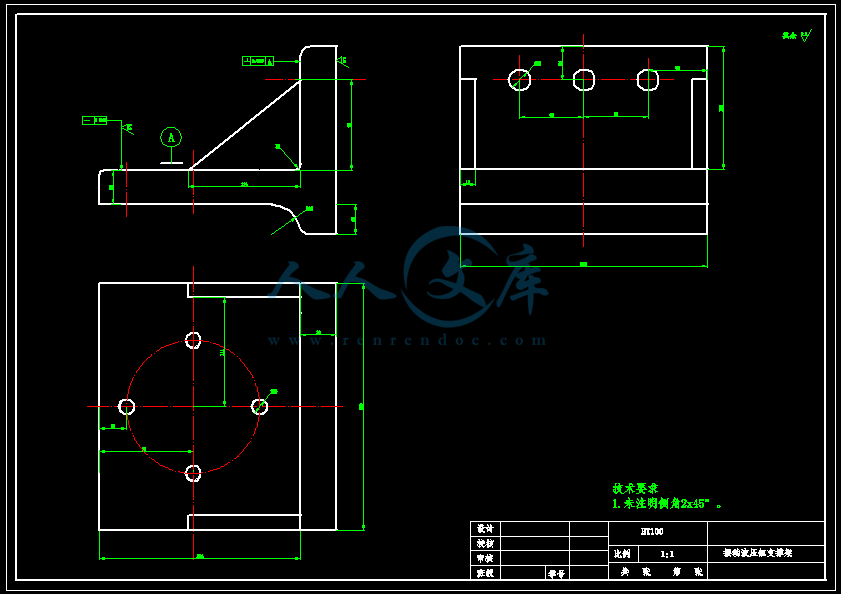

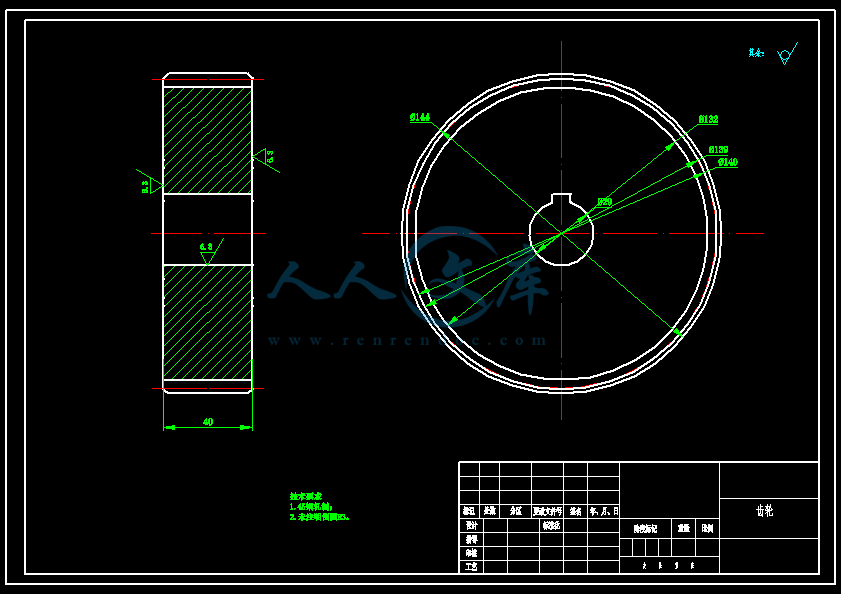

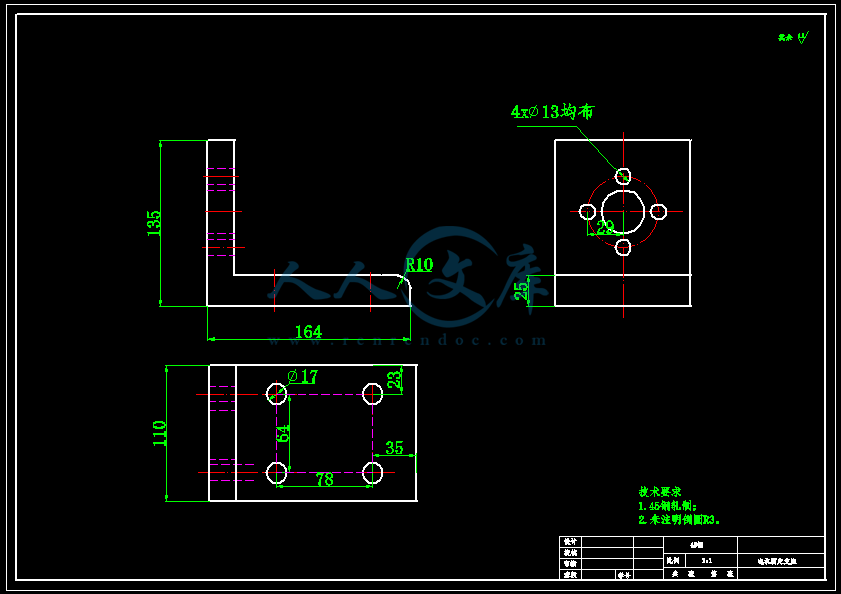

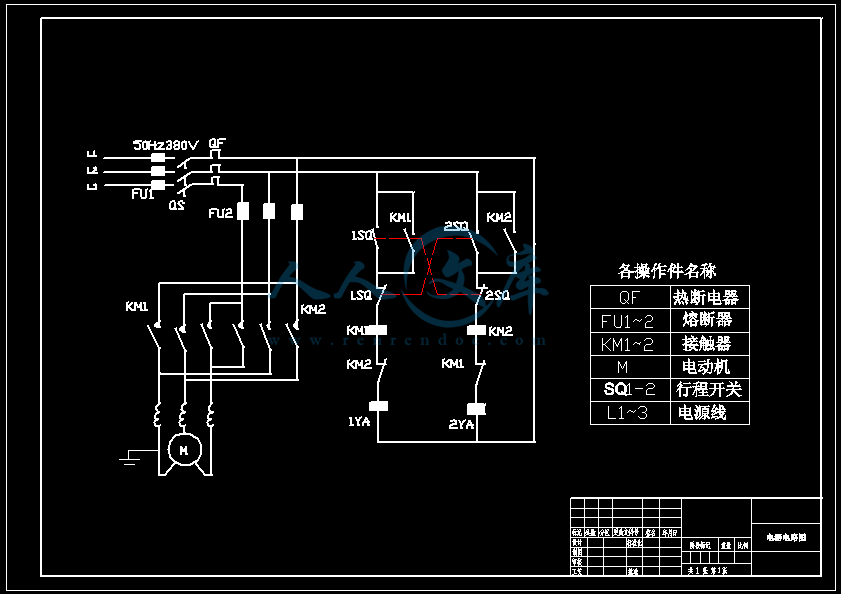

弯管机总体设计(机械CAD图纸设计、说明书)

收藏

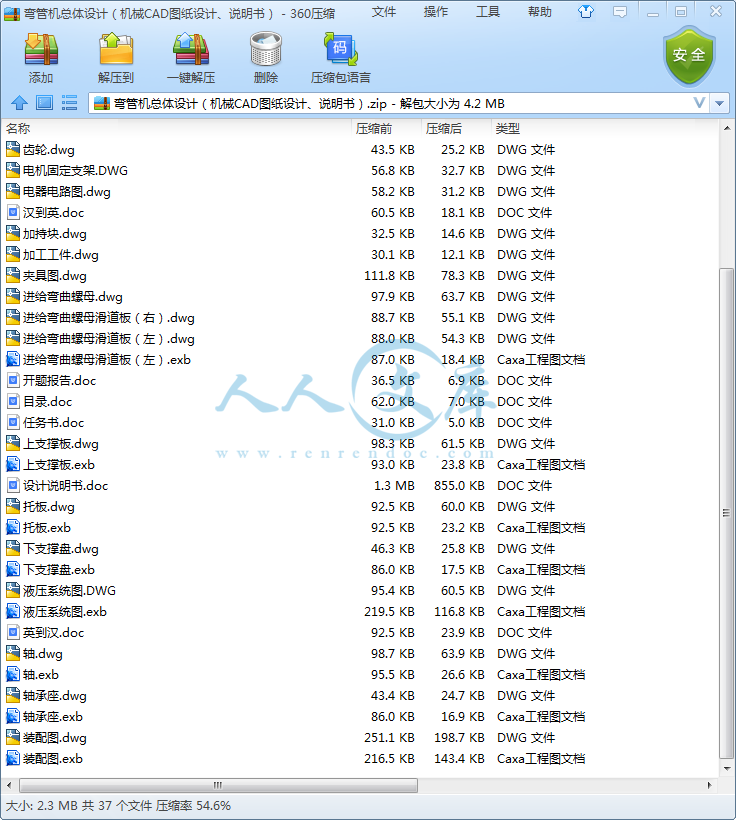

资源目录

压缩包内文档预览:

编号:23169727

类型:共享资源

大小:2.33MB

格式:ZIP

上传时间:2019-11-07

上传人:机****料

认证信息

个人认证

高**(实名认证)

河南

IP属地:河南

120

积分

- 关 键 词:

-

弯管

总体

设计

机械

CAD

图纸

说明书

- 资源描述:

-

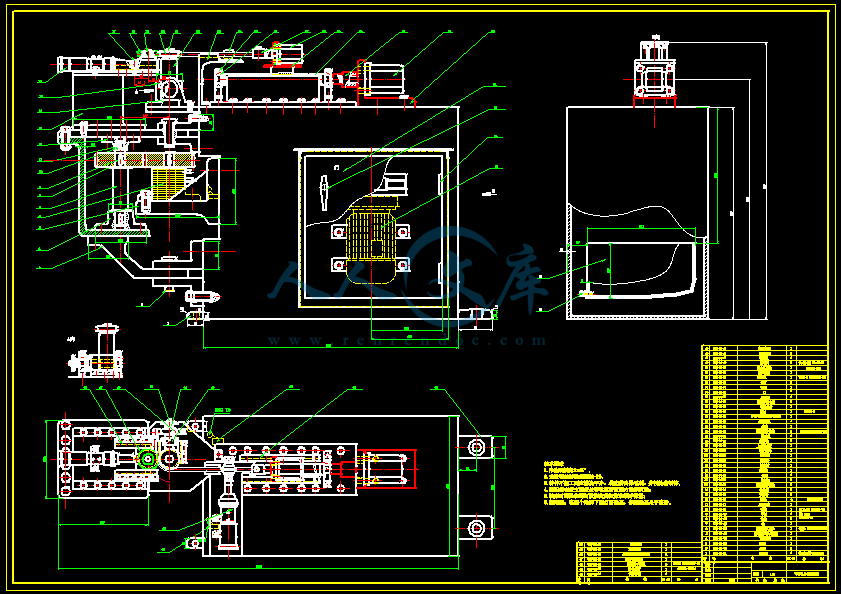

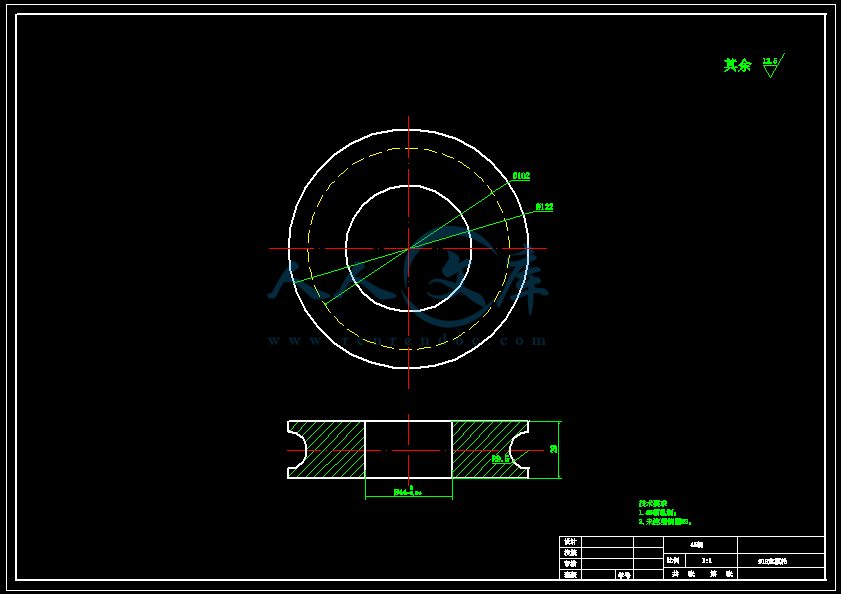

