资源目录

压缩包内文档预览:

编号:22906639

类型:共享资源

大小:1.21MB

格式:ZIP

上传时间:2019-11-04

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

50

积分

- 关 键 词:

-

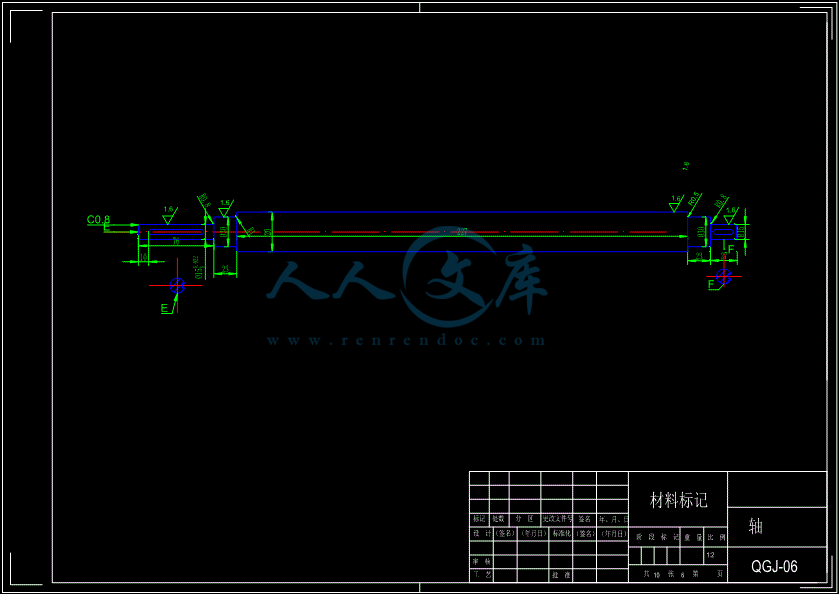

