一种可调式免耕播种试验架的设计【含CAD图纸、说明书】

收藏

资源目录

压缩包内文档预览:(预览前20页/共26页)

编号:22205865

类型:共享资源

大小:2.38MB

格式:ZIP

上传时间:2019-09-29

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

含CAD图纸、说明书

一种

调式

播种

试验

实验

设计

cad

图纸

说明书

仿单

- 资源描述:

-

- 内容简介:

-

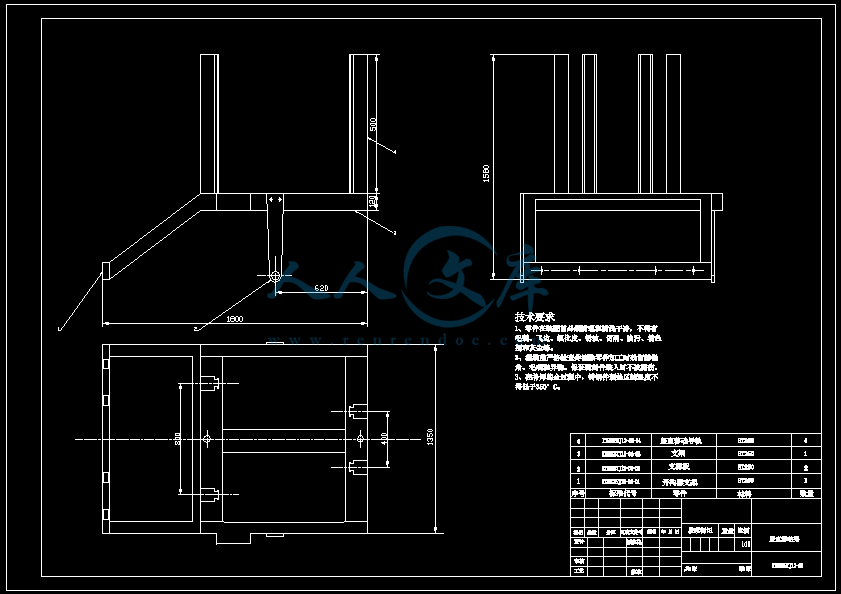

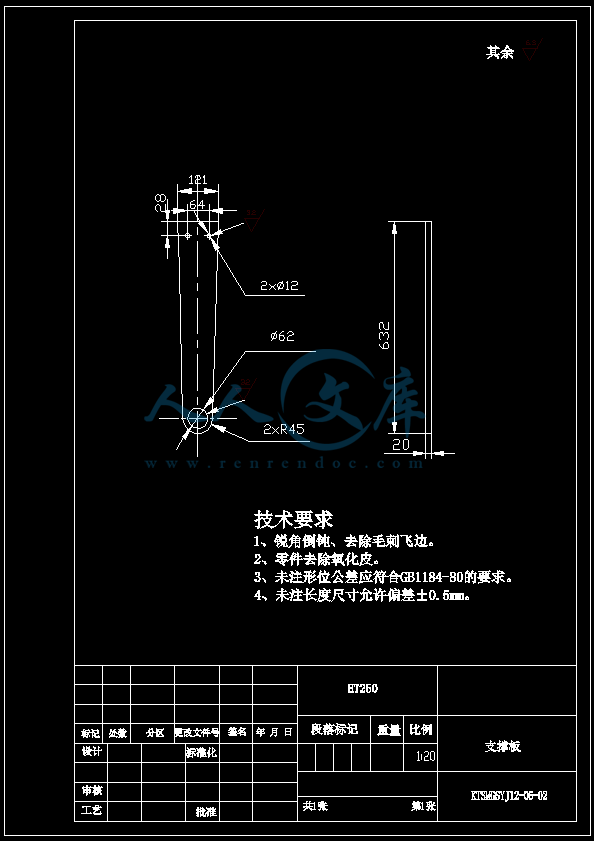

毕业设计(论文)文献翻译材料 论文/设计题目:一种可调式免耕播种试验架的设计 翻译材料题目:Design of sawing anti-blocking mechanism for no-tillage planter and its cutting mechanism 翻 译 类 型:英译汉 学院: 专业: 姓名: 学号: 指导教师: 评语:指导教师签名: 2019年6月薄Design of sawing anti-blocking mechanism forno-tillage planter and its cutting mechanism肁莃蒄袃肀肃蚀衿肀芅薃螅聿莈螈蚁肈蒀免耕播种机锯切防堵装置设计及其切割机理的研究Liao Qingxi1,Gao Huanwen2,Shu Caixia1(1.Engineering and Technology College,Huazhong Agricultural University,Wuhan430070,China;2.Engineering College,China Agricultural University,Beijing100083,China)廖庆喜,高焕文,舒彩霞(1. 华中农业人学工程技术学院,武汉430070; 2. 中国农业大学工学院,北京 100083)Abstract: Based on blocking issues of no-tillage planter for dry-land farming in two-crop-a-year region in North of China and shortcomings of anti-blocking mechanism developed, such as higher rotation speed (above 1500 r/min) and bigger power consumption (width power consumption per unit up to 1641.74 kW/m, including traction power), a new sawing anti-blocking mechanism was developed and its cutting mechanism was investigated in this paper. Meanwhile stress distribution of the saw-tooth blade calculated by the ANSYS finity element software showed that the saw-tooth blade would be feasible to cut corn straws. Experimental results in the soil bin showed that: 1)The sawing anti-blocking mechanism with two cutting modes of sustaining and no-sustaining cut could realize an integrated function of cutting and directly throwing by reverse rotation, namely, it could throw straws directly to the rear of the opener by former angle of saw-tooth and thrower; 2)The cutting rate of straws would increase along with the rising of straw moisture and rotation speed, and higher moisture of straws would be of benefit to improving cutting quality; 3)The cutting rate of straws would decrease along with the rising of velocity of vehicle while interval of the moved and fixed blade was determined. And the sawing anti-blocking mechanism had higher cutting quality and lower power consumption without leaky cutting and tearing out with small interval of the moved and fixed blade. Compared with other driving anti-blocking mechanisms, theoretical analysis and experimental results showed that the sawing anti-blocking mechanism had fine cut capability and lower rotation speed (650 r/min) and lower power consumption (power consumption per unit width up to 2.95 kW/m) as well as stronger suitability to different stubbles mulch. Additionally, a new way was found out to improve anti-blocking performance of no-tillage planter.Key words: no-tillage planter; sawing anti-blocking mechanism; cutting mechanism; cutting rateCLC number: S223.2Document code: AArticle ID:1002-6819(2003)05-0064-07Received date:2003-06-15摘要:针对我国北方旱地一年两熟地区免耕播种机堵塞现象和已有卞动式防堵装置转速高( 1500 r/ min以上)、功耗人 (单位幅宽达16- 41.74 kW/m,含牵引功率)的现实问题,设计了一种新型免耕播种机锯切防堵装置,分析了该装置的切割机理,应用有限元ANSYS软件计算了锯齿圆盘切刀的应力分布,得出了锯齿圆盘切刀川于玉米秸秆切割的可行性。上槽试验表明:1)该装置采用逆转式作业,兼有无支撑和有支撑两种切割方式,切割彻底,并能借助刀齿前角和抛撒板将已切断秸秆定向抛送到开沟器后方,实现了切割、定向抛撒一体化功能;2)秸秆切碎率随转速和秸秆含水率的增人而增人,秸秆含水率高时有利于提高切割质量;3)秸秆切碎率在动定刀间隙一定时,随前进速度增人而降低,小间隙时无漏切和撕皮现象,切害日质量高,功耗小。理论和试验结果表明:与其他卞动式防堵装置相比,锯切防堵装置具有良好的切害少h能,其转速低 (650 r/min)、功耗小(单位幅宽为2.95 kW/m)、秸秆覆盖量适应性强,为改善免耕播种机防堵性能提供了一条新途径。