变压器储油柜端盖复合模具设计

60页 20000字数+说明书+外文翻译+11张CAD图纸

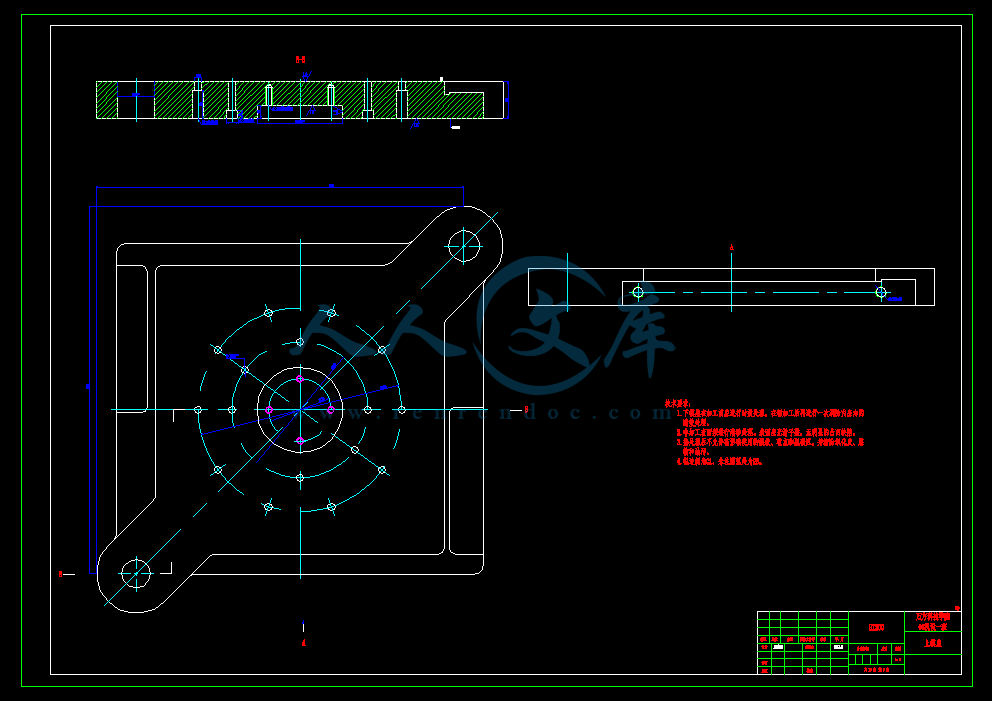

上模座A1.dwg

下模座A1.dwg

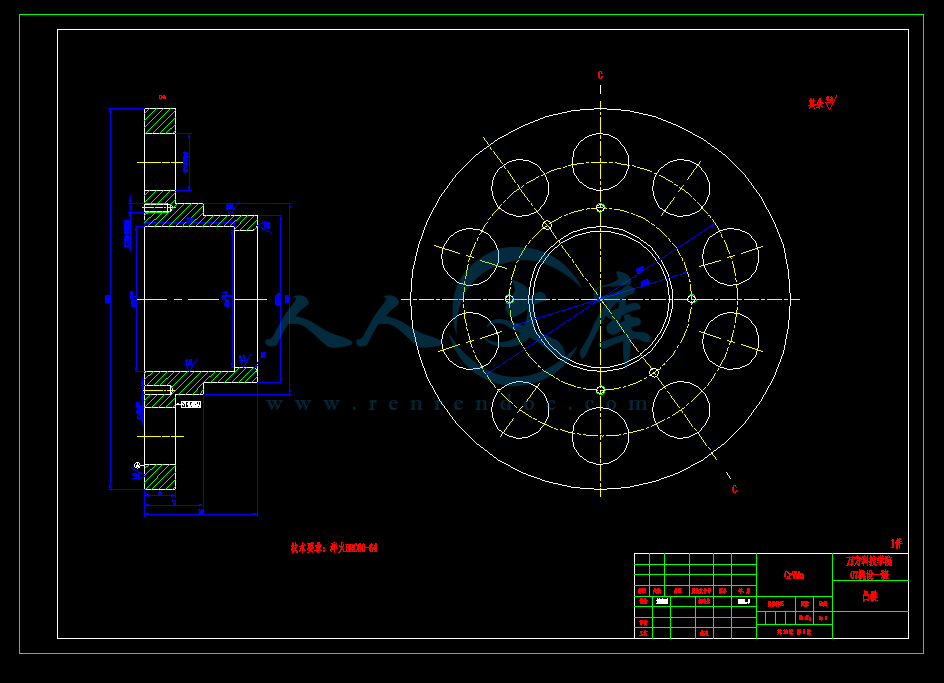

凸模1A2.dwg

凸模2A2.dwg

凸模3A4.dwg

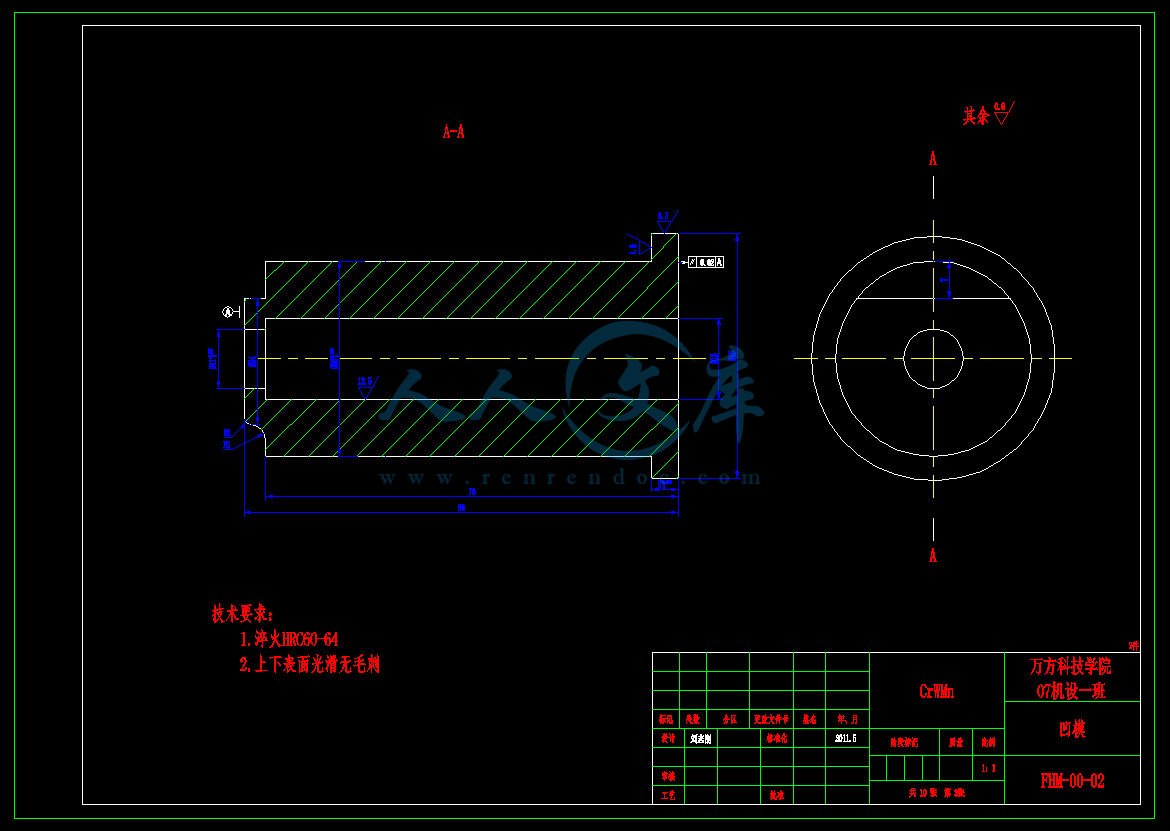

凹模1A3.dwg

凹模2A2.dwg

凹模3A3.dwg

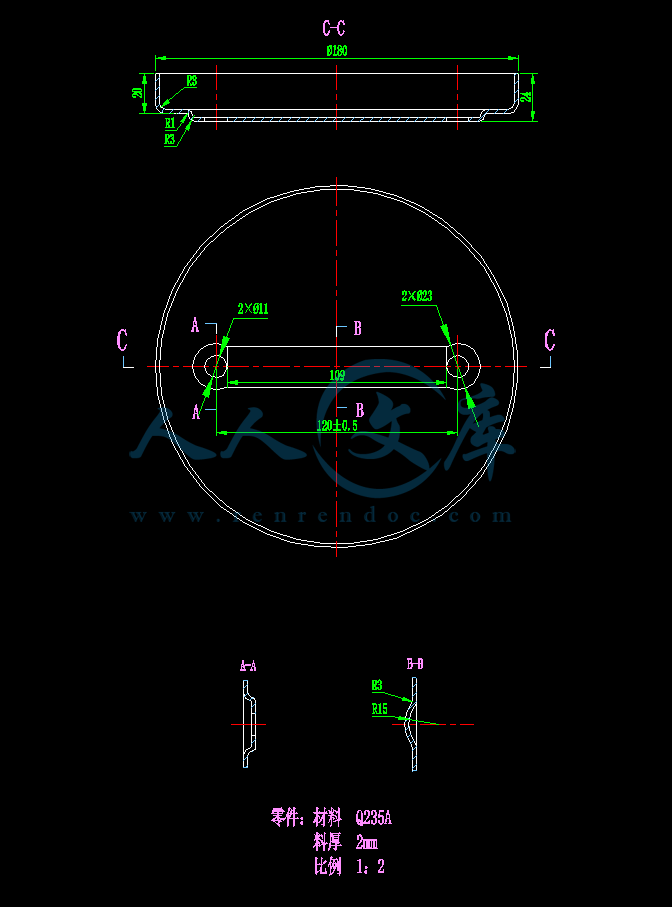