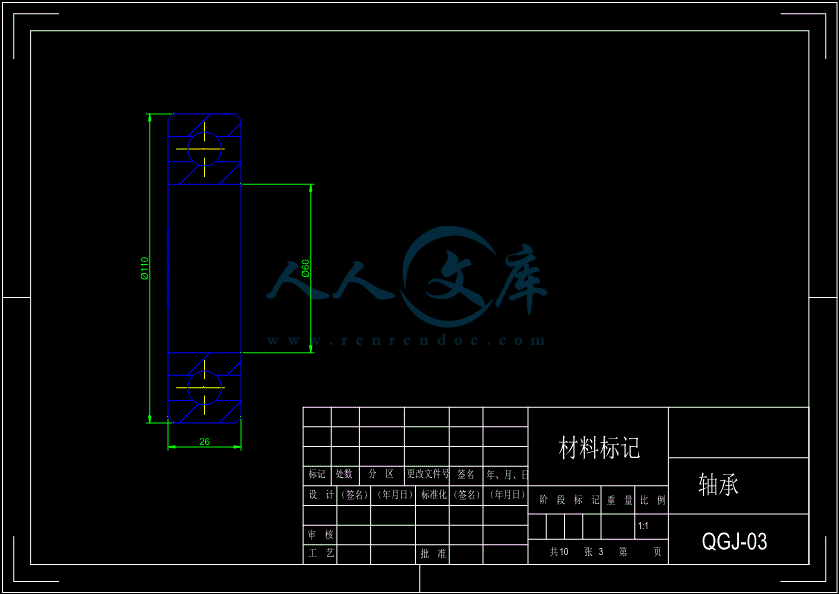

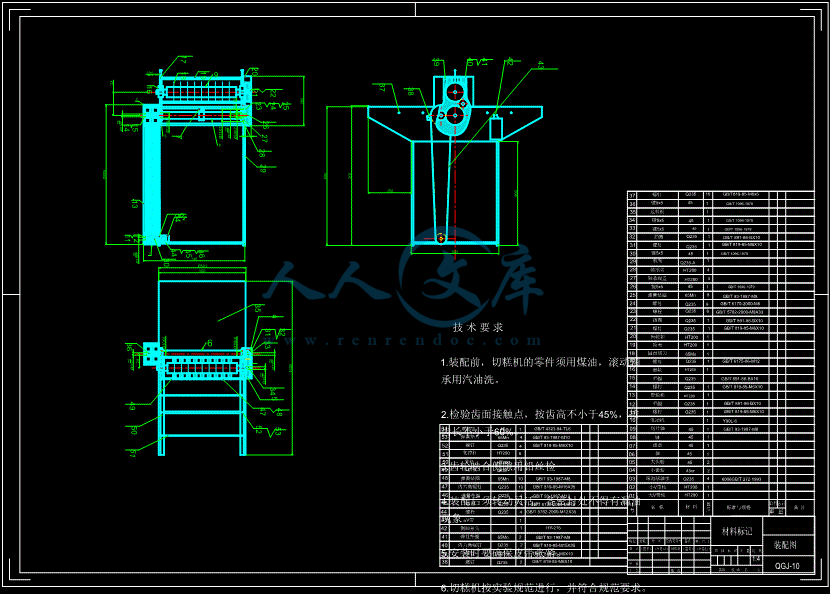

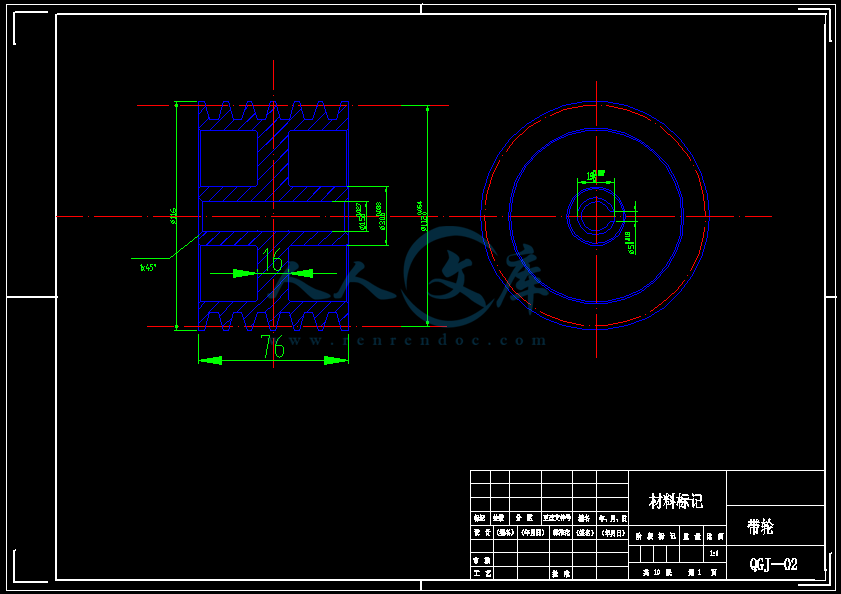

含CAD图纸、说明书

糕点

切片机

设计

CAD

图纸

说明书

- 资源描述:

-

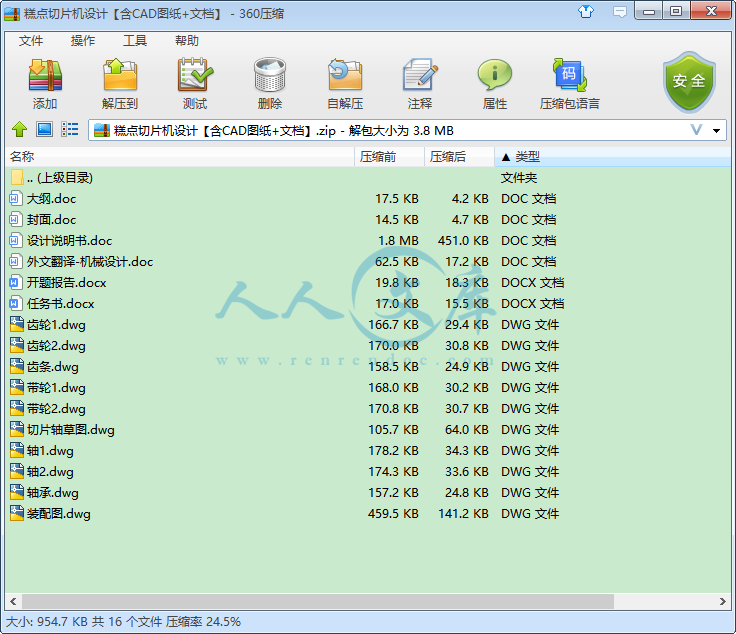

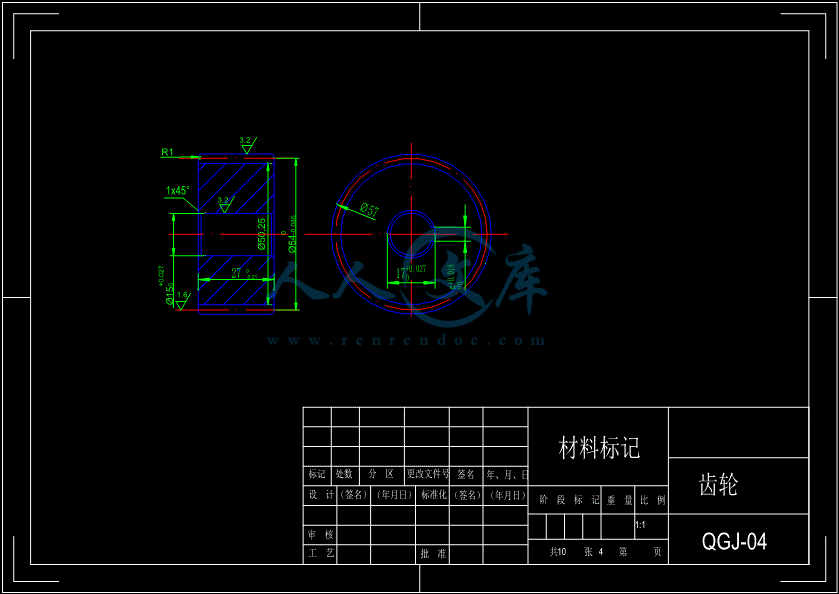

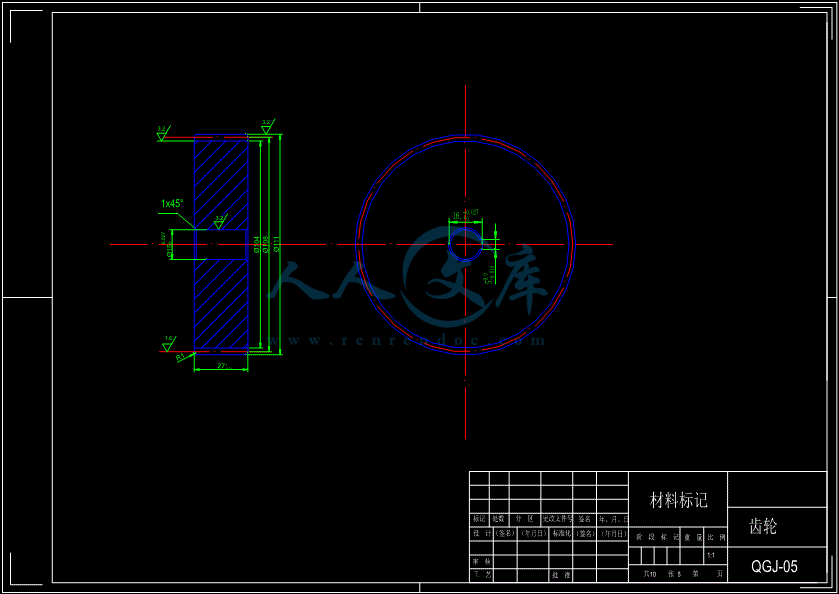

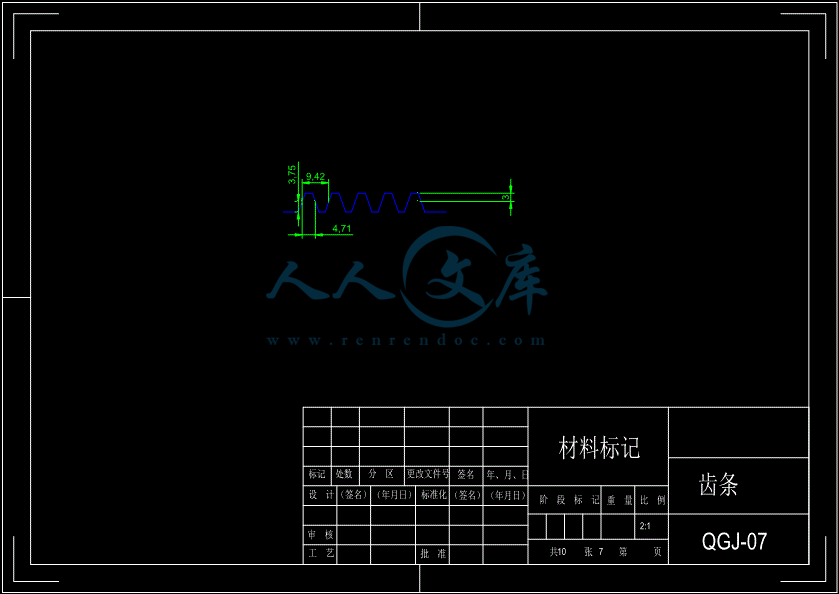

【温馨提示】压缩包内含CAD图有下方大图片预览,下拉即可直观呈现眼前查看、尽收眼底纵观。打包内容里dwg后缀的文件为CAD图,可编辑,无水印,高清图,压缩包内文档可直接点开预览,需要原稿请自助充值下载,所见才能所得,请见压缩包内的文件及下方预览,请细心查看有疑问可以咨询QQ:11970985或197216396

- 内容简介:

-

毕 业 设 计(论 文)外 文 参 考 资 料 及 译 文译文题目: Mechanical Design 机 械 设 计 学生姓名: 学 号: 专 业: 所在学院: 指导教师: 职 称: 20xx年 2月 27日Mechanical DesignJohn ErnstAbstractA machine is a combination of mechanisms and other components which transforms transmits. Examples are engines, turbines, vehicles, hoists, printing presses, washing machines, and movie cameras. Many of the principles and methods of design that apply to machines also apply to manufactured articles that are not true machines. The term mechanical design is used in a broader sense than machine design to include their design. The motion and structural aspects and the provisions for retention and enclosure are considerations in mechanical design. Applications occur in the field of mechanical engineering, and in other engineering fields as well, all of which require mechanical devices, such as switches, cams, valves, vessels, and mixers. Keywords: Mechanical Design;Mechanisms Design Process;Application1. The Design Progress Designing starts with a need real. Existing apparatus may need improvements in durability, efficiency, weight, speed, or cost. New apparatus may be needed to perform a function previously.Done by men, such as computation, assembly, or servicing. With the objective wholly or partly.In the design preliminary stage, should allow to design the personnel fully to display the creativity, not each kind of restraint. Even if has had many impractical ideas, also can in the design early time, namely in front of the plan blueprint is corrected. Only then, only then does not send to stops up the innovation the mentality. Usually, must propose several sets of design proposals, and then perform the comparison. Has the possibility very much in the plan which finally designated, has used certain not in plan some ideas which accepts. When the general shape and a few dimensions of the several components become apparent, analysis can begin in earnest. The analysis will have as its objective satisfactory or superior performance, plus safety and durability with minimum weight, and a competitive cost. Optimum proportions and dimensions will be sought for each critically loaded section, together with a balance between the strengths of the several components. Materials and their treatment will be chosen.Theseimportantobjectivescanbeattainedonlybyanalysisbasedupontheprinciplesofmechanics,suchasthoseofstaticforreactionforcesandfortheoptimumutilizationoffriction;ofdynamicsforinertia,acceleration,andenergy;ofelasticityandstrengthofmaterialsforstressanddeflection;ofphysicalbehaviorofmaterials;andoffluidmechanicsforlubricationandhydrodynamicdrives.Theanalysesmaybemadebythesameengineerwhoconceivedthearrangementofmechanisms,or,inalargecompany,theymaybemadebyaseparateanalysisdivisionorresearchgroup.Designisareiterativeandcooperativeprocess,whetherdoneformallyorinformally,andtheanalystcancontributetophasesotherthanhisown.Productdesignrequiresmuchresearchanddevelopment.ManyConceptsofanideamustbestudied,tried,andtheneitherusedordiscarded.Althoughthecontentofeachengineeringproblemisunique,thedesignersfollowthesimilarprocesstosolvetheproblems.Productliabilitysuitsdesignersandforcedinmaterialselection,usingthebestprogram.Intheprocessofmaterial,themostcommonproblemsforfive(a)dontunderstandornotuseaboutthelatestapplicationmaterialstothebestinformation,(b)failedtoforeseeandconsiderthereasonableusematerialmay(suchaspossible,designersshouldfurtherforecastandconsiderduetoimproperuseproducts.Inrecentyears,manyproductsliabilityinlitigation,theuseofproductsandhurttheplaintiffaccusedmanufacturer,andwonthedecision),(c)ofthematerialsusedallorsomeofthedata,data,especiallywhentheuncertaintylong-termperformancedataisso,(d)qualitycontrolmethodisnotsuitableandunproven,(e)bysomecompletelyincompetentpersonschoosematerials.Throughtotheabovefivequestionsanalysis,mayobtainthesequestionsisdoesnothavethesufficientreasonexistencetheconclusion.Mayforavoidthesequestionstothesequestionsresearchanalysestheappearanceindicatingthedirection.Althoughusesthebestchoiceofmaterialmethodnottobeabletoavoidhavingtheproductresponsibilitylawsuit,designsthepersonnelandtheindustrycarriesonthechoiceofmaterialaccordingtothesuitableprocedure,maygreatlyreducethelawsuitthequantity.Mayseefromtheabovediscussion,thechoicematerialpeopleshouldtothematerialnature,thecharacteristicandtheprocessingmethodhavecomprehensiveandthebasicunderstanding.Finally,adesignbaseduponfunction,andaprototypemaybebuilt.Ifitstestsaresatisfactory,theinitialdesignwillundergocertainmodificationsthatenableittobemanufacturedinquantityatalowercost.Duringsubsequentyearsofmanufactureandservice,thedesignislikelytoundergochangesasnewideasareconceivedorasfurtheranalysesbasedupontestsandexperienceindicatealterations.Salesappeal.2. SomeRulesforDesignInthissectionitissuggestedthat,appliedwithacreativeattitude,analysescanleadtoimportantimprovementsandtotheconceptionandperfectionofalternate,perhapsmorefunctional,economical,anddurableproducts.Tostimulatecreativethought,thefollowingrulesaresuggestedforthedesignerandanalyst.Thefirstsixrulesareparticularlyapplicablefortheanalyst.(1)Acreativeuseofneedofphysicalpropertiesandcontrolprocess.(2)Recognizefunctionalloadsandtheirsignificance.(3)Anticipateunintentionalloads.(4)Devisemorefavorableloadingconditions.(5)Provideforfavorablestressdistributionandstiffnesswithminimumweight.(6)Usebasicequationstoproportionandoptimizedimensions.(7)Choosematerialsforacombinationofproperties.(8)Selectcarefully,stockandintegralcomponents.(9)Modifyafunctionaldesigntofitthemanufacturingprocessandreducecost.(10)Provideforaccuratelocationandnoninterferenceofpartsinassembly.Machinerydesigncoversthefollowingcontents.(1).Providesanintroductiontothedesignprocess,problemformulation,andsafetyfactors.(2).Reviewsthematerialpropertiesandstaticanddynamicloadinganalysis,Includingbeam,vibrationandimpactloading.(3)Reviewsthefundamentalsofstressanddefectionanalysis.(4)Introducesfatigue-failuretheorywiththeemphasisonstress-lifeapproachestohigh-cyclefatiguedesign,whichiscommonlyusedinthedesignofrotationmachinery.