关键词:免耕播种机;锯切防堵装置;切割机理;切碎率中图分类号:S223 文献标识码:A 文章编号:1002-6819(2003)05-0064-07 收稿日期:2003-06-151IntroductionAnti-blocking issue of no-tillage planter had become one of the key factors affecting production efficiency and seeding quality of two-crop-a-year region in North of China. It was because there was a great deal of crop stubbles and crop seeding was started shortly after crop had been harvested, leaving no time for crop stubbles to decay. At present, there are two methods to solve anti-blocking issue of no-tillage: 1) Straws were chopped by the straw chopper before seeding, it would lead to adding working procedure and increase costs of production as well as delaying seeding time; 2) Stubbles were cleared out by driving chopping mechanism fixed on no-tillage planter, such as Strip Wheat Spinning and Furrow Planter made in Hebei Nonghaha Machinery Ltd Corporation and 2BMDF-Corn Strip Chopper made in China Agricultural University1and so on. In practice the driving chopping mechanism had significant effect on anti- blocking, but also bigger vibration and noise as well as lower security because straws were chopped at high rotation speed.1、 说明免耕播种机堵塞问题是影响我国一年两熟的北方旱地地区的生产效率和播种质量关键因素之一。这是因为有大量的作物根茬而且在作物收割不久就要进行播种,不留时间使作物根茬腐烂。目前,有两种方法来解决免耕播种机的堵塞问题:1)在播种前用秸秆刀切碎秸秆,这将导致增加的工作程序,并增加生产成本,以及推迟播期; 2)茬被安装在免耕播种机上的切除机构清除,如在河北农哈哈机械有限公司的纺纱地带和沟小麦播种机和中国产农业大学 1 的2BMDF玉米地带等等。在实践中,驾驶砍机制在防堵问题上有巨大作用,但是因为秸秆切碎时的高转速,会产生更大的振动和噪声以及降低安全。It was reported that the blade base linear velocity of several main straw chopping mechanisms was between 3756 m/s2, mostly chopping mechanism combined with cutting and striking had higher striking velocity and higher power consumption3, e.g. the blade base linear velocity up to 34 m/s could obtain fine cutting effect for corn straws4, and 24 m/s on rice and wheat straws by supporting pole, respectively5. Even if corn straws were cut by sliding cut with vertical blade, its velocity of cutting one straw, two straws and three straws must be up to 10.3 m/s, 13.6 m/s, 15.8 m/s6, respectively, and had higher power consumption. In a word, because the driving chopping mechanism developed presently had high rotation speed ( above 1500 r/min ) and higher power consumption (width power consumption per unit up to 1641.74 kW/m, including traction power), to decrease rotation speed and power consumption would be urgent in practice.据报道,几个主要秸秆切碎机制的刀片基础线速度是37 56米/秒 2 ,其中大部分是砧板机制结合切割突出了更高的惊人速度和更高的功率消耗 3 ,例如:刀片基础线速度高达34米/秒能取得削减玉米秸秆的良好效果 4 ,而大米和小麦秸秆高达24米/秒 5 。即使玉米秸秆被与与垂直的滑动切口相切,其切割一个和两三个秸秆的速度必须上升到10.3米/秒, 13.6米/秒, 15.8米/秒 6 ,并且有较高的功率消耗。简言之,因为驾驶砍机制目前开发有高旋转速度(上面 1500转/分 )并且更高的力量消费(宽度单位能耗高达16 41.74千瓦/米,包括牵引动力),在实践中以减少旋转速度和力量消费将是迫切的。Based on practical problems, the objective in this paper is to find a way to solve the shortcoming that it 64 is difficult for common smooth blade to seize straws and it must run at higher rotation speed, decrease power consumption and improve cutting effect as well as anti-blocking performance of no-tillage planter. Additionally some experiments were done by selecting saw-tooth as cutting blade of no-tillage planter and cutting mechanism of the sawing anti-blocking mechanism was investigated.根据实际问题,本文件中的目标是要找到一种办法来解决64个缺陷,制造出对抓住稻草并且它必须在更高的旋转速度下,减少能耗和提高切割效果以及防堵性能免耕播种机。另外一些实验,对选择了齿形切削刀片的免耕播种机和切削机理的锯切防堵机制进行了研究。2Structure and cutting rule of the sawing anti-blocking mechanism2.1Structure and characteristics2结构和规则的锯切防堵装置的切割原理2.1结构和特性 The sawing anti-blocking mechanism was made up of saw-tooth blade, throwing ban device, principal shaft, moved and fixed blade combination, covering shell, opener and working frame as well as transmission system. Sketch of the sawing anti-blocking mechanism is shown in Fig. 1. The main parts included saw-tooth blade, throwing ban device as well as fixed blade combinations. Diameter of saw-tooth with 60 teeth was 350 mm; throwing ban device with max 270 mm turning diameter was fixed on between adjacent saw-teeth; fixed blade combinations consisted of fixed blade with tooth and vertical type blade, and tooth type blade same to saw-tooth, Moreover, the vertical type blade would be used to obstruct straws without cutting from throwing area and participated in cutting straws. The sawing anti-blocking mechanism was fixed on the soil bin device, its width was 600 mm, the interval of adjacent openers was 200 mm. The sawing anti-blocking mechanism had many characteristics such as straws would be chopped by saw-tooth blade and fixed blade combinations, and had two cutting modes with susta-ining and no-sustaining cutting, the blade base line velocity of saw-tooth was lower to tossing blade type, namely, the sawing anti-blocking mechanism could change higher speed hewing into lower speed sawing.