QD10t-31.5m箱形双梁桥式起重机起重小车的设计【word+7张CAD图纸全套】【优秀机械毕业设计】

【带外文翻译】【57页@正文17970字】【详情如下】.bat

侯跃龙目录及摘要封面.doc

卷筒图A2.dwg

吊钩图A3.dwg

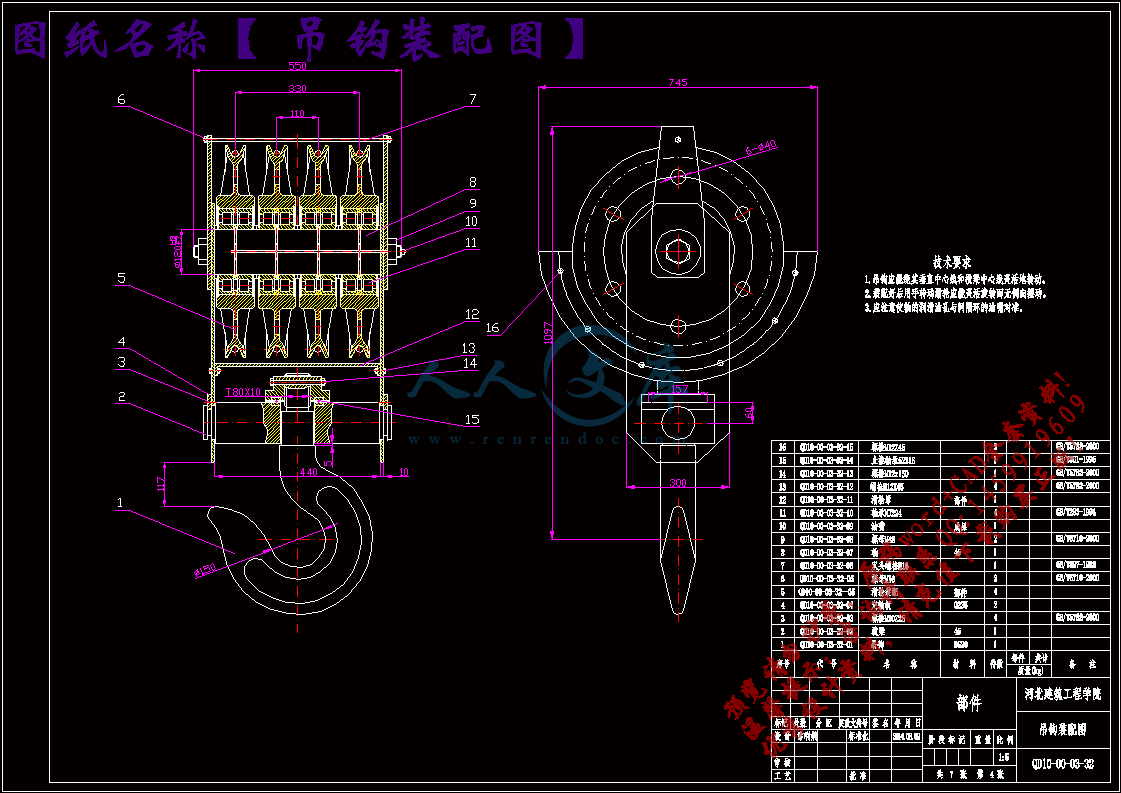

吊钩装配图.dwg

外文翻译

封面.doc

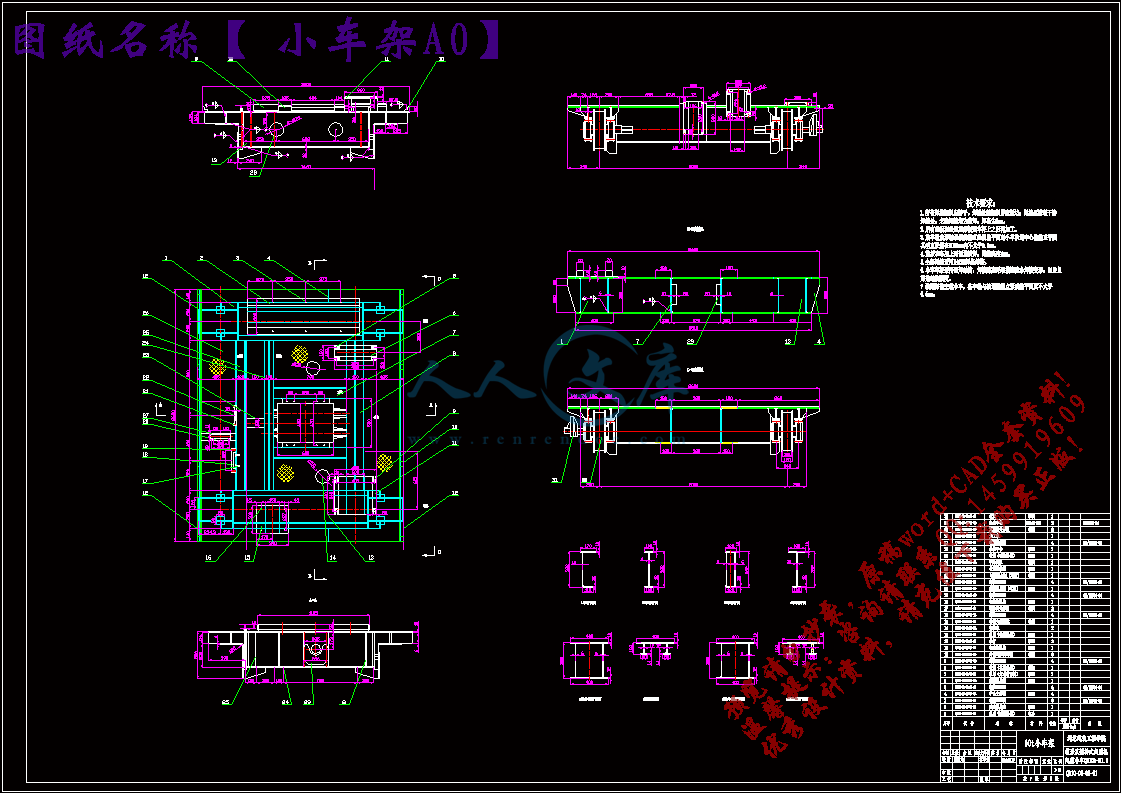

小车架A0.dwg

小车装配图A0.dwg

正文.doc

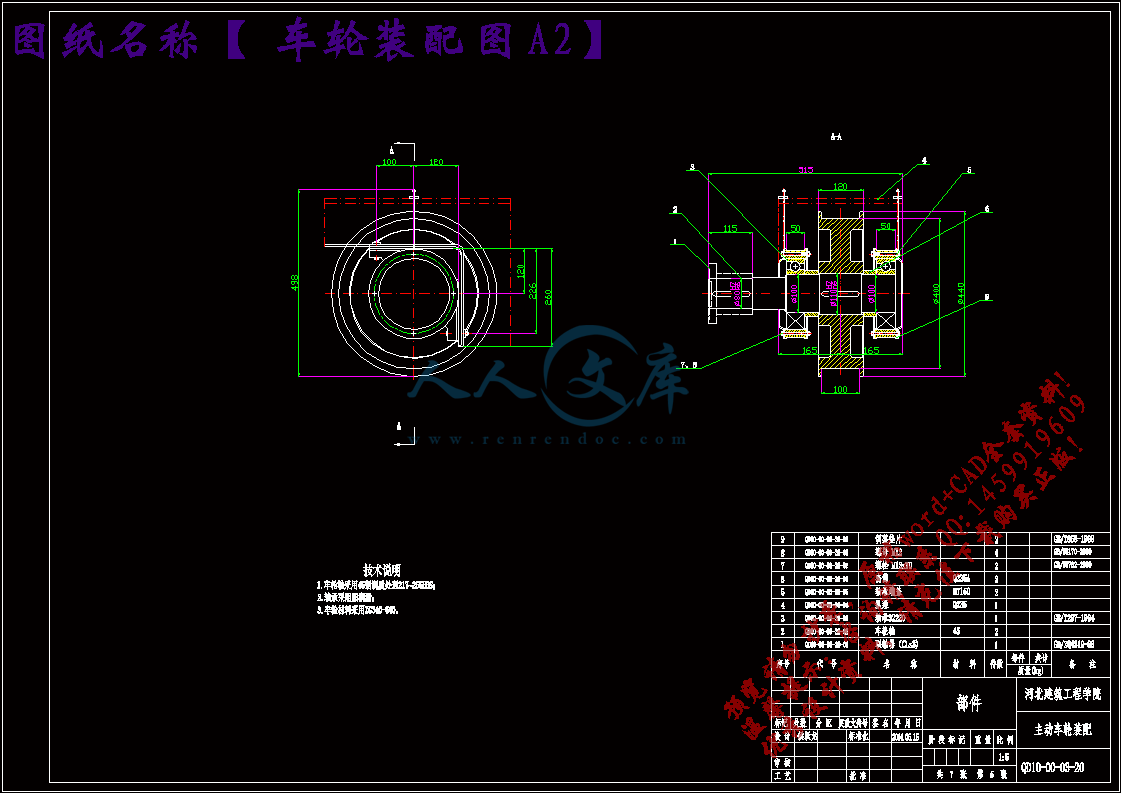

车轮装配图A2.dwg

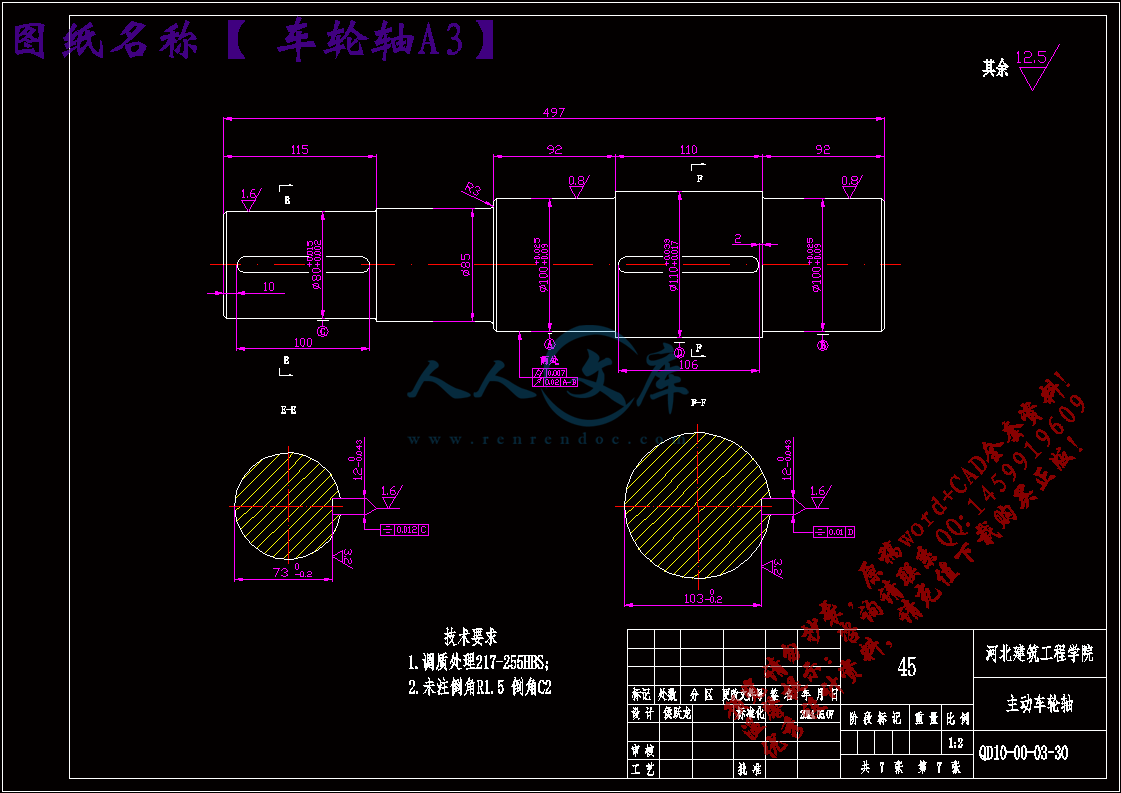

车轮轴A3.dwg

目录

第1章 前言1

1.1 国内外起重机发展情况1

1.2 桥式起重机定义及特点4

1.3 实习地点及实习内容4

