螺旋运输机机械结构设计【含CAD图纸、SW三维模型、说明书】

收藏

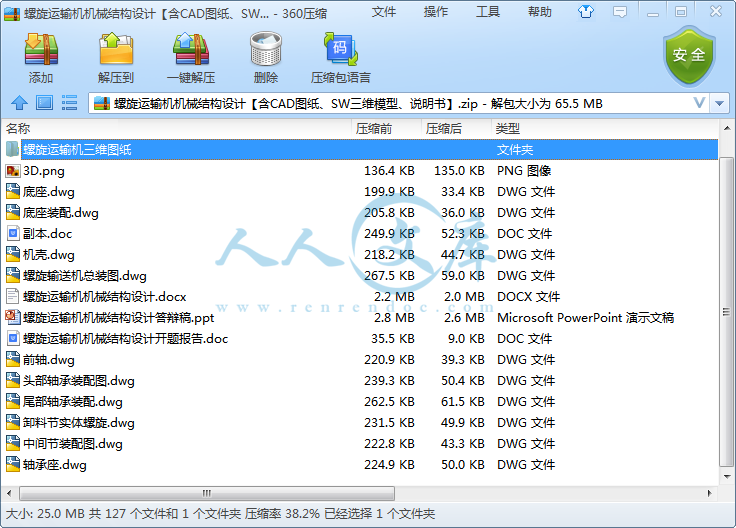

资源目录

压缩包内文档预览:

编号:22884067

类型:共享资源

大小:25.26MB

格式:ZIP

上传时间:2019-11-03

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

含CAD图纸、SW三维模型、说明书

螺旋

运输机

机械

结构设计

CAD

图纸

SW

三维

模型

说明书

- 资源描述:

-

【温馨提示】压缩包内含CAD图有下方大图片预览,下拉即可直观呈现眼前查看、尽收眼底纵观。打包内容里dwg后缀的文件为CAD图,可编辑,无水印,高清图,压缩包内文档可直接点开预览,需要原稿请自助充值下载,所见才能所得,请见压缩包内的文件及下方预览,请细心查看有疑问可以咨询QQ:11970985或197216396

- 内容简介:

-

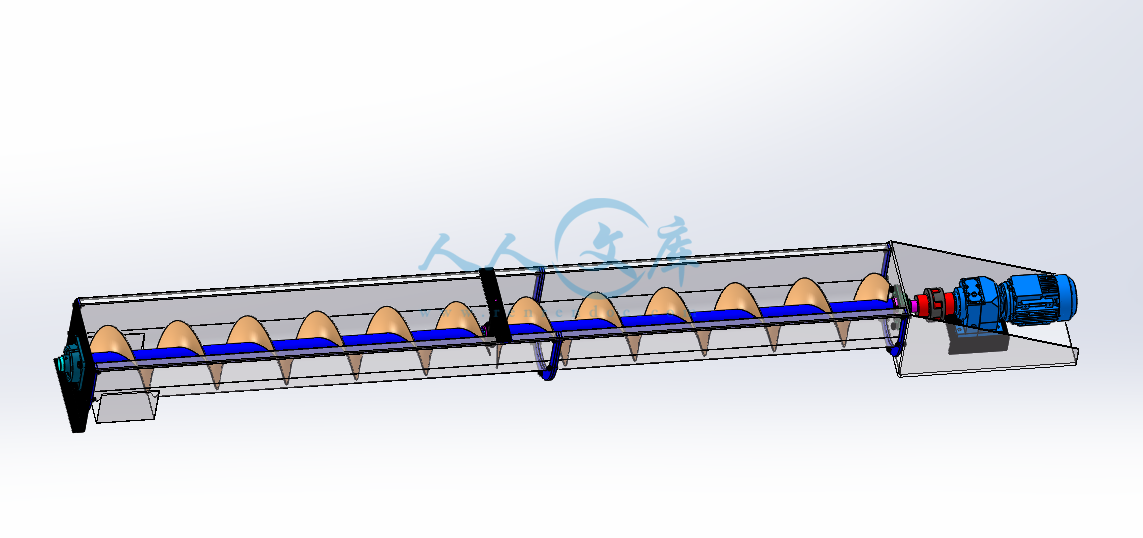

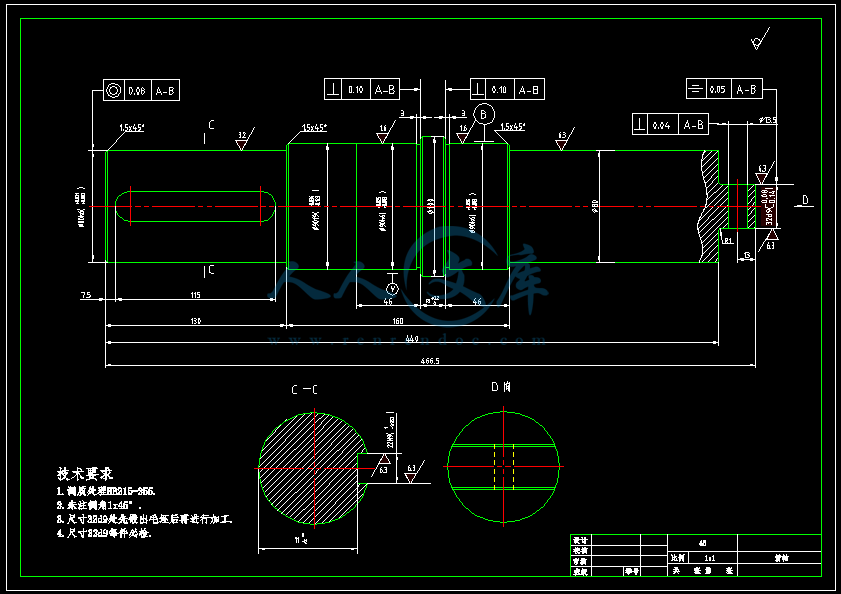

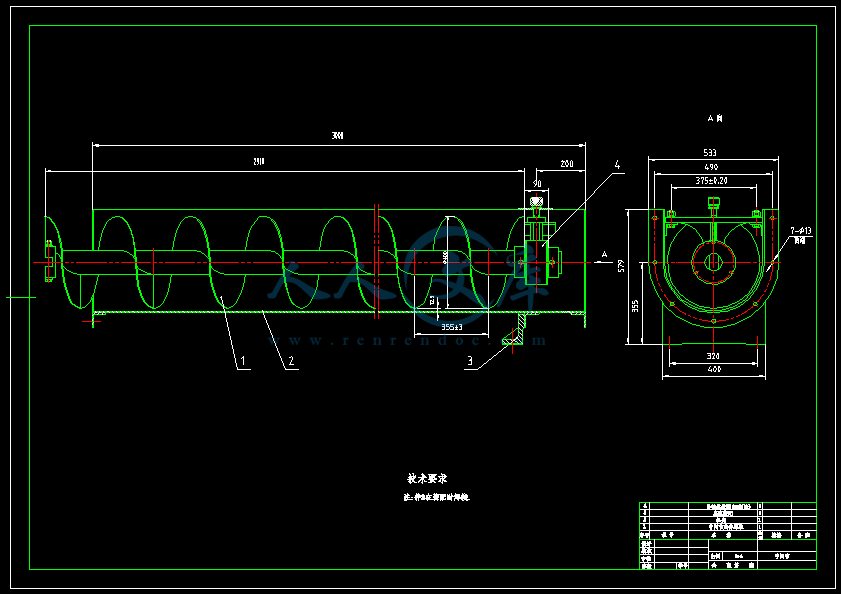

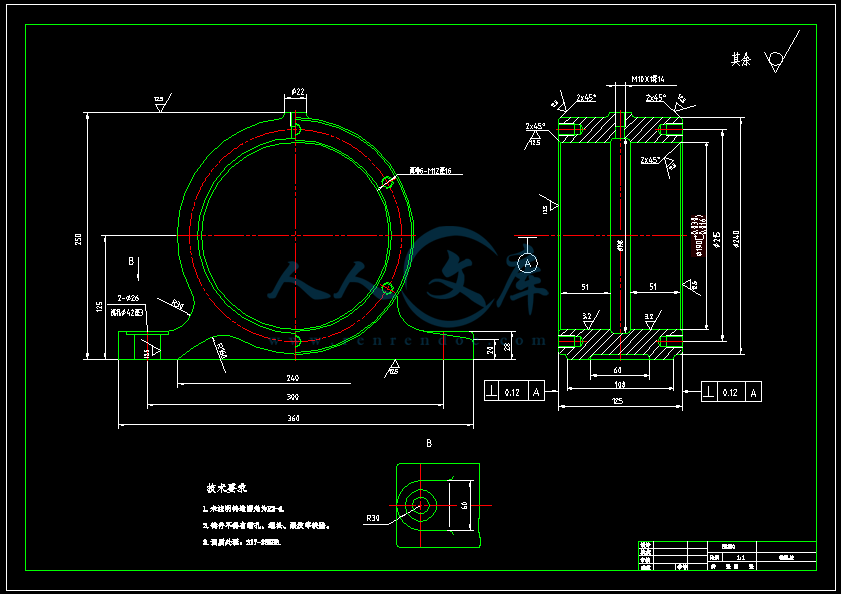

压缩包内含CAD图纸和三维建模及说明书,咨询Q 197216396 或 11970985摘要螺旋运输机是一种连续的物料运输机机械,通过电动机作为动力源带动螺旋轴转动进而带动螺旋叶片的旋转,使物料槽内的物料沿物料槽做轴向的移动,因为物料的自身重力,排出卸料口。随着现代运输物料的种类增多,运输成本也在逐渐的增加,合理的设计选择螺旋运输机也变得至关重要,首先要了解螺旋运输机的工作原理;其次根据要运输物料的种类、运输要求、工作环境等选择要设计的螺旋运输机。此次要运输的物料时干燥的煤粉,根据运输量和运输距离计算输出功率,接下来根据功率选型减速机、电动机来解决当前的问题。关键词 螺旋运输机;螺旋轴;物料 3AbstractScrew conveyer is a kind of continuous material conveyor machinery, through the motor as power to drive the rotation of the screw axis rotation to drive the spiral blade, make the material slot materials along the material tank do axial movement, because the material of its own gravity, the discharging mouth eduction.With modern transportation material increase in the number of species, transportation costs are also gradually increased, the reasonable design of screw conveyer has become very important, must first understand the working principle of screw conveyer; Secondly, according to the types of transportation materials, transportation requirements, working environment, and so on, the design of screw conveyor. The transporting materials dry pulverized coal, according to the traffic and transport distance calculation power output, then according to the selection of reducer, motor to solve the current problem.Key words helix transport Screw axis materialII目 录摘要IABSTRACTII1绪论11.1螺旋运输机的简介11.2螺旋运输机的发展史11.3螺旋运输机的现状和发展前景22螺旋运输机的结构及工作原理32.1螺旋运输机的基本结构32.2螺旋运输机的工作原理32.3螺旋运输机的类型32.3.1水平螺旋运输机32.3.2倾斜螺旋运输机42.3.3垂直螺旋运输机43结构方案与参数选用53.1设计条件53.2螺旋运输机的选型53.2.1 螺旋体53.2.2 螺距83.2.3螺旋体的轴径83.2.4螺旋体的转速113.2.5计算功率113.2.6螺旋体布置方式134螺旋运输机驱动装置164.1电动机的选择164.2减速机的选择174.3轴承的选择194.3.1头尾部轴承的选择194.3.2中间悬挂轴承的选择224.4键的选择和校核235螺旋运输机的安装调试和使用维护255.1螺旋运输机的安装调试255.1.1螺旋运输机的安装条件255.1.2螺旋运输机调整255.2螺旋运输机的使用维护266螺旋运输机的三维立体式图286.1螺旋运输机三维图28结论31致谢32参考文献33VI1绪论1.1螺旋运输机的简介螺旋运输机被称为“蛟龙运输机”,螺旋运输机主要使用于物料的运输的行业,螺旋运输机是一种使用实体螺旋叶片旋转,推动物料沿着物料槽轴线方向运动的运送设备,运用于运输粘度较小、不容易结块的粉状,颗粒状和小块的物料,因为运输的物料如果粘度较大,输送时会粘附在螺旋叶上,导致不能排出运输机,同时发生的物料的积塞也会使螺旋运输机不能正常的运行。螺旋运输机在各行各业被广泛应用,如矿业、建筑、粮食、冶金、电力及食品等行业,适用于不同角度输送物料,如水泥、农作物、煤矿、化学肥料、沙子、灰渣等物料,运输的物料热度不能高于200。螺旋运输机的特点:(1)结构简单,成本较低;(2)工作可靠,维护方便,寿命长;(3)密封性好,可以进行密封运输,输送易飞扬、有异味的及高温的物料,从而减少对环境的影响;(4)整机体积较小,装卸方便,操作安全简便;(5)螺旋叶片和料槽会使物料在运输过程中磨损较严重。1.2螺旋运输机的发展史 在17世纪初,出现架空索道运输一些散状物料;到1887年,螺旋运输机由阿基米德创造出来,其后被改良,用于运输散状或固态的物料,经过时间发展,出现了许多不同类型的螺旋运输机,使得螺旋运输机有了较大的发展。螺旋运输机的发展过程,大方向分为有轴螺旋运输机和无轴螺旋运输机这两个发展方向。有轴螺旋运输机是由螺杆、盖板、进料口、出料口、U型料槽和驱动装置构成的,螺旋运输机按运输轴的轴线方向不同,分为水平式、垂直式和倾斜式三种;而无轴螺旋运输机则是在有轴螺旋运输机的基础上将螺旋杆变为无轴的,同时在物料槽内安装可换衬套。一般情况下,我们指的螺旋运输机都是有轴式的螺旋运输机。对于很多运输比较困难的物料,研究人员一直在寻找一种可靠地运输方式,而无轴运输机则有较好的发展前景。2GX螺旋运输机是一款最先出现的螺旋运输机,同时也是国家最早确定型号,进行制造的运输设备。GX型螺旋运输机的优点有,运输机的头尾部的轴承安装在机壳外,保证了良好的密封性;GX螺旋运输机的不足是,零部件磨碎较快,能耗严重,运输物料时破碎严重1。LS螺旋运输机是新一代螺旋运输机,LS型螺旋运输机具有结构新,设计指标先进,性能可靠,动力损耗较低,适用范围较广的特点1。1.3螺旋运输机的现状和发展前景螺旋运输机被称为不具有挠性牵引构件的连续输送机,现代已成为机械化流水作业的基础设备。螺旋运输机在我国各农业工业部门帮助实现了机械自动化,提高生产效率。但是因为其运输效率的较低,已经成为制约螺旋运输机发展的主要问题,国外已有不少的研究成果,而国内的相较于国外的研究成果较少。国外的研究方向主要有两个:一是螺旋运输机的多元化功能如高倾角带输送机、管状螺旋输送机等各种机型;二是在螺旋运输机本身能力上加强了改进,如在距离、运输量、速度上的改进已成为了主要发展方向。 2 螺旋运输机的结构及工作原理2.1螺旋运输机的基本结构螺旋运输机的基本结构是由驱动装置、旋转螺旋轴、物料槽、轴承等主体部分组成的。其结构如下图1-1图2-1 螺旋运输机的基本结构1-驱动装置;2-头节装配;3-中间节装配;4-选配中间节总成5-尾节装配;6-机盖总成;7-进料口;8-出料口;2.2螺旋运输机的工作原理旋转螺旋轴通过轴承安装在料槽内,螺旋轴的一端与驱动装置联结,物料槽顶面和底面设有进料口和出料口。工作时,先由驱动装置提供动力,带动螺旋轴转动,物料从进料口输入,物料受到螺旋叶片的推动力而移动,推动力分为轴向和径向力,径向力有让螺旋轴和物料一起运动的趋势,而物料自身的重力和物料槽对物料的摩擦力影响,使物料是不跟着螺旋叶片同时旋转的,而是在螺旋叶片法向推力的轴向分力作用下,沿着物料槽做轴向的移动,直到排除出料口。螺旋轴的旋向决定着螺旋运输机的物料运输方向1,大部分螺旋运输机的运输方向都是按照单方向向设计的,当反向运输时会影响螺旋运输机的使用寿命8。2.3螺旋运输机的类型2.3.1水平螺旋运输机水平螺旋运输机大多采用“U”型槽体、固定的安装结构、较低的螺旋旋转速度,如图1-1所示。工作时,物料先由进料口进入物料槽,被运输到出料口卸出。2.3.2倾斜螺旋运输机倾斜螺旋运输机运输倾角一般在20o ,结构与水平螺旋运输机相同。螺旋运输机的运输倾角如在20o90o ,则采用圆桶状槽体及短螺距螺旋,同时旋转螺旋轴的转速也要提高,其结构与垂直螺旋运输机相同,如图1-2。图2-2 倾斜式螺旋运输机结构示意图2.3.3垂直螺旋运输机垂直螺旋运输机是垂直方向运输散状物料,物料的颗粒大小要12mm8。垂直螺旋运输机是由底端或者顶端驱动的,槽体为封闭的桶装形。垂直螺旋运输机的优势是机构简单,占地面积较小,制造成本较低;缺点是运输物料能力较低,运输高度不能超过8m。如图1-3所示。 图2-3 垂直螺旋运输机结构简图 3 结构方案与参数选用3.1设计条件运输物料:干燥的煤粉,运输量:20 t/h运输方式:水平运输运输距离: 10 m3.2 螺旋运输机的选型3.2.1 螺旋体螺旋体由螺旋轴和焊在其上的螺旋叶片构成的。叶片的旋向有左旋和右旋,螺旋叶片的旋向和螺旋轴的转向决定着物料运输的方向2。此次设计以运输散状物料为目的,故采用标准形式的单头右旋螺旋。按照输送的要求不同,可以分为实体式、带式、桨叶式、齿形式等四种形式,如图3-1。 (a) (b) (c) (d)图3-1 螺旋形状(a)实体式 (b)带式 (c)桨叶式 (d)齿形式根据被运输物料的种类、特点进行选用。实体式螺旋应用最为广泛,其结构简单,运输能力强,用于流动性较好的、干燥的、粉状的或者颗粒状的物料;带式螺旋多用于运输有粘滞性的物料或者小块状的物料,有较强的搅拌能力,但效率较低;桨叶式与齿形式螺旋用于运输过程中易受挤压的物料,当在运输物料时,有对物料搅拌、松散等要求时,应优先考虑桨叶式或者齿形式。根据此次运输物料特点,选用实体式螺旋叶片。综上所述,根据物料情况,我们选用水平方向螺旋运输机,右旋单头螺距,标准形式的实体式螺旋面。按公式(3-1) (3-1)式中; ; 表3-1 常用物料的填充、特性、综合系数物料粒度0.350.400.0415750.250.350.0490500.250.300.0537400.200.250.064525表3-2 倾角系数表由表3-1,查得运输煤粉时的参数:=0.0415;=0.350.4,此处取=0.4;=0.6; =75; 由表3-2,=1.0;将原始数据,代入式(3-1),得将上式得出的螺旋直径D进行圆整到标准系列,从下列标准直径中:。故螺旋轴直径。螺旋轴直径,必须进行物料粒度的校核2:对没有挑选过的物料取直径对挑选过的物料取直径 式中:;。如上,运输物料为煤粉,故满足要求。3.2.2 螺距螺距的设计影响着在一定的填充系数F物料运行的滑移面上,所以运输过程中螺距的大小至关重要1。对标准的螺旋运输机而言,可按下式(3-2)计算螺距: (3-2)式中:,当物料流动性较差或倾斜安放时,;当水平安装时,。水平布置K取较大的值,倾斜布置K取较小的值,故取时,存在如下:则螺距。螺距一般设计成前密后疏的结构,来防止在物料运输中发生堵塞,同时为了防止出料口的堵塞,在螺旋体的尾部设计时,卸料节尾端设计有反螺旋的结构,以此来解决运输过程中物料末端堵塞的问题。3.2.3螺旋体的直径螺旋体直径的大小和螺距有关,两者影响着螺旋叶片的升角,也就影响了物料的滑移方向和速度分布,所以应该从考虑螺旋面和物料的摩擦关系以及速度各分量的适当分布来明确最合理的螺距和轴径的关系1。根据物料运动的分析得,先保证轴径处的轴向速度0 即螺旋内升角,才能保证物料在料槽中做轴向移动,由于螺旋底部的螺旋升角最大,所以此处的轴向力最小,由于,所以螺距与轴径要满足的其中一个条件是8: 对于大部分的螺旋运输机而言,其螺旋轴一般能满足第一个条件但对于一些轴径较小的螺旋运输机来说,其不一定能确保满足第一个条件,所以我们在确保较小直径螺旋轴S和d的同时,要进行验算处理8。轴径与螺距的还应满足第二个条件:螺旋轴径处各点的圆周速度要小于其轴向速度,同时保证物料有最大的轴向速度8。和如下式(3-3)和(3-4): (3-3) (3-4)式中:s螺旋的螺距(m) n螺旋的转速(r/min) r物料颗粒离轴线的半径(m)面物料与螺旋面的摩擦系数(其中面=tan)图32 螺旋叶片速度分析得出式(3-5) (3-5)根据上式计算,取,时,则因为,有 所以 63.7。由式子可得,当增大时,同样在增大,也就是说,计算出的轴径就越大,这必定会降低有效输送截面的面积。要想保证有效地输送截面进而保证运输物料的能力,势必会增大整个螺旋运输机的结构,会导致运输机结构巨大笨重,同时增加制造成本,所以应综合考虑轴径与螺距的关系,在能满足运输机的输送能力的情况下,要使结构紧凑。螺旋运输机的填充系数较低,只要确保靠近叶片的物料的轴向速度尽可能大,且要大于圆周速度即可3。一般的轴径计算公式(3-6)为: (3-6)在此取 即 。综上所述,螺旋体直径。3.2.4螺旋体的转速螺旋体在满足运输的前提下,转速尽可能低,防止过大的切向力导致物料飞出,使运输机无法正常工作,所以需要校核螺旋轴转速n,下式(3-7): (3-7) 式中:螺旋轴的极限转速;物料综合特性的系数。由题意得 ,查表3-1得 则 螺旋轴标准转数系列为;单位:。根据计算结果螺旋轴极限转速为150,故选取螺旋轴标准转速。选取标准转速之后,螺旋直径和螺旋轴极限转速都选取的标准值,与计算结果有些许偏差,其填充系数可能不是原参考文献中选取的值了,利用公式(3-8)校核填充系数: (3-8)式中:螺距本次设计采用D制法,所以。通过上述公式校核填充系数 :这时(0.350.45),所以确定螺旋体转速n=120r/min 。 3.2.5计算功率螺旋运输机的总功率由运行工作功率、空载功率以及倾斜附加功率组成。由螺旋输送设计手册查得,螺旋运输机总功率(3-9): (3-9)式中 ; ;参见表3-3;将,,带入上式得到电动机的功率(3-10): (3-10) 式中为驱动装置的总效率,一般取0.850.9,此处按最低效率设计取则电动机功率:表3-3物料阻力系数3.2.6螺旋体布置方式螺旋运输机是由驱动装置、头节、尾节、选配中间节、进料口、出料口、料槽组成的,如图3-3所示,除头节和选配中间节除外,各节螺旋及机壳均有互换性。图3-3 螺旋运输机布置形式 1-驱动装置;2-头节装配;3-中间节装配;4-选配中间节总成5-尾节装配;6-机盖总成;7-进料口;8-出料口;在布置一台水平螺旋运输机时,首选将驱动装置安装在进料口端,因为将出料口和驱动装置安装在头节有止推轴承处,可以使螺旋轴维持张紧的状态1。总体布置时机壳接头的法兰处、机盖接头和悬挂轴承上方不应出现料口1。螺旋运输机有五种安装布置形式,如下图3-4 (1) (2) (3) (4)(5)图3-3 螺旋运输机的布置形式布置形式结合结合实际情况具体场合选择,选取参数有:螺旋叶片的旋向、进料口出料口位置、螺旋体的旋转方向等。此次设计,选择第三种安装布置方式。螺旋运输机长度组合如下表3-5所示,已知螺旋运输机设计的运输距离为10m。故查表3-4得,头节一个,长度3m,两个选配节,一个1.5m,一个2.5m,尾节一个,长度3m。即螺旋运输机的长度组合:10m =3m(头)+1.5m(选配)+2.5(选配)+3m(尾) 表3-4 螺旋运输机的长度组合螺旋输送长度 m头节L01=3m选配节L02=1.5m选配节L02=2m选配节L02=3m尾节L03=3m81118.511191119.5111110111110.5111螺旋运输机的物料槽体如下图3-5所示,大多数槽体截面为“U”形钢制槽体还有一些是圆筒型的,U型槽最为常用,长度为3000或者3660mm。一般用2-10mm的薄板钢制成U型物料槽,其底部制成圆弧形,横截面上两侧壁垂直,上端法兰是由同一块钢材折边加工而成的,这样的物料槽体刚性更好,同时上端边沿焊接有纵向角钢,加强了物料槽刚性,实现上部盖板与物料槽的联结。圆弧底部的半径应大于螺旋叶片的半径,留有4-8mm的间隙。为方便安装,物料槽体每节制成2-4m,两端节边制成法兰边并用角钢加固,便于螺栓连接,为了避免槽体过长而导致的弯曲不平,每隔2-3m设置一支架承托槽体。根据设计要求,选用(a)型槽体。图35 螺旋运输机螺旋槽体的形式; ; ; ; ; 。粉尘类的运输,螺旋槽体通常情况配有顶盖进行封闭,根据实际使用情况,可使用防尘型。顶盖一般是用薄板钢制成,可以用螺栓固定在上端角钢法兰上或者弹簧卡子夹紧在物料槽上。螺旋体和物料槽制造和装配精度越高,磨损损耗越小,动力消耗越小,一般留有间隙6-9.5mm。4 螺旋运输机驱动装置4.1电动机的选择根据工作条件,此次选用选用交流,鼠笼三相异步电动机,封闭型电机,电压380V,Y型。