农用车离合器的设计【全套设计含CAD图纸、说明书】

收藏

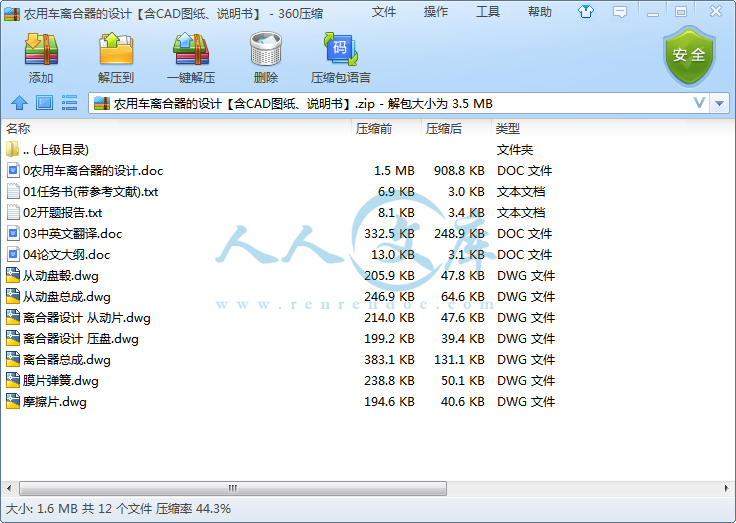

资源目录

压缩包内文档预览:

编号:22889670

类型:共享资源

大小:1.76MB

格式:ZIP

上传时间:2019-11-03

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

全套设计含CAD图纸、说明书

农用车

离合器

设计

全套

CAD

图纸

说明书

- 资源描述:

-

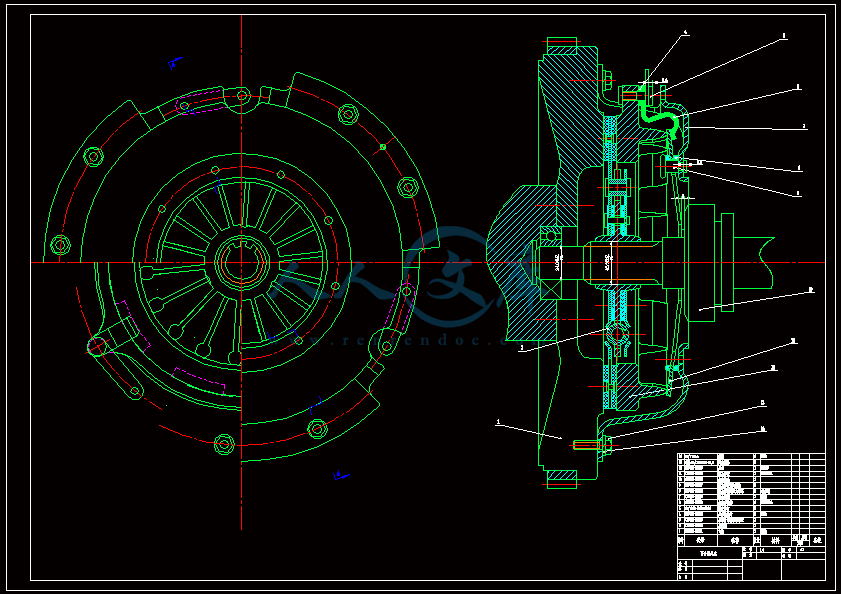

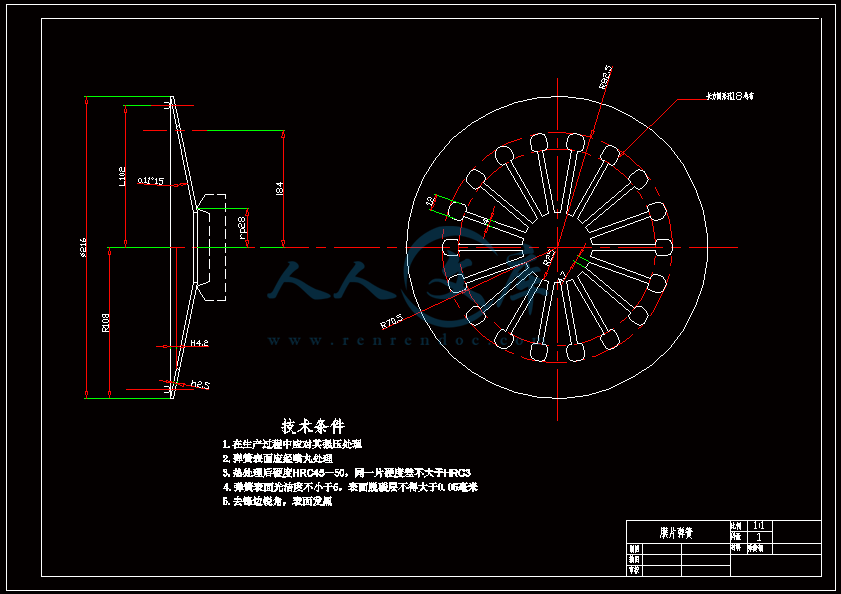

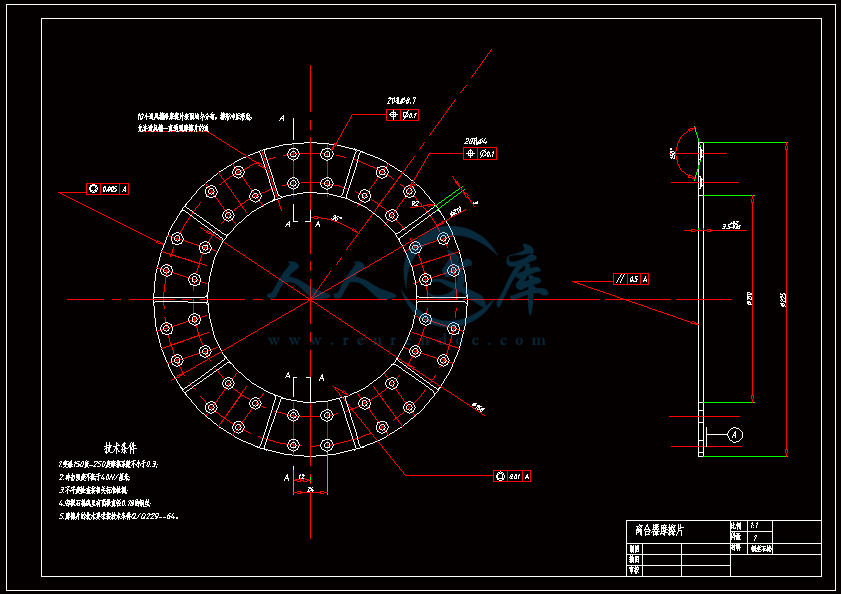

【温馨提示】压缩包内含CAD图有下方大图片预览,下拉即可直观呈现眼前查看、尽收眼底纵观。打包内容里dwg后缀的文件为CAD图,可编辑,无水印,高清图,压缩包内文档可直接点开预览,需要原稿请自助充值下载,所见才能所得,请见压缩包内的文件及下方预览,请细心查看有疑问可以咨询QQ:11970985或197216396

- 内容简介:

-

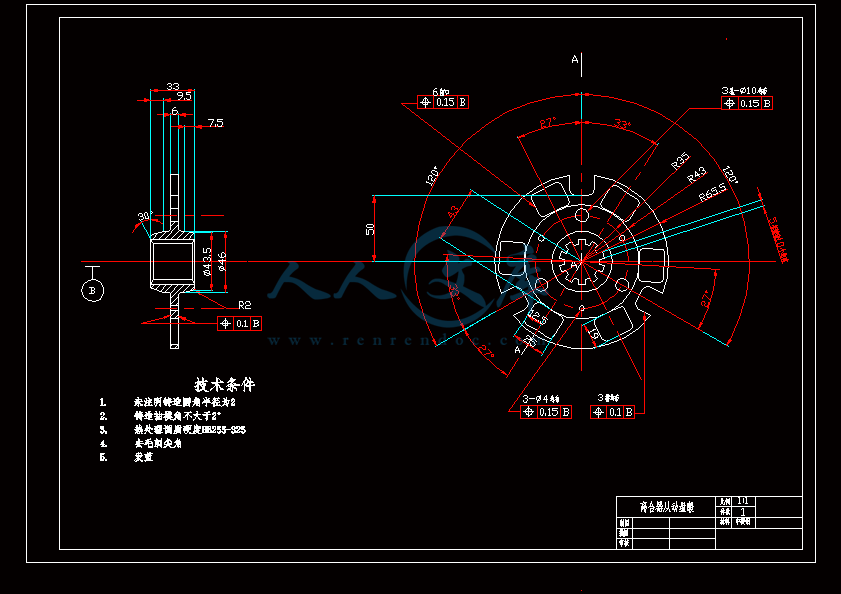

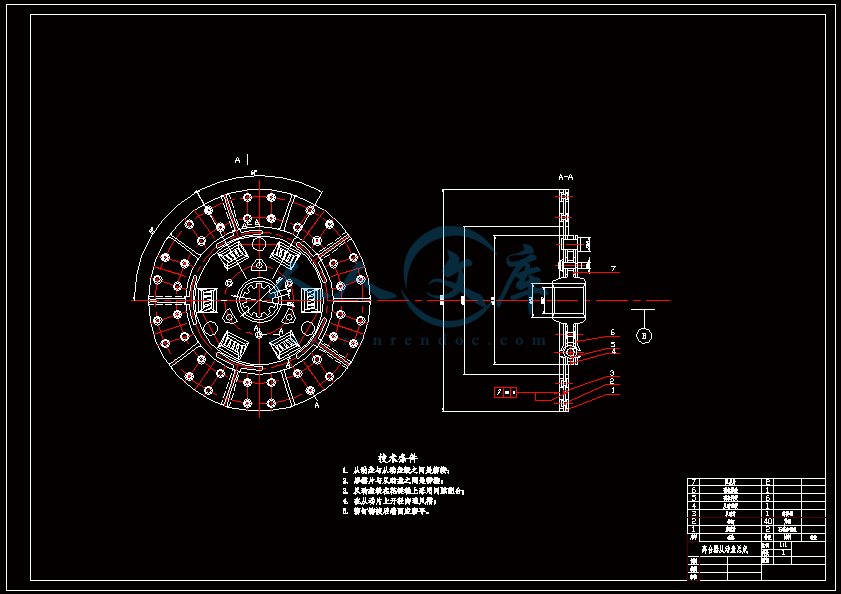

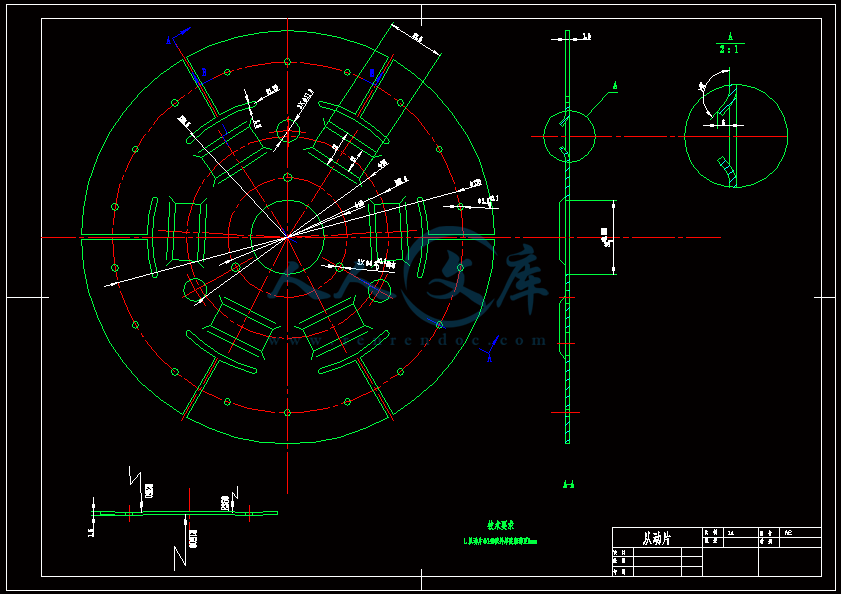

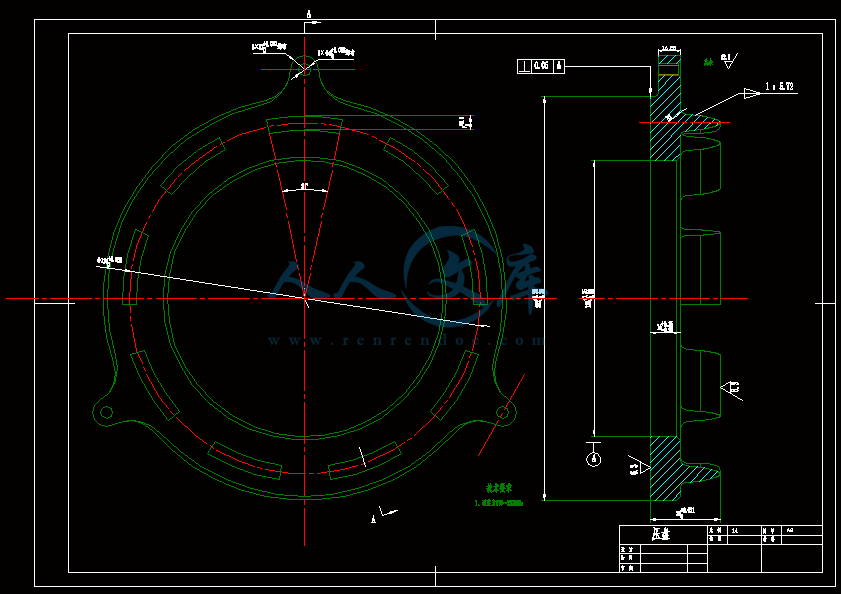

毕 业 设 计(论 文)任 务 书 设计(论文)题目:农用车离合器的设计 学生姓名:发任务书日期:2015年12月30日 任务书填写要求1毕业设计(论文)任务书由指导教师根据各课题的具体情况填写,经学生所在专业的负责人审查、系(院)领导签字后生效。此任务书应在毕业设计(论文)开始前一周内填好并发给学生。2任务书内容必须用黑墨水笔工整书写,不得涂改或潦草书写;或者按教务处统一设计的电子文档标准格式(可从教务处网页上下载)打印,要求正文小4号宋体,1.5倍行距,禁止打印在其它纸上剪贴。3任务书内填写的内容,必须和学生毕业设计(论文)完成的情况相一致,若有变更,应当经过所在专业及系(院)主管领导审批后方可重新填写。4任务书内有关“学院”、“专业”等名称的填写,应写中文全称,不能写数字代码。学生的“学号”要写全号,不能只写最后2位或1位数字。 5任务书内“主要参考文献”的填写,应按照金陵科技学院本科毕业设计(论文)撰写规范的要求书写。 6有关年月日等日期的填写,应当按照国标GB/T 740894数据元和交换格式、信息交换、日期和时间表示法规定的要求,一律用阿拉伯数字书写。如“2002年4月2日”或“2002-04-02”。毕 业 设 计(论 文)任 务 书1本毕业设计(论文)课题应达到的目的: 毕业设计是高等学校培养高级技术人才的最后一个教学环节。毕业设计能够很好地检验和巩固学生在校期间的学习成果,是培养学生综合运用所学基础理论、专业知识、专业技能来解决工程实际问题的重要途径。通过农用车离合器的设计、计算及绘图工作,使学生掌握基本的设计(科研)方法,受到初步的工程技术训练,学习与掌握相应的国家标准和设计规范,使学生具备一定的独立分析和解决实际问题的能力,也能培养学生不怕困难、严谨细致的工作作风。2本毕业设计(论文)课题任务的内容和要求(包括原始数据、技术要求、工作要求等): 本毕业设计课题为对农用车的膜片式弹簧离合器进行设计。根据车辆使用条件和车辆参数,按照离合器系统的设计步骤和要求,选择膜片式弹簧离合器相关设计参数,包括摩擦片外径 的确定,离合器后备系数的确定,单位压力的确定;总成设计主要有:分离装置的设计,以及从动盘设计(从动盘毂的设计)等。毕业设计的内容有:1离合器总成总体方案论证计算、方案确定;2总装配图及主要零部件设计计算;3总装配图及主要零部件图的设计与绘制;4设计说明书及相关技术文件。5主要技术要求:发动机额定转速下功率29kw/3200(r/min) ;发动机最大转矩97Nm/2200(r/min);额定载质量1000kg;总质量2510kg;最高车速68kM/h毕业设计要求:1要求在毕业设计过程中,应有严肃认真的科学态度,严谨求实的工作作风;2依据课题设计任务,认真进行资料收集、阅读、整理,正确使用工具书和网络,熟练掌握相关软件,按时完成开题报告、外文参考资料等;3完成课题任务,设计内容正确合理,能够体现一定的创新性,撰写一份不少于2万字的毕业论文,内容完整,语言通顺,符合本科生毕业设计规范;4按时参加答辩,答辩前各项规定的资料要完整、齐全。毕 业 设 计(论 文)任 务 书3对本毕业设计(论文)课题成果的要求包括图表、实物等硬件要求:外文翻译1份(含英文原文),毕业设计说明书1本,毕业设计图纸一套。4主要参考文献: 1汽车工程手册编辑委员会.汽车工程手册(设计篇)M.北京:人民交通出版社,2001.2林秉华.最新汽车设计实用手册M.黑龙江:黑龙江人民出版社,2005.3陈家瑞.汽车构造(上册、下册)M.北京:机械工业出版社,2005.4清华大学汽车工程系编写组编著.汽车构造M.北京:人民邮电出版社,2000.5刘涛.汽车设计M.北京:北京大学出版社,2008.6王望予.汽车设计(第3版)M.北京:机械工业出版杜,2000.57刘惟信.汽车设计M,北京:清华大学出版社出版,2004.8林宁等.汽车设计M.北京:机械工业出版社,1999.9周明衡.离合器、制动器选用手册M.北京:化学工业出版社,2003.10徐石安,江发潮.汽车离合器.北京:清华大学出版社,2005.11林世裕.膜片弹簧与蝶形弹簧离合器设计与制造M.南京:东南大学出版社,1995.12徐石安、肖德炳、刘惟信.离合器(汽车设计)M.北京:人民交通出版社1981.13张一民.汽车零部件可靠性设计M.北京:北京理工大学出版社,2000.14张宝生,李杰,林明芳.汽车优化设计理论与方法M. 北京:机械工业出版社,2000.15张文春.汽车理论M.北京:机械工业出版社,2005.16余志生.汽车理论(第5版)M.北京:机械工业出版社,2009.17机械设计手册编委会.机械设计手册(1-5卷) M.北京:机械工业出版社,2004.18濮良贵,纪名刚.机械设计(第七版)M.北京:高等教育出版社,2006.19孙桓,陈作模.机械原理(第五版)M.北京:高等教育出版社,2006.20范钦珊,郭光林.工程力学1,2(第2版)M.北京:高等教育出版社,2011.毕 业 设 计(论 文)任 务 书5本毕业设计(论文)课题工作进度计划:2015.11.082015.12.14:课题调研、收集相关资料、拟题、选题;2015.12.152016.01.10:查阅文献,完成外文翻译、开题报告、论文大纲;2016.02.242016.02.28:提交开题报告、外文参考资料及译文、论文大纲;2016.03.012016.03.14:总体方案论证,确定方案,完成方案论证报告,并整理成初稿并提交,保持与指导老师进行交流和联系;2016.03.152016.04.04:进行相关设计计算,完成总装配图;2016.04.052016.04.20:进行零件、部件设计,撰写设计说明书及相关技术文件(完成初稿);2016.04.212016.04.30:定稿、完成全部毕业设计文档;2016.05.012016.05.10:提交毕业设计纸质文档,学生准备答辩;评阅教师评阅学生毕业设计(论文);2016.05.112016.05.26:根据学院统一安排,进行毕业设计(论文)答辩及修改毕业设计。所在专业审查意见: 通过 负责人: 2016 年 1 月 22 日毕 业 设 计(论 文)开 题 报 告 设计(论文)题目:农用车离合器的设计 学生姓名:开题报告填写要求 1开题报告(含“文献综述”)作为毕业设计(论文)答辩委员会对学生答辩资格审查的依据材料之一。此报告应在指导教师指导下,由学生在毕业设计(论文)工作前期内完成,经指导教师签署意见及所在专业审查后生效;2开题报告内容必须用黑墨水笔工整书写或按教务处统一设计的电子文档标准格式打印,禁止打印在其它纸上后剪贴,完成后应及时交给指导教师签署意见;3“文献综述”应按论文的框架成文,并直接书写(或打印)在本开题报告第一栏目内,学生写文献综述的参考文献应不少于15篇(不包括辞典、手册);4有关年月日等日期的填写,应当按照国标GB/T 740894数据元和交换格式、信息交换、日期和时间表示法规定的要求,一律用阿拉伯数字书写。如“2004年4月26日”或“2004-04-26”。5、开题报告(文献综述)字体请按宋体、小四号书写,行间距1.5倍。 毕 业 设 计(论文) 开 题 报 告 1结合毕业设计(论文)课题情况,根据所查阅的文献资料,每人撰写不少于1000字左右的文献综述: 一、选题目的和意义1本次毕业设计课题为“农用车离合器的设计”。离合器作为底盘传动系统中的重要部件,它在发动机到传动系中齿轮之间起连接的作用。2离合器组成:主动部分、从动部分、压紧机构、操纵机构。3离合器设计基本要求: (1)切断和实现对传动系的动力传递,以保证汽车起步时将发动机与传动系平顺地接合,确保汽车平稳起步; (2)在换挡时将发动机与传动系分离,减少变速器中换挡齿轮之间的冲击; (3)在工作中受到大的动载荷时,能限制传动系所承受的最大转矩,防止传动系各零件因过载而损坏; (4)有效地降低传动系中的振动和噪声。二、离合器研究的动态 随着汽车发动机转速、功率的不断提高和汽车电子技术的高速发展,人们对离合器的要求越来越高。从提高离合器工作性能的角度出发,传统的操纵形式正向自动操纵的形式发展。因此,提高离合器的可靠性和延长其使用寿命,适应发动机的高转速,增加离合器传递转矩的能力和简化操纵,已成为离合器的发展趋势。国内外主要汽车离合器有摩擦式离合器、液力偶合器、电磁离合器等几种。