第2章 总体设计4

2.1 概述5

2.2 传动方案的确定6

2.3 基本参数10

第3章 起升机构的设计计算12

3.1 选择钢丝绳12

3.2 滑轮和卷筒的计算13

3.3 计算静功率15

3.4 选择电动机15

3.5 验算电动机的发热条件15

3.6 减速机的初选16

3.7 校核减速机16

3.8 制动器的选择17

3.9 联动器的选择17

3.10 验算起动时间18

3.11 浮动轴强度验算19

第4章 运行机构的设计计算21

4.1 确定机构传动方案21

4.2 选择车轮与轨道并验算其强度21

4.3 运行阻力计算23

4.4 选择电动机24

4.5 验算电动机发热条件25

4.6 选择减速器25

4.7 验算运行机构和实际所需功率25

4.8 验算起动时间26

4.9 验算起动不打滑条件27

4.10 制动器的选择27

4.11 选择联轴器28

4.12 验算低速浮动轴强度29

第5章 零部件的设计计算31

5.1 滑轮的尺寸计算与选择31

5.2吊钩组的选择32

5.3 车轮轴的设计计算35第6章 零部件的设计计算38

6.1 梁Ⅰ38

6.2 梁Ⅱ40

6.3 梁Ⅲ42

6.4 梁Ⅵ44

6.5 梁Ⅴ48

第7章 毕业设计小节53

参考文献54

附:英文原文

英文译文

毕业实习报告

第1章 前言

1.1国内外起重机发展概况

起重运输机械行业在我国从上世纪五六十年代开始建立并逐步发展壮大,该行业已形成了各种门类的产品范围和庞大的企业群体,服务于国民经济各行业。随着我国经济的快速发展,起重运输机械制造业也取得了长足进步。2005年起重运输机械行业销售额达到1272亿元,“十五”期间平均每年增长超过30%,2006年依然保持着持续增长的态势,目前市场前景非常好。近年来,国家重点发展能源(其中煤炭工业迅猛发展,起重运输机械制造业将提供所需的竖井提升设备、斜井防爆下运带式输送机、防爆移置式带式输送机、装车机、露天矿连续开采输送设备、用于洗选设备的各种输送设备等)、电力(各种电站专用桥式/门式起重机、料场用物料搬运装卸设备、输煤给煤栈桥内物料输送设备、环保排灰输送设备、水电站用闸门启闭机械、升船机、核电站废料处理专用起重机等将有较大需求)、石化(起重运输机械制造业将提供所需的自动灌装和包装码垛设备、仓储专用设备、厂内和车间内物料搬运装卸设备等)、冶金(对各种冶金起重机、厂内和车间内物料搬运装卸设备、料场堆取料与混匀料设备等将有较大需求)、造船、交通等工业领域(需要大量的高效、节能、低污染、智能化、柔性化、成套化的物料搬运装卸设备)。

十一五”期间,我国起重运输机械产品的工业总产值、销售收入和利润总额的年平均增长率将超过15%。到2010年,该行业的工业总产值将达到2670亿元,销售收入将达到2560亿元,利润总额将达到148亿元;出口额约达65亿元,平均年增长11%;而国内市场增长的速度会呈逐年小幅递减趋势,其主要原因是国内市场开放程度大幅度提高、而行业又均