选用电动机,首先需要根据工作机的功率和减速器联轴器的效率而言,才能得出所需要的电动机功率,之前已经得出螺旋运输机的总功率为P0=0.78kw,根据运输设计手册而得,一般螺旋运输机的总效率是0.85到0.9之间。则电动机的功率Pd=0.92kw。螺旋运输机运输平稳,故电动机的额定功率只需略大于电动机的功率就可,根据Y系列电动机型号大全,选用额定功率的电动机。选用电动机,其次考虑电动机的转速,已知螺旋轴的转速n=120,本次设计采用摆线针轮减速机,此减速机传动比范围6到87之间,故电动机的转速如下式(4-1): (4-1)符合这额定功率的同步转速由Y系列电动机型号大全得1000r/min,1500r/min,3000r/min。现对这三种方案进行比较,如下表4-1所示。表4-1 Y系列电动机型号比较型 号额定功率 额定电流 转速 效率 功率因数 堵转转矩堵转电流最大转矩噪声振动速度 重量额定转矩额定电流额定转矩1级2级kWAr/min%COS倍倍倍dB(A)mm/skgY80M2-21.12.5283077.00.862.27.02.365711.818Y90S-41.12.71400780.782.36.52.361671.825Y90L-61.13.291073.50.72.05.52.256651.824综上考虑成本、效率、重量等因素,选择电动机的型号为:Y90S-4。由型号查表4-2 Y系列外形及安装尺寸和图4-1外形及安装尺寸得电动机的外形及安装尺寸:轴颈D:24mm 伸出长E:50mm 中心高H:90mm 图4-1外形及安装尺寸表4-2 Y系列外形及安装尺寸机座号级数安装尺寸外形尺寸HABCDEFGKMNPRSTABACADHDL80M2,480125100501940615.5101651302000123.516517515017529090S2,4,690140100562450820101651302000123.518019516019531590L2,4,690140125562450820101651302000123.5180195160195340100L2,4,61001601406328608241221518025001542052151802453804.2减速机的选择减速器的选择直接影响到运输时的效率及其承载能力,需要综合考虑其传动比、安装形式、输入输出转速、功率的要素,此次设计采用摆线针轮减速器,具有减速比大,传动效率高,体积小,重量轻,故障少,寿命长,运转平稳可靠,噪音小,拆装方便,容易维修,结构简单,过载能力强,耐冲击,惯性力矩小,等特点。首先按照安装的形式选择减速机的安装形式为卧式W型,其次因为配带的电机为异步电机,所以为Y型。然后,已知电动机转速1400r/min,螺旋轴的转速为120r/min,故得减速比如下时(4-2): (4-2)故减速比i=11。已知电动机功率,减速比i=11,根据下表4-3选择机型号为14,综上所述,确定螺旋运输机的减速机型号为: BWY14-11-1.1。表4-3 单级减速机型规格选择表机型号B10A101112131414A15161718输出转速r/min减速比输入功率KW90.750.751.547.511-150/106110.750.751.547.5111518.5224555127/87150.750.751.547.5111518.522455593/64170.750.751.535.5111118.522405582/56230.750.751.135.511111518.5405560/41290.550.751.12.2411111515374548/32350.550.551.11.547.57.51111304543/27430.370.551.11135.55.51111223032.5/22470.370.370.751.12.2447.51118.53030/20590.250.370.751.12.2447.57.518.52232.5/1671-0.751.5337.57.518.52219.5/13.5输入转速14009604.3轴承的选择螺旋运输机上有三处使用到轴承,分别是与减速机连接的头部轴承,还有螺旋运输机尾部末端的尾部轴承,最后是克服螺旋轴运输过程中产生的挠度的中间悬挂吊轴承。4.3.1头尾部轴承的选择 螺旋运输机在工作时会产生很大的轴向力,头部轴承是接近电动机的那一端,轴承要承受物料运输中的轴向力,故选择推力轴承以平衡轴向力,同时螺旋轴承受的是拉伸作用,比轴向压缩的状况有利。止推式如图4-2所示。图4-2 首端止推轴承因为首端需要承受大的轴向力,考虑使用推力球轴承,并且成对使用,能承受双向轴向载荷,提高其稳定性。(1)计算轴承所受的轴向力物料在物料槽的运输可认为是滑动摩擦,所以轴承所受的轴向力可近似等于物料的摩擦力,首先煤粉的摩擦阻力系数 ,选择较大的摩擦阻力系数计算,故取,其次计算煤粉运输的重力,先计算运输体积,按照最大体积计算,即以壳体的内径0.27m,运输距离为10m,同时把壳体近似成圆柱体,得运输的最大体积如下公式(4-3) : (4-3)由于煤粉的密度为 ,故运输的质量 。 所以煤粉重力 : 摩擦力:轴承所受的轴向力。故推力球轴承轴向当量静载荷。(2)计算轴的当量动载荷设螺旋运输机一天工作10小时,运作10年。故轴承的预期寿命:由工作时间查得 轴承的寿命系数;参考机械设计手册,查得速度系数;根据载荷平稳性,参考表4-4,螺旋运输机载荷平稳无冲击故取 : 螺旋运输机输出力矩载荷较小,则取力矩载荷因数;根据螺旋运输机工作环境温度120,查表4-5得出温度系数: 表4-4载荷系数载荷性质fP举例平稳运转或有轻微冲击1.01.2电动机、通风机、水泵、汽轮机等中等冲击1.21.8机床、车辆、冶金设备、起重机等强大冲击1.83.0轧钢机、破碎机、振动筛、钻探机等表4-5温度系数轴承工作温度/oC153030505070同轴度(mm)3.04.05.05.0(2)保证所有螺旋连接可靠。(3)螺旋运输机的减速机和主轴要满足同轴度要求GB1184-80形状和位置工差,未注公差的规定附表4中10级的规定。(4)螺旋运输机安装完成后,检查各部分储油处保证润滑油的充足,之后进行无负载试车,至少连续运行5个小时再检查螺旋运输机安装和调整的可靠性,发现运行时有问题,立即停车检查,直至最后运行状况良好为止。(5)螺旋运输机的进出料口与机壳法兰的连接不得有间隙,应紧密贴合。5.2 螺旋运输机的使用维护此次螺旋运输机是运输煤粉的,所以轴承、螺旋体、减速机等机件都工作在粉尘条件下,具体操作保养要求如下:(1)螺旋运输机必须无负载启动,在启动时物料槽内不允许有物料,只有在启动后才可以添加物料。(2)螺旋运输机初始添加物料时,逐步增加添加物料速度以达到额定的运输能力。正常工作时,物料应被均匀的添加进运输机,以免造成物料堵塞运输机的情况,导致驱动部分过载,影响运输机的使用寿命。(3)为保证运输机无负载启动,每次运输机在停车前都不允许加料,直至物料排尽才可停车。(4)运输的物料内不允许有大块的坚硬成分,以免损坏螺旋体。(5)在使用中要时刻检查螺旋运输机紧固件的情况,一经发现松动的情况,要立即拧紧螺栓,重新紧固。(6)运输机的机上盖在机器运行时不能卸下来,以免物料飞出发生意外。(7)螺旋运输机的在运行的时候发现的不正常的现象都应停车,立即检查问题,不允许强行继续运行。(8)加强螺旋叶片耐磨性的方法 螺旋运输机的使用寿命取决于螺旋体叶片的耐磨性,而螺旋叶片磨损最严重的位置为叶片的顶部,磨损方式有:热磨损、颗粒磨损和氧化磨损。加强耐磨性可采用如下方法:表面采用电弧和火焰方法加强金属材料表层的硬度。在螺旋叶片的上端加上耐磨钢片或覆盖增强高分子耐磨片,磨损后可随时替换。涂刷耐磨涂层,涂料要具有一定的机械强度,如耐磨涂料。此工艺简单,适合温度小于100的场合,但抗冲击能力差。(9) 建立封液与冷却系统,加强对两端面的冷却,需要经常更换泠却液。(10) 安装和检查时,不允许敲打密封件,以免发生局部变形为腐蚀提供基础。每个密封件在使用时都必须清洗干净。 6 螺旋运输机的三维立体式图6.1 螺旋运输机三维图螺旋运输机总装图(6-1)和(6-2): (6-1) (6-2)螺旋运输机分为:驱动装置、螺旋体、物料槽和轴承部分。驱动装置:给整个螺旋运输机动力,支持整个机器运作,如图(6-3)(6-4)。 (6-3) (6-4)螺旋体:螺旋运输机的执行部分,用来运输物料,和驱动部分通过联轴器联结在一起,图(6-5)。(6-5)物料槽:存放物料,和螺旋体共同作用运输物料,图(6-6)和(6-7)。 (6-6) (6-7)轴承部分:分为头部轴承(6-8)、尾部轴承(6-9)和中间悬挂轴承(6-10)和(6-11)三部分,起支撑运动的作用。 (6-8) (6-9) (6-10) (6-11)螺旋运输机半剖视图(6-12):(6-12)结论此次几个月的学习收获良多,螺旋运输机工作原理的分析和对结构特点设计选择都是我获益良多。在螺旋运输机设计过程中要注意两类参数,一类为已存在客观参数,只需要根据已有的条件就能选取可用的参数,运用到具体的计算或者设计中了,这类参数可以根据图表或者书籍类资料查询得到;还有一类参数为设计变量,往往通过计算得出,根据物料种类、机器工作方式、工作条件等等条件而改变。因此要根据多方面的参考才能确定最后的螺旋运输机的设计。随着设计的一步步进行遇到了很多问题,比如让螺旋运输机末端出料口不堵塞这种运输机械中很常见的问题,往往要参考资料再结合自己的思考来解决问题从中学习到很多。在具体的设计过程中,资料的查阅必不可少,逐步优化螺旋运输机的设计,在设计过程中优化参考数据,满足运输煤粉的要求,减少对环境的污染,创造更好的经济效益。致谢经过几个月来的努力,毕业设计接近尾声。在此次设计过程中遇到了很多困难,常常遇到一个坎自己就要花很多时间与精力去解决,但在指导老师和组员的帮助下,克服了一个个问题,使毕业设计逐步完善。这次的毕业设计是大学中最重要的一次设计,衡量一个大学生是否能合格毕业的标准,是我们展现自己在大学所学所得的体现。此次毕业设计,开始是毫无头绪,从哪儿开始,需要什么参数等等都使我焦头烂额手足无措,但是在我的指导老师和组员帮助下一步步的克服,此次毕设每个部分都必须按照国家标准设计,深感过去设计的不标准,但心力交瘁的同时我收获了很多,毕业设计也是专业能力成长的一次很好的机会。在做毕业设计的过程中,感到自己的专业知识非常有限,希望各位老师能够多加点评,并且指正我的不足之处,以此,我对各位老师不甚感激!参考文献1 张东海.螺旋输送机的优化研究D.大连理工大学,2006. 2陆洋.介绍一种螺旋输送机吊轴承J.江苏建材,2005,(04). 3陈广福,徐余伟.饲料螺旋输送机设计参数的选择和确定J.饲料工业.2008,29(15):1-5. 4陈敏超.一种电动车用三挡变速器的研发D,重庆:重庆大学,2012.5 徐东威, 刘广兵, 程道武,等. TPS310型螺旋输送机设计与改造J. 包装与食品机械, 2002, 20(5):35-37.6 刘海军, 孙井坤, 郑先哲. 螺旋输送机参数设计系统的开发J. 包装工程, 2012(11):15-17.7 舒服华. 基于遗传算法的螺旋输送机优化设计J. 砖瓦世界, 2008(5):49-51.8 徐余伟. 橡胶工业螺旋输送机设计参数的选择和确定J. 橡塑技术与装备, 2008, 34(10):52-58.9 陈广富, 徐余伟. 陶瓷工业螺旋输送机设计参数的选择和确定J. 陶瓷, 2008, 29(11):47-52.10 李英, 许诘, 刘光蓉. 基于VC+6.0的水平螺旋输送机选型设计研究J. 武汉轻工大学学报, 2002(1):51-54.11 舒服华, 乔天琴. 遗传算在螺旋输送机优化设计中的应用J. 陶瓷, 2008(10):47-50.12 陶亮, 何船, 陈娟. 螺旋输送机的设计计算及其关键零部件的仿真分析J. 矿山机械, 2015(8):66-69.13 龚玉友. 炭素沥青糊料螺旋输送机设计理论研究与应用D. 中南大学, 2009.14 徐余伟. 砖瓦工业螺旋输送机设计参数的选择J. 砖瓦, 2008(7):21-26.15 任进, 门庄妍. 大倾角螺旋输送机设计与参数的选择J.内蒙古公路与运输, 1995(2):37-39.16 莫恭倩, 李舟轮, 郑佳德,等.特殊用途螺旋输送机的设计J. 机械工程师, 1999(5):13-14.17Wang T L, Guo X M, Zhang Q E, et al. FEA and Optimization Design of Screw of Screw ConveyorJ. Coal Mine Machinery, 2012.18Meng H W, Kan Z, Zhi-Jiang N I, et al. Design of screw conveyor in the fodder feeds device for cowJ. Machinery, 2009.19Lu X, Kong H. Six Sigma quality optimal design of screw conveyor based on iSIGHTJ. Journal of Chinese Agricultural Mechanization, 2015.40 毕业设计附本螺旋运输机机械结构设计SCREW CONVEYOR MECHANISM DESIGN学生姓名班 级学 号学院名称专业名称指导教师年5 月30 日目 录毕业设计(论文)课题申报表1毕 业 设 计(论 文) 任 务 书 2毕业设计(论文)开题报告5毕业设计(论文)指导手册10学生毕业设计(论文)中期汇报表15学生毕业设计(论文)中期情况检查表16毕业设计(论文)指导教师评阅表17毕业设计(论文)评阅教师评阅表18毕业设计(论文)答辩及综合成绩评定表19外文翻译20毕业设计(论文)课题申报表指导教师职称副教授教研室机械设计制造及其自动化申报课题名称螺旋运输机机械结构设计课题类型工程设计类课题来源B.社会生产实践课题简介螺旋输送机俗称绞龙,是一种无挠性牵引构件的连续输送设备,它借助旋转螺旋输送叶片的推力将物料沿着机槽进行输送。螺旋输送机对输送粉状、粒状和小块状物料,如:水泥、煤粉、粮食、化肥、灰渣、砂子等,螺旋机不宜输送易变质的、粘性大的、易结块的物料。因为这些物料在输送时会粘结在螺旋上,并随之旋转而不向前移动,形成物料的积塞而使螺旋机不能正常工作。主要完成各参数设计计算,各主要结构的设计计算,Pro/E三维建模。课题要求(包括所具备的条件)1.学生应具备机械设计制造方面的基础知识和工程软件AutoCAD、UG或Pro/E等的基本操作能力;2.要求学习态度端正、责任心强,具有较强的文献查询、整理、消化能力。课题工作量要求1.与课题相关的英文文献翻译不少于4000词;2.设计论文(说明书)的字数不少于12000字,纸张不少于30页;3.毕业答辩图纸若干,达到设计任务要求;4.参考文献不少于15篇(其中包含2篇英文文献)。教研室审定意见 同意教研室主任签字:学 院审定意见同意 教学院长签字: 毕 业 设 计(论 文) 任 务 书 学院(系):机电工程学院专 业:机械设计制造及其自动化学生姓名:学 号:设计(论文)题目:螺旋运输机机械结构设计起 迄 日 期:2018年 2月 26日 2018年 5月26日指 导 教 师:教研室主任: 发任务书日期: 年 3月 4日毕 业 设 计(论 文)任 务 书 1毕业设计的背景:螺旋输送机俗称绞龙,是一种无挠性牵引构件的连续输送设备,它借助旋转螺旋输送叶片的推力将物料沿着机槽进行输送。螺旋输送机对输送粉状、粒状和小块状物料,如:水泥、煤粉、粮食、化肥、灰渣、砂子等,螺旋机不宜输送易变质的、粘性大的、易结块的物料。因为这些物料在输送时会粘结在螺旋上,并随之旋转而不向前移动,形成物料的积塞而使螺旋机不能正常工作。2毕业设计(论文)的内容和要求:内容:主要完成各参数设计计算,各主要结构的设计计算,Pro/E三维建模,总装配图,主要零件的零件图。要求:1.学生应具备机械设计制造方面的基础知识和工程软件AutoCAD、UG或Pro/E等的基本操作能力;2.要求学习态度端正、责任心强,具有较强的文献查询、整理、消化能力。3主要参考文献:1朱里.机械原理M.北京: 高等教育出版社, 2010.2濮良贵.机械设计M.北京:高等教育出版社, 2014.3邢邦圣.机械制图与计算机绘图M.北京:化学工业出版社, 2011.4陈秀宁.机械设计课程设计M.浙江:浙江大学出版社, 2012.5机械设计手册编委会机械设计手册(新版)M北京:机械工业出版社,2004.4毕业设计(论文)进度计划(以周为单位):第1周 查阅资料、英文翻译;第2周 撰写开题报告;第3周 总体结构设计;第4周 各参数设计计算;第5、6周 各部分零件结构设计计算、强度计算;第7周 部分零件零件图绘制;第8周 完成总装配图;第911周 撰写毕业设计说明书初稿、查重;第12周 修改毕业设计说明书、定稿;第13周 准备答辩。