摩擦式离合器又分为湿式和干式两种。而比较先进的离合器为液力偶合器、电磁离合器。三、总结通过查阅大量的离合器设计资料懂得了如何正确选择离合器,通过对王望予出版的汽车设计第四版,了解如何选择合适的离合器,常见的摩擦离合器有周置弹簧离合器,中央弹簧离合器以及膜片弹簧离合器,而周置弹簧离合器和中央弹簧离合器由于缺点比较多,所以周置弹簧离合器和中央弹簧离合器已经逐步被淘汰了,而膜片弹簧离合器正是由于有很多的优点越来越被市场看好,比如膜片弹簧离合器有以下诸多优点:1、膜片弹簧的轴的尺寸较小而径向尺寸很大,这有利于在提高离合器传递扭矩能力的情况下,减小离合器的轴向尺寸;2、膜片弹簧的分离指起分离杠杆的作用,故不需专门的分离杠杆,使离合器结构大大简化;3、由于膜片弹簧轴向尺寸小,所以可以适当增加压盘的厚度,提高势容量;4、膜片弹簧离合器的主要部件形式简单,可以采用冲压加工,大批量生产时可以降低生产成本。根据毕业设计任务书主要技术要求:发动机额定转速下功率29kw/3200(r/min) ;发动机最大转矩97Nm/2200(r/min);额定载质量1000kg;总质量2510kg;最高车速68kM/h,选择膜片式弹簧离合器相关设计参数,包括摩擦片外径 的确定,离合器后备系数的确定,单位压力的确定;总成设计主要有:分离装置的设计,以及从动盘设计(从动盘毂的设计)等。本人将以严肃认真的科学态度,严谨求实的工作作风完成农用车离合器毕业设计。四、参考文献1汽车工程手册编辑委员会.汽车工程手册(设计篇)M.北京:人民交通出版社,2001.2林秉华.最新汽车设计实用手册M.黑龙江:黑龙江人民出版社,2005.3陈家瑞.汽车构造(上册、下册)M.北京:机械工业出版社,2005.4清华大学汽车工程系编写组编著.汽车构造M.北京:人民邮电出版社,2000.5刘涛.汽车设计M.北京:北京大学出版社,2008.6王望予.汽车设计(第3版)M.北京:机械工业出版杜,2000.57刘惟信.汽车设计M,北京:清华大学出版社出版,2004.8林宁等.汽车设计M.北京:机械工业出版社,1999.9周明衡.离合器、制动器选用手册M.北京:化学工业出版社,2003.10徐石安,江发潮.汽车离合器.北京:清华大学出版社,2005.11林世裕.膜片弹簧与蝶形弹簧离合器设计与制造M.南京:东南大学出版社,1995.12徐石安、肖德炳、刘惟信.离合器(汽车设计)M.北京:人民交通出版社1981.13张一民.汽车零部件可靠性设计M.北京:北京理工大学出版社,2000.14张宝生,李杰,林明芳.汽车优化设计理论与方法M. 北京:机械工业出版社,2000.15张文春.汽车理论M.北京:机械工业出版社,2005.16余志生.汽车理论(第5版)M.北京:机械工业出版社,2009.17机械设计手册编委会.机械设计手册(1-5卷) M.北京:机械工业出版社,2004.18濮良贵,纪名刚.机械设计(第七版)M.北京:高等教育出版社,2006.19孙桓,陈作模.机械原理(第五版)M.北京:高等教育出版社,2006.20范钦珊,郭光林.工程力学1,2(第2版)M.北京:高等教育出版社,2011. 毕 业 设 计(论文) 开 题 报 告 2本课题要研究或解决的问题和拟采用的研究手段(途径): 一、本课题要研究或解决的内容:1膜片弹簧离合器总体设计;2摩擦片外径 的确定;3离合器后备系数的确定;4单位压力的确定;5分离装置的设计;6从动盘设计。二、拟采用的研究手段(途径) 本设计要求认真进行资料收集、阅读、整理,正确使用工具书和网络,熟练掌握相关软件,再进行离合器的基本结构尺寸和参数的选择及计算;最后进行离合器主要零部件的结构选型及设计计算,并利用软件进行必要的校核,绘制离合器零件图。 毕 业 设 计(论文) 开 题 报 告 指导教师意见:1对“文献综述”的评语:在“文献综述”中,能够结合“农用车离合器的设计”课题及专业知识,针对课题所涉及的内容及设计要求等,查阅了有关文献资料。在理解的基础上对汽车离合器的作用、分类和特点以及技术要求等内容进行综合分析和评述,符合文献综述的要求。 2对本课题的深度、广度及工作量的意见和对设计(论文)结果的预测:设计课题的深度与广度适中,工作量符合我校的毕业设计要求:经过认真充分的准备工作,应当能够如期完成毕业设计工作。 3.是否同意开题: 同意 不同意 指导教师: 2016 年 03 月 24 日所在专业审查意见:开题报告符合毕业设计要求,同意开题。 负责人: 2016 年 04 月 05 日毕 业 设 计(论 文)外 文 参 考 资 料 及 译 文译文题目: 农用车离合器设计 学生姓名: 专业:所在学院:指导教师:职称:外文原文7Design Principle of Series (Electrical Coupling) Hybrid Electric Drive TrainThe concept of a series hybrid electric drive train was developed from the EV drive train.As mentioned in Chapter 4, EVs, compared with conventional gasoline- or diesel-fueled vehicles,have the advantages of zero mobile pollutant emissions, multienergy sources, and high efficiency. However, EVs using present technologies have some disadvantages: a limited drive range due to the shortage of energy storage in the on-board batteries, limited payload and volume capacity due to heavy and bulky batteries, and long battery charging time. The initial objective of developing a series HEV was aimed at extending the drive range by adding an engine/alternator system to charge the batteries on-board.A typical series hybrid electric drive train configuration is shown in Figure 7.1. The vehicle is propelled by a traction motor. The traction motor is powered by a battery pack and/or an engine/generator unit. The powers of both power sources are merged together in a power electronics-based and controllable electrical coupling device. Many operation modes are available to choose, according to the power demands of the driver and the operation status of the drive train system.Vehicle performance (in terms of acceleration, gradeability, and maximum speed) is completely determined by the size and characteristics of the traction motor drive. Motor power capability and transmission design are the same as in the EV design discussed in Chapter 4. However, the drive train control is essentially different from the pure electric drive train due to the involvement of the additional engine/generator unit. This chapter will focus on the design principles of the engine/alternator system, the drive train control, and the energy and power capacity of the battery pack. In this chapter,the term “peak power source” will replace “battery pack” because, in HEVs,the major function of the batteries is to supply peaking power and they can be replaced with other kinds of sources such as ultracapacitors, flywheels, or Combinations. 