基于UG的家电风扇造型设计及动态仿真

43页 20000字数+说明书+任务书+开题报告+外文翻译+UG三维图+10张CAD图纸【详情如下】

UG三维图.rar

任务书.doc

基于UG的家电风扇造型设计及动态仿真开题报告.doc

基于UG的家电风扇造型设计及动态仿真论文.doc

外文翻译--数控技术.doc

底座-A3.dwg

扇叶-A3.dwg

扇叶注塑模A0.dwg

操作面板-A3.dwg

支架-A3.dwg

旋钮-A4.dwg

电风扇A0.dwg

电风扇后盖-A4.dwg

电风扇支架-A3.dwg

相关资料.doc

计划周记进度检查表.xls

锁套-A4.dwg

摘 要

面对激烈的市场竞争,制造业必须加速产品开发进程,缩短设计开发周期。计算机技术和计算机图形学的不断发展,为人们提供了强有力的工具,三维CAD/CAM/CAE集成化软件被广泛应用于制造业。与传统的装配设计相比,虚拟装配技术能满足并行工程的要求,实现产品可装配的设计,及时发现产品设计中的问题,提高装配质量和装配效果。

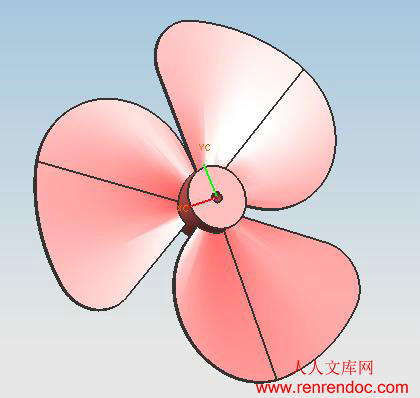

研究是在UG软件设计平台上完成风扇的三维造型设计。立式电风扇的外形结构较为复杂,如果用传统的CAD绘图软件设计非常困难,UG可以轻松解决这个问题,UG软件具有很强大的实体造型、曲面造型、虚拟产品装配仿真、工程图生成等功能。论文以从实物到模具的逆向设计过程论述了风扇虚拟设计中的关键环节,即零部件建模、虚拟装配、动态仿真和扇叶的注塑模设计等。并对产品设计中的虚拟设计方法与传统设计方法的差异、优越性进行了比对。通过可视化显示装配、干涉分析然后以求达到准确运动仿真,使生产真正在高效、高质量、低成本的环境下完成。