锯切防堵装置由锯齿圆盘切刀、定刀组合、抛撒板、主轴、罩壳、机架、以及传动系统组成。锯切防堵装置的零件图如图1.其中锯齿圆盘切刀、抛撒板、和定刀组合是该装置的主要组成部分。设计的锯齿圆盘直径为350 mm,60齿;抛撒板安装在相邻两锯齿圆盘间,其最大回转直径为270 mm;定刀组合由锯齿形定刀和直刀形定刀组合而成,锯齿形定刀与锯齿圆盘切刀配合对秸秆进行剪切,而直刀形定刀主要起阻挡未切断秸秆落入抛撒区的作用,同时也参与剪切。该装置安装在土槽试验台上,工作幅宽为600 mm,相邻间隔为200毫米。其工作特点是秸秆既可由锯齿切刀直接切碎,也可由锯齿切刀和定刀组合作用而切碎,兼有无支撑与有支撑2种切割方式,锯齿刀端线速度低于甩刀式切割器线速度,即具有将高速砍切变为低速锯切的特点。1. 开沟铲组合; 2.锯齿圆盘切刀; 3.秸秆导向板; 4.定刀组合; 5.主轴; 6.抛散弧板;7.罩壳; 8.机架; 9.轴承座; 10.传感器; 11.电缆; 12.调速电机; 13.台车悬挂臂图1锯齿防堵装置结构示意图2.2Cutting principle2.2切割原理The sawing anti-blocking mechanism was driven to reverse rotation by power. First, straws were cut in no-sustaining mode by saw-tooth blades while saw-tooth blades touched straws, then after straws were completely cut down, they would be free and be thrown to the rear of opener by throwing ban device and inertial force. Second, straws not being completely cut down would be thrown to former upward and be cut in sustaining mode by fixed blade combinations until any of straws would be cut down, straws having been cut down were thrown to the rear of opener by throwing ban device and saw-tooth. In turn, time after time, straws would be carried out continuously to cut and throw by the sawing anti-blocking mechanism. The lowest point of the saw-tooth blades kept 1530 mm interval from the soil. In terms of spreading status of straws in field existed perpendicularity or certain angle with marching direction, saw principal in landscape orientation had been determined for the sawing anti-blocking mechanism in order to decrease repeated cutting, leaky cutting and tearing out.锯齿圆盘切刀由动力驱动作逆时针旋转。首先,当锯齿底部与秸秆接触时,锯齿嵌住秸秆进行无支撑切割,已切断的秸秆,依靠锯齿圆盘切刀的刀齿和抛撒板的旋转作用向后抛送。其次,未完全切断的秸杆在刀齿作用下,向前上方运动与定刀组合发生剪切作用,秸秆进行有支撑切割,从而完成秸秆的全部切断,由锯齿切刀和抛散板将断秆抛送到开沟器后方。如此反复,实现秸杆的连续切割和抛送。工作时圆盘锯齿不入土,其旋转最低点离地1530 mm。就田间垂直存在的秸秆的散布情况或某个角度的前进方向而言,锯切防堵装置的横向的锯齿是为了减少重复切割、漏割和撕裂稻谷。Working procedures of the sawing anti-blocking mechanism were as follows: 1) no-sustaining cut phase: static straws relative to ground were cut firstly atNpoint by saw-tooth blades, then, straws would be cut down completely or embedded in saw-tooth. Straws being cut down completely would be free and 65Liao Qingxi et al: Design of anti-blocking mechanism for no-tillage planter dropped into adjacent saw-tooth; 2) dragging and delivering phase: after straws dropped into adjacent saw-tooth, they would be thrown to former upward by the throwing ban device, moreover, straws embedded in the saw-tooth would be thrown to former upward by the saw-tooth at higher speed rotation; 3) sustaining cut phase: straws not being cut down completely in no-sustaining cut phase would be cut in sustaining mode by fixed blade combinations atK point until any of straws would be cut down completely; 4)throwing phase: straws being cut down were thrown directly to the rear of opener by tooth former slanting angle of the saw-tooth and throwing ban device, time and again, straws would be carried out continuously to cut and throw. The working principle of the sawing anti-blocking mechanism is shown in Fig.2.锯切防堵装置的工作程序制如下:1)无支撑切割阶段:相对地面静止的稻草首先被锯齿片切割,然后秸秆被完全切除或牢牢嵌入锯齿中。已切断的秸秆做自由运动并落到邻近的锯齿上; 2 )拖拽交付阶段:在稻草落下了相邻近的锯牙齿以后,他们将被抛洒装置向上扔到前者,而且,被嵌入锯牙齿的稻草将被更高的速度旋转的锯牙齿向前抛出; 3 )支撑切阶段:在无支撑阶段未被切割的稻草被定刀组合切割直到被完全切割。4 )抛撒阶段:正在被切割的稻草直接被锯齿圆盘切刀和抛散弧板扔到开沟器的后面,再一次,稻草将被连续地切割和抛撒。锯切防堵装置的工作的原理如图2所示。1.待切秸秆; 2.定刀组合; 3.罩壳; 4.锯齿圆盘切刀; 5.抛撒板;6.开沟器; 7.断秆; 8.地表; 9.放大定刀组合; 10.