7.1 Operation PatternsIn series hybrid electric drive trains, the engine/generator system is mechanically decoupled from the driven wheels as shown in Figure 7.1. The speed and torque of the engine are independent of vehicle speed and traction torque demand, and can be controlled to any operating point on its speed-torque plane.Generally, the engine should be controlled in such a way that it always operates in its optimal operation region, where fuel consumption and emissions of the engine are minimized (see Figure 7.2). Due to the mechanical decoupling of the engine from the driven wheels, this optimal engine operation is realizable. However, it heavily depends on the operating modes and control strategy of the drive train.The drive train has several operating modes, which can be used selectively according to the driving conditions and wish of the driver. These operating modes are as follows:1. Hybrid traction mode: When a large amount of power is demanded,that is, the driver depresses the accelerator pedal deeply, both engine/generator and peaking power source (PPS) supply their powers to the electric motor drive. In this case, the engine should be controlled to operate in its optimal region for efficiency and emission reasons as shown in Figure 7.2. The PPS supplies the additional power to meet the traction power demand. This operation mode can be expressed asPdemand=Pe/g+Ppps,2. Peak power source-alone traction mode: In this operating mode, the peak power source alone supplies its power to meet the power demand,that is,Pdemand= Ppps. (7.2)3. Engine/generator-alone traction mode: In this operating mode, the engine/generator alone supplies its power to meet the power demand,that is,Pdemand= Pe/g. (7.3)4. PPS charging from the engine/generator: When the energy in the PPS decreases to a bottom line, the PPS must be charged. This can be done by regenerative braking or by the engine/generator. Usually,engine/generator charging is needed, since regenerative braking charging is insufficient. In this case, the engine/generator power is divided into two parts: one to propel the vehicle and the other to charge the PPS. That is,Pdemand= Pe/g+ Ppps. (7.4)It should be noticed that the operation mode is only effective when the power of the engine/generator is greater than the load powerdemand. It should be noted that PPS power is given a negative sign when it is being charged.5. Regenerative braking mode: When the vehicle is braking, the traction motor can be used as a generator, converting part of the kinetic energy of the vehicle mass into electric energy to charge the PPS.As shown in Figure 7.1, the vehicle controller commands the operation of each component according to the traction power (torque) command from the driver, the feedback from each of the components, and also the drive train and the preset control strategy. The control objectives are to (1) meet the power demand of the driver, (2) operate each component with optimal efficiency,(3) recapture braking energy as much as possible, and (4) maintain the state of charge (SOC) of the PPS in a preset window.7.2 Control StrategiesA control strategy is a control rule that is preset in the vehicle controller and commands the operation of each component. The vehicle