任务书

一.毕业设计(论文)的内容、要求

(一)内容

查找相关的资料并阅读消化,明确设计要求,分析该粉料送进装置的设计可能性和经济性等因素。对零件图纸进行结构和工艺分析,设计成型工艺;

进行市场调查,了解现有粉料送进装置的结构与工作原理,做好设计前的准备工作;

完成粉料送进装置的结构的总体尺寸设计和结构草图的绘制,模具结构总装图和零件工作图的设计绘制等;

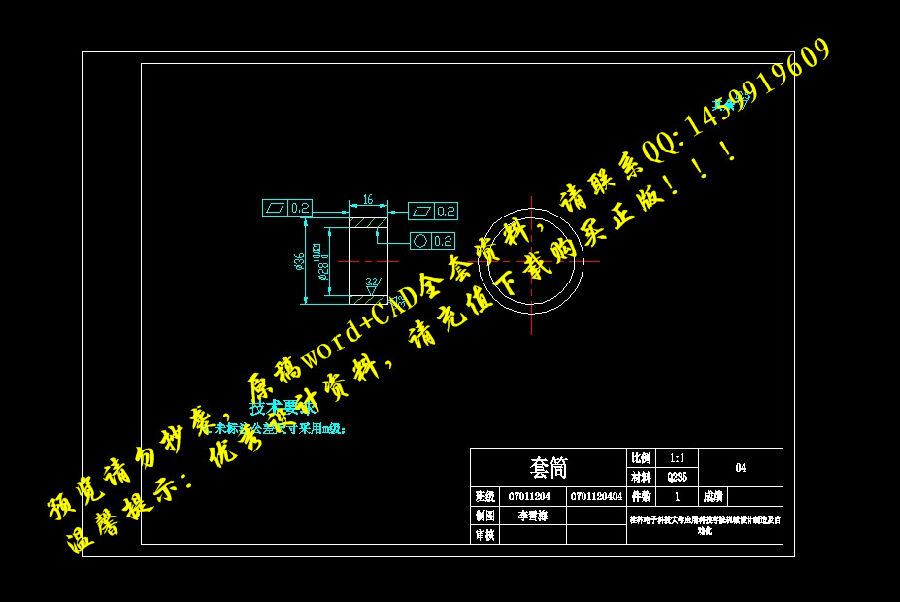

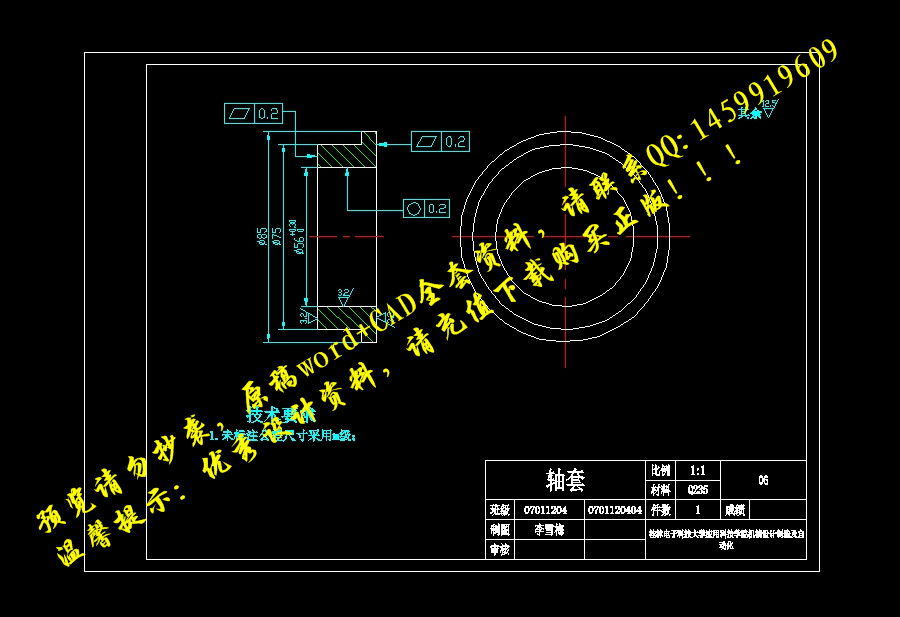

编制主要零件的制造工艺;合理选用零件的材料,绘制零件图,标注技术要求;

合理选择相关组件,进行传动系统的设计。

(二)要求

保证粉料送进装置机构的运动达到预期的要求,要求结构紧凑、合理。完成装配图的绘制。进行相关的理论计算;