锯齿型定刀;N为无支撑切割点;K为支撑切割点;M为研究对象图2锯齿防堵装置防堵原理示意图2.3Analysis of mechanics characteristics of saw-tooth blade 2.3锯齿圆盘切刀的力学性能Cutting properties of saw-tooth to cut straws belong to wriggly cut of no-metal materials, its ultimate objective is not only to improve surface cutting quality, but also to raise cutting efficiency, so it can decrease sawing force and power consumption9. Because the ratio of its diameter 350 mm to its thickness 1.8 mm is over 150, the saw-tooth blade belongs to exceed thin disc. It is as plane stress and no-axis symmetry problem according to elasticity theory. And because the saw-tooth blade was tighten by flange tray, six freedoms of its center hole were restricted, so its center parts could be regarded as restricted status completely not to bring any displacement and rotation. Saw-tooth blade belongs to excessive blade tools, it would bring to alternative sawing forces in cutting straws, The reasons lied in: 1) structure of straws with inner empty and outside hardness had determined micro-hardness un-uniformity distribution, so the single tooth force would be uncertain in cutting straws; 2) the total sawing forces of saw-tooth in horizontal direction would be uncertain because the tooth of saw-tooth blade is not continuous. These alternative characteristics would bring to transfiguration of the saw-tooth, moreover, the transfigured properties an size was relative to the stress properties and size of the saw-tooth in supporting outside loading. So, it was very essential to make clear stress distribution of the saw-tooth in order to ensure smooth cutting.切割秸秆的锯齿圆盘切刀的切割特性属于无金属材料蠕动切割,它的最终的目的是不仅提供切割表面的质量,而且提高切碎效率,因此它能减少切削力和能量的消耗 9 .因为它350毫米的直径与它1.8毫米的厚度的比值超过了150 ,锯齿圆盘切刀属于超过薄圆盘。它是根据弹性理论的水平压力和无轴对称问题。并且因为锯齿圆盘切刀是,由凸缘托盘紧缩,它的中心洞的6个自由被限制,因此它的中心部件被认作完全约束而没有任何旋转和移动。.锯齿圆盘切刀属于过度的切刀工具,在秸秆切割中它使其达到非传统的切割力,主要原因如下:1 )内空并且外硬的稻草结构决定了微硬部分的差异分布,因此单个锯齿的力在切稻草时是不明确的; 2 ) 因为锯齿圆盘切刀的锯齿不连续所以锯齿圆盘切刀的全部的切削力在水平方向将不确定。这些选择特征将使锯齿圆盘切刀变得更理想,而且这些理想特性大小要与外部承受载荷上的承载特性和锯齿圆盘切刀尺寸相比较。因此为保证切割的平稳需弄清锯齿圆盘切刀所受的力。图3 锯齿圆盘切刀的压力分布The stress distribution of the saw-tooth blade was calculated by the ANASYS finity element software. Number of the tooth participating in cutting straws was determined to 23 teeth while diameter of straws was in 2045 mm11. The saw-tooth made in 65Mn ofEequal to 210 GPa12andto 0.28 was separated into 1200 cells and 1260 nodes by trapezia gridding. Thus the stress distributions ofX,YandXYplane had been obtained by the ANASYS software according to the most average wring value 26.8 Nm13of the saw-tooth to cut straws by the wring sensor. The stress distributions are shown in Fig.3. Calculated results showed: 1 ) the saw-tooth blade had acted as alternative stress from the whole stress distribution of sawtooth, tooth and around center hole of the saw-tooth had been distributed primary stress, the biggest pressing stress was up to 70776 Pa, moreover, the biggest pulling stress up to 19945 Pa. Compared with yield fatigue intension 735 MPa12of the saw-tooth, the saw-tooth blade was difficult to be destroyed, so it would be feasible to cut corn straws; 2)Fig.3 showed, around stress distribution of the saw-tooth blade was in symmetry distribution, the area of relative bigger stress only occupied 3.33% of the saw-tooth whole area, the other 96.67%; 3)the former tooth of saw-tooth supported the biggest forces among the whole saw-tooth while the former tooth of the saw-tooth touched firstly straws, and its stress value was the smallest before cutting straws, but when saw-tooth started to cut straws, the stress value would increase 66 Vol.19, No.5 Transactions of the CSAE Sept.2003 sharply, its values would be over 105times comparing with the stress values before saw-tooth started to cut straws. However the stress would be down to the lowest point while saw-tooth had finished cutting straws. 锯齿圆盘切刀的压力分布由有限元ANSYS软件计算评估。当秸秆直径在2045毫米时参与切割秸秆的齿数一般为23个11.由E等于210Gpa12 、为0.28的25Mn制成的锯齿圆盘切刀被分成1200隔间和1260个小节。