教研室审查意见:教研室主任签名: 年 月 日学院审查意见: 教学院长签名: 年 月 日 毕业设计(论文)开题报告 课题名称:螺旋运输机机械结构设计学生姓名: 学号: 指导教师:职称: 所在学院:机电工程学院专业名称:机械设计制造及其自动化 日期: 年 3 月 16 日 说 明1根据毕业设计(论文)管理规定,学生必须撰写毕业设计(论文)开题报告,由指导教师签署意见、教研室审查,学院教学院长批准后实施。2开题报告是毕业设计(论文)答辩委员会对学生答辩资格审查的依据材料之一。学生应当在毕业设计(论文)工作前期内完成,开题报告不合格者不得参加答辩。3毕业设计开题报告各项内容要实事求是,逐条认真填写。其中的文字表达要明确、严谨,语言通顺,外来语要同时用原文和中文表达。第一次出现缩写词,须注出全称。4本报告中,由学生本人撰写的对课题和研究工作的分析及描述,没有经过整理归纳,缺乏个人见解仅仅从网上下载材料拼凑而成的开题报告按不合格论。 5课题类型填:工程设计类;理论研究类;应用(实验)研究类;软件设计类;其它。6课题来源填:教师科研;社会生产实践;教学;其它 毕业设计(论文)开题报告课题名称螺旋运输机机械结构设计课题来源B.社会生产实践课题类型工程设计类1选题的背景及意义:螺旋输送机俗称绞龙,是一种无挠性牵引构件的连续输送设备,它借助旋转螺旋输送叶片的推力将物料沿着机槽进行输送。螺旋输送机对输送粉状、粒状和小块状物料,如:水泥、煤粉、粮食、化肥、灰渣、砂子等,螺旋机不宜输送易变质的、粘性大的、易结块的物料。因为这些物料在输送时会粘结在螺旋上,并随之旋转而不向前移动,形成物料的积塞而使螺旋机不能正常工作。2研究内容拟解决的主要问题:(1) 螺旋运输机结构方案的确定,参考收集的资料,提出不同的方案进行比较,选择比较优化的一种;(2)螺旋运输机的设计计算:由于此设计计算比较成熟,可根据运输机械设计选用手册所提供的计算公式和限制条件,对输送量、螺旋轴转速、螺旋叶片直径、螺距、螺旋轴直径、填充系数、倾斜角及传动功率进行计算,并根据这些条件进一步确定螺旋运输机的结构和几何尺寸,在确定螺旋运输机的主要参数时,要从其输送机理、物料的特性等方面着手,尽可能进行多种试验,取得一些设计参数,从而设计出比较符合实际情况的螺旋运输机;(3)减速器的设计计算:决定传动装置的总体设计方案;选择电动机;计算传动装置的运动和动力参数;传动零件、轴的设计计算;轴承、联接件、润滑密封和两周期的选择及校验计算;机体结构及其附件的设计。3研究方法技术路线:主要研究方法:首先通过计算机进行查阅,对螺旋运输机进行了解,了解各项数据之后再对材料和电机进行选择,再通过查阅书籍、计算机等工具对要设计的各项数据进行整理、调整,最终完成设计。在传统设计的基础上,借用计算机辅助设计软件进行,绘制三维零件图及二维零件图,并进行虚拟装配,并生成对应的工程图。 4研究的总体安排和进度计划:第1周 查阅资料、英文翻译;第2周 撰写开题报告;第3周 总体结构设计;第4周 各参数设计计算;第5、6周 各部分零件结构设计计算、强度计算;第7周 部分零件零件图绘制;第8周 完成总装配图;第911周 撰写毕业设计说明书初稿、查重;第12周 修改毕业设计说明书、定稿;第13周 准备答辩。5主要参考文献:1朱里.机械原理M.北京: 高等教育出版社, 2010.2濮良贵.机械设计M.北京:高等教育出版社, 2014.3邢邦圣.机械制图与计算机绘图M.北京:化学工业出版社, 2011.4陈秀宁.机械设计课程设计M.浙江:浙江大学出版社, 2012.5机械设计手册编委会机械设计手册(新版)M北京:机械工业出版社,2004. 6中国农业机械化科学研究院.实用机械设计手册K.北京:中国农业机械出版社, 1985:231-244. 7胡家秀,简明机械零件设计实用手册北京:机械工业出版社,1999.10 8 张荣善. 散料输送与贮存M. 北京: 化学工业出版社,1994.9张东海. 螺旋输送机的优化研究D. 大连: 大连理工大学硕士论 文, 2006. 10黄石茂. 螺旋输送机输送机理及其主要参数的确J. 广东造纸, 1998(3):27-31.) 11运输机械手册. 北京:化学工业出版社,1983 12 洪致育、林良明主编. 连续运输机. 北京:机械工业出版社,1982.13 杜君文主编.机械制造技术装备及设计.天津大学出版社,1998. 14 毛广卿主编.粮食输送机械与应用.北京:科学出版社,2003. 15 王文丽.螺旋输送机在粮食钢板仓中的改进应用J.安阳大正钢板仓有限责 任公司,2014. 17 刘海军.螺旋输送机参数设计系统的开发J.东北农业大学,2012.18 中国矿业大学. 矿山运输机械J. 煤矿工业出版社,1987.1. 19Tugomir Surina, Clyde Herrick. Semiconductor Electronics. Copyright 1964 by Holt, Rinehart and Winston, Inc., 12025020Colby RSA State Analysis of LCI fed Synchronous Motor Drive System. IEEE Trans, 1984, 21(4):68指导教师意见:对“文献综述”的评语:文献查阅完整,兼顾中文与外文文献,能够满足设计基本需求。 对总体安排和进度计划的评语研究的总体安排和进度计划合理,同意开题。 指导教师签名: 年 月 日教研室意见: 通过,同意开题 教研室主任签名: 年 月 日学院意见:教学院长签名: 年 月 日毕业设计(论文)指导手册设计(论文)题目 螺旋运输机机械结构设计 学生姓名 学号 年 级 2014级 专业(全称) 机械设计制造及其自动化指导教师 所在学院 机电工程学院 毕业设计(论文)指导记录第一次指导记录: 指导地点 年 月 日第二次指导记录:指导地点 年 月 日第三次指导记录: 指导地点 年 月 日第四次指导记录: 指导地点 年 月 日 第五次指导记录: 指导地点 年 月 日第六次指导记录:指导地点 年 月 日第七次指导记录:指导地点 年 月 日第八次指导记录: 指导地点 年 月 日 第九次指导记录: 指导地点 年 月 日 第十次指导记录: 指导地点 年 月 日 第十一次指导记录: 指导地点 年 月 日 第十二次指导记录: 指导地点 年 月 日 第十三次指导记录: 指导地点 年 月 日 第十四次指导记录: 指导地点 年 月 日 第十五次指导记录: 指导地点 年 月 日 学生毕业设计(论文)中期汇报表学生姓名专 业机械设计制造及其自动化学 号设计(论文)题目螺旋运输机机械结构设计毕业设计(论文)前期工作小结1、简述开题以来所做的具体工作和取得的进展或成果(1)收集有关螺旋运输机的资料,为后续设计做准备;(2)完成开题报告、外文文献及其翻译;(3)确定螺旋运输机的布置形式;(4)根据载荷确定电机功率;(5)对一部分的螺旋运输机进行选型。2 设计中遇到的问题在设计过程中对于一些计算参数的查表不是很灵活、对于三维软件的使用也不是很得心应手。在绘制二维图时,对一些制图标准也很模糊。3 下一步主要任务(1)根据电机的功率和螺旋运输机所需的转速确定减速机;(2)完成剩余部分螺旋运输机的选型;(3)查找螺旋运输机安装和维护的资料;(4)绘制二维图和三维图。指导教师意见该生前期已完成的工作基本上与毕业设计任务书以及开题报告中要求的内容基本相吻合,整体完成情况良好。签名: 年 月 日学生毕业设计(论文)中期情况检查表 学院名称: 机电工程学院 检查日期: 2018年 4月 24日学生姓名专 业机械设计及其自动化指导教师设计(论文)题目螺旋运输机机械结构设计工作进度情况通过查阅相关的专业资料,完成了开题报告的撰写任务;完成了外文翻译;对螺旋输送机机械结构的总体方案进行了设计,并对各部件进行了选用、计算和强度校核;符合任务书进度要求。 是否符合任务书要求进度是 能否按期完成任务能 工作态度情况(态度、纪律、出勤、主动接受指导等)该同学工作态度认真、端正,设计严谨、出勤率高、能够按时主动接受指导,有较强的自主学习能力,能够及时完成设计任务,对不能解决的问题能及时向同学和老师求教。 质量评价(针对已完成的部分)该生前期已完成的工作基本上与毕业设计任务书以及开题报告中要求的内容基本相吻合,整体完成情况良好。 存在问题和解决办法继续查阅相关资料,丰富设计思路,修改完善设计中存在的问题;对二维软件还需进一步学习。 检查人签名 教学院长签名 毕业设计(论文)指导教师评阅表学院: 机电工程学院 专业: 机械设计制造及其自动化 学生: 学号: 题目: 机械设计及其自动化 评价项目评价要素成绩评定优良中及格不及格工作态度工作态度认真,按时出勤能按规定进度完成设计任务选题质量选题方向和范围选题难易度选题理论意义和实际应用价值能力水平查阅和应用文献资料能力综合运用知识能力研究方法与手段实验技能和实践能力创新意识设计论文质量内容与写作结构与水平规范化程度成果与成效指导教师意见建议成绩是否同意参加答辩评语: 指导教师签名:年 月 日 毕业设计(论文)评阅教师评阅表学院: 机电工程学院 专业: 机械设计制造及其自动化 学生: 学号: 题目: 螺旋运输机机械结构设计 评价项目评价要素成绩评定优良中及格不及格选题质量选题方向和范围选题难易度选题理论意义和实际应用价值能力水平查阅和应用文献资料能力综合运用知识能力研究方法与手段实验技能和实践能力创新意识设计论文质量内容与写作结构与水平规范化程度成果与成效评阅教师意见建议成绩 是否同意参加答辩 评语: 评阅教师签名:年 月 日 毕业设计(论文)答辩及综合成绩评定表学 院 机电工程学院专 业 机械设计制造及其自动化学生姓名 学 号 指导教师 设计论文题 目螺旋运输机机械结构设计 答辩时间2018 年 5月28日 8 时 15分至 8时 30分答辩地点敬本楼C503 答辩小组成 员姓名张元越石荣玲孙健田晶范天锦职称副教授教授副教授讲师高级工程师答辩记录提问人提问主要内容学生回答摘要 答辩记录人签名:答辩小组意见答辩评语: 答辩成绩: 答辩小组组长签名:综合成绩评定指导教师评定成绩评阅教师评定成绩答辩成绩综合评定成绩答辩委员会主任签名: 年 月 日毕业设计(论文)外文翻译学生姓名班 级 14机械单学 号学院名称 机电工程学院专业名称机械设计制造及其自动化指导教师2018年5 月26 日Basic Machining Operations and Cutting TechnologyBasic Machining Operations Machine tools have evolved from the early foot-powered lathes of the Egyptians and John Wilkinsons boring mill. They are designed to provide rigid support for both the work piece and the cutting tool and can precisely control their relative positions and the velocity of the tool with respect to the work piece. Basically, in metal cutting, a sharpened wedge-shaped tool removes a rather narrow strip of metal from the surface of a ductile work piece in the form of a severely deformed chip. The chip is a waste product that is considerably shorter than the work piece from which it came but with a corresponding increase in thickness of the uncut chip. The geometrical shape of work piece depends on the shape of the tool and its path during the machining operation. Most machining operations produce parts of differing geometry. If a rough cylindrical work piece revolves about a central axis and the tool penetrates beneath its surface and travels parallel to the center of rotation, a surface of revolution is produced, and the operation is called turning. If a hollow tube is machined on the inside in a similar manner, the operation is called boring. Producing an external conical surface uniformly varying diameter is called taper turning, if the tool point travels in a path of varying radius, a contoured surface like that of a bowling pin can be produced; or, if the piece is short enough and the support is sufficiently rigid, a contoured surface could be produced by feeding a shaped tool normal to the axis of rotation. Short tapered or cylindrical surfaces could also be contour formed. Flat or plane surfaces are frequently required. They can be generated by radial turning or facing, in which the tool point moves normal to the axis of rotation. In other cases, it is more convenient to hold the work piece steady and reciprocate the tool across it in a series of straight-line cuts with a crosswise feed increment before each cutting stroke. This operation is called planning and is carried out on a shaper. For larger pieces it is easier to keep the tool stationary and draw the work piece under it as in planning. The tool is fed at each reciprocation. Contoured surfaces can be produced by using shaped tools. Multiple-edged tools can also be used. Drilling uses a twin-edged fluted tool for holes with depths up to 5 to 10 times the drill diameter. Whether the drill turns or the work piece rotates, relative motion between the cutting edge and the work piece is the important factor. In milling operations a rotary cutter with a number of cutting edges engages the work piece. Which moves slowly with respect to the cutter. Plane or contoured surfaces may be produced, depending on the geometry of the cutter and the type of feed. Horizontal or vertical axes of rotation may be used, and the feed of the work piece may be in any of the three coordinate directions. Basic