完成装配图的绘制。进行相关的理论计算。确定该装置的形状特点并对其进行经济分析;

尽量选用标准件,常用件、降低成本。

二.毕业设计(论文)应完成的工作

阅读一定数量的参考文献,了解本课题国内外研究现状,撰写开题报告;

完成装置的结构总体方案设计;

合理选用标准件,完成零件间的配给选用及相关的设计计算;

用0号图纸绘制搅拌机装置的装配图,采用CAD软件绘制零件图,绘图量达到学院 的要求;

完成二万字左右的毕业设计说明书(论文);在毕业设计说明书(论文)中必须包括300-500个单词详细的英文摘要;

独立完成与课题相关,不少于四万字符的指定英文资料翻译(附英文原文);

完成导师所指定的其它工作,并附有开题报告一份。

三.应收集的资料及主要参考文献

[1] 孙恒编. 机械原理. 北京 :高教出版社 , 2002.4

[2] 廖汉元,孔建益.机械原理. 北京:机械工业出版社,2008

[3] 濮良贵. 机械设计. 北京: 高教出版社 , 2002.1

[4] 陈国华编著.机械机构及应用.北京:机械工业出版社,2008

[5] 周开勤. 机械零件手册. 北京: 高教出版社 , 2001.7

[6] 朱张娇. 工程材料. 北京: 清华大学出版社,2004.7

[7] 杨好学. 互换性与技术测量. 西安: 西安电子科技大学出版社,2006.2

[8] 王大康. 机械设计基础.北京:机械设计出版社,2003

[9] 董玉红. 数控技术.北京:高等教育出版社,2008

[10]刘国庆等编.AutoCAD 2004基础教程[M].北京:清华大学出版社,2003

[11] 刘竹清编.Pro/E Wildfire实用教程[M].中国铁道出版社,2004

[12] Chin Fu Tsang, Thomas Buscheck, Christine Doughty. Aquifer thermal energy storage: a numerical simulation of Auburn university field experiments. Water resource research, vo1.17,No. 3, June 2000

[13] Sergison, J. Wicks, F. Mulligan, G Becker, M. Yerazunis, S. System Evaluation of Heat Pumps Operated in Both Heating and Air Conditioning Modes;Volume PAS-99, Issue 3, May 2000

四.试验、测试、试制加工所需主要仪器设备及条件

计算机一台;

摘 要

本次设计的是食品搅拌机,这种搅拌机是我们生活中使用的搅拌机的其中一种,搅拌机在生活中的应用相当的广泛,搅拌水果,奶油,得出的味道爽口,还可以搅拌蛋糕液,馅料、打蛋及和制面团,特别在酒家、饭店、面包屋以及食品厂家等作搅拌食料,揉和面团之用,是生产优质糕点的理想设备,使我们的生活更加方便。搅拌非常均匀,生产率高,质量好,成本低。整机结构紧凑,其主要组成结构包括:搅拌装置,搅拌传动系统。它是通过电动机带动皮带轮,用联轴器连接,经过减速器后通过四杆机构搅拌。本设计主要设计内容是食品搅拌机的机架设计、传动设计、搅拌动作的设计、电机选用,四杆机构设计,机架外型尺寸的确定,各零部件结构的选材、校核,完成总装图和零件图。

关键词:食品搅拌机;联轴器;四杆机构设计;传动设计;

Abstract

The design of the food mixer, this mixer is a mixer used in our lives in one of mixer applications in life quite extensive, stirring fruit, cream, come to the taste of refreshing, you can stir the cake liquid filling, beat eggs and and made the dough, especially in restaurants, hotels, housing and food manufacturers such as bread for stirring foodstuffs, dough kneading and use, is ideal for production of high quality bakery equipment, make our lives more convenient. Mixing is very uniform, high productivity, good quality and low cost. Compact structure, the structure of its main components are: stirrer, stirring drive. It is driven by the motor pulley, with the coupling connection, after a gear after the mixing through the four-bar linkage. The design of the main design elements are food mixer rack design, transmission design, mixing action design, motor selection, the four-bar linkage design, frame shapes and sizes determine the structure of each component selection, verification, complete the assembly map and part drawing.