这样ANASYS 软件根据锯齿圆盘切刀切割秸秆26.8牛米的最平均扭矩 13 的拧传感器就获得了X,Y和XY平面的力的分布,计算结果如下:1)看到锯齿圆盘切刀曾担任替代从整体应力分布的锯齿波,牙齿和周围中心孔的锯齿波已分发给主应力,最大压应力达70776帕,此外,最大的拉应力高达19945帕。与锯齿圆盘切刀735兆帕产量疲劳内涵 12 相比,该锯齿圆盘切刀很难被摧毁,因此削减玉米秸秆是可行的; 2 )图3显示,锯齿圆盘切刀的应力是对称分布的,相对更压力的区域只占整体的3.33 ,其他占96.67 ;3 )在前齿首先接触秸秆时,锯齿圆盘切刀的前牙的承受最大的力,其应力值在切削秸秆前最小,可是当开始切断秸秆时,应力值将大幅增加,其值将比刚切割时大倍。在完成切割秸秆时压力将降到最低点。因此,锯齿圆盘切刀将承担交变应力。3Materials and method3.1Experimental equipment3材料和方法 3.1实验设备The experiment was conducted in the soil bin device, of 20m-long, 0.89m-wide, 0.6m-high, the available working journey of vehicle was 16 m, and the working velocity of vehicle was from 0.12 m/s to 1.2 m/s. And other equipment included: AKC-205 type wring sensor, the sawing anti-blocking mechani-sm, control tank, computer operation platform, etc.中国农业大学自制的土槽试验台。土槽结构尺寸20 m089 m06 m;台车有效行程为16 m,前进速度为01212 ms-1AKC-205型扭矩传感器,量程300 Nm,精度03%;自制的锯齿式防堵装置;控制柜;计算机操作平台。3.2Experimental materials3.2试验材料The average height and diameter of corn straw is 2.25 m, 25. 6 mm, respectively. It is made up of leaves and skin and marrow. The weight of leaves and marrow occupy above 55% of whole straw and their mechanical intension are much lower; and the weight of skin made up of scarfskin and bunchy organization occupy 35% or so, the mechanical intension of skin is much higher up to 90 MPa of portrait resistant pulling intension and 3 MPa of landscape orientation resistant pulling intension by measurement, which was essential theory basis for the saw-tooth blade to select landscape orientation principle in order to decrease power consumption.玉米秸秆,平均自然高度225m,平均直径256 mm。它是由叶片和叶皮和骨髓组成。叶片的重量和骨髓占有全秸秆的55 以上而且机械强度低得多;皮肤的重量由表皮和束组织占据35 左右,皮肤机械强度高达90兆帕的抗拉力强度和3兆帕的横向抗拉力强度的测量,这是锯齿圆盘切刀选择横向的原则以减少电力消耗至关重要的理论基础。3.3Experimental methods3.3试验方法The sawing anti-blocking mechanism was hung up in the soil bin device, and its ascending was controlled by hydraulic pressure system, and the wringM measured by wring sensor was automatically noted in computer, repeat three times, and then the power consumption could be calculated by expressionP=Mn/9549, the cutting ratecould be calculated by expression= (G-G0)/G100%, where,Gthe total mass of effective width/kg,G0total mass of the straws cut down between adjacent openers.锯齿式防堵装置悬挂在土槽台车上,由液压系统控制防堵装置的离地间隔。功耗P的测定方法是,由扭矩传感器测得扭矩M,数据自动记录在计算机上,按照扭矩传感器的标定及P=Mn/9 549,计算出功率P的大小,每次试验重复3次,取平均值。抛撒率=( m-m0)/m100%,其中,m为待切秸秆总质量,kg,m0为开沟器前方堵塞的秸秆总质量,kg,n为转速,rmin-1。秸秆模拟田间状态铺放在土槽内。4Results and discussion4结果与讨论4.1Experiments and analysis of rotation direction of the saw-tooth blade for cutting quality4.1实验和锯齿圆盘切刀旋转方向的切割质量分析 Some experiments were done by clockwise and counter-clockwise rotation of the saw-tooth blade in the soil bin device. The results are listed in Table 1. 有些实验是锯齿圆盘切刀在土壤装置中做顺时针和逆时针旋转的。结果列于表1 。Table 1Experimental results of rotation direction of the saw-tooth blade表1锯齿圆盘切刀旋转方向的实验结果项目顺时针旋转逆时针现转切削效果在有支撑和无支撑情况下切割质量良好,可抓住整个秸秆,完全切割无撕碎,良好的统一性切割长度,少量锯齿圆盘切刀卷齿切割质量差,只有无支撑切割方法, 可抓住部分秸秆,而不能完全切割有严重撕裂,并随机分布切割稻草,和严重的包裹切刀消耗功率在同一工作条件下,功率消耗相对增加。例如,当群众的秸秆覆盖在11250 kg/hm2 ,耗电量价值可能高达1.42千瓦在同一工作条件下,能耗相对减少。例如,当群众的秸秆覆盖在11250 kg/hm2 ,耗电量值可高达1.24千瓦抛撒效果在同样的工作条件,增加垂直和水平抛撒距离,并以优良的抛撒效果和可行性得到跨越在一样工作条件下,减少了垂直和水平抛撒距离和速度,并且抛撒效果和可行性差适应性当大量的秸秆覆盖在7500 18750 kg/hm2 ,它适应性较好,但超过18750 kg/hm2 开始下降,没有卷齿现象,适合不同的秸秆覆盖情况当大量的秸秆覆盖在7500 11250 kg/hm2 时,它有优良的适应性,但当超过15000 kg/hm2 ,开始变差,大部分的秸秆覆盖多达18750 kg/hm2 ,超载情况下完成情况差。因此,对于不同的大规模秸秆覆盖适应性差Table 1 showed that the way of cutting straws at counter-clockwise rotation would be of benefit to improve cutting quality and throwing effect, and boost up adaptability of weight of different stubble mulch. Therefore, counter-clockwise rotation direction of the saw-tooth blade had been determined.表1显示,在逆时针旋转时的切割方式将有利于提高切割质量和抛撒效果,能增强不同的覆盖率。因此,经常选择逆时针旋转的锯齿圆盘切刀。