controller receives operation commands from the driver and feedback from the drive train and all the components, and then makes decisions to use proper operation modes.Obviously, the performance of the drive train relies mainly on control quality,in which control strategy plays a crucial role.In practice, there are a number of control strategies that can be employed in a drive train for vehicles with different mission requirements. In this chapter,two typical control strategies are introduced: (1) maximum state-of-charge of peaking power source (Max. SOC-of-PPS) and (2) engine turn-on and turn-off(engine on/off) or thermostat control strategies.7.2.1 Max. SOC-of-PPS Control StrategyThe target of this control strategy is to meet the power demand commanded by the driver and, at the same time, maintain the SOC of the PPS at its high level. The engine/generator is the primary power source, and the PPS is the secondary source. This control strategy is considered to be the proper design for vehicles in which performance (speed, acceleration, gradeability, etc.) is the first concern, such as vehicles with frequent stopgo driving patterns and military vehicles in which carrying out their mission is the most important objective. A high SOC level in the PPS will guarantee the high performance of vehicles at any time.The Max. SOC-of-PPS control strategy is depicted in Figure 7.3, in which points A, B, C, and D represent the power demands that the driver commanded in either traction mode or braking mode. Point A represents the commanded traction power that is greater than the power that theengine/generator can produce. In this case,the PPS must produce its power to make up the power shortage of the engine/generator. Point B represents the commanded power that is less than the power that the engine/generator produces when operating in its optimal operation region (refer to Figure 7.2).In this case, two operating modes may be used, depending on the SOC level of the PPS. If the SOC of the PPS is below its top line, such as less than 70%, the engine/generator is operated with full load. (The operating point of the engine/generator with full load depends on the engine/generator design. For details, see the next section.) Part of its power goes to the traction motor to propel the vehicle and the other part goes to the PPS to increase the energy level. On the other hand, if the SOC of the PPS has reached its top line, the engine/generator traction mode alone is supplied,that is, the engine/generator is controlled to produce power equal to the demanded power, and the PPS is set at idle. Point C represents the commanded braking power that is greater than the braking power the motor can produce (maximum regenerative braking power).In this case, a hybrid braking mode is used, in which the electric motor produces its maximum braking power and the mechanical braking system produces the remaining braking power. Point D represents the commanded braking power that is less than the maximum braking power that the motor can produce. In this case, only regenerative braking is used. The control flowchart of the Max. SOC-of-PPS is illustrated in Figure 7.4.7.2.2 Engine OnOff or Thermostat Control StrategyThe Max. SOC-of-PPS control strategy emphasizes maintaining the SOC of the PPS at a high level. However, in some driving conditions, such as drivingfor a long time (with a low load) on a highway at constant speed, the PPS can be easily charged to its full level, and the engine/generator is forced to operate with power output smaller than its optimum. Hence, the efficiency of the drive train is reduced. In this case, the engine onoff or thermostat