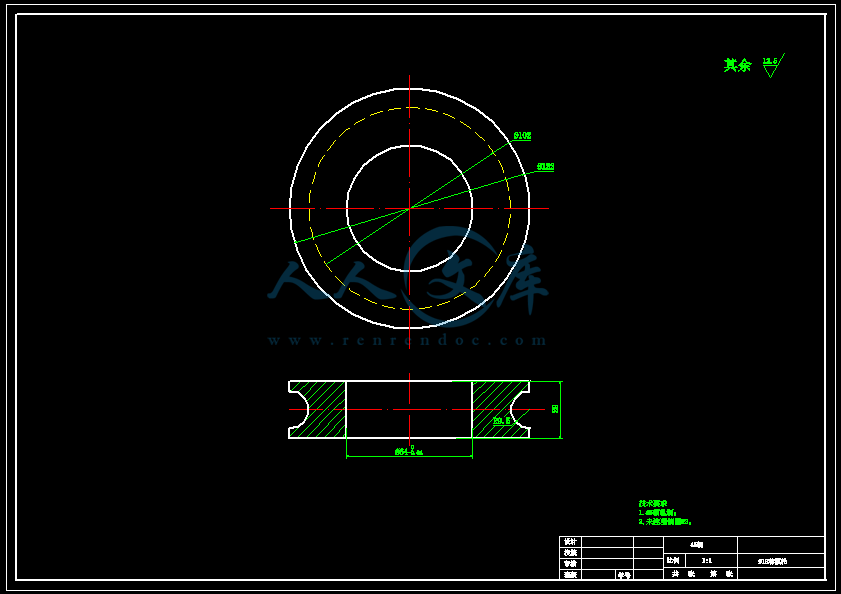

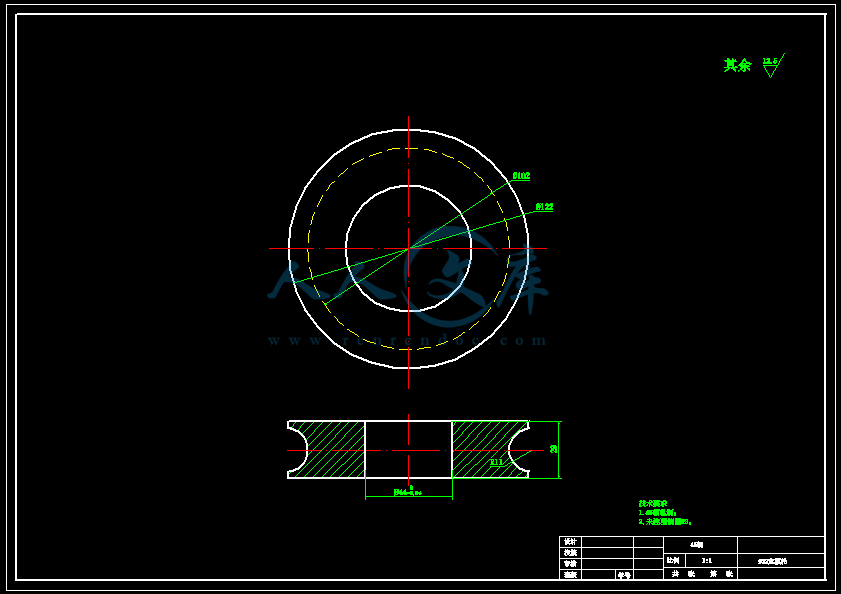

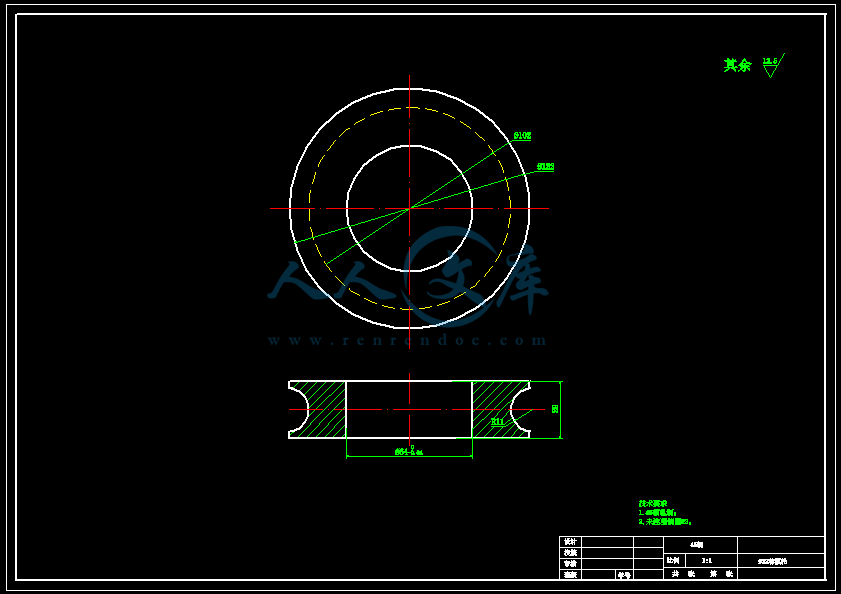

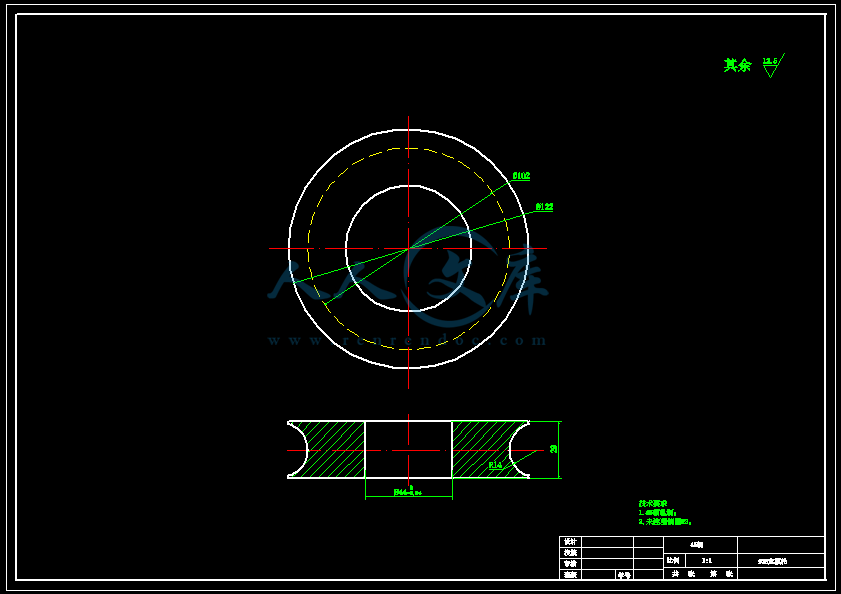

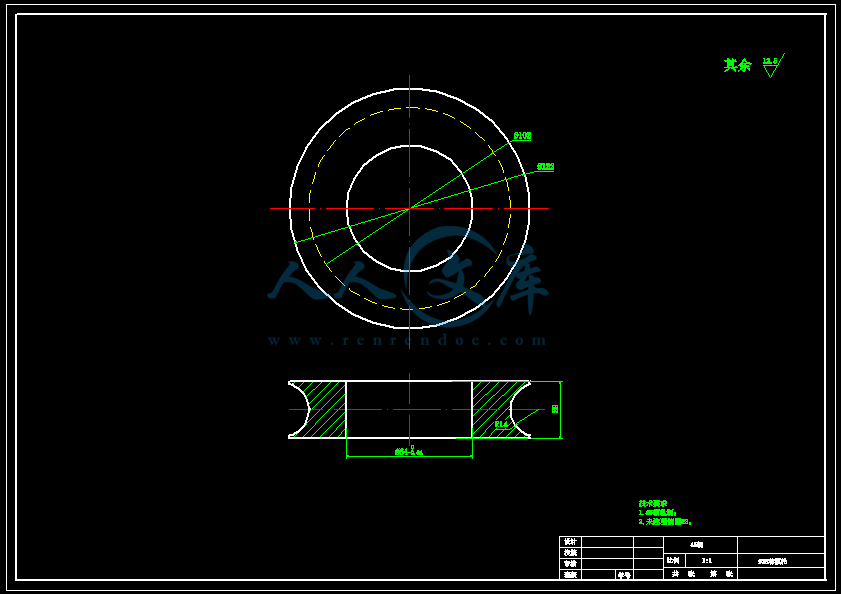

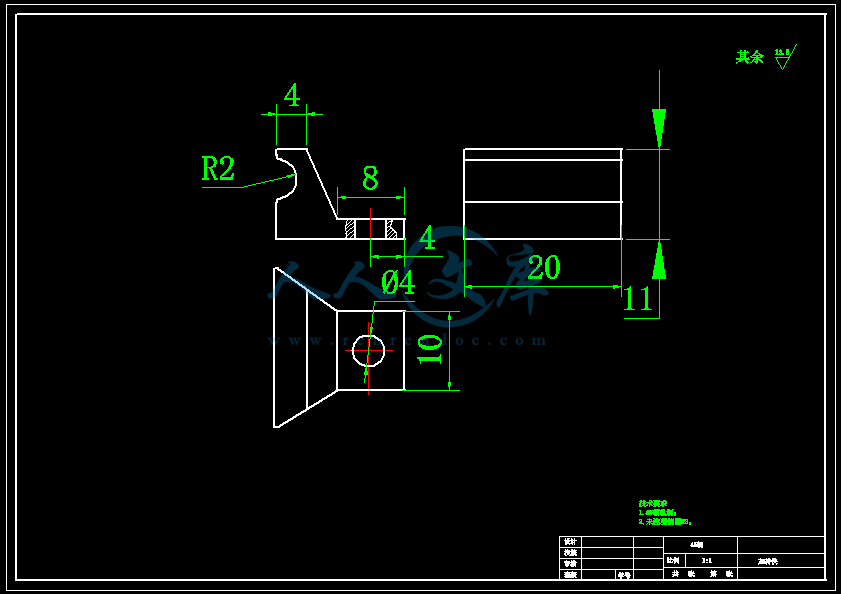

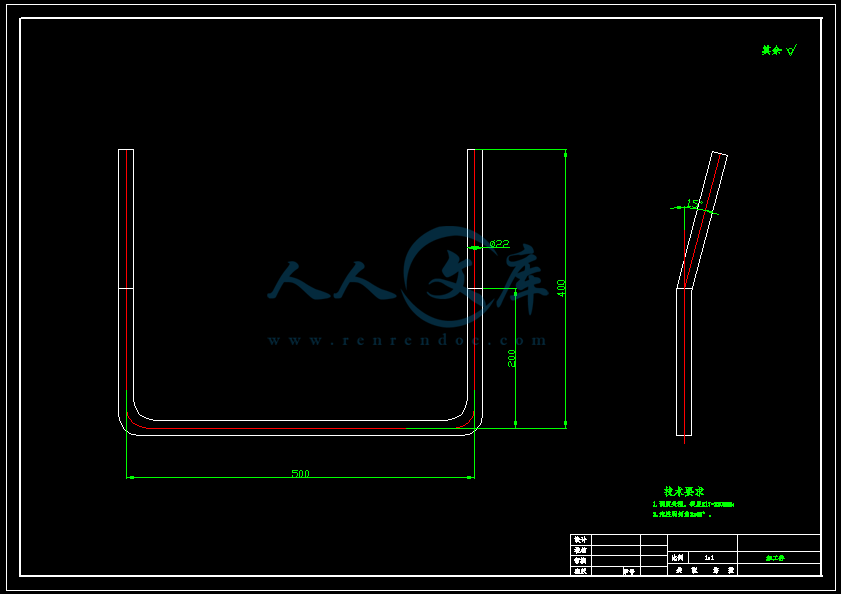

