vol. 222 Part E: J. Process Mechanical Engineering194H Sato,M Fujitani,H Kobayashi,H Mizuno,andT ItohFig.1Three-dimensional scroll compressorFig.2Sectional view of the conventional and the three-dimensional scrollFigure 2 shows a schematic diagram of the sectionalview of the conventional and the three-dimensionalscroll. The wrap height of the conventional scroll isconstant throughout the compression process, andtherefrigerantiscompressedtwo-dimensionallyfromthe outer side to the inner side as the compressionchamber continuously becomes smaller in volume.Forthethree-dimensionalscroll,incontrast,theouterwrap is higher than the inner one by installing stepsin the scroll tip and the end plate. Therefore, three-dimensional compression, radial and axial direction,becomes possible.The three-dimensional scroll has the following fea-tures.1. Higher compression ratio is obtained by radial andaxial compression.2. The strength of scroll wrap is improved and higherreliability is obtained by decreasing the height ofinner wrap, which receives a heavy load.3. Largercapacityisobtainedwithoutextensionoftheouter diameter of scroll by increasing the height ofouter wrap, and thus the three-dimensional scrollhas smaller size and lighter weight.2.2Compression mechanism and leakageclearances in the three-dimensional scrollThecompressionmechanismofthethree-dimensionalscroll is shown in Fig. 3. The three-dimensional scrollhas steps in the scroll tip (tip step) and the end plate(bottom step).When these steps are not engaged (seeFigs 3(b) and (d), compression chambers across thestep have the same pressure. Therefore, no leakageProc. IMechE Vol. 222 Part E: J. Process Mechanical EngineeringJPME189IMechE 2008Development of a three-dimensional scroll compressor195Fig.3Compression mechanism of the three-dimensional scrolloccurs in the steps. On the other hand, when these areengaged (see Figs 3(a) and (c), seal lines are formedby the engagement of both steps.Figure 3 also shows the enlarged view of the stepand the sectional view in the longitudinal directionof the orbiting scroll. Leakage clearances in the step(hereafter called step clearances) can be broadly clas-sified into tip clearance and side clearance, and thegas leakage occurs from the high-pressure chamber tothe low-pressure chamber through these clearances.Therefore, the key point of efficiency improvement inthe three-dimensional scroll is to minimize the gasleakageinthestepsbyoptimizationofstepclearances.3EFFICIENCY IMPROVEMENT OFTHREE-DIMENSIONAL SCROLL3.1Optimization of clearances in the stepsAs mentioned above, it is important for three-dimensional scroll to reduce the gas leakage in thesteps. To investigate leakage characteristics in thestepclearances,cylinderpressuremeasurementswereconducted and indicative efficiencies were obtainedfromPV diagram.Figure4showsanexampleofmea-suredPV diagram.Thisshowsthatthepressurecurvefollows about the same line as the ideal one when thestep clearance is small. However, when it becomeslarge the pressure curve moves in a direction awayfrom the ideal curve due to increase in gas leakage.Figure 5 shows the variation of indicative efficiencyiobtained from the PV diagrams against step clear-ances where Fig. 5(a) is the result when the sideclearance is fixed and the tip clearance is varied andFig.4PV diagramFig. 5(b) is when the tip clearance is fixed and theside clearance is varied.The indicative efficiency ratiois defined as the proportion of the result at /0= 1.From Fig. 5(a), it can be seen that the indicativeefficiency is improved with decreasing tip clearance.However,itplateauedintheregionwherethetipclear-ance is small because the clearance is filled with oilwhen it is sufficiently small, and thus the gas leak-age is decreased. As can be seen in Fig. 5(b), it hasthe same tendency when the side clearance is varied.Theseresultsindicatethatthereductionofleakagelosscan be obtained by setting the step clearances withinthe range between the minimum value determinedfrom the tolerance of profile, thermal deformation,and pressure deformation, and the maximum valuedetermined from the permitted limit of efficiency.JPME189IMechE 2008Proc. IMechE Vol. 222 Part E: J. Process Mechanical Engineering196H Sato,M Fujitani,H Kobayashi,H Mizuno,andT ItohFig.5Variation of indicative efficiency against step clearances3.2Sensitivity of leakage in the step clearancesInthenextstep,sensitivityofleakageinthestepclear-ances is considered. Quantities of leakage flow in thetip clearance and the side clearance are examinedbyexperimentalandanalyticalapproach,respectively.Thesensitivityofleakageineachclearanceisobtainedby the following processes.1. PV diagrams are drawn by cylinder pressure mea-surementsvaryingtipandsideclearancesindepen-dently.2. Considering mass and heat balance, leakage analy-sesareconducted.Here,leakageflowG issupposedto be governed by the equation of nozzle flow asfollowsG = C A ?2 1P11?P2P1?2/?P2P1?