control strategy would be appropriate. This control strategy is illustrated in Figure 7.5. The operation of the engine/generator is completely controlled by the SOC of the PPS. When the SOC of the PPS reaches its preset top line, the engine/generator is turned off and the vehicle is propelled only by the PPS. On the other hand,when the SOC of the PPS reaches its bottom line, the engine/generator is turned on. The PPS gets its charging from the engine/generator. In this way,the engine can be always operated within its optimal deficiency region.7.3 Design Principles of a Series (Electrical Coupling)Hybrid Drive TrainSuccessful design of the drive train system means ensuring the vehicle being capable of achieving the desired performance, such as acceleration, grade-ability, high speed, and high operating efficiency. The traction motor drive,engine/generator unit, PPS, and electrical coupling device are the major design components of concern. Their design should primarily be considered at the system level so as to ensure that all the components work harmoniously.7.3.1 Electrical Coupling DeviceAs mentioned above, the electrical coupling device is the sole linkage point for combining the three sources of powers together: engine/generator, PPS, and traction motor. Its major function is to regulate the power (electric current)flow between these power sources and sinks. The power (current) regulation is carried out based on the proper control of the terminal voltages. The simplest structure is to connect the three terminals together directly as shown in Figure 7.6.This configuration is the simplest and has the lowest cost. Its major feature is that the bus voltage is equal to the rectified voltage of the generator and that of the PPS. The bus voltage is determined by the minimum of the two voltages above. The power flow is solely controlled by the voltage of the generator. To deliver its power to the traction motor and/or the PPS, the open circuit voltage(zero current) of the generator, rectified, must be higher than the PPS voltage.This can be done by controlling the engine throttle and/or the magnetic field of the generator. When the engine/generator is controlled to generate the rectified terminal voltage equal to the open circuit voltage of the PPS, the PPS does not deliver power and the engine/generator alone powers the electric motor. When the rectified voltage of the engine/generator is lower than the PPS voltage, the PPS alone powers the electric motor. In regenerative braking,the generated bus voltage by the traction motor must be higher than the PPS voltage. However, the voltage generated by the traction motor is usually proportional to the rotational speed of the motor. Therefore, the regenerative braking capability in low speed will be rather limited for this design. It is also obvious that this simple design requires the engine/generator and the PPS to have the same rated voltage. This constraint may result in a heavy PPS due to the high voltage.Adding a DC/DC converter, and thus releasing the voltage constraints,may significantly improve the performance of the drive train.Two alternative configurations are shown in Figures 7.7 and 7.8. In the configuration of Figure 7.7, the DC/DC converter is placed between the PPS and the DC bus and the enginegeneratorrectifier is connected directly to the DC bus.In this configuration, the PPS voltage is allowed to be different from the DC bus voltage, and the rectified voltage of the engine/generator is always equal to the DC bus voltage. In the configuration of Figure 7.8, the DC/DC converter is placed between the enginegeneratorrectifier and the DC bus and the PPS is