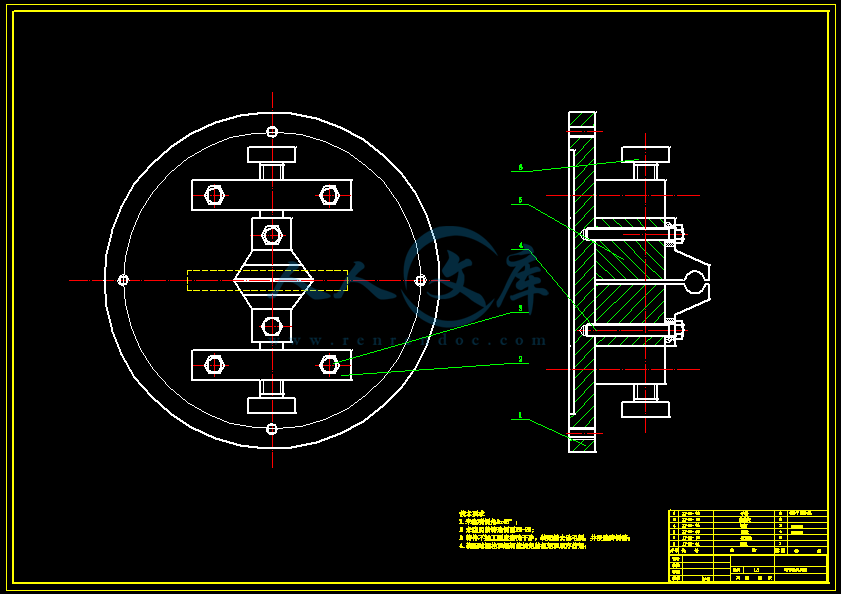

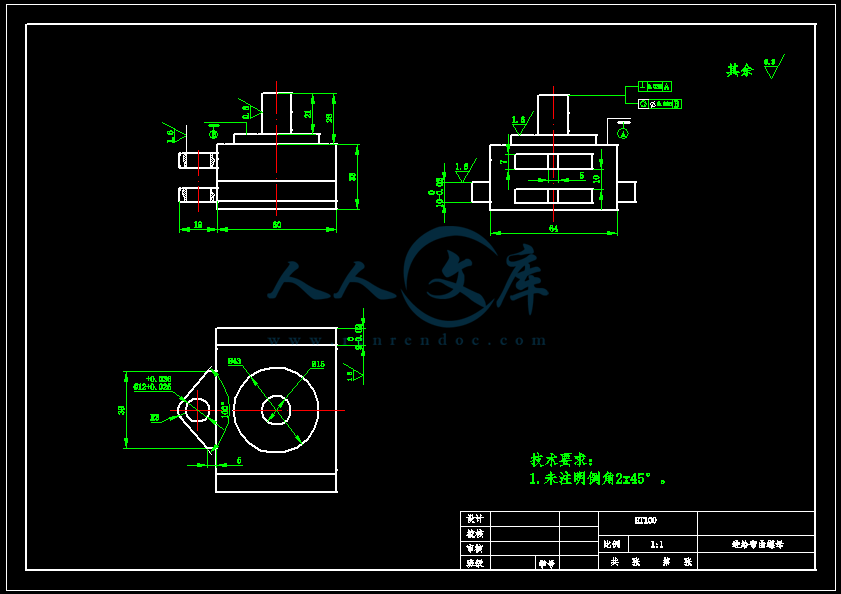

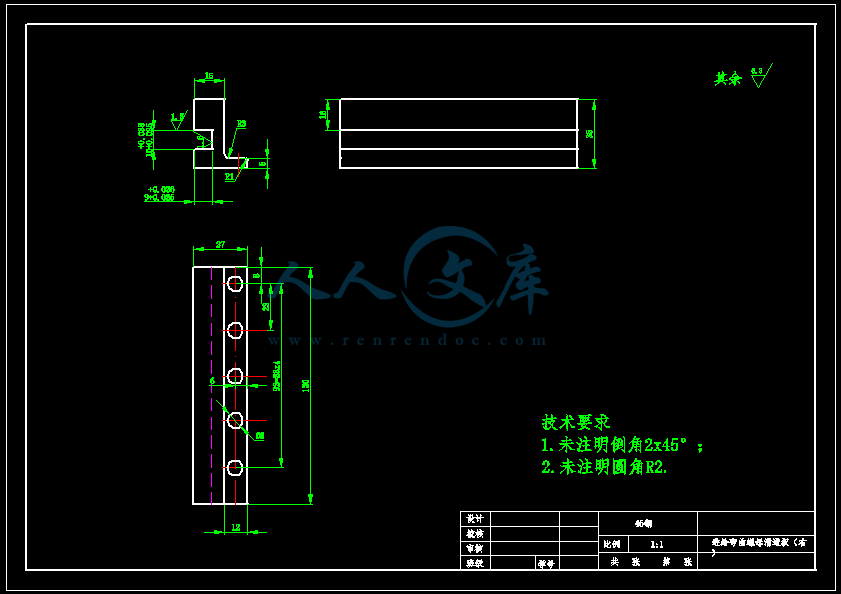

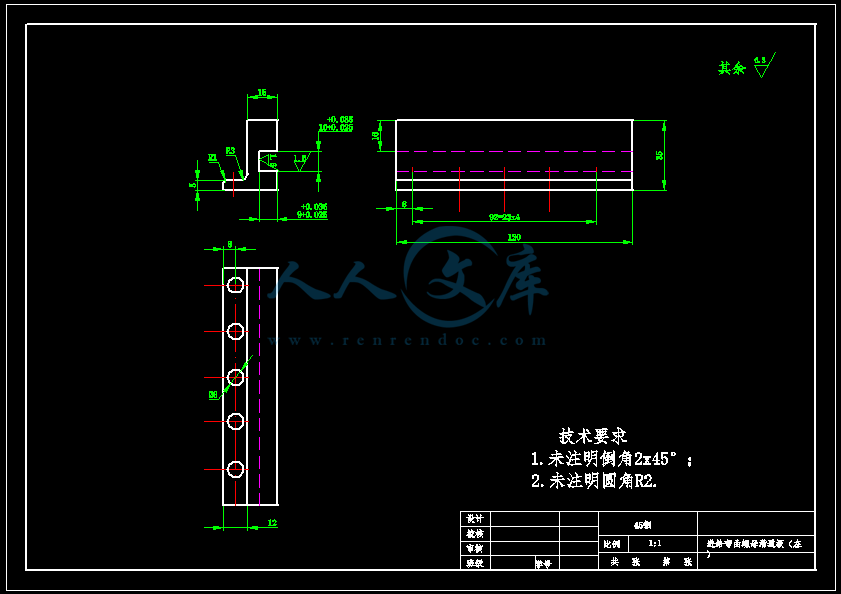

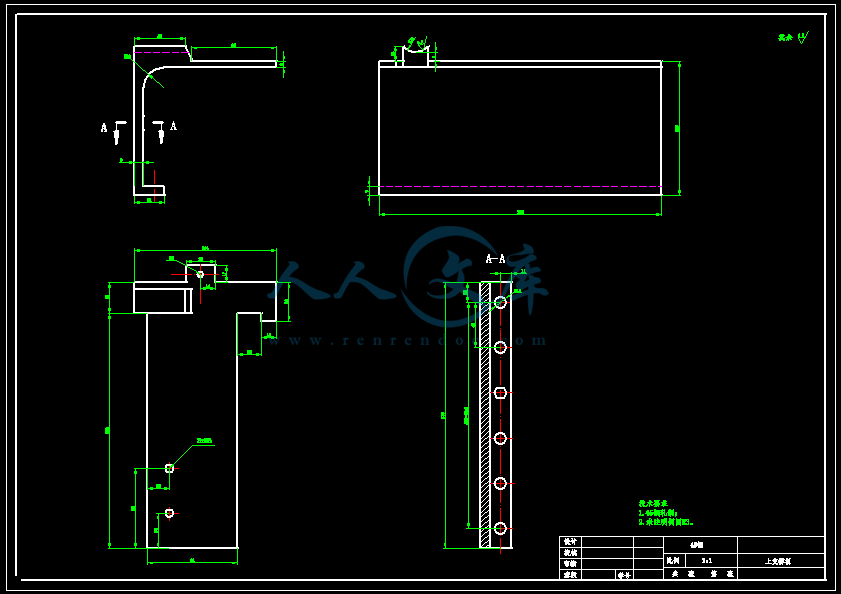

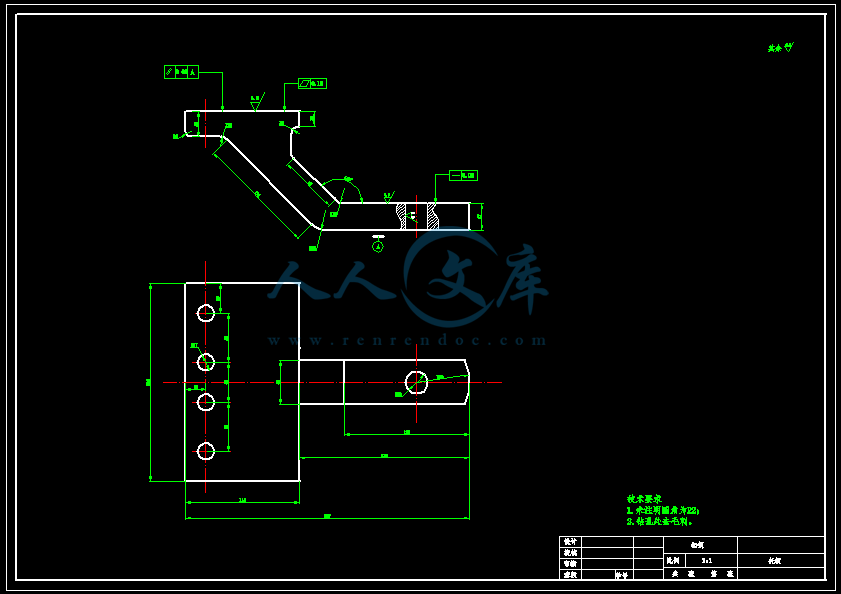