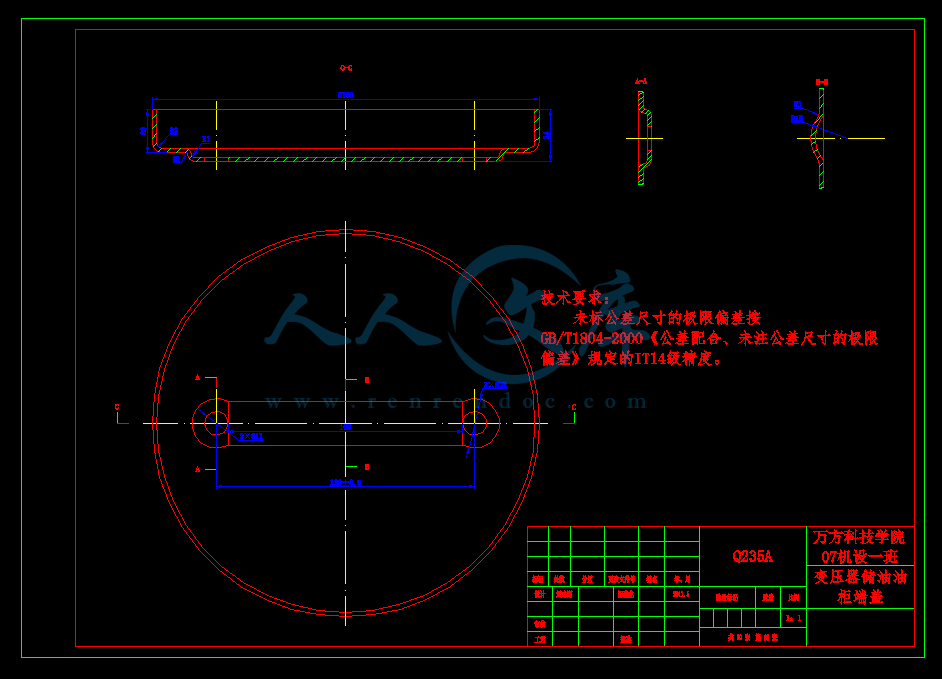

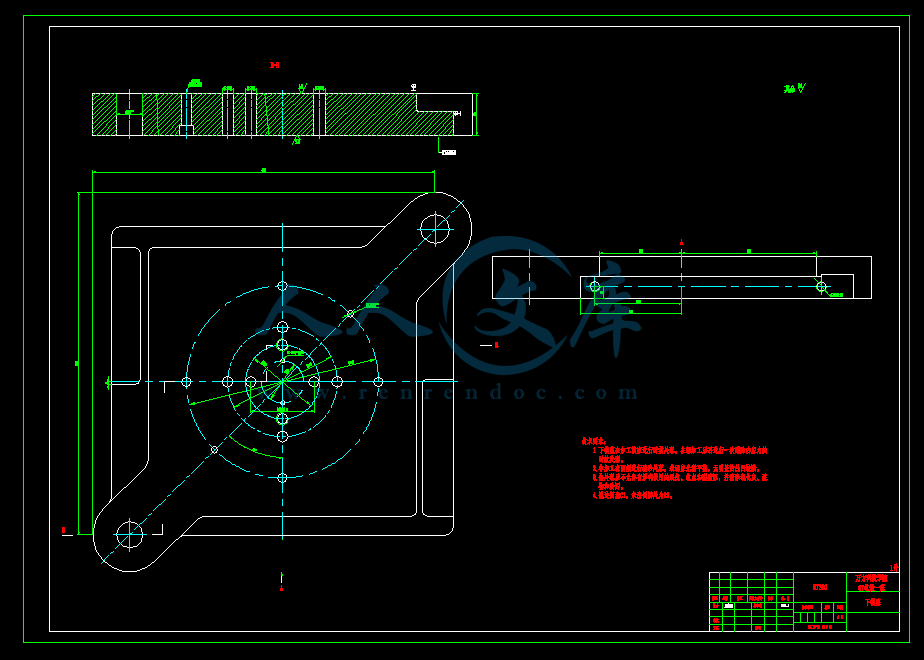

变压器储油柜端盖.dwg

变压器储油柜端盖复合模具设计论文.doc

外文翻译--单螺杆加工机床的布局和结构.doc

端盖A3.dwg

装配图A0.dwg

摘 要

分析了变压器储油柜端盖的结构和成形工艺,计算了毛坯尺寸和冲压力。为了提高端盖的生产效率,设计了集三工序为一体的落料拉深冲孔复合模的结构,经过工艺分析、结构设计,论证了其可能性,保证了制品的质量。

在模具设计中,为了提高速度和效率,充分利用已经掌握的知识和资源。利用Pro/E曲面设计功能快速求出曲面的面积。利用冲模设计手册软件版快速设计冲压模具,并对模具的强度进行检验。实践证明,确实提高了设计的速度和效率。本模具设计中,由于卸料力较大,采用了组合弹簧力较大的优点解决了这一问题。在模具结构中,用顶板做凸模的定位元件,由于配合定位的距离小,容易造成凸模的折断,因而设计了凹模导向凸模,增强了凸模的强度。

关键词:落料 拉深 冲孔 复合模 模具结构

Abstract

The structure and processing property of bellows?oil?conservator end cover for?transformers were analyzed. The blank dimensions and pressing force were calculated. The compound die of cut-tandem-punch combined with three procedures is designed in order to improve the production of end cover. The article proves its availability through technological analysis and structural design to guarantee products’ quality .