(5)Discussesthoroughlythephenomenaofwearmechanisms,surfacecontactstresses,andsurfacefatigue.(6)Investigatesshaftdesignusingthefatigue-analysistechniques.(7)Discussesfluid-filmandrolling-elementbearingtheoryandapplication.(8)Givesathoroughintroductiontothekinematics,designandstressanalysisofspurgears,andasimpleintroductiontohelical,bevel,andwormgearing.(9)Discussesspringdesignincludingcompression,extensionandtorsionsprings.(10)Dealswithscrewsandfastenersincludingpowerscrewandpreloadfasteners.(11)Introducesthedesignandspecificationofdiskanddrumclutchesandbrakes.Thecompletedesignofamachineisacomplexprocess.Themachinedesignisacreativework.Projectengineernotonlymusthavethecreativityinthework,butalsomustinaspectandsoonmechanicaldrawing,kinematics,engineeringmaterial,materialsmechanicsandmachinemanufacturetechnologyhasthedeepelementaryknowledge.Oneofthefirststepsinthedesignofanyproductistoselectthematerialfromwhicheachpartistobemade.Numerousmaterialsareavailabletotodaysdesigners.Thefunctionoftheproduct,itsappearance,thecostofthematerial,andthecostoffabricationareimportantinmakingaselection.Acarefulevaluationofthepropertiesofa.materialmustbemadepriortoanycalculations.Carefulcalculationsarenecessarytoensurethevalidityofadesign.Incaseofanypartfailures,itisdesirabletoknowwhatwasdoneinoriginallydesigningthedefectivecomponents.Thecheckingofcalculations(anddrawingdimensions)isofutmostimportance.Themisplacementofonedecimalpointcanruinanotherwiseacceptableproject.Allaspectsofdesignworkshouldbecheckedandrechecked.Thecomputerisatoolhelpfultomechanicaldesignerstolightentediouscalculations,andprovideextendedanalysisofavailabledata.Interactivesystems,basedoncomputercapabilities,havemadepossibletheconceptsofcomputeraideddesign(CAD)andcomputer-aidedmanufacturing(CAM).Howdoesthepsychologistfrequentlydiscusscausesthemachinewhichthepeopleadaptsthemtooperate.Adesignpersonnelsbasicresponsibilityisdiligentlycausesthemachinetoadaptthepeople.Thiscertainlyisnotaneasywork,becausecertainlydoesnothavetoallpeopletosayinfactallisthemostsuperioroperatingareaandtheoperatingprocess.Anotherimportantquestion,projectengineermustbeabletocarryontheexchangeandtheconsultationwithotherconcernedpersonnel.Intheinitialstage,designsthepersonneltohavetocarryontheexchangeandtheconsultationonthepreliminarydesignwiththeadministrativepersonnel,andisapproved.Thisgenerallyisthroughtheoraldiscussion,theschematicdiagramandthewritingmaterialcarrieson.Iffrontsues,themachinedesigngoalistheproductioncanmeetthehumanneedtheproduct.Theinvention,thediscoveryandtechnicalknowledgeitselfcertainlynotnecessarilycanbringtheadvantagetothehumanity,onlyhaswhentheyareappliedcanproduceontheproductthebenefit.Thus,shouldrealizetocarriesonbeforethedesigninaspecificproduct,mustfirstdeterminewhetherthepeopledoneedthiskindofproduct.Mustregardasthemachinedesignisthemachinedesignpersonnelcarriesonusingcreativeabilitytheproductdesign,thesystemanalysisandaformulationproductmanufacturetechnologygoodopportunity.Graspstheprojectelementaryknowledgetohavetomemorizesomedataandtheformulaismoreimportantthan.Themerelyservicedataandtheformulaisinsufficienttothecompletelydecisionwhichmakesinagooddesignneeds.Ontheotherhand,shouldbeearnestpreciselycarriesonalloperations.Forexample,evenifplaceswrongadecimalpointposition,alsocancausethecorrectdesigntoturnwrongly.Gooddesignpersonnelshoulddaretoproposethenewideamoreoveriswillingtoundertakethecertainrisk,whenthenewmethodisnotsuitable,useoriginalmethod.Therefore,designsthepersonneltohavetohavetohavethepatience,becausespendsthetimeandtheendeavorcertainlycannotguaranteebringssuccessfully.Abrand-newdesign,therequestscreenabandonsabsolutelymany,knowsverywellthemethodforthepeople.Becausemanypersonofconservativenessdoesthiscertainlyisnotaneasymatter.Amechanicaldesignershouldunceasinglyexploretheimprovementexistingproductthemethod,shouldearnestlychooseoriginally,theprocessconfirmationprincipleofdesigninthisprocess,withhasnotunifieditaftertheconfirmationnewidea.Humanlifecannotbeseparatedfromthemachinery,itiseverywhere,butforthemechanicalmanufacturing,production,anditsdevelopmentandfuture,weknowlittleabout.Afterthissemester,Ihavemoreknowledgeandunderstandingoftheprofessionofthemechanical.Fromtheprimitivesocietyofearlyhumanusesuchasaxes,knivesandothersimpletools,toasimplelever,pulley,humanbicycles,animal-KipShumcartools,developedtoamorecomplexhydraulicdrive,wind-drivenShuinianandwindmillsmorecomplexmachinery.Afterthe18thcenturyBritishIndustrialRevolution,thesteamengine,internalcombustionengines,electricmotors,mechanicalpowersourcefortherapiddevelopmentofmanufacturing,transport,humanbeingsbegantoenterthemoderncivilizedsociety.The20thcentury,thecomputerissuingautomaticcontroltechnology,informationtechnology,infectiousorganiccombinationoftechnology,sothatthemachineryisfullymodernizedphase.Robotics,CNCmachinetools,high-speeddeliveryvehicles,heavymachineryandthelargenumberofadvancedmachineryandequipmenttoacceleratetheprosperityandprogressofhumansociety,humanscantravelintospace,landingonthemoon,youcanexplorethevastdepthsofthesea,toliveandpassbelowthesurfaceallofwhichcannotbeseparatedfromthemachinery,thedevelopmentofthemachineryintotheintelligentstage.Machineryhasbecomeoneofthefiveelementsofproductionandservicesofmodernsociety.Thehistoryofthedevelopmentofthemechanicalhistoryofthedevelopmentofhumancivilization.InancientChinesemechanicalengineering,inventionandcreativityisverybrilliant,suchasgrindingtechnology,metalsmeltingtechnology.Chinasmachinerymanufacturingindustrydevelopedafter1949.AfterthefoundingofnewChina,thetremendousachievementsofChinaseconomyareinseparablefromtheprogressofthemanufacturingsector.Afterdecadesofstruggle,Chinasmanufacturingcomponentswithconsiderablescaleandlevelofmanufacturingsystems,todayChinahavebecomearemarkablemanufacturingcountry.Machinerymanufacturingindustryoverallscaleofproductionisconstantlyincreasing,machinerymanufacturingismorethan100industry,8.57millionenterprises(largeenterprisesaccountedfor1%)and60,000kindsofproductsacompleterangeofindustrialsystem.ForsixconsecutiveyearsinChinaslargestexportcommoditystatus,themachineryindustryproductioncapacityis2600timesthatoftheliberationoftheworld5,themachinehasaworld,vehicleproductionintheworld4.ButwestillneedtoclearlyrecognizethatChinaisabigmanufacturingcountry,farfrombeingamanufacturingpowerhouse.TheoverallsizeoftheaddedvalueofproducttechnologyandpercapitalaborefficiencyisfarbetterthantheUnitedStates,Japanandothermanufacturingpower.Therefore,thetaskofdevelopmentofChinasmanufacturingindustryalongwaytogo.Withthediversificationofthehigh-techdevelopmentandsocialneedsoftheindustrialproductionrapidlytowardlarge-scale,integratedandcomplex,sothatthemodernindustrialmachineryindustryisfacingnewopportunitiesandchallenges,andmoreemphasisonthecreativityandtheefficiencyoftheworkers.ThereforeneedtocontinuouslyenhancethelevelofChinasMechanicalDesignManufacturingandAutomation,therebycontributingtothedevelopmentofChinasmachinerymanufacturingindustry.机械设计作者:JohnErnst摘要一台机器是一种转换传输机制和其他组件的组合。例如发动机,发电机,车辆,吊机,印刷机,洗衣机,和电影摄影机等。许多应用到机器的设计的原理和方法也适用于制造的物品不是真正的机器。机械设计一词用在了更广泛的意义,不仅仅只是包括机械的设计。运动和结构方面及规定保留和围栏是机械设计要考虑的因素。机械工程领域和其他工程领域中的应用都需要机械设备,例如开关、凸轮、阀门、器皿、搅拌机。关键词:机械设计;机械设计过程;应用第1章 设计过程真正地开始设计,在耐久性、效率、重量、速度、成本上可能需要改进现有的设备,新设备之前可能需要做一个函数。如计算、装配、或维修全部或者部分和客观由人工做。在初步设计阶段,应该让设计人员充分发挥创造,而不是(受制于)每一种约束。即使有许多不切实际的想法,也可以在设计早期时间,即在前面的计划蓝图上修正。只有这样,才不会停止创新的心态。通常情况下,必须提出几套设计方案,然后进行比较。非常有可能在最后制定的计划中,使用已经被接受的一些想法。通用形状和少数几个部件的尺寸变得明显,分析就可以从开始中解脱出来。这种分析可以作为它的目标“满意”或“卓越”的性能,以及安全性和耐久性与最小重量,以及具有竞争力的成本。最佳比例和尺寸将寻找每个极加载部分,连同之间的一个平衡点的若干优点组件,材料和它们的加工选择。这些重要的目标达到,只有通过后,根据力学原理,如反应部队和静态摩擦的最佳利用,分析应力材料弹性和强度的惯性,加速度和能源的动力和挠度,材料的物理性能和润滑和水力驱动器的流体力学。分析可以由相同的工程师安排或者在一个大公司,他们可以由一个独立的分析或研究小组。设计是一个反复和合作的过程,不论是做正式的或非正式的,分析师能有助于其他阶段,而不是他自己的。产品设计需要大量的研究和发展。必须研究一个想法很多的概念,尝试,然后或者使用或丢弃。虽然每一个工程的内容的问题都是独特的,设计者遵循类似的程序去解决问题。产品责任诉讼的设计师和强度材料选型中要使用最优方案。在材料的过程中,最常见的问题有五个:(a)不理解或不使用最新的申请材料的最佳信息;(b)未能预见到,并考虑合理利用材料(尽可能设计者应进一步预测,并考虑由于使用不当造成的产品在近几年中,许多产品责任诉讼中,产品的使用和伤害原告指控制造商,并赢得了决定);(c)全部或部分使用的材料的数据,数据,尤其是在长期的不确定性的性能数据是这样;(d)质量控制方法是不适合的和未经证实的;(e)由一些完全不称职的人选择材料。通过对上述五个问题分析,可获得这些问题没有充足的理由存在的结论。为避免这些问题,对这些问题的研究分析表明出现方向。尽管使用了最好的选材方法不能够防止产品责任诉讼,设计人员和行业进行选材根据适当的程序,可大大降低诉讼的条件从上面的讨论中可以看到,人们应该选择材料的材料性质、特点及处理方法有全面而基本的理解。最后,设计基于功能,一个样机可以被建立。如果它是令人满意的测试,初步设计将接受一定的修改,使它能够以较低的成本生产一定的数量。在接下来的几年的生产和服务,设计可能要进行构思的变化或新思想的进一步分析表明基于试验和经验的主因销售的吸引力。第2章 一些设计的规则这一节里,我们建议,通过创造性的态度,分析可以引起重要性的提高,也可引起多样性,或者功能性,经济性和耐用产品的完善和备用。为了激发创造性思维,以下规则是设计师和分析师的建议。首六个规则是特别适用于使用分析师。(1)一个创造性的使用需要的物理性质和控制过程;(2)识别功能负荷及它们的意义;(3)预期无意的负载;(4)设计更有利的加载条件;(5)提供良好的应力分布和刚度和最低重量;(6)使用基本方程比例和优化尺寸;(7)选择材料的结合性能;(8)选择小心,股票和整体部件;(9)修改功能设计以适应市场;(10)提供准确的位置和不干预各部分的装配;机械设计包括以下内容:(1)介绍了设计过程,制定问题,安全的因素;(2)综述了材料的性质,静态和动态载荷分析(包括梁、振动和冲击载荷);(3)综述了应力和损伤分析基础。(4)介绍了fatigue-failure理论重点high-cycle疲劳设计方差方法,也就是一般用于旋转机械的设计。(5)讨论了彻底的磨损机理的现象;(6)调查轴设计,利用疲劳分析技术。(7)讨论了流体膜和滚动元件轴承的理论和应用(8)给出了一个全面地介绍了直齿圆柱齿轮的运动学,设计和应力分析,并简单介绍螺旋锥,环面蜗杆传动。(9)讨论弹簧设计,包括压缩,扩展和扭转弹簧。(10)包括电源螺钉和预紧紧固件用螺钉和紧固件的优惠活动。(11)介绍了磁盘和鼓离合器和制动器的设计和规范。一台机器的完整的设计是一个复杂的过程。本机的设计是一项创造性的工作。项目工程师不仅要在工作中有创造力,而且还必须对机械制图,运动学,工程材料,材料力学,机械制造技术等方面有着深厚的基础知识。任何产品设计的首要步骤之一,是从每个部分作出选择材料。今天的设计师提供许多材料。产品的外观,材料成本和制造成本的作用是重要的选择。仔细评估的一个属性。材料必须作出之前的任何计算。仔细计算是很有必要的,可以保证设计的有效性。如有任何部分的失败,这是合乎情理

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号