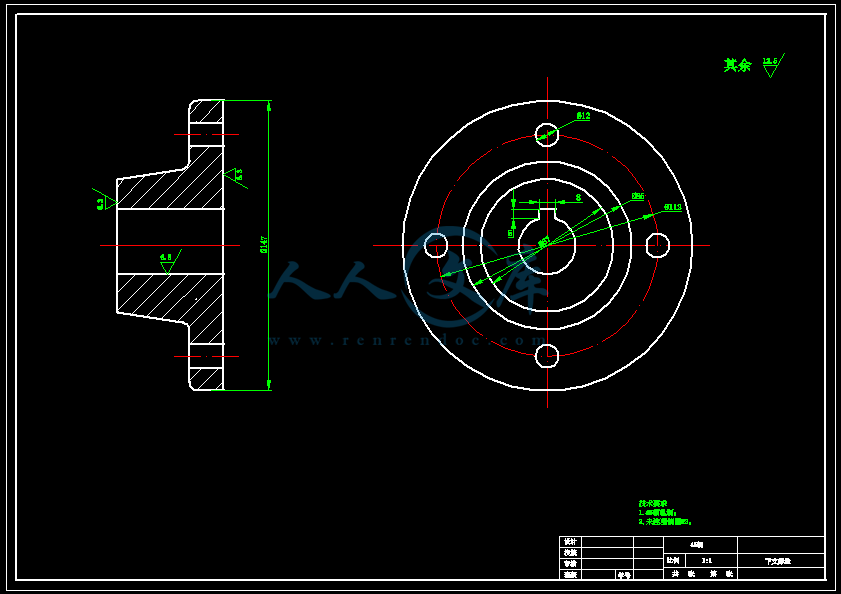

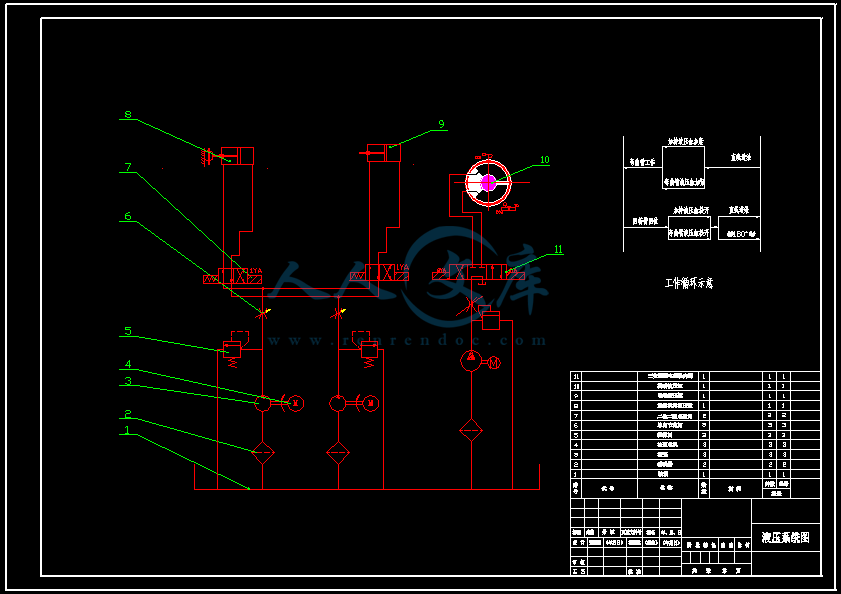

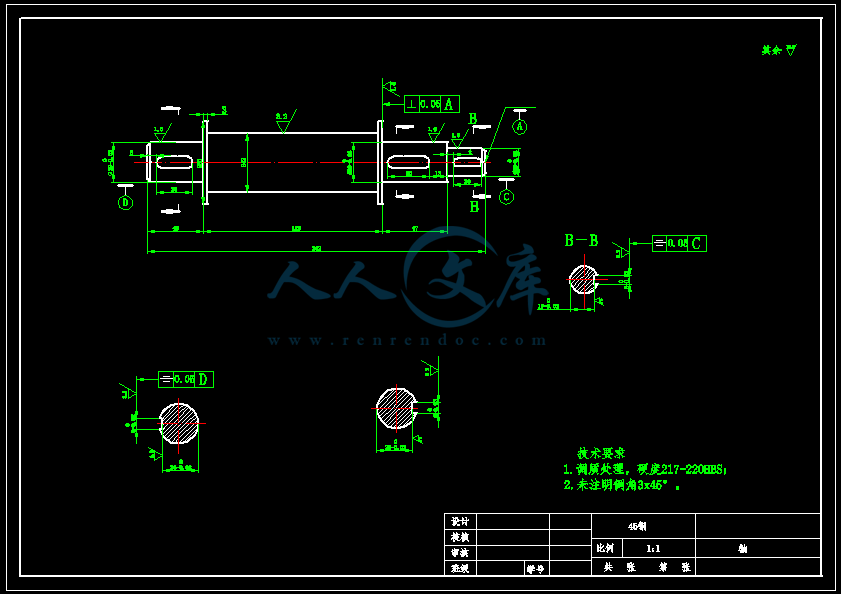

【温馨提示】压缩包内含CAD图有下方大图片预览,下拉即可直观呈现眼前查看、尽收眼底纵观。打包内容里dwg后缀的文件为CAD图,可编辑,无水印,高清图,压缩包内文档可直接点开预览,需要原稿请自助充值下载,所见才能所得,请见压缩包内的文件及下方预览,请细心查看有疑问可以咨询QQ:11970985或197216396