In mold design, in order to improve pace and efficiency, fully utilize knowledge and resource that has already been grasped. Utilize Pro/E curved surface design function ask , produce area of curved surface fast , utilize the design manual software edition of the trimming die to design and press the mould fast, and the intensity to the mould is examined. Practice has proved , have really improved pace and efficiency designed. In this mold design, because of unload material to be strength relatively heavy, adopt , make up spring loud advantage solve this problem. In the mould structure, make the localization component of the protruding mould with the roof, the distance making a reservation is little because of cooperating, apt to cause protruding rupture of mould, design concave mould pour , to protruding mould , strengthen protruding intensity of mould.

Key words: cut tandem punch compound die die structure

目 录

前 言1

1 绪 论2

1.1 我国模具市场的发展趋势3

1.2 模具技术的发展趋势5

1.2.1 模具产品发展将大型化精密化5

1.2.2 模具高速扫描及数字化系统将发挥更大的作用5

1.2.3 模具研磨抛光将向自动化、智能化方向发展6

1.2.4 模具标准件的应用将日渐广泛6

1.2.5 在模具设计制造中将全面推广CAD/CAM/CAE技术7

1.2.6 快速经济模具的前景十分广阔7

1.2.7 模具自动加工系统的研制和发展8

2 设计题目9

3 工艺分析12

3.1 经济分析12

3.1.1 冲压件成本分析12

3.1.2 降低制造成本的措施13

3.2 技术分析15

3.2.1 冲裁的结构工艺性15

3.2.2 拉深的结构工艺性16

3.3 变压器储油柜端盖的工艺分析20

3.3.1 材料20

3.3.2 零件结构20

3.3.3 尺寸精度21

4 工艺方案的制定22

4.1 工艺方案的分析22

4.1.1 修边余量22

4.1.2 计算毛坯尺寸22

4.1.3 确定是否用压边圈23

4.1.4 确定拉深次数(采用查图法)23

4.2 工艺方案的确定24

5 工艺计算26

5.1 材料排样及材料利用率的计算26

5.1.1 材料排样的选用原则26

5.1.2 确定板料规格和裁料方式27

5.2 冲压力的计算及设备的选择28

5.2.1 落料28

5.2.2 拉深29

5.2.3 起伏成形32

5.2.4 冲孔32

5.2.5 冲压设备的选择33

5.3 模具压力中心的确定36

5.4 模具刃口尺寸和公差确定36

5.4.1 坯料冲裁间隙的确定36

5.4.2 落料刃口尺寸的计算38

5.4.3 冲孔刃口尺寸的计算39

5.4.4 拉深工序工作部分的尺寸及间隙39

5.5 模具强度校核41

5.5.1 冲孔凸模的强度校核41

5.5.2 螺钉的强度校核42

6 模具主要零件结构设计44

6.1 弹性元件的设计44

6.1.1 弹簧的设计计算44

6.1.2 卸料橡胶的设计计算45

6.2 模架的选择45

6.3 工作零件的设计46

6.3.1 凹模刃口的结构型式确定46

6.3.2 凸模刃口的结构型式确定47

6.4 其它主要零件设计47

6.4.1 镶块的设计47

6.4.2 压边圈的设计48

6.4.3 卸料板的设计49

6.4.4 顶板的设计49

6.4.5 垫板的设计50

7 模具结构合理性分析52

7.1 模具结构图52

7.2 模具的工作过程53

结 论54

致 谢55

参考文献56

1.2 模具技术的发展趋势

1.2.1 模具产品发展将大型化精密化

模具产品成形零件的日渐大型化,以及由于高效率生产要求的一模多腔(如塑封模已达到一模几百腔)使模具日趋大型化。随着零件微型化,以及模具结构发展的要求(如多工位级进模工位数的增加,其步距精度的提高)精密模具精度已由原来的5μm提高到2~3μm,今后有些模具加工精度公差要求 在1μm以下,这就要求发展超精加工。