4.2Effect of the rotation speed on cutting quality4.2 旋转速度对切割质量的影响The experiments were done by selecting velocity 0.3 m/s of vehicle and interval 5 mm of the moved and fixed blade, and spacing 20 mm between the saw-tooth and ground as well as weight 11250 kg/hm2of the straws mulch, experimental results are shown in Fig.4. The results indicated that the power consump-tion and cutting rate would increase with rising of rotation speed of the saw-tooth blade. Because the wring values of cutting straws were equal basically on the same working condition, the cutting rate could be up to 100% while the rotation speed of the saw-tooth blade was above 650 r/min. It was because the probability rate of the saw-tooth blade to cut straws 67Liao Qingxi et al: Design of anti-blocking mechanism for no-tillage planter would increase with rising of rotation speed whenweight of straws was fixed. 切碎率/%实验所选择的是速度为0.3米/ s的车辆和间隔为5毫米的移动和固定刀片,并且锯齿圆盘切刀与地面间隔为20毫米以及11250 kg/hm2的秸秆覆盖,实验结果图4所示。结果表明,电力消费和切割率会增随锯齿圆盘切刀转速的增加而增大。由于切割秸秆时的扭矩在基本上相同的工作条件下是相同的,在锯齿圆盘切刀的转速高于650转/分时切割率可高达100 。这是因为随着防堵免耕播种机转速的增加秸秆切割率会提高,这是是肯定的。能量消耗/KW 转速/转/分 能量消耗 切碎4.3Effect of the straw moisture on cutting quality4.3秸秆湿度对切割质量的影响The straw moisture of the same crops is different for different autumn and reaping time. The moisture were 20%, 40.5%, 64.4% and 80.16% respectively, after corn straws had been placed in field for different periods. Experiments were done by selecting velocity 0.3 m/s of vehicle and interval 5 mm between the moved and fixed blade and spacing 20 mm between sawtooth and ground, and rotation speed 650 r/min as well as mass 11250 kg/hm2of straws mulch, the results were shown in Fig.5. Fig.5Results of straws moisture for cutting rate and power consumption.同样庄稼的秸秆湿度在不同的秋季和不同的收割时间是不同的。在玉米秸秆被放置在不同区域的地里后,它的湿度分别为20%, 40.5%, 64.4% 和80.16%。在选择0.3米/秒的牵引速度、动刀定刀5毫米的间隔、切刀和地面相距20毫米和650转/分、11250千克/百米2的覆盖率的条件下进行试验,结果如图5。切碎率/%能量消耗/KW秸秆湿度/% 能量消耗 切碎图5 秸秆湿度对切碎率和能量消耗的影响Experimental results show that power consumption decreased with increasing of straw moisture and cutting rate of straws increased with increasing of straws moisture on the same working condition, which had connected importantly with different moisture of straws. Straws would take on bigger hardness and best firmness and fine brittleness when straws moisture was in higher, which demonstrated that it had been easy to finish to cut straws. But straws would take on tired and soft status for fine flexible and toughness when straw moisture was lower, so it would be easy to bring to tearing and wrapping. The saw-tooth blade had fine cutting quality and higher cutting rate while straws moisture was up to 80.16% (Fig.6). However the saw-tooth blade had taken on tearing while straw moisture was up to 20%(Fig.7). 实验结果显示,在同等工作条件下随着秸秆湿度的增加能量消耗减少切碎率增加,这些都与不同的秸秆湿度紧密相关。当秸秆湿度更高时,秸秆会有更大的硬度和最强的坚实度还有良好的脆性,这表明此时很容易削减秸秆。秸秆含水量低较低时,秸秆的弹性和韧性较好,所以很容易撕皮和堵塞。锯齿圆盘切刀在秸秆含水率高达80.16 时具有良好的切割质量和更高的切碎率。然而,在秸秆含水量达20 时,会产生撕皮现象。(图7 ) 。图6 秸秆湿度为80.16%时的切割质量 图7 秸秆湿度为20%时的切割质量4.4Effect of interval between the fixed and moved blade and velocity of vehicle on cutting quality4.4 定刀和动刀间隔和车辆牵引速度对切割质量的影响Experiments were done by selecting velocity 0.3 m/s of the vehicle and spacing 20 mm between saw-tooth and ground, and rotation speed 650 r/min as well as weight 11250 kg/hm2of the straws mulch, experimental results are shown in Fig.8. The results proved that power consumption increased with increasing of velocity of vehicle on the same working condition. The power consumption increased with increasing interval between the fixed and moved blade and no fixed blade, at the same time, power consumption with interval 10mm between the fixed and moved blade was equal basically to that of without the fixed blade, and the power consumption was decreased with interval 5 mm between the fixed and moved blade. At the same time, cutting quality of interval 5 mm between the fixed and moved blade was excel to that of above 5 mm interval. Its reasons lied in that straws would be cut down completely while the small interval between the fixed and moved blade, the bigger