- 内容简介:

-

机械工程摘要:机械工程是工程学的一个分支,它主要研究机械和动力学。蒸汽机的发明标志着工业革命的开始,人们利用蒸汽机提供的能源,发明各种各样的机器,同时也制造了很多与器械相关的工具。这样机械得到很大的发展,同时一个新的工程学分支从民用工程学中分离出来机械工程。机械工程已经由一门主要用于技工应用的技术发展成为专业工程师在研究、设计和生产领域中使用的科学方法。动力机械的发展生产机械必须先有充足的动力供应。新的机械工程业面临的最初挑战之一就是增加热效率和动力, 这一点随着蒸汽涡轮机和大的联合蒸汽锅炉的发展而基本实现了。生物工程是机械工程中的一个相对新的领域,它用来替换或增加人体功能的机器和进行医疗的设备。 人造肢体已被开发出来, 并且具有诸如有力的运动和触摸反应等人体功能。 在人工器官移植手术方面的发展史迅速的, 复杂的心肺机器和类似的设备使越来越复杂的手术得以进行, 并使受重伤和重病病人的生命功能得以持续。机械设计是设计具有机械性质的事物或系统,机械工程设计包括所有的机械设计,但它研究得更广,因为它也包括所有机械工程的分支科学,设计的各个阶段设计的整个过程从开始到结束,在这一过程中, 设计是以认定一个需求并决定去为它做些什么而开始的。经过很多重复之后,最后提出满足这一要求的计划而结束这一设计过程。关键词:机械工程 蒸汽机 动力机械 机械设计1.机械工程的历史18世纪后期,蒸汽机的发明为工业革命提供了一个主要的能量,它极大地推动了各种机械的发展。这样,一个新的工程学的重要分支从民用工程学中分离出来的关于工具和机器的分支就发展了起来,并随着在1847年英国伯明翰机械工程师协会的建立得到了正式承认。机械工程已经由一门主要用于技工应用的技术发展成为专业工程师在研究、设计和生产领域中使用的科学方法。从最广义的角度讲,增进效率的需求不断地促使机械工程师提高工作质量,并要求他接受中高程度的教育和训练。不仅机器运转要讲求经济,而且基建费也要降到最低。2.机械工程的领域商品机械的发展在发达国家中,高水平的物质生活很大程度上取决于机械工程中得以实现的各种机械。 机械工程师们不断地发明机器来生产商品,不断的开发精确性和复杂性越来越高的机械工具来生产机器。机械发展的主要线索是:为提高生产率而增加机器的运转速度、为获得物美价廉的产品而提高精度以及降低生产成本。这3个要求促进了复杂的控制系统的发展。最成功的机械制造是其机器的机械设计能与控制系统紧密融合,不论这种控制系统从本质 上是机械的还是电子的。现代化的汽车发动机生产传送线(传动带) 就是一系列复杂的生产工艺机械化的很好例子。人们正在着手开发以使机械生产进一步自动化,利用计算机来存储和处理大量数据,这些数据是少量多功能机床生产多种零件所必须的。其中一个目标就是使批量生产车间完全自动化,三班轮换, 但每天只需一班人员来操作。 动力机械的发展生产机械必须先有充足的动力供应。 蒸汽机最先提供了用热能来产生动力的实际可行的方法, 在旧有的人力、风力和水力之外增加了动力源。 新的机械工程业面临的最初挑战之一就是增加热效率和动力, 这一点随着蒸汽涡轮机和大的联合蒸汽锅炉的发展而基本实现了。20世纪, 涡轮机为发电机提供的动力得到了持续快速的增长,同时热效率也在稳定增长,而且大电站每千瓦的资本消耗也在下降。最后,机械工程师们获得了核能源。这种核能源的应用需要有特别高的可靠性和安全性,这就需要解决许多全新的问题。大型电厂和整个核电站的控制系统已变成高度复杂的电子、流体、电、水力和机械零件的网络这一切都涉及到机械工程师的所有学术领域。小型的内燃机,不论是往复式(汽油机和柴油机)还是旋转式(燃气轮机和旺克尔机),以及它们在运输领域的广泛应用也都要归功于机械工程师们。在整个运输业,不论是在空中和太空, 还是在陆地和海洋,机械工程师创造了各种设备和动力装置,他们越来越多的与电气工程师合作,尤其是在开发适合的控制系统方面。 军用武器的开发机械工程师应用于战争的技术与民用中需要的类似,尽管其目的是增强毁坏力而不是提高生产率。然而,战争的需要使得大量的资源用于技术领域,很多发展在和平时期有着深远的效益。喷气式飞机和核反应堆就是众所周知的例子。生物工程是机械工程中的一个相对新的领域,它用来替换或增加人体功能的机器和进行医疗的设备。 人造肢体已被开发出来, 并且具有诸如有力的运动和触摸反应等人体功能。 在人工器官移植手术方面的发展史迅速的, 复杂的心肺机器和类似的设备使越来越复杂的手术得以进行, 并使受重伤和重病病人的生命功能得以持续。 环境控制机械工程师的一些最初的努力是要通过抽水来排涝或灌溉土地以及给矿井通风来控制人类的环境。 现代的制冷和空调厂普遍采用反向的热引擎,在这些地方动力吧热从冷的地方抽出送到更热的外部。 很多机械工程的产品以及其他领域的技术发展对环境有副作用, 产生了噪音, 引起了水和空气的污染,破坏了土地和风景。 商品和动力的生产率提高太快,以至于自然力的再生跟不上步伐。对于机械工程师和他人来说,环境控制是一个快速发展的领域,它包括开发尽可能产生少量污染物的机器和生产上序,以及开发新的设备和技术来减少和消除已造成的污染。3.机械工程设计 机械设计是设计具有机械性质的事物或系统, 如:各种机器、产品、结构、器械和仪表在很多情况下, 机械设计要用到数学、材料科学和工程力学等学科的知识。机械工程设计包括所有的机械设计,但它研究得更广,因为它也包括所有机械工程的分支科学, 如热力学和流体力学除了所需的基本学科外, 在机械工程设计中最初学习的还是机械设计。 设计的各个阶段设计的整个过程从开始到结束,在这一过程中, 设计是以认定一个需求并决定去为它做些什么而开始的。经过很多重复之后,最后提出满足这一要求的计划而结束这一设计过程。 设计中考虑的因素,有时在某个系统中零件所需的强度是决定这零件的几何形状和尺寸大小的重要因素在这种情况下, 我们说强度就是设计中要考虑的重要因素。 当我们使用设计考虑因素这一表达方式时, 我们是指影响零件设计或许整个系统设计的一些性能。 在指定的设计情况下, 通常必须对一系列这样的性能加以考虑。然而, 为正确起见,我们应看到, 在很多设计情况中, 重要的设计考虑因素是不需进行计算或试验就能确定此零件或系统。特别是学生们, 当处于需要做出重要的设计决定而实际上又无法进行任一运算的情形时, 他们常常感到困惑。这些并不是特别的情况,他们每天都发生、设想一下,比如在一个医疗实验室机械的设计中,从销售的角度看, 人们期望产生具有很高的强度和实用性的印象。 厚重的零件安装在一起:能产生机器很坚固的印象。 而有时机器和零件的设计完全是从风格的角度而并非其他角度考虑的。 我们陈述这些的目的就是为了你不被误导去相信每个设计决定都需要合理的数学方法。制造是指企业参与把原材料变成成品。制造有3个明确的阶段。他们是:输入、加工输出。第一个阶段包括所有生产符合市场需要产品的必要因素。首先要有对该产品的需求, 有必要的材料, 同时还需要诸如能源、时间、人类的知识和技术等资源。最后, 需要资金来获取所有其他的资源。 输入阶段的资源经过第二个阶段的各个过程加以分配。这些过程吧原有材料加工成成品。先完成设计,基于这个设计, 再形成各种计划。计划通过各种生产工艺得以实施。对各种资源和工艺进行管理以保证效率和生产率。 例如必须要仔细管理资源以确保使用得当。最后, 所谈论的产品被投入市场。最后阶段是输出阶段或成品阶段。一旦成品为人所购买, 就必须把它运送到用户手中。根据产品的性能, 可能要进行安装和进一步调试, 此外有些产品尤其是那些非常复杂的产品对用户进行培训很重要。4.制造中的材料和工艺这里所说的工程材料分成两大类:金属和非金属材料。金属材料又进一步分为黑色金属和有色金属、高性能合金和粉末金属。 非金属进一步分为塑料、合成橡胶、复合材料和陶瓷。 这里所说的生产过程分成几个打的过程, 其中包括成型、锻造、铸造翻砂、热处理、固定连接,计量质量控制以及材料的切削。 其中的每一个工艺又可进一步分成其他的工艺。 制造业发展的各个阶段这些年来, 制造过程走过了四个截然不同的发展阶段, 尽管相互重叠。 这些阶段是:第一阶段手工阶段,第二阶段机械化,第三阶段自动化, 第四阶段集成化。当人类最初将原材料加工成成品时,他们使用手工工艺。每件东西都是用手和手工操作的工具制成的。 这是完全集成化生产的雏形。 一个人确定需求、收集材料、设计一个产品来满足这种需求,生产这种产品并使用它。从开始到结束, 一切都集中于做这个工作的人的头脑中。后来在工业革命时期引入了机械化的生产过程, 人们开始使用机器来完成先前手工完成的工作。 这导致了工作的专门化。专门化反过来也减少了制造中集成化的因素。在这一发展阶段, 制造工人仅能看到他们生产的具体的工件所代表的整个生产过程的那一部分。人们无法说明白他们的工作是如何配合整个生产过程的,或者他们生产的零件时如何装进一个成品的。制造工艺发展下的一个阶段是选定的工艺的自动化。 这就是用计算机控制机器和工艺。 在这一阶段, 自动化孤岛开始出现在车间里。每个岛代表了产品生产的一个明确的工艺或一组工艺。 尽管这些自动化孤岛的确提高了岛内部的单个工艺的生产率,但是整体的生产率往往没有变化。这是因为这些岛是夹在其他没有自动化的生产过程的中间,而且不与他们同步。最终的结果是,工件高校快速的通过自动化的工艺,可是却在人工部分停滞了下来,造成了瓶颈现象。为更好的理解这一问题,你可以设想一下在交通高峰期驾车从一个红灯处到下一个红灯处的情景。偶尔你会找到车少的地段,超过正在缓慢移动的车,可结果却发现在下一个红灯处被耽搁了。你在短时间的加速行驶的实质的效果被下一个红灯处的阻塞抵消了。如果你和其他司机能使你们的速度与红灯的变化同步。就会前进的更快。那么,所有的车都会始终如一地、平稳地运行,最后每个人都前进较快。在车间里对稳定同步的流水作业的需求,促使了集成化制造的发展。这是一个仍在形成中的工艺。在完全集成化情况下,机器和加工都是计算机控制的, 集成化也是通过计算机完成的。比如在上一段的模拟问题中,计算机将使所有车的行进与红灯的变化相配合。以使每个人都能稳定地行驶。科学地分析运动、时间和各种力的学科叫力学,它由两部分组成:静力学和动力学。静力学研究分析静止不动的系统,也就是说在这些系统中,时间不是考虑的因素, 而动力学研究分析随时间变化而变化的系统。动力学也由两部分构成。欧拉在1775年首次将它们看作两个不同的分支:刚体运动的研究可以方便地分成两部分: 一是几何, 另一个是力学。 第一部分是在不考虑运动原因的情况下来研究刚体从一个指定位置到另外任一点的移动,而且必须用解析公式来体现,公式将确定刚体没一点的位置。因此, 这一研究仅仅是关于几何学的, 更确切地说是关于实体物切割术的。 很明显, 把一部分和本来属于机械学的那一部分分开,从动力学原理来研究运动, 这比把两部分合起来考虑容易很多。 属于动力学的这两部分后来被分成两个不同的学科, 运动学和动力学, 分别研究运动和产生运动的力。 因此, 设计机械系统的首要问题是理解它的运动学。运动学研究运动, 而不是研究产生它的力。更确切的运动学是研究位移、位置、旋转、速度、速率和加速度的学科,比如说, 研究行星或轨道的运动也是一个运动学问题。 在上述引用的内容中应注意的是欧拉把动力学分成运动学和动力学是基于它们是研究刚体的假设基础之上的。 在这个非常重要的前提基础上才允许分别对待这两门学科。对于柔体、柔体本身的形状乃至于柔性物体的运动取决于作用于它们身上的力。在这种情况下,须同时研究力和运动, 因此很大程度上增加了分析的复杂性。幸运的是,尽管真正的机器零件或多或少都是可弯曲的,设计机器时通常是设计用刚性材料, 使零件挠曲降到最低。因此,当分析机器的运动学的性能时,人们常常假设挠曲是可忽略的,零件是刚性的, 而且当载荷以知时, 在运动分析结束后, 再设计零件以便证实这个假设。Mechanical engineeringAbstract:Mechanical engineering is a branch of engineering, it mainly study mechanical and dynamics. The invention of the steam engine marks the beginning of the industrial revolution, people use steam engine to provide energy, invented all kinds of machine, also made a lot of tools and equipment related. This machine got a lot of development, and a new engineering branch of civil engineering from separate-mechanical engineering. Mechanical engineering has a mechanic is mainly used in the application development of technology of becoming a professional engineer in research, design and production in the field of the scientific method to use.The development of mechanical power production machinery must first have plenty of power supply. New mechanical engineering is one of the first challenges facing increase the thermal efficiency and power, this with steam turbines and large joint steam boiler and the development of the basic realization. Biological engineering is one of the mechanical engineering relatively new field, it is used to replace or increase the bodys function of machine and medical equipment. Artificial limbs have been developed, and has the powerful sports such as touch response and human body function. Artificial organ transplant surgery in the history of the development of the rapid, and complex cardiopulmonary machine and similar equipment to make more and complex surgery are to be carried out, and seriously wounded and serious illness the patients life function continues. The mechanical design is the design of mechanical properties of things or system, mechanical engineering design including all of the mechanical design, but it research wider, because it also includes all mechanical engineering branch of science, design of each stage of design the whole process from start to finish, in the process, the design that is a demand