1.2.2 模具高速扫描及数字化系统将发挥更大的作用

英国雷尼绍公司的模具扫描系统,已在我国200多家模具厂点得到应用,取得良好效果。该系统提供了从模型或实物扫描到加工出期望的的模型所需的诸多功能,大大缩短的研制制造周期。如RENSCAN200快速扫描系统,可快速安装在已有的数控铣床及加工中心上, 用雷尼绍的SP2-1扫描测头实现快速数据采集,控制核心是雷尼绍TRACECUT软件,可自动生成各种不同数控系统的加工等程序及不同格式的CAD数据。用于模具制造业的“逆向工程”。该公司又推出了CYCLON高速扫描机,这是一台独立工作的专门用来扫描的设备,不占用加工机床的工作时间。其扫描速度最高可达3m/min,大大缩短了模具制造周期,另外,其数据采集速度比RENSCAN200快,定时探针接触力小,因此可以用非常细的探针,用来扫描细小的模具和细微的特征表面 ,扩大模具生产的品种范围。由于模具扫描系统已在汽车、摩托车、定电等行业得到成功应用,相信在“十五”期间将发挥更大作用。

1.2.3 模具研磨抛光将向自动化、智能化方向发展

模具表面的精加工是模具加工中未能很好解决的难题之一。模具表面的质量对模具使用寿命、制件外观质量等方面均有较大的影响,我国目前仍以手工研磨抛光为主,不仅效率低(约占整个模具制造周期的1/3),且工人劳动强度大,质量不稳定,制约了我国模具加工 向更高层次发展。因此,研究抛光的自动化、智能化是重要的发展趋势。日本已研制了数控 研磨机,可实现三维曲面模具研磨抛光的自动化、智能化是重要的发展趋势。日本已研制了 数控研磨机,可实现三给曲面模具研磨抛光的自动化。另外,由于模具型腔形状复杂,任何 一种研磨抛光方法都有一定局限性。应注意发展特种研磨与抛光、如挤压衍磨、电化学抛光、超声抛光以及复合抛光工艺与装备,以提高模具表面质量。

1.2.4 模具标准件的应用将日渐广泛

使用模具标准件不但能缩短模具制造周期,而且能提高模具质量和降低模具制造成本。因此,模具标准件的应用必将日渐广泛。为此,首先要制订统一的国家标准,并严格按标准生产;其次要逐步形成规模生产,提高标准件质量、降低成本;再次是要进一步增加标准件规格品种,发展和完善联销网,保证供货迅速。

1.2.5 在模具设计制造中将全面推广CAD/CAM/CAE技术

模具CAD/CAM/CAE技术是模具技术发展的一个重要里程碑。实践证明,模具CAD/CAM/CAE 技术是模具设计制造的发展方向。现在,全面普及CAD/CAM/CAE技术已基本成熟。由于模具 CAD/CAM技术已发展成为一项比较成熟的共性技术,近年来模具CAD/CAM技术的硬件与软件价格已降低到中小企业普遍可以接受的程度,特别是微机的普及应用,更为广大模具企业普及模具CAD/CAM技术创造了良好的条件。随着微机软件的发展和进步,技术培训工作也日趋简化。在普及推广模具CAD/CAM技术的过程中,应抓住机遇,重点扶持国产模具软件的开发 和应用。

加大技术培训和技术服务的力度。应进一步扩大CAE技术的应用范围。对于已普及了模具CAD/CAM技术的一批以家电行业代表的企业来说,应积极做好模具CAD/CAM技术的深化应用工作,即开展企业信息化工程,可从CAPP,PDM, CIMS,VR逐步深化和提高。

1.2.6 快速经济模具的前景十分广阔

现在是多品种、少批量生产的时代,到下一个世纪,这种生产方式占工业生产的比例将达75%以上。一方面是制品使用周期短,品种更新快,另一方面制品的花样变化频繁,均 要求模具的生产周期越快越好。因此,开发快速经济具越来越引起人们的重视。例如,研制 各种超塑性材料(环氧、聚脂等)制作或其中填充金属粉末、玻璃纤维等的简易模具;中、低 熔点合金模具、喷涂成型模具、快速电铸模、陶瓷型精铸模、陶瓷型吸塑模、叠层模及快速 原型制造模具等快速经济模具将进一步发展。快换模架、快换冲头等也将日益发展。另外, 采用计算机控制和机械手操作的快速换模装置、快速试模技术也会得到发展和提高。