Machine Tools Machine tools are used to produce a part of a specified geometrical shape and precise I size by removing metal from a ductile material in the form of chips. The latter are a waste product and vary from long continuous ribbons of a ductile material such as steel, which are undesirable from a disposal point of view, to easily handled well-broken chips resulting from cast iron. Machine tools perform five basic metal-removal processes: I turning, planning, drilling, milling, and grinding. All other metal-removal processes are modifications of these five basic processes. For example, boring is internal turning; reaming, tapping, and counter boring modify drilled holes and are related to drilling; bobbing and gear cutting are fundamentally milling operations; hack sawing and broaching are a form of planning and honing; lapping, super finishing. Polishing and buffing are variants of grinding or abrasive removal operations. Therefore, there are only four types of basic machine tools, which use cutting tools of specific controllable geometry: 1. lathes, 2. planers, 3. drilling machines, and 4. milling machines. The grinding process forms chips, but the geometry of the abrasive grain is uncontrollable. The amount and rate of material removed by the various machining processes may be I large, as in heavy turning operations, or extremely small, as in lapping or super finishing operations where only the high spots of a surface are removed. A machine tool performs three major functions: 1. it rigidly supports the work piece or its holder and the cutting tool; 2. it provides relative motion between the work piece and the cutting tool; 3. it provides a range of feeds and speeds usually ranging from 4 to 32 choices in each case. Speed and Feeds in Machining Speeds, feeds, and depth of cut are the three major variables for economical machining. Other variables are the work and tool materials, coolant and geometry of the cutting tool. The rate of metal removal and power required for machining depend upon these variables. The depth of cut, feed, and cutting speed are machine settings that must be established in any metal-cutting operation. They all affect the forces, the power, and the rate of metal removal. They can be defined by comparing them to the needle and record of a phonograph. The cutting speed (V) is represented by the velocity of- the record surface relative to the needle in the tone arm at any instant. Feed is represented by the advance of the needle radially inward per revolution, or is the difference in position between two adjacent grooves. The depth of cut is the penetration of the needle into the record or the depth of the grooves. Turning on Lathe Centers The basic operations performed on an engine lathe are illustrated. Those operations performed on external surfaces with a single point cutting tool are called turning. Except for drilling, reaming, and lapping, the operations on internal surfaces are also performed by a single point cutting tool. All machining operations, including turning and boring, can be classified as roughing, finishing, or semi-finishing. The objective of a roughing operation is to remove the bulk of the material as rapidly and as efficiently as possible, while leaving a small amount of material on the work-piece for the finishing operation. Finishing operations are performed to obtain the final size, shape, and surface finish on the work piece. Sometimes a semi-finishing operation will precede the finishing operation to leave a small predetermined and uniform amount of stock on the work-piece to be removed by the finishing operation. Generally, longer work pieces are turned while supported on one or two lathe centers. Cone shaped holes, called center holes, which fit the lathe centers are drilled in the ends of the work piece-usually along the axis of the cylindrical part. The end of the work piece adjacent to the tail stock is always supported by a tail stock center, while the end near the head stock may be supported by a head stock center or held in a chuck. The head stock end of the work piece may be held in a four-jaw chuck, or in a type chuck. This method holds the work piece firmly and transfers the power to the work piece smoothly; the additional support to the work piece provided by the chuck lessens the tendency for chatter to occur when cutting. Precise results can be obtained with this method if care is taken to hold the work piece accurately in the chuck. Very precise results can be obtained by supporting the work piece between two centers. A lathe dog is clamped to the work piece; together they are driven by a driver plate mounted on the spindle nose. One end of the Work piece is mecained;then the work piece can be turned around in the lathe to machine the other end. The center holes in the work piece serve as precise locating surfaces as well as bearing surfaces to carry the weight of the work piece and to resist the cutting forces. After the work piece has been removed from the lathe for any reason, the center holes will accurately align the work piece back in the lathe or in another lathe, or in a cylindrical grinding machine. The work piece must never be held at the head stock end by both a chuck and a lathe center. While at first thought this seems like a quick method of aligning the work piece in the chuck, this must not be done because it is not possible to press evenly with the jaws against the work piece while it is also supported by the center. The alignment provided by the center will not be maintained and the pressure of the jaws may damage the center hole, the lathe center, and perhaps even the lathe spindle. Compensating or floating jaw chucks used almost exclusively on high production work provide an exception to the statements made above. These chucks are really work drivers and cannot be used for the same purpose as ordinary three or four-jaw chucks. While very large diameter work pieces are sometimes mounted on two centers, they are preferably held at the headstock end by faceplate jaws to obtain the smooth power transmission; moreover, large lathe dogs that are adequate to transmit the power not generally available, although they can be made as a special. Faceplate jaws are like chuck jaws except that they are mounted on a faceplate, which has less overhang from the spindle bearings than a large chuck would have. Introduction of Machining Machining as a shape-producing method is the most universally used and the most important of all manufacturing processes. Machining is a shape-producing process in which a power-driven device causes material to be removed in chip form. Most machining is done with equipment that supports both the work piece and cutting tool although in some cases portable equipment is used with unsupported work piece. Low setup cost for small Quantities. Machining has two applications in manufacturing. For casting, forging, and press working, each specific shape to be produced, even one part, nearly always has a high tooling cost. The shapes that may he produced by welding depend to a large degree on the shapes of raw material that are available. By making use of generally high cost equipment but without special tooling, it is possible, by machining; to