Keywords:food mixer;coupling; four-bar linkage design;transmission design;

目 录

引言1

1食品搅拌机的工作原理和原理图3

2食品搅拌机的用途3

3食品搅拌机的设计要求和原始数据4

4设计方案的分析4

5连杆机构的设计4

5.1曲柄存在的条件5

5.2运动轨迹的计算6

6电动机选择7

6.1电动机选用的基本原则7

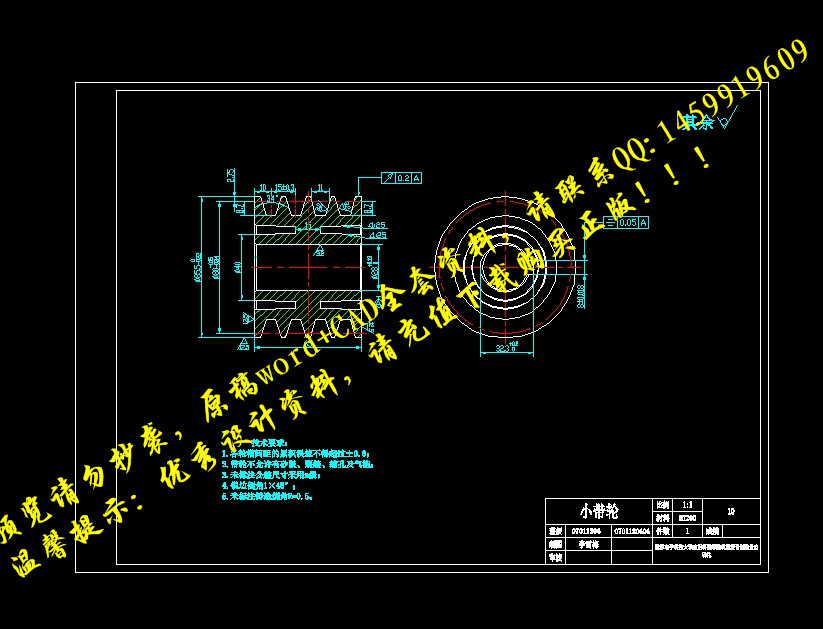

7带传动的设计9

7.1带传动组成、类型9

7.1.1传动带的组成及工作原理9

7.1.2V带的类型9

7.2带传动的设计计算和参数选择10

7.2.1确定计算功率Pc10

7.2.2确定V带的型号11

7.2.3确定带轮直径11

7.2.4确定带长及中心距a012

7.2.5验算包角13

7.2.6确定V带的根数z14

7.2.7确定初拉力F015

7.2.8计算带轮轴所受的压力Q15

7.3V带的截面尺寸15

7.4带轮的设计16

8减速器的选用18

9轴系零、部件的设计19

9.1轴的设计19

9.2轴的校核21

9.3轴承的选用23

9.3.1轴承的型号23

9.3.2滚动轴承的配合形式23

9.3.3滚动轴承的轴向定位23

9.4联轴器的选用23

9.4.1选用的联轴器型号23

9.4.2联轴器的配合形式24

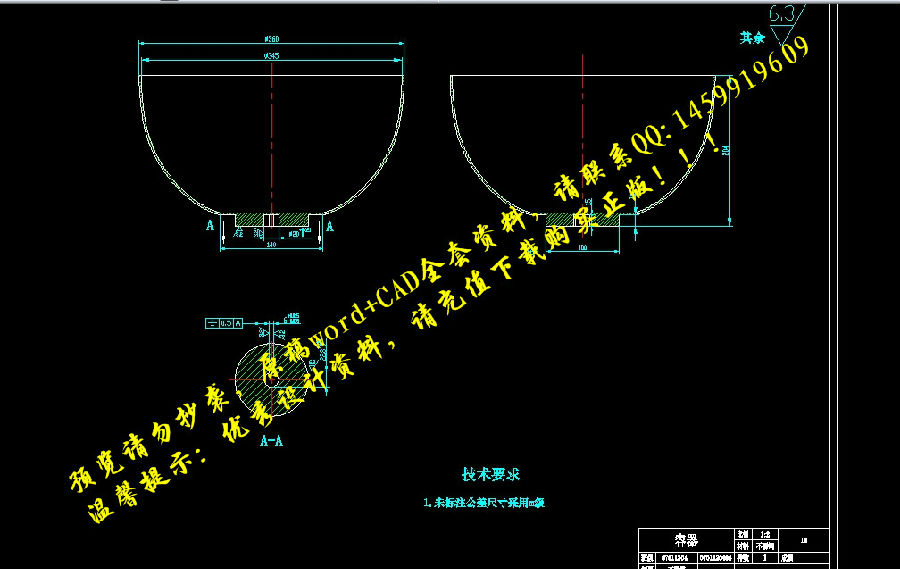

10搅拌容器的设计24

11机架的设计24

11.1底架的设计24

11.1.1底架的材料选择24

11.1.2底架的大体尺寸25

11.2支架的设计25

11.3减速器底架的设计25

12零件的加工工艺规程26

12.1工艺路线26

结论28

谢 辞30

参考文献31

附录31

引言

饮食水平是一个国家文明程度和人民生活质量高低的重要标志。食品的质量和供应状况,直接关系着全民族的体质,影响到国家的政治安定和社会进步。世界上经济发达的国家都十分重视发展食品工业。中国食品工业负有满足人民日益增长的物质文化生活需要和为国家经济建设提供积累的双重任务,是国民经济的重要组成部分。发展食品工业可以加速农业结构及其产品品质的优化调整,提高农产品经济价值,促进农业生产的良性循环。同时,对于带动和促进饲料工业、包装机械工业、机械工业、电子工业和精细化学工业等相关行业协调发展,适应餐饮业,旅游业等第三产业崛起的需要,繁荣城乡市场,扩大外贸出口以及扩大劳动就业等都具有十分重要的作用。 80年代以来,中央和地方都十分重视食品工业的发展,制定了一系列支持食品工业发展的政策。同时,国务院制定了“90年代中国食物结构发展与改革纲要”中国食品工业协会制定了“九五中国食品工业科技发展纲要”。