+1/?whereC istheflowcoefficient,A istheareaofclear-ance, P1and P2are the pressure at inlet and outlet,respectively, 1is the density of fluid at inlet, and is the specific heat ratio.3. Flow coefficients Ctipand Csideare determined bycomparing analytical results with PV diagramsfrom cylinder pressure measurements.In this study, 45 cases of cylinder pressure measure-ments(tipclearance:threecases,sideclearance:threecases, and operating condition: five cases) and corre-spondinganalysesweremade.Asaresult,itwasfoundthat flow coefficients Ctipand Csidehave a relationshipas followsCside= 1.7 CtipThis indicates that the quantity of leakage flow parsectionalareainthesideclearanceislargerthanthatinthetipclearance.Thedifferenceisattributedtothedif-ference of longitudinal shapes of each clearance. Theside clearance is composed of two circular walls (tipstep and bottom step). Therefore, the length of sideclearance in the direction of leakage flow is shorterthan the wrap thickness, whereas the length of tipclearance is equal to the wrap thickness.3.3Visualization of leakage flow in the stepclearanceVisualization tests were performed to examine thebehaviour of leakage flow in the step clearance. A pro-totype compressor that can observe the behaviour ofleakageflowinthestepclearancewasmade.Thiscom-pressor equipped a sight glass in the end plate of fixedscroll, and the orbiting motion of the orbiting scrollandthebehaviourofleakageflowwerevisualizedwitha high-speed video camera.Photographs of leakage flow are shown in Fig. 6. Ineachphotograph,thehigh-pressurechamberisontheright side and the low-pressure chamber is on the leftside. Figures 6(a), (b), and (c) show the variation withthe oil circulation ratio (OCR). Focusing on the sideclearance marked with circles, it is found that thereis no oil in the clearance and the gas leakage occursthrough the clearance when the OCR is small (seeFig. 6(a). On the other hand, when the OCR increasesas shown in Figs 6(b) and (c), the clearance is filledwith oil and an oil-flow along the bottom step is alsoobserved. Figures 6(d) and (e) show the variation withthe magnitude of clearance setting the OCR at a con-stant value. The clearance is filled with oil when itis small as in Fig. 6(d). However, when the clearanceis large as in Fig. 6(e), it is no longer filled with oiland the gas leakage occurs. This indicates that therequired OCR to seal the step clearances depends onProc. IMechE Vol. 222 Part E: J. Process Mechanical EngineeringJPME189IMechE 2008Development of a three-dimensional scroll compressor197Fig.6Visualization of leakage flow in step clearancethe magnitude of clearance, and it is also important toset the oil content in the cylinder at a proper value.Bytheabove-mentionedapproaches,thestepclear-ances in the developed three-dimensional scroll com-pressor were optimized keeping the OCR in the samelevel as the conventional one.3.4Reduction of thrust bearing lossThe coefficient of friction in the thrust bearing is con-sidered rather higher than that in the journal bearingsin scroll compressor due to the difference of lubrica-tion condition 1. Therefore, the thrust bearing lossoccupies a large part of the total mechanical lossand it is necessary for performance improvement todecrease the thrust bearing loss.The thrust bearing loss Wthrustis given as followsWthrust= thrustFthrust(2 N)where thrustis the coefficient of friction of the thrustbearing, Fthrustis the thrust gas force, is the orbit-ing radius, and N is the rotation speed. Assuming thatthelubricationconditionofthethrustbearingandtheoperating condition are constant, the thrust bearingloss depends only on the thrust gas force and orbitingradius.Figure 7 shows a schematic diagram of thrust bear-ing in the conventional and the three-dimensionalscroll. By introducing three-dimensional scroll, thewrap height can be set at a higher value, and the outerdiameter can be decreased compared with the con-ventional scroll, which has the same capacity. Accord-ingly, the area of end plate which receives cylinderpressure can be decreased and thus the thrust gasforce is reduced. Moreover, the orbiting radius can bealso set at a smaller value and the sliding distance isdecreased.For the developed three-dimensional scroll com-pressor described in the next section, the scroll diam-eter and the orbiting radius are decreased by 9 and 20percentrespectively,comparedwiththeconventionalscroll. As a result, a substantial reduction of thrustbearing loss is archived.4FEATURES OFTHE DEVELOPEDTHREE-DIMENSIONAL SCROLL COMPRESSORThe main changes from