start with nearly any form of raw material, so tong as the exterior dimensions are great enough, and produce any desired shape from any material. Therefore .machining is usually the preferred method for producing one or a few parts, even when the design of the part would logically lead to casting, forging or press working if a high quantity were to be produced. Close accuracies, good finishes. The second application for machining is based on the high accuracies and surface finishes possible. Many of the parts machined in low quantities would be produced with lower but acceptable tolerances if produced in high quantities by some other process. On the other hand, many parts are given their general shapes by some high quantity deformation process and machined only on selected surfaces where high accuracies are needed. Internal threads, for example, are seldom produced by any means other than machining and small holes in press worked parts may be machined following the press working operations. Primary Cutting Parameters The basic tool-work relationship in cutting is adequately described by means of four factors: tool geometry, cutting speed, feed, and depth of cut. The cutting tool must be made of an appropriate material; it must be strong, tough, hard, and wear resistant. The tool s geometry characterized by planes and angles, must be correct for each cutting operation. Cutting speed is the rate at which the work surface passes by the cutting edge. It may be expressed in feet per minute. For efficient machining the cutting speed must be of a magnitude appropriate to the particular work-tool combination. In general, the harder the work material, the slower the speed. Feed is the rate at which the cutting tool advances into the work piece. Where the work piece or the tool rotates, feed is measured in inches per revolution. When the tool or the work reciprocates, feed is measured in inches per stroke, Generally, feed varies inversely with cutting speed for otherwise similar conditions. The depth of cut, measured inches is the distance the tool is set into the work. It is the width of the chip in turning or the thickness of the chip in a rectilinear cut. In roughing operations, the depth of cut can be larger than for finishing operations. The Effect of Changes in Cutting Parameters on Cutting Temperatures In metal cutting operations heat is generated in the primary and secondary deformation zones and these results in a complex temperature distribution throughout the tool, work piece and chip. A typical set of isotherms is shown in figure where it can be seen that, as could be expected, there is a very large temperature gradient throughout the width of the chip as the work piece material is sheared in primary deformation and there is a further large temperature in the chip adjacent to the face as the chip is sheared in secondary deformation. This leads to a maximum cutting temperature a short distance up the face from the cutting edge and a small distance into the chip. Since virtually all the work done in metal cutting is converted into heat, it could be expected that factors which increase the power consumed per unit volume of metal removed will increase the cutting temperature. Thus an increase in the rake angle, all other parameters remaining constant, will reduce the power per unit volume of metal removed and the cutting temperatures will reduce. When considering increase in unreformed chip thickness and cutting speed the situation is more complex. An increase in undeformed chip thickness tends to be a scale effect where the amounts of heat which pass to the work piece, the tool and chip remain in fixed proportions and the changes in cutting temperature tend to be small. Increase in cutting speed; however, reduce the amount of heat which passes into the work piece and this increase the temperature rise of the chip m primary deformation. Further, the secondary deformation zone tends to be smaller and this has the effect of increasing the temperatures in this zone. Other changes in cutting parameters have virtually no effect on the power consumed per unit volume of metal removed and consequently have virtually no effect on the cutting temperatures. Since it has been shown that even small changes in cutting temperature have a significant effect on tool wear rate it is appropriate to indicate how cutting temperatures can be assessed from cutting data. The most direct and accurate method for measuring temperatures in high -speed-steel cutting tools is that of Wright &. Trent which also yields detailed information on temperature distributions in high-speed-steel cutting tools. The technique is based on the metallographic examination of sectioned high-speed-steel tools which relates microstructure changes to thermal history. Trent has described measurements of cutting temperatures and temperature distributions for high-speed-steel tools when machining a wide range of work piece materials. This technique has been further developed by using scanning electron microscopy to study fine-scale microstructure changes arising from over tempering of the tempered martens tic matrix of various high-speed-steels. This technique has also been used to study temperature distributions in both high-speed -steel single point turning tools and twist drills. Wears of Cutting Tool Discounting brittle fracture and edge chipping, which have already been dealt with, tool wear is basically of three types. Flank wear, crater wear, and notch wear. Flank wear occurs on both the major and the minor cutting edges. On the major cutting edge, which is responsible for bulk metal removal, these results in increased cutting forces and higher temperatures which if left unchecked can lead to vibration of the tool and work piece and a condition where efficient cutting can no longer take place. On the minor cutting edge, which determines work piece size and surface finish, flank wear can result in an oversized product which has poor surface finish. Under most practical cutting conditions, the tool will fail due to major flank wear before the minor flank wear is sufficiently large to result in the manufacture of an unacceptable component. Because of the stress distribution on the tool face, the frictional stress in the region of sliding contact between the chip and the face is at a maximum at the start of the sliding contact region and is zero at the end. Thus abrasive wear takes place in this region with more wear taking place adjacent to the seizure region than adjacent to the point at which the chip loses contact with the face. This result in localized pitting of the tool face some distance up the face which is usually referred to as catering and which normally has a section in the form of a circular arc. In many respects and for practical cutting conditions, crater wear is a less severe form of wear than flank wear and consequently flank wear is a more common tool failure criterion. However, since various authors have shown that the temperature on the face increases more rapidly with increasing cutting speed than the temperature on the flank, and since the rate of wear of any type is significantly affected by changes in temperature, crater wear usually occurs at high cutting speeds. At