1.2.7 模具自动加工系统的研制和发展

随着各种新技术的迅速发展,国外已出现了模具自动加工系统。这也是我国长远发展的目标。模具自动加工系统应有如下特征:多台机床合理组合;配有随行定位夹具或定位盘;有完整的机具、刀具数控库;有完整的数控柔性同步系统;有质量监测控制系统。 变压器除应用于电力系统外,还应用于一些工业部门中,如:在电炉整流、电焊设备中、在船舶、电机等设备中都应用特种变压器,此外,在高压试验,测量设备和控制设备中也应用着各式的变压器。

储油柜是油浸式变压器重要的保护性器件,是用于满足绝缘油因温度变化而产生体积变化(热胀冷缩)所必需的补偿容器。对于35KV以上油浸式变压器要求储油柜做到全密封(一般通过全焊接固定),即绝缘油与大气隔离,防止空气中的水和氧使绝缘油受潮和老化,影响绝缘性能。

该端盖是变压器储油柜上的一个零件,里面安装有油量管,安装在储油柜的上端。变压器储油柜端盖是一种工业用品,市场需求量较大,所以这种端盖的生产批量较大,其产品图二维CAD图如图2-2:

材料Q235,厚度t=2mm。3 工艺分析

工件的工艺性是指工件对冲压加工工艺的适应性,它是从冲压加工角度对产品设计提出的工艺要求。工艺分析就是要判断产品在技术上能否保质,保量地稳定生产,在经济上是否有效益。因此,冲压工艺就是对产品的冲压工艺方案进行技术和经济的可行性分析。良好的工艺性体现在材料消耗少,工序数目少,模具结构简单而寿命长,产品质量稳定,操作简单方便。

3.1 经济分析

所谓经济性,就是以最小的耗费取得最大的经济效果。也就是生产中的“最小最大”原则。在冲压生产中,保证产品质量,完成产品数量、品种计划的前提下,产品成本越低,说明企业经济效果越大。

3.1.1 冲压件成本分析

产品成本受产量的影响较大,特别是冲压生产尤为突出。在一定条件下,企业生产产品数量的增减,将会引起成本中某些费用的变化,其结果使得成本发生波动。为此可将产品成本分为固定费用和变动费用两部分。固定费用是指在一定时期和一定产量范围内,它的总额不随产量变动而变动,它是维持生产能力而基本不变的费用。例如模具、设备折旧费,加工费中的固定工资部分和各种经费等。但是单位固定费用,也就是分摊在每个产品上的固定费用却是可变的。即单位固定费用与产量成反比例变化。

变动费用是指它的总额随产量的增减而成比例增减。例如产品直接耗用的原材料费、外购件费、外协件加工费等等。但就产品单位费用而言,变动费用则基本不变。

上述可知,冲压件生产成本是由固定费和可变费这两部分组成的,所以只要设法降低固定费用或可变费用,都能使生产成本降低,利润增加。可见企业要提高经济效益,就要在降低成本上下功夫。

3.1.2 降低制造成本的措施

降低产品成本,包括增产、节约两个方面。增产可降低产品成本中的固定费用,相对地减少消耗,节约便能直接降低消耗,它们都是降低成本的重要途径。冲压件的成本包括材料费、加工费、模具费等项。因此,降低成本,就是要降低以上各项费用。以下讨论降低成本的措施。

3.1.2.1 工艺合理化

冲压生产中,工艺合理化是降低成本的有力手段,一般在制定新产品工艺时进行。当产量发生变化,模具寿命短或因事故发生损坏时,由于更改产品设计而改变模具时,以及变更设备等生产条件发生变化时,要重新讨论(研究)产品工艺。由于工艺的合理化能降低模具费、节约加工工时降低材料费等,所以必然降低零件总成本。