for it and decided to do something and began. After many after repeated, and finally put forward to meet the requirements of the plan and a end the design process.Key words: Mechanical engineering Steam engine Power machinery Mechanical design1. The history of mechanical engineeringThe late eighteenth century, the invention of the steam engine for the industrial revolution offers a major energy, which greatly promoted the development of of all kinds of machines. So, a new engineering is an important branch of the civil engineering from separate about tools and machine of the branch is development up, and in 1847, with the Birmingham mechanical engineer, the establishment of the association was formally recognized. Mechanical engineering has a mechanic is mainly used in the application development of technology of becoming a professional engineer in research, design and production in the field of the scientific method to use. From the standpoint of the most general, increase the efficiency of the mechanical engineer to demand constantly improve the quality of work, and ask him to accept the education and training of high degree. Not only machine wants be particular about the economy, and JiJianFei will to a minimum.2. Mechanical engineering fieldThe development of mechanical products in developed countries, a high level of material life depends largely on the mechanical engineering to the realization of all kinds of machinery. Mechanical engineers constantly invention machines to produce goods, the continuous development of high accuracy and complexity more and more mechanical tools to production machines. The development of mechanical main clue is: to increase productivity and increase machine operation speed, to gain the good and cheap products and improving precision and reduce the production cost. The three requirements promote the complex control system development. The most successful machinery manufacturing is the mechanical design of the machine can control system with closer integration, whether this kind of control system from essentially is the mechanical or electronic. Modern automobile engine production transmission line (transmission belt) is a complex set of production process of mechanized very good example. People are to develop in order to make mechanical production further automation, the use of a computer to storage and processing of large quantities of data, the data is a few multi-function machine produces various parts must. One of the goals is to make the batch production workshop is fully automated and class 3 rotation, but every day just a personnel to operate. The development of mechanical power production machinery must first have plenty of power supply. The first steam engine provides on the power of heat to transform the producing power practical ways, in the old human, wind and hydraulic increased outside power supply. New mechanical engineering is one of the first challenges facing increase the thermal efficiency and power, this with steam turbines and large joint steam boiler and the development of the basic realization. The 20 th century, turbines for generators to provide power to get the continuous rapid growth, and the thermal efficiency is also in steady growth, and big power plant every kilowatts of capital cost is also on the decline. Finally, mechanical engineers won the nuclear energy. The nuclear energy application needs a special high reliability and safety, this need to solve the many new problems. Large power plants and the whole control system of the nuclear power station has become a highly complex electronics, fluid, electric, hydraulic and mechanical parts of the network all this involves the mechanical engineer all academic field. Small internal combustion engines, whether reciprocating (gasoline and diesel engine) or rotary (gas turbine and prosperous Kerr machine), and they are in the field of transportation and the wide application of thanks to a mechanical engineers. In the whole transportation, both in the air and space, or on land and sea, mechanical engineer created various equipment and power plant, they more and more and electrical engineer cooperation, especially in suitable for the development of control systems. The development of military weapons used in the mechanical engineer and technical and civil war need in similar, although its purpose is to enhance destroy force not to raise productivity. However, the needs of war makes a large amount of resources in technology, many development in times of peace is of profound benefits. Jet aircraft and nuclear reactor is known as a example.Biological engineering is one of the mechanical engineering relatively new field, it is used to replace or increase the bodys function of machine and medical equipment. Artificial limbs have been developed, and has the powerful sports such as touch response and human body function. Artificial organ transplant surgery in the history of the development of the rapid, and complex cardiopulmonary machine and similar equipment to make more and complex surgery are to be carried out, and seriously wounded and serious illness the patients life function continues. Environmental control of some of the original mechanical engineer in the effort to through pumping irrigation and drainage or to land for mine ventilation to control the human environment. The modern refrigeration and air conditioning enterprise widespread use of the reverse of heat engine, where power it heat from cold place to take hotter outside. A lot of mechanical engineering products, as well as other areas of technology development of environment have side effects, and produced the noise, caused the water and air pollution, destruction of the land and the scenery. Goods and the power of the productivity of too fast, so that the regeneration of the natural force to keep up with the pace. For mechanical engineers and others for, environment control is a rapid development in the field, it includes development as produce a small number of pollutants and production machine sequence, and the development of new equipment and technology to reduce and eliminate has caused pollution.3. Mechanical engineering designThe mechanical design is the design of mechanical properties of things or system, such as: all kinds of machines, products, structure, equipment and instrument in many cases, the mechanical design should use mathematics, materials science and engineering mechanics of the knowledge of the subject.Mechanical engineering design including all of the mechanical design, but it research wider, because it also includes all mechanical engineering branch of science, such as the thermodynamics and fluid mechanics, in addition to the basic subject outside, in mechanical engineering design of the first study or mechanical design. Design of each stage of design the whole process