关键词:三维造型设计;虚拟装配;运动仿真

目 录

摘 要III

AbstractIV

目 录V

1 绪论1

1.1 三维造型设计的现状和发展前景1

1.2 常用三维造型软件介绍2

1.3 UG软件的介绍2

1.4 论文主要内容及研究意义3

2 基于UG的风扇设计5

2.1 电风扇的发展现状5

2.2 UG在产品中的设计思路5

2.3 电风扇的建模设计分析5

2.3.1 电风扇的虚拟装配介绍6

2.4 电风扇主要零件的建模绘制8

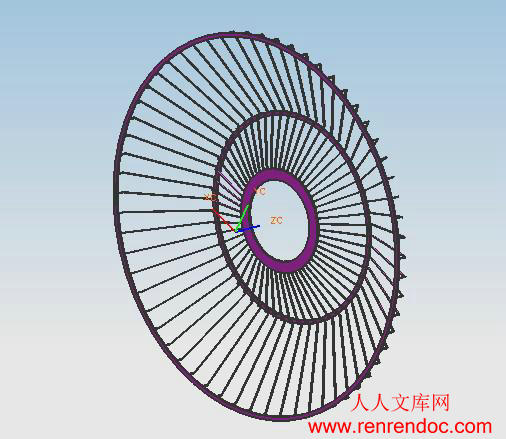

2.4.1 电风扇罩的绘制8

2.4.2 电风扇叶的绘制10

2.4.3 电风扇后座的绘制12

2.4.4 电风扇支架部分的绘制14

2.4.5 电风扇操作面板的绘制15

2.4.6 电风扇其他零件的绘制16

2.5 电风扇的装配体建模及爆炸图17

2.5.1 装配风扇本体17

2.5.2 电风扇的爆炸视图及干涉分析21

3 动态仿真24

3.1 关于动态仿真24

3.1.1 动态仿真的起源24

3.1.2 仿真技术在产品开发制造过程中的应用24

3.2 电风扇的动态仿真25

3.2.1 机构运动仿真25

3.2.2 电风扇模拟仿真25

4 电风扇叶注塑模设计29

4.1 注塑模设计的基本流程29

4.2 注塑模具的基本结构设计30

4.2.1 扇叶材料的分析30

4.2.2 分型面的选择30

4.2.3 扇叶注塑模具结构及工作原理31

5 结论与展望33

5.1结论33

5.2不足之处及未来展望33

致 谢34

参考文献35

1 绪论

计算机辅助设计是一种将人和计算机的最佳特性结合起来以用来辅助进行产品的设计和分析的技术,是综合了计算机与工程设计方法的最新发展成果一门新兴学科。它的产生和不断发展,对工业生产、工程设计、科学研究等领域的技术进步和发展产生了巨大影响。

1.1 三维造型设计的现状和发展前景

市场需求是技术创新的原动力,二十一世纪的一个重大变革是全球市场的统一,它使市场竞争更加激烈,产品更新周期加快。在这种背景下,CAD技术得到迅速普及和极大发展。1991年,美国评出的二十世纪最具影响的十大技术中,CAD便榜上有名。CAD技术从最初的工业设计领域已渗透到人们日常生活的每个角落,从机械、电子、建筑、教学、管理等,可以说无数不包。经过四十多年的发展,CAD/CAM技术有了长足的进步,而三维CAD技术到目前为止共经历了4次大的技术革新。

三维线框系统

20世纪60年代,新出现的三维CAD系统是简单的线框式系统,只能表达基本的几何信息,而不能有效地表达几何数据间的拓扑关系[1]。

曲面造型系统

法国达索飞机制造公司基贝塞尔算法,在上个世纪70年代开发出以表面模型为特点的三维造型系统 CATIA,从而标志着CAD技术突破了单纯模仿工程图纸三视图的模式,首次实现完整描述产品零件的主要信息,使得CAD技术有了实现基础。

实体造型技术

早在60年代初,就提出了实体造型的概念,但由于当时理论研究和实践都不够成熟,实体造型技术发展缓慢。70年代初出现了简单的具有一定实用性的基于实体造CAD/CAM系统,实体造型在理论研究方面也相应取得了发展。到70年代后期,实体造型技术在理论、算法和应用方面逐渐成熟。它带来算法改进和未来发展的希望,同时也带来了数据计算量的急速膨胀。

参数化设计

参数化设计是通过改动图形的某一部分或某几部分的尺寸,或者修改定义好的零件参数,自动完成图形中相关部分的改动,从而实现对图形的驱动。参数化使设计极大地改善了图形的修改手段,提高了设计的柔性,在概念设计、动态设计、实体造型、装配、公差分析与综合、机构仿真、优化设计等领域发挥着越来越大的作用,体现了很高的应用价值。

三维CAD系统的核心是产品的三维模型,它所表达的几何信息越来越完整和准确,解决问题的范围越来越广三维模型包含了更多的实际结构特征,通过赋予零部件一定的物理属性,就可以进行产品的结构分析和各种物性计算,并为后续设计制造模块应用奠定基础,使用户在采用三维CAD造型工具进行产品结构设计时,就能反映实际产品的构造或者加工制造过程,成为实现CAD/CAE/CAPP/CAM集成的基础。

我国在软件和设备方面的发展一直比较缓慢,直到进入21世纪以来,我国的计算机行业有了突飞猛进的发展,正是因为这样,我国的CAD技术才有了进一步发展的空间,在现

川公网安备: 51019002004831号

川公网安备: 51019002004831号