directly connected to the DC bus. Contrary to the configuration of Figure 7.7, the DC/DC converter conditions the rectified voltage of the engine/generator and the voltage of the PPS is always equal to the DC bus voltage.Among these two configurations, the one in Figure 7.7 seems to be more appropriate. Its advantages over the other one are mainly the following: (1)changes in the voltage of PPS do not affect the DC bus voltage, (2) the energy in the PPS can be fully used, (3) the voltage of the DC bus can be maintained by controlling the engine throttle and/or the magnetic field of the generator, (4)a low PPS voltage can be used, which may lead to small and light PPS pack and less cost, and (5) the charging current of PPS can be regulated during regenerative braking and charging from the engine/generator.It is obvious that the DC/DC converter in this configuration has to be bidirectional. In the case of the rated voltage of the PPS being lower than the DC bus voltage, the DC/DC converter has to boost the PPS voltage to the level of the DC bus to deliver its power to the DC bus and buck the DC bus voltage to the level of the PPS charging voltage to charge the PPS. In regenerative braking, if the voltage generated by the traction motor at a given low speed is still higher than the voltage of the PPS, the buck DC/DC converter in the PPS charging direction is still usable. However, if the voltage generated by the traction motor at the given low speed is lower than the terminal voltage of the PPS, the DC/DC converter may need to boost the DC bus voltage to charge the battery. In this case, a buck/boost (step down/step up) converter is needed. The basic functions of the DC/DC required converter are summarized in Figure 7.9.中文译文系列的设计原理(电耦合)的混合动力传动系串联式混合动力电动传动系的概念是从EV开发传动系。正如在第4章,电动汽车,与传统的汽油或柴油为燃料的汽车相比,具有零移动污染物的排放,多能量源,效率高的优点。然而,使用本技术的电动车具有一些缺点:由于在车载电池,有限的有效载荷和体积容量能量储存器的短缺的有限驱动范围由于笨重的电池,和长的电池充电时间。开发一系列的HEV的初步目标是针对通过将发动机/交流发电机系统的车载电池充电延伸的驱动范围。一个典型的串联式混合动力传动系统的配置如图7.1所示。车辆由一个牵引电动机推动。牵引电机由电池组和/或发动机/发电机单元供电。两个电源的功率被合并在一起,基于电力电子的和可控的电耦合装置。许多操作模式来选择,根据驾驶和驱动系系统的操作状态的电力需求。车辆性能(在加速,爬坡能力,和最大速度方面)完全由大小和牵引电动机驱动器的特性来确定。马达功率能力和传输设计是相同的如在第4章中讨论的电动汽车的设计但是,传动系控制是从纯电动驱动系本质上的不同,由于附加的发动机/发电机单元的参与。本章将集中在发动机/交流发电机系统,该传动系控制,以及对电池组的能量和功率容量的设计原则。在这一章中,术语“峰值功率源”将代替“电池组”,是因为,在混合动力汽车中,电池的主要功能是提供峰值功率,它们可以被替换为其他种类的来源,如超级电容器,飞轮,或组合。7.1操作模式在串联式混合动力驱动系统中,发动机/发电机系统被机械地从从动轮解耦,如图7.1。所述的速度以及发动机的扭矩是独立的车速和牵引转矩的需求,并且可被控制以在它的速度转矩平面上的任何工作点。通常,发动机应该以这样一种方式,它总是在它的优化运行区域进行操作,其中,燃料消耗和发动机的排放最小化的控制(见图7.2)。由于从驱动轮的发动机的机械去耦,这最佳发动机操作是可实现的。然而,它在很大程度上取决于传动系的操作模式和控制策略。传动系具有多种操作模式,其中可以有选择地根据驱动条件和驾驶员的愿望被使用。这些操作模式如下:1. 混合牵引模式:当大量的功率被要求,也就是,驾驶员尽力踩下加速器踏板,发动机/发电机和峰值功率源(PPS)即提供其功率给电动马达驱动。在这种情况下,发动机应控制在提高效率和发射的原因及其最佳区域中操作,如图7.2。该PPS提供的额外功率,以满足所需牵引功率。这种操作模式可以表示为:Pdemand=Pe/g+Ppps。这里Pdemand是指驾驶员所需求的能量,Pe/g是指发动机/发电机所提供的能量,Ppps是指峰值功率源所提供的能量。2. 峰值功率源单独牵引模式:在此操作模式中,峰值功率源单独提供其功率,以满足电力需求,也就是Pdemand=Ppps3. 发动机/发电机单独牵引模式:在此操作模式中,发动机/发电机单独提供其功率,以满足电力需求,也就是Pdemand=Pe/g4. 从发动机/发电机的PPS充电:当在PPS的能量减小到底线,将PPS必须充电。这可以通过再生制动或发动机/发电机来实现。一般,发动机/发电机充电是必要的,因为再生制动充电不足。在这种情况下,发动机/发电机的功率被分成两个部分:一个用于推进车辆,而另一个以将PPS充电。也就是Pdemand=Pe/g+Ppps应当注意到,当发动机/发电机的功率大于负载所需的电源的操作模式是唯一有效的。应当指出的是,PPS功率被赋予负号时,它被充电。5. 再生制动模式:当车辆处于破碎,牵引电机可以用作发电机,将所述车辆质量的动能的一部分转换成电能,以将PPS充电。如图7.1,车辆控制器根据所述牵引动力(转矩)命令从驱动,从各成分的反馈,并且也驱动系和预置控制策略命令的每个组件的操作。控制目标是:(1)满足驾驶员的要求功率;(2)操作的每个组件具有最佳效率,(3)夺回制动能量尽可能,和(4)保持的充电量(SOC)的状态将PPS在预先设定的窗口。7.2控制策略控制策略是预置在车辆控制器和命令每个组件的操作的控制规则。车辆控制器接收从传动系驱动器和反馈和所有的部件操作命令,然后做出决定,以使用正确的操作模式。显然,传动系的性能主要依赖于控制质量,在这种控制策略中起着至关重要的作用。在实践中,有许多可在传动系被用于车辆具有不同的任务要求的控制策略。在这一章中,两个典型的控制策略进行了介绍:(1)(最大充电状态的PPS)最大状态的充电调峰电源和(2)发动机的导通和关断(发动机/关)或恒温器控制策略。7.2.1最大充电状态的PPS这种控制策略的目标是满足由驾驶员指令,并在同一

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号