河南省食品工业经过20多年的快速发展,各项指标已走在中国的前列,尤其是作为一个农业大省,在调整经济结构、推进农业产业化进程中,大力发展食品工业更是具有重要的意义。因此,在刚刚结束的省人代会上把以畜产品加工、粮油加工、果蔬加工为主体的食品工业做为第一大支柱产业来培育。目前,中国食品工业已初步形成门类比较齐全、技术不断进步、产品日益丰富、运销网络通畅的生产经营体系,成为国民经济中处于重要战略地位的一大产业。年产值5400多亿元。在中国各工业门类中,产值第一。

由上可知,食品机械在国民经济中的地位是如此之高。搅拌机在生活中的应用相当的广泛,搅拌水果,奶油,得出的味道爽口,还可以搅拌蛋糕液,馅料、打蛋及和制面团,特别在酒家、饭店、面包屋以及食品厂家等作搅拌食料,揉和面团之用,是生产优质糕点的理想设备。因此设计一个合理的搅拌机是非常的必要。

在目前市场上,搅拌机的种类很多,食品搅拌机也有各种各样的。因此,对一个搅拌机进行设计和研究是很有必要的,同时也有一定实践价值。从学习层面及设计手法上看:使用了UG或PRO/E等软件来完成机构的三维造型,并用软件对其机构进行模拟运动仿真,分析其可行性。这是一种有别于以前靠用做出相应的实物来验证其可行性的新设计方法。使用运动仿真的优点:节省了实验成本、缩短了设计时间、能轻易通过软件改变一些参数实现更多的验证方案、有利于创新设计的实现等等。

这是一个比较综合性的设计课题,自己的经验也不足,要想做好该课题,必须要熟悉的掌握机械原理、机械优化设计、工程力学、机械设计、数控加工、机械制造基础、产品造型等方面的一些理论知识。因此,这也是对我大学四年所学专业知识的一个综合应用。通过做此课题,我将能了解这本科四年来我对专业知识掌握的程度,同时也是一个系统的复习。这将给我以后走向社会起到一个很好的开头作用。

搅拌机包含的机构及需要实现的动作:

搅拌机构:实现模仿手的动作对食品作用。可以将搅拌机构设计为4杆机构,实现搅拌头的曲线运动。

容器机构:使容器得以不断有序的循环转动。可以将容器机构看作是一个圆周运动,容器盆下加一块装有电机的支撑板,由带传动带动容器盆旋转运动。

中间机构:实现搅拌机构与容器盘机构连接,保证他们相互间的联合运动。

食品搅拌机的工作原理和原理图

通过电机带动皮带轮转动,经过减速器减速后,传力给四杆运动,连杆上的E点作曲线轨迹和容器绕Z-Z轴的转动,达到均匀搅拌溶液的要求。四杆的运动是电动机带动皮带轮传力给四杆机构,容器的转动直接采用一个小电机带动旋转运动。其原理图1-1和框图1-2如下:

食品搅拌机的用途

用于搅拌各种食品,搅拌蛋糕液、馅料、打蛋及和制面团,特别在酒家、饭店、面包屋以及食品厂家等作搅拌食料,揉和面团之用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号