the conventional compressorto the developed one are listed below.1. The newly developed three-dimensional scroll wasemployed.2. Bypass ports are installed to avoid over compres-sion.3. A higher efficiency motor was adopted.The main dimensional data of the developed three-dimensional scroll compressor for 10PS commercialair-conditioner and the conventional one, which hasthe same capacity, are shown in Table 1 and theoutlines of both compressors are shown in Fig. 8.The developed three-dimensional scroll compressorJPME189IMechE 2008Proc. IMechE Vol. 222 Part E: J. Process Mechanical Engineering198H Sato,M Fujitani,H Kobayashi,H Mizuno,andT ItohFig.7Schematic diagram of thrust bearingTable 1Dimension comparisons between the conven-tional and the three-dimensional scrollDevelopedthree-dimensionalConventionalscrollscrollCooling capacity28kW28kWRatio of orbiting radius3D/conv0.801Ratio of wrap heightL3D/Lconv1.241Ratio of scroll diameterD3D/Dconv0.911Fig.8Outlineofthedevelopedthree-dimensionalscrollcompressor and the conventional onearchived 35 per cent reduction of volume and 26per cent reduction of weight by introducing three-dimensional scroll.Figure 9 shows the efficiency improvement ofthe developed three-dimensional scroll compressor.Figure 9(a) shows the variation of efficiency againstoperating pressure ratio. In this figure, the motor effi-ciency was eliminated from the total efficiency tofocus on the performance of the mechanical part.The compression ratio of the three-dimensional scrollcan be set at a higher value than the conventionalscrollandare-compressionlossduetotheshortageofcompression ratio is decreased. As a result, substan-tial improvement of efficiency on high-pressure-ratiocondition is obtained. This indicates that the three-dimensional scroll has a special advantage for appli-ances operating under high compression ratio such asheat pump for cold area and refrigeration in additionto air-conditioning. On the other hand, an over com-pression loss on the low-pressure-ratio condition canbeavoidedbyinstallationofbypassports.TheworkingmechanismofthebypassportsisshowninFig.9(b).Incase the operating pressure ratio is below the built-inpressure ratio, the pressure of intermediate compres-sionchambersexceedsdischargepressureandanovercompression loss occurs. By installing bypass portson intermediate compression chambers, the refrig-erant that reaches discharge pressure is released tothe discharge chamber through the bypass ports, andthe pressure of intermediate compression chambers,which is communicated with the bypass ports, is keptat discharge pressure.Figure 10 shows loss classifications based on thecylinder pressure measurements on rated condi-tion (Pd/Ps= 3.4) and high-pressure-ratio condition(Pd/Ps= 6.3). Loss ratio is defined as the percent-age of total loss of the conventional compressor. Thefollowing improvements are made for the developedthree-dimensional scroll compressor.Proc. IMechE Vol. 222 Part E: J. Process Mechanical EngineeringJPME189IMechE 2008Development of a three-dimensional scroll compressor199Fig.9Efficiency improvement of the developed three-dimensional scroll compressorFig.10Loss classifications1. Reduction of indicative loss by the optimizationof compression ratio with the three-dimensionalscroll and the minimization of the leakage loss inthesteps(12percentonratedconditionand26percent on high-pressure-ratio condition).2. Reduction of mechanical loss by miniaturization ofmechanicalpartswiththethree-dimensionalscroll(15 per cent on rated condition and 12 per cent onhigh-pressure-ratio condition).3. Reduction of motor loss by introducing a highefficiency motor (15 per cent).Bytheimprovementsmentionedabove,5.5percentimprovementoftotalefficiencyonratedconditionand12.5 per cent on high-pressure-ratio condition werearchived.5CONCLUSIONSTheefficiencyimprovementtechnologiesinthethree-dimensionalscrollwereinvestigatedandthefollowingconclusions were obtained.1. The indicative efficiency plateaus in the regionwherethestepclearanceissmallduetotheoilseal.2. Theflowcoefficientinthesideclearanceis1.7timeslarger than that in the tip clearance.3. Visualizationtestsgavetheconfirmationthatfillingthe step clearance with oil decreases the leakage.4. Thethrustbearinglossisreducedbydecreasingtheouter diameter and the orbiting radius of scroll.Based on the above conclusions, the authors havedeveloped high efficiency, small size, and lightweightthree-dimensional scroll compressor for commercialair-conditioner, featuring the following, comparedwith the conventional scroll compressor.1. Thirty-five per cent smaller volume and 26 per centlighter weight.2. A 5.5 per cent improvement of efficiency on ratedcondition an

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号