the end of the major flank wear land where the tool is in contact with the uncut work piece surface it is common for the flank wear to be more pronounced than along the rest of the wear land. This is because of localised effects such as a hardened layer on the uncut surface caused by work hardening introduced by a previous cut, an oxide scale, and localised high temperatures resulting from the edge effect. This localised wear is usually referred to as notch wear and occasionally is very severe. Although the presence of the notch will not significantly affect the cutting properties of the tool, the notch is often relatively deep and if cutting were to continue there would be a good chance that the tool would fracture. If any form of progressive wear allowed to continue, dramatically and the tool would fail catastrophically, i. e. the tool would be no longer capable of cutting and, at best, the work piece would be scrapped whilst, at worst, damage could be caused to the machine tool. For carbide cutting tools and for all types of wear, the tool is said to have reached the end of its useful life long before the onset of catastrophic failure. For high-speed-steel cutting tools, however, where the wear tends to be non-uniform it has been found that the most meaningful and reproducible results can be obtained when the wear is allowed to continue to the onset of catastrophic failure even though, of course, in practice a cutting time far less than that to failure would be used. The onset of catastrophic failure is characterized by one of several phenomena, the most common being a sudden increase in cutting force, the presence of burnished rings on the work piece, and a significant increase in the noise level. Mechanism of Surface Finish Production There are basically five mechanisms which contribute to the production of a surface which have been machined. These are:(l) The basic geometry of the cutting process. In, for example, single point turning the tool will advance a constant distance axially per revolution of the workpiecc and the resultant surface will have on it, when viewed perpendicularly to the direction of tool feed motion, a series of cusps which will have a basic form which replicates the shape of the tool in cut. (2) The efficiency of the cutting operation. It has already been mentioned that cutting with unstable built-up-edges will produce a surface which contains hard built-up-edge fragments which will result in a degradation of the surface finish. It can also be demonstrated that cutting under adverse conditions such as apply when using large feeds small rake angles and low cutting speeds, besides producing conditions which lead to unstable built-up-edge production, the cutting process itself can become unstable and instead of continuous shear occurring in the shear zone, tearing takes place, discontinuous chips of uneven thickness are produced, and the resultant surface is poor. This situation is particularly noticeable when machining very ductile materials such as copper and aluminum. (3) The stability of the machine tool. Under some combinations of cutting conditions; work piece size, method of clamping ,and cutting tool rigidity relative to the machine tool structure, instability can be set up in the tool which causes it to vibrate. Under some conditions this vibration will reach and maintain steady amplitude whilst under other conditions the vibration will built up and unless cutting is stopped considerable damage to both the cutting tool and work piece may occur. This phenomenon is known as chatter and in axial turning is characterized by long pitch helical bands on the work piece surface and short pitch undulations on the transient machined surface. (4)The effectiveness of removing swarf. In discontinuous chip production machining, such as milling or turning of brittle materials, it is expected that the chip (swarf) will leave the cutting zone either under gravity or with the assistance of a jet of cutting fluid and that they will not influence the cut surface in any way. However, when continuous chip production is evident, unless steps are taken to control the swarf it is likely that it will impinge on the cut surface and mark it. Inevitably, this marking besides looking. (5)The effective clearance angle on the cutting tool. For certain geometries of minor cutting edge relief and clearance angles it is possible to cut on the major cutting edge and burnish on the minor cutting edge. This can produce a good surface finish but, of course, it is strictly a combination of metal cutting and metal forming and is not to be recommended as a practical cutting method. However, due to cutting tool wear, these conditions occasionally arise and lead to a marked change in the surface characteristics. Limits and Tolerances Machine parts are manufactured so they are interchangeable. In other words, each part of a machine or mechanism is made to a certain size and shape so will fit into any other machine or mechanism of the same type. To make the part interchangeable, each individual part must be made to a size that will fit the mating part in the correct way. It is not only impossible, but also impractical to make many parts to an exact size. This is because machines are not perfect, and the tools become worn. A slight variation from the exact size is always allowed. The amount of this variation depends on the kind of part being manufactured. For examples part might be made 6 in. long with a variation allowed of 0.003 (three-thousandths) in. above and below this size. Therefore, the part could be 5.997 to 6.003 in. and still be the correct size. These are known as the limits. The difference between upper and lower limits is called the tolerance. A tolerance is the total permissible variation in the size of a part. The basic size is that size from which limits of size arc derived by the application of allowances and tolerances. Sometimes the limit is allowed in only one direction. This is known as unilateral tolerance.Unilateral tolerancing is a system of dimensioning where the tolerance (that is variation) is shown in only one direction from the nominal size. Unilateral tolerancing allow the changing of tolerance on a hole or shaft without seriously affecting the fit.When the tolerance is in both directions from the basic size it is known as a bilateral tolerance (plus and minus). Bilateral tolerancing is a system of dimensioning where the tolerance (that is variation) is split and is shown on either side of the nominal size. Limit dimensioning is a system of dimensioning where only the maximum and minimum dimensions arc shown. Thus, the tolerance is the difference between these two dimensions. Surface Finishing and Dimensional Control Products that have been completed to their proper shape and size frequently require some type of surface finishing to enable them to satisfactorily fulfill their function. In some cases, it is necessary to improve the physical properties of the surface material for resistance to penetration or abrasion. In many manufacturing processes, the product surface is left with dirt .chips, grease, or other harmful material upon it. Assemblies that are made of different materials, or from the same materials processed