from start to finish, in the process, the design that is a demand for it and decided to do something and began. After many after repeated, and finally put forward to meet the requirements of the plan and a end the design process. In the design of the consideration. Sometimes in a system of the strength of the decision is needed parts this part of geometric shape and size of important factors in this case, we say that strength is in the design of the important factors to consider. When we use the design considerations this expression, we mean the whole system design may affect parts of the design of some performance. In the design of the designated, usually to a series of such performance must be considered. However, for the right reasons, we should see, in many design, the design of the important factor is to calculate or test can confirm the parts or system. Especially the students, when in need to make important design decision but in fact and unable to any operation situation, they often feel confused. These are not special circumstances, they happen every day, just imagine, for instance in a medical laboratory mechanical design, from the point of view of sales, people expect has a very high strength and practical impression. Heavy parts installation together: can produce machines are very strong impression. And sometimes machines and parts of the design completely from the point of view of style and not other Angle consideration. We state the purpose of these is to you dont be misled to believe that every design decision all need reasonable mathematical method.Manufacturing is to show the enterprise the raw material into finished products in. Manufacturing has three clear stage. They are: input, processing output. The first stage includes all production meet the needs of the market of product factors necessary. The first to have demand for this product, has the necessary material, also need such as energy, time, of human knowledge and technology, and other resources. Finally, need money to get all the other resources. The input stage after the second stage of the resources of each process were distribution. The original material processing process it into finished products. Finish design, based on the design, and the formation of plan. Plan through the various production process can be carried out. To all sorts of resources and process management to ensure efficiency and productivity. For example must carefully management resources to ensure proper use. Finally, the talk was put into the market of product. The last stage is the output stage or finished stage. Once finished a buy, have had to transport it to the users hand. According to the products performance, it may be for installation and debugging further, in addition some products especially those very complex products to the user training is important.4. Production of material and processHere said the engineering materials into two categories: metallic and non-metallic materials. Metal materials and further divided into the ferrous and non-ferrous metals, high-performance alloy and powder metal. Nonmetallic further divided into the plastic, synthetic rubber, composite materials and ceramic. Here said the production process is divided into several dozen process, including molding, forging, casting/FanSha, heat treatment, fixed/connections, measurement/quality control and material cutting. One of the each process and can be further divided into the rest of the process. Manufacturing at various stages of development in these years, manufacturing process through the four very different stages of development, although overlap each other. The stage is: the first stage by stage, the second stage mechanization, the third stage automation, the fourth stage integration.When the human will initially be raw materials into finished products processing, they used manual craft. Everything is by hand and hand operated tools are made. This is completely integrated the prototype of the production. A person define demand, collecting material, design a product to meet this need, produce such products and use it. From start to finish, all focused on do the work of the mind of the person. Later during the industrial revolution into the mechanization of the production process, people began to use the machine to complete previously done by hand. This leads to the work of specialization. Specialization in turn also reduced the manufacture of integrated factors. In this stage of development, manufacturing workers can see only the concrete work they produce represents that part of the whole production process. People cant say know that the work is how to cooperate with the whole process of production, or they production parts with how to put into a finished product. The development of the manufacturing process under a stage is selected process automation. This is to use the computer to control the machine and process. In this one phase, Automation Island began to appear in the workshop. Every island represents the product production a clear process or a set of process. Although these automation island did improve island of the productivity of single internal process, but the overall productivity often without change. This is because the island is caught in the other automation production process of no middle, and not with their synchronization. The end result is the work of the fast through automation technology, but in the artificial part is stagnant down and caused bottlenecks. To better understand this problem, you can imagine in the rush hour drive from a red light to the next scene of the red light. Occasionally, you will find less car location, more than was slowly moving car, can find the next a red light has been delayed. You in a short time the essence of the throttle the effect was under a red light is offset by the obstruction. If you and other drivers can make your speed and red light changes synchronization. Before the faster it into. Then, all the car will be consistently, smooth operation, and then everyone forward rapidly. In the workshop and stability of the water demand of homework synchronization, contributed to the development of the integrated manufacturing. This is a still in the process of forming. In a fully integrated case, machine and processing are computer control, integration is also through the computer to complete. For example in the last paragraph of the simulation, the computer will make all of the red car travel and match the change. In order to make everyone can steadily down.Scientific analysis, time and all kinds of force movement of the subject called mechanics, it consists of two parts: the statics and dynamics. The statics research analysis the stationary system, that is in these systems, time is not the factors considered, and

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号