受到发达国家技术壁垒等限制;另一方面我国市场对高质量高水平的起重运输机械需求旺盛,而我国行业的技术竞争能力有待提高。政府主管部门应加强对起重运输机械行业的政策引导和管理,树立规模生产方式。国家应重点培育3~4个起重运输机械集团和重点配套件的生产体系,加大技术改造的力度,提升装备水平,保证产品质量,提高生产效率,降低制造成本,提高市场竞争力。培育自主创新能力,走引进国外先进技术、消化吸收再创新、集成创新的道路。发展自主品牌的新产品,替代进口产品,并出口国际市场,参与国际竞争。2010年力争有25%~30%的产品接近或达到国际先进水平。树立品牌意识,推进名牌战略,努力创建中国名牌产品、行业名牌产品。充分认识“科技是第一生产力”的观点。建立各类行业培训中心,加强对重点骨干企业、起重机械制造基地的管理干部、科技人才和高级技工的培训。树立知识产权意识,加大保护知识产权的力度,严厉打击各种违法行为,有利于调动广大科技人员和企业创新的积极性。加强调整各级行业协会,选拔一批有科技、生产、企业管理经验的专职人员充实到各级行业协会。行业协会要积极推行职业化、专业化、年轻化,配合国务院有关部门加强对行业的管理。

在国外,尤其是美国、日本和西欧的一些发达国家,机械产品的结构优化已有几十年的历史,门桥式起重机已完全采用了模块化设计,它可以根据用户对设备起重量、起升高度和轨道跨距等主参数的要求,并结合用户现场的实际空间和工作环境特点,直接调用参数化3D模型进行现场组装,然后对起重机结构进行有限元分析和优化,直到满足用户的要求。而在国内,由于主梁结构比较复杂,传统的设计方法很难分析主梁局部应力和变形,使一些真正危险点被忽 略,或对一些本已比较安全的部位无畏地加大或加厚,造成材料的浪费和生产成本的增加,不利于产品的市场竞争。因此,对门桥式起重机主梁结构的有限元分析和优化具有很重要的现实意义。另外,随着社会的进步,环保意识和劳动保护意识的提高,冶金起重机设计过程中把人机工程及操作环境舒适要求提到了较高的要求,如:司机室加装冷、暖空调、隔热保护、地面无线遥控、车上有线和无线通讯、航空座椅、司机休息室,上、下吊车全部采用斜梯、电气室加装隔热防护和冷风机,较窄的人行通道采取防滑措施,经常检修部分加装吊笼等都为操作维护人员提供了较好的工作环境和条件。特别是双层壁、双层玻璃的司机室与可躺式航空座椅、冷暖空调、有线、无线通讯配合使用。为改善司机的工作条件、提高工作效率、减少工作失误起到了很好的作用。人机工程合理化正逐步成为现代冶金起重机发展的主要趋势之一,越来越引起人们的重视。

桥架、小车架整体加工的应用。桥架、小车架包括一些大型结构件整体加工是保证冶金起重机产品质量的一项重要措施和有效途径。由于冶金起重机工作的特殊性,对质量提出了较高的要求,小车架整体加工指焊在小车架上的电动机底座,制动器底座,减速器支承座,卷筒支承座,和小车车轮支承座等机座一次性地划线加工而成,相互间的形位、尺寸公差由机床保证,因此装配工作变得特别简单。只要把电动机、制动器、减速器、卷筒、车轮就位即可,不像旧的办法,它们间的形位、尺寸误差靠塞垫片来调节。简而言之,这些部件间的形位公差由机床精度保证与装配工人的技术等级无关,排除了人为因素,因而大大提高了装配精度和使用性能,同时也大大缩短了用户的维修时间。

我们认为未来中国起重机的几个发展趋势如下:

1、重点产品大型化、高速化、耐久化和专用化

2、系列产品模块化、组合化、标准化和实用化

3、通用产品小型化、轻型化、简易化和多样化

4、产品性能自动化、智能化、集成化和高效化

5、产品组合成套化、系统化、复合化和信息化

6、产品设计微机化、精确化、快速化和全面化

7、产品构造新型化、美观化、宜人化和综合化

8、产品制造柔性化、灵捷化、精益化和规模化

1.2桥式起重机定义及特点

取物装置悬挂在可沿桥架运行的起重小车或运行式葫芦上的起重机,称为“桥架型起重机”;桥架两端通过运行装置直接支撑在高架轨道上的桥架型起重机,称为“桥式起重机”。

桥式