in different manners, may require some special surface treatment to provide uniformity of appearance. Surface finishing may sometimes become an intermediate step processing. For instance, cleaning and polishing are usually essential before any kind of plating process. Some of the cleaning procedures are also used for improving surface smoothness on mating parts and for removing burrs and sharp corners, which might be harmful in later use. Another important need for surface finishing is for corrosion protection in a variety of: environments. The type of protection procedure will depend largely upon the anticipated exposure, with due consideration to the material being protected and the economic factors involved. Satisfying the above objectives necessitates the use of main surface-finishing methods that involve chemical change of the surface mechanical work affecting surface properties, cleaning by a variety of methods, and the application of protective coatings, organic and metallic. In the early days of engineering, the mating of parts was achieved by machining one part as nearly as possible to the required size, machining the mating part nearly to size, and then completing its machining, continually offering the other part to it, until the desired relationship was obtained. If it was inconvenient to offer one part to the other part during machining, the final work was done at the bench by a fitter, who scraped the mating parts until the desired fit was obtained, the fitter therefore being a fitter in the literal sense. J It is obvious that the two parts would have to remain together, and m the event of one having to be replaced, the fitting would have to be done all over again. In these days, we expect to be able to purchase a replacement for a broken part, and for it to function correctly without the need for scraping and other fitting operations.When one part can be used off the shelf to replace another of the same dimension and material specification, the parts are said to be interchangeable. A system of interchangeability usually lowers the production costs as there is no need for an expensive, fiddling operation, and it benefits the customer in the event of the need to replace worn parts. Automatic Fixture Design Traditional synchronous grippers for assembly equipment move parts to the gripper centre-line, assuring that the parts will be in a known position after they arc picked from a conveyor or nest. However, in some applications, forcing the part to the centre-line may damage cither the part or equipment. When the part is delicate and a small collision can result in scrap, when its location is fixed by a machine spindle or mould, or when tolerances are tight, it is preferable to make a gripper comply with the position of the part, rather than the other way around. For these tasks, Zaytran Inc. Of Elyria, Ohio, has created the GPN series of non- synchronous, compliant grippers. Because the force and synchronizations systems of the grippers are independent, the synchronization system can be replaced by a precision slide system without affecting gripper force. Gripper sizes range from 51b gripping force and 0.2 in. stroke to 40Glb gripping force and 6in stroke. Grippers Production is characterized by batch-size becoming smaller and smaller and greater variety of products. Assembly, being the last production step, is particularly vulnerable to changes in schedules, batch-sizes, and product design. This situation is forcing many companies to put more effort into extensive rationalization and automation of assembly that was previouslyextensive rationalization and automation of assembly that was previously the case. Although the development of flexible fixtures fell quickly behind the development of flexible handling systems such as industrial robots, there are, nonetheless promising attempts to increase the flexibility of fixtures. The fact that fixtures are the essential product - specific investment of a production system intensifies the economic necessity to make the fixture system more flexible. Fixtures can be divided according to their flexibility into special fixtures, group fixtures, modular fixtures and highly flexible fixtures. Flexible fixtures are characterized by their high adaptability to different work pieces, and by low change-over time and expenditure. There are several steps required to generate a fixture, in which a work piece is fixed for a production task. The first step is to define the necessary position of the work piece in the fixture, based on the unmachined or base pan, and the working features. Following this, a combination of stability planes must be selected. These stability planes constitute the fixture configuration in which the work piece is fixed in the defined position, all the forces or torques are compensated, and the necessary access to the working features is ensured. Finally, the necessary positions of moveable or modular fixture elements must be calculated- adjusted, or assembled, so that the work piece is firmly fixed in the fixture. Through such a procedure the planning and documentation of the configuration and assembly of fixture can be automated.The configuration task is to generate a combination of stability planes, such that fixture forces in these planes will result in work piece and fixture stability. This task can be accomplished conventionally, interactively or in a nearly fully automated manner. The advantages of an interactive or automated configuration determination are a systematic fixture design process, a reduction of necessary designers, a shortening of lead time and better match to the working conditions. In short, a significant enhancement of fixture productivity and economy can be achieved.外文文献下载地址:/view/2b39a320b307e87101f69678.html基本加工工序和切削技术机床是从早期的埃及人的脚踏动力车和约翰威尔金森的镗床发展而来的。它们为工件和刀具提供刚性支撑并可以精确控制它们的相对位置和相对速度。基本上讲,金属切削是指一个磨尖的锲形工具从有韧性的工件表面上去除一条很窄的金属。切屑是被废弃的产品,与其它工件相比切屑较短,但对于未切削部分的厚度有一定的增加。工件表面的几何形状取决于刀具的形状以及加工操作过程中刀具的路径。大多数加工工序产生不同几何形状的零件。如果一个粗糙的工件在中心轴上转动并且刀具平行于旋转中心切入工件表面,一个旋转表面就产生了,这种操作称为车削。如果一个空心的管子以同样的方式在内表面加工,这种操作称为镗孔。当均匀地改变直径时便产生了一个圆锥形的外表面,这称为锥度车削。如果刀具接触点以改变半径的方式运动,那么一个外轮廓像球的工件便产生了;或者如果工件足够的短并且支撑是十分刚硬的,那么成型刀具相对于旋转轴正常进给的一个外表面便可产生,短锥形或圆柱形的表面也可形成。平坦的表面是经常需要的,它们可以由刀具接触点相对于旋转轴的径向车削产生。在刨削时对于较大的工件更容易将刀具固定并将工件置于刀具下面。刀具可以往复地进给。成形面可以通过成型刀具加工产生。多刃刀具也能使用。使用双刃槽钻钻深度是钻孔直径5-10倍的孔。不管是钻头旋转还是工件旋转,切削刃与工件之间的相对运动是一个重要因数。在铣削时一个带有许多切削刃的旋转刀具与工件接触,工件相对刀具慢慢运动。平的或成形面根据刀具的几何形状和进给方式可能产生。可以产生横向或纵向轴旋转并且可以在任何三个坐标方向上进给。基本机床机床通过从塑性材料上去除屑片来产生出具有特别几何形状和精确尺寸的零件。后者是废弃物,是由塑性材料如钢的长而不断的带状物变化而来,从处理的角度来看,那是没有用处的。很容易处理不好由铸铁产生的破裂的屑片。机床执行五种基本的去除金属的过程:车削,刨削,钻孔,铣削。所有其他的去除金属的过程都是由这五个基本程序修改而来的,举例来说,镗孔是内部车削;铰孔,攻丝和扩孔是进一步加工钻过的孔;齿轮加工是基于铣削操作的。抛光和打磨是磨削和去除磨料工序的变形。因此,只有四种基本类型的机床,使用特别可控制几何形状的切削工具1.车床,2.钻床,3.铣床,4.磨床。磨削过程形成了屑片,但磨粒的几何形状是不可控制的。通过各种加工工序去除材料的数量和速度是巨大的,正如在大型车削加工,或者是极小的如研磨和超精密加工中只有面的高点被除掉。一台机床履行三大职能:1.它支撑工件或夹具和刀具2.它为工件和刀具提供相对运动3.在每一种情况下提供一系列的进给量和一般可达4-32种的速度选择。加工速度和进给速度,进给量和切削深度是经济加工的三大变量。其他的量数是攻丝和刀具材料,冷却剂和刀具的几何形状,去除金属的速度和所需要的功率依赖于这些变量。切削深度,进给量和切削速度是任何一个金属加工工序中必须建立的机械参量。它们都影响去除金属的力,功率和速度。切削速度可以定义为在旋转一周时速度记录面相对任何瞬间呈辐射状扩散的针,或是两个相邻沟槽的距离。切削深度是进入的深度和沟槽的深度。在车床中心的车削在机动车床上完成的基本操作已被介绍了。那些用单点刀具在外表面的操作称为车削。除了钻孔,铰孔,研磨内部表面的操作也是由单点刀具完成的。所有的加工工序包括车削,镗孔可以被归类为粗加工,精加工或半精加工。精加工是尽可能快而有效的去除

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号