在制定工艺时,工序的分散与集中是比较复杂的问题。它取决于零件的批量、结构(形状)、质量要求、工艺特点等。对于板材冲压件,一般说来,在大批量生产情况下,应当尽量把工序集中起来,采用复合或连续模进行冲压,很小的零件,适合于复合或连续冲压加工,这样既提高了生产率,又能安全生产。复合模对于大的零件也是适合的,因为一副大的复合模,有时比两副同样大小的单工序模的费用低,而小批量生产时,则以采用单工序模分散冲压为宜。

根据实践经验,集中到一副模具上的工序数量不宜太多,对于复合模,一般为2~3个工序,最多4个工序,对于连续模,集中的工序数可以多些。

3.1.2.2 多个工件同时成形

产量较大时,采用多件同时冲压,可使模具费、材料费和加工费降低,同时有利于成形表面拉力均匀化。左右对称成形时,不仅可使变形均匀,改善受力状况,同时还降低了成本。

3.1.2.3 冲压过程的自动化及高速化

自动化生产,从安全和降低成本两个方面来看,将成为冲压加工的发展方向。今后不仅大批量生产中采用自动化,在小批量生产中也可采用自动化生产。在大批量生产中采用自动化时,虽然模具费用较高,但生产率高,产量大,分摊到每个工件上的模具折旧费和加工费却比单件小批生产时要低

从生产安全性考虑,在小批量多品种生产中采用自动化也是可取的,但自动化的经济性问题,急待研究。在自动化生产中,降低成本的手段是高速化。与高速化并行的是多列化,这样可以降低加工费用和提高材料利用率。

为实现压力机的高速化,需要相应解决噪音振动和延长模具寿命问题。高速压力机要求足够的刚度和精度,一般以闭式双点结构为宜,为减少噪音和振动,倾向于铸铁机身,而且运动部件要求实现动平衡。为延长模具寿命,可采用高寿命的新材料,如硬质合金模具和模具表面强化处理。

3.1.2.4 提高材料利用率,降低材料费

在冲压生产中,工件的原材料费占制造成本的60%,左右,所以节约原材料,利用废料具有非常重要的意义。提高材料利用率是降低冲压件制造成本的重要措施之一。特别是材料单价高的工件,必须慎重研究。降低材料费的方法如下:

(1)在满足零件强度和使用要求的情况下,减少材料厚度。

(2)降低材料单价。

(3)改进毛坯形状,合理排样。

(4)减少搭边,采用少废料或无废料排样。

(5)对称压制。

(6)组合排样。

参考文献

[1]党根茂,骆志斌,李集仁.模具设计与制造[M].西安电子科技大学出版社,2001

[2]中国机械工业教育协会.冷冲模设计及制造[M].机械工业出版社,2005

[3]彭建声.冷冲压技术问答[M].机械工业出版社,1984

[4]彭建声,王新华,张敬国.冷冲模制造与修理[M].机械工业出版,1985

[5]梁炳文,胡世光.板料成型塑性理论[M].机械工业出版社,1987

[6]姜军辉.汽车车架横梁冲压工艺设计[J].汽车研究与开发,1995

[7]翟德梅.提高电机冲片冷冲模寿命的措施[J].电加工与模具,2001

[8]周科年.汽车纵梁冲孔落料复合模[J].模具工业,1999

[9]肖景容.冲压工艺学[M].机械工业出版社,1999

[10]钟翔山.轴壳扩径、缩口复合模设计[J].模具技术,2006

[11]杨宝顺.锅盖落料拉深冲孔切边复合模设计[J].模具技术,2006

[12]翟德梅,李铁明.机架复合冲裁模具的研制[J].电加工与具,2004

[13]模具实用技术丛书编委会.冲模设计应用实例[M].机械工业出版社,2004,4

[14]姜奎华.冲压工艺与模具技术[M].机械工业出版社,2005,8

[15]郑家贤.冲压工艺与模具设计实用技术[M].机械工业出版社,2005,8

川公网安备: 51019002004831号

川公网安备: 51019002004831号