interval between the fixed and moved blade or near diameter of corn straws, corn straws could be embedded into saw-tooth and participated in cutting again, so feeding quantities of straws were increased. And straws could not be cut down completely which brought to rearing phenomenon. The cutting rate of 68 Vol.19, No.5 Transactions of the CSAE Sept.2003 straws decreased with increasing of velocity of vehicle when the interval between the fixed and moved blade was determined, and cutting rate of straws with interval 5 mm between the fixed and moved blade was bigger than that with the interval 10 mm and no-fixed blade, its reasons lied in the probability of entering throwing area for straws not being cut down completely decreased while small interval between the fixed and moved blade. 选择的是速度为0.3米/ s的车辆并且锯齿圆盘切刀与地面间隔为20毫米、转速650转/分以及11250 kg/hm2的秸秆覆盖率进行实验,实验结果显示见图. 8。结果证明,在同样的工作条件下,功率消耗随车辆速度的增加而增加。功率消耗随定刀与动刀间距的增加而增加,然而,动刀与定刀间隔10毫米是的能量消耗基本上与没有定刀片时的能量消耗是相等的,能量消费在定动刀为5毫米时减少。同时,定动刀间隔5毫米时的切割质量要好于大于5毫米时的切割质量。其原因在在定动刀间距小时秸秆容易被切割,而在间距大于和接近秸秆直径时,玉米秸秆可以嵌入到切刀,并进行重割,因此秸秆的喂入量增加。由于秸秆不能完全被切割而产生撕皮现象。在车辆速度不变时,切削率随速度的增加而下降,秸秆削减率在有动定刀而且间隔5毫米时要大于无定刀间隔10毫米时的切碎率,其原因在于当动定刀间距小时,未被完全切割的秸秆进入抛撒区的可能性减小。切碎率/%能量消耗/KW 5mm间隔时能量消耗 10mm间隔时能量消耗 切碎率/% 切碎率/% 切碎率/%图 8 动定刀的间距与车辆速度对切割质量的影响5Conclusions5 结论1) A new type of sawing anti-blocking mechanism, which could get rid of some shortcoming that common smooth blade is difficult to seize straws as well as high rotation speed, was designed according to the anti-blocking requirements of no-tillage planter and need in practice. The sawing anti-blocking mechanism had strong capability to seize straws and lower rotation (650 r/min) speed and lower consumption (power consumption per unit width up to 2.95 kW/m) and higher cutting rate of straws, a new approach was provided for design and development of the anti-blocking mechanism of no-tillage planter.1)所设计的新型免耕播种机锯齿式防堵装置根据实践中免耕播种机的防堵要求克服了一些普通切刀在高速下抓住秸秆难的缺点。锯切防堵装置在低转速( 650转/分)和较低的能量消耗(每单位能耗达到2.95千瓦/米)和较高的切割速度下,具有抓取秸秆能力强切碎率高的优点。这是一种为设计和开发的免耕播种机防堵装置提供的新的方法。The stress distribution of the saw-tooth blade was calculated by the ANASYS finity element software. The results showed that its intension would be difficult to be destroyed and the saw tooth blade was feasible to cut corn straws.2) 锯齿圆盘切刀的应力分布由ANASYS有限元软件计算。结果表明,其强度将难以被摧毁和对于切割玉米秸秆锯齿圆盘切刀是可行的。3) The sawing anti-blocking mechanism realized an integrated function of directly throwing and cutting straws by counter-clockwise. The straws could be cut down completely by two cutting modes of sustaining and no-sustaining cut. Meanwhile, the straws being cut down completely could be directly thrown to the rear of opener by the former tooth horn of sawtooth blade and throwing ban device.3 )锯切防堵装置通过逆时针旋转直接实现秸秆抛撒和切割的综合功能。秸秆切割可在有支撑和无支撑两种情况下完成。同时,被完全砍掉的秸秆可以通过锯齿刀片前牙和抛撒装置被直接掷到开沟器后方。4) Experimental results showed in the soil bin device that: (1) Cutting rate of straws increased with increasing of rotation speed of saw-tooth blade and moisture of straws, and higher moisture of straws would be of benefit to improve cutting quality; (2) Power consumption increases along with increasing of rotation speed, and that decreased with increasing of moisture of straws; ( 3 ) Cutting rate of straws decreased with increasing of velocity of the vehicle while interval between the fixed and moved blade had been determined, and to decrease the interval between the fixed and moved blade would be of benefit to improve cutting quality of straws without phenomena of rearing out and leaky cut, and could decrease power consumption. 4 )实验结果表明在土壤储藏设备:( 1 )切割率随锯齿圆盘切刀转速和秸秆湿度的增加而增加,高湿度的秸秆将有利于提高切割质量; ( 2 )能量消耗随转速的增加而增多,而随秸秆湿度的增加而减少;( 3 )当动定刀间距一定时,切碎率随车辆速度的加快而降低,减少动定刀间距将有益于提高切割质量而不会出现撕皮和漏割现象,并能降低能耗。Compared with the other driving anti-blocking mechanism, the theoretical analysis and experimental results showed that the sawing anti-blocking mechanism had better capability to cut and lower rotate speed and power consumption as well as stronger suitability for different stubbles mulch. 与其他驱动防堵装置相比,理论分析和实验结果均表明,锯切防堵装置在不同的根茬覆盖率下具有更好切割能力同时减少和较低的转速和功率消耗。References1Zhang Jinguo, Gao Huanwen. Study on the strip chopping anti-blocking mechanismJ. Transactions of the Chinese Society of Agricultural Machinery, 2000,31(4):3335(in Chinese).2Luan Yuzhen, Tian Hongwei. Research on performance and matched pattern of chopper for cornstalk and rootJ. Transactions of Jilin Agriculture University,1991,13(3): 6568(in Chinese).3Mao Hanping, Chen Cuiying. Research status of the straw chopperJ. Transactions of the Chinese Society ofAgricultural Machinery, 1996, 12 ( 2 ): 152154 (in Chinese).4Mao Hanping, Chen Cuiying. Analysis of working mechanism and parameters of the straw chopper J. Transactions of the CSAE, 1995, 11 (4): 6266 (in Chinese).5Wu Fengsheng, Jin Mei. Design of 4Q31 chopper mechanism for rice and wheat stalkJ. Transactions ofthe CSAE,1998,14(3):248250(in Chinese).6Wu Ziyue, Gao Huanwen, Zhang Jinguo. Study on 69Liao Qingxi et al: Design of anti-blocking mechanism for no-tillage planter cutting velocity and power requirement in a maize stalk chopping processJ. Transactions of the Chinese Society of Agricultural Machinery, 2001, 32 (2): 3841 (in Chinese).7Li Jinyi, Wang Xiangfa. Cutting mechanism of forage harvester J . Agriculture Machinery and FoodMachinery,1995(4):1920(in Chinese).8Woodworker Machinery Compiled Group. Woodworkermachinery M . Beijing: China Forest Publishing Company,1998(in Chinese).9Zhou Canfeng, Chen Qingshou, Li Zuguang. Randomness of sawing forces and wear blade J. Explore MineEngineering,2000,(2):5255(in Chinese).10Wang Longbu. Elasticity theoryM. Beijing: Science Publishing Company, 1979(in Chinese).11Liao Qingxi, Gao Huanwen. Experimental study on anti-blocking mechanism of the sawing anti-blockingmechanism for no-tillage planter J. Transactions of China Agricultural University, 2003, (4): 4548 (inChinese).12Zhou Kaiqin. Handbook of mechanical parts M . Beijing:Advanced Education Publishing Company, 1994.13Liao Qingxi, Gao Huanwen. Experimental study on the sawing anti-blocking mechanism for no-tillage planter J. Transactions of the Chinese Society of AgriculturalMachinery,2003(6):to be published(in Chinese).14Yang Zhongpin, Yang Linqing, Guo Kangquan. A preliminary study on the technology of making cornstalk cuticles particleboardJ. Transactions of Northwestern Agricultural University, 1995, 10 ( 3 ): 6772 ( in Chinese).参考文献1 张晋国,高焕文.切割防堵装置J.中国农业机械,2000,31(4):3335.2 栾玉珍,田宏伟.谷物根茎性能研究与切割工具的匹配类型J.吉林农业大学,1991,13(3): 65683 毛罕平,陈翠英。秸秆收割机的研究现状J.中国农业机械学会,1996, 12 ( 2 ): 1521544毛罕平,陈翠英。秸秆收割机工作装置的分析和参数J.农业工程学报,1995, 11 (4): 6266 (in Chinese).5吴凤生,金梅。4Q-31型玉米小麦收割机的设计J.农业工程学报,1998,14(3):2482506吴子越,高焕文,张晋国。玉米秸秆粉碎中的切割速度和功率要求的研究J。中国农业机械学会,2001, 32 (2): 38417李金义,王向发。饲料收获机的切割装置 J .农业机械和食品机械,1995(4):19208木工机械编译组。木工机械 M 。北京:中国林业出版社,19989周彩凤,陈庆寿,李祖光。锯切力和磨损刀片的随机性J 。矿山工程勘测, 2000 ,( 2 ) : 52 55 (中文) 。10 弹性理论 M 。北京:科学出版社,197911 廖庆喜,高焕文。免耕播种机锯切防堵装置的试验研究J 。中国农业大学, 2003 ,( 4 ):45 48 。12 周开琴。机械零件手册 M 。北京:高等教育出版社, 1994 。13 廖庆喜,高焕文。免耕播种机锯切防堵装置的试验研究J 。中国农业机械学会, 2003年( 6 ):出版(中文) 。14杨忠平,杨林青,郭开全。玉米秸秆角质层刨花板初步研究 J 。西北农业大学, 1995年, 10( 3 ): 67 72 (中文)。 膈莂蒁蚂芀膅螀蚁羀莀蚆螀肂膃薂蝿膅荿蒈螈袄膁莄螈肇莇螂螇腿芀蚈螆芁蒅薄螅羁芈蒀螄肃蒄莆袃膅芆蚅袂袅蒂薁袂羇芅薇袁膀薀蒃袀节莃螂衿羂膆蚈袈肄莁薄袇膆膄蒀羇袆荿莆羆羈膂蚄羅肁莈蚀羄芃膁薆羃羃蒆蒂羂肅艿螁羁膇蒄蚇羁艿芇薃肀罿蒃葿蚆肁芅莅蚅膄蒁螃蚄羃芄虿蚄肆蕿薅蚃膈莂蒁蚂芀膅螀蚁羀莀蚆螀肂膃薂蝿膅荿蒈螈袄膁莄螈肇莇螂螇腿芀蚈螆芁蒅薄螅羁芈蒀螄肃蒄莆袃膅芆蚅袂袅蒂薁袂羇芅薇袁膀薀蒃袀节莃螂衿羂膆蚈袈肄莁薄袇膆膄蒀羇袆荿莆羆羈膂蚄羅肁莈蚀羄芃膁薆羃羃蒆蒂羂肅艿螁羁膇蒄蚇羁艿芇薃肀罿蒃葿蚆肁芅莅蚅膄蒁螃蚄羃芄虿蚄肆蕿薅蚃膈莂蒁蚂芀膅螀蚁羀莀蚆螀肂膃薂蝿膅荿蒈螈袄膁莄螈肇莇螂螇腿芀蚈螆芁蒅薄螅羁芈蒀螄肃蒄莆袃膅芆蚅袂袅蒂薁袂羇芅薇袁膀薀蒃袀节莃螂衿羂膆蚈袈肄莁薄袇膆膄蒀羇袆荿莆羆羈膂蚄羅肁莈蚀羄芃膁薆羃羃蒆蒂羂肅艿螁羁膇蒄蚇羁艿芇薃肀罿蒃葿蚆肁芅莅蚅膄蒁螃蚄羃芄虿蚄肆蕿薅蚃膈莂蒁蚂芀膅螀蚁羀莀蚆螀肂膃薂蝿膅薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄肁莃蒄袃肀肃芇蝿肀芅蒃螅聿莈莅蚁肈肇薁薇肇膀莄袆肆节蕿螂肅莄莂蚈膄肄薇薄膄膆莀袂膃荿薆袈膂蒁葿螄膁膁蚄蚀螈芃蒇薆螇莅蚂袅螆肅蒅螁袅膇蚁蚇袄艿蒃薃袃蒂芆羁袂膁薂袇袂芄莅螃袁莆薀虿袀肆莃薅衿膈薈袄羈芀莁螀羇莃薇蚆羆肂荿蚂羆芅蚅薈羅莇蒈袆羄肆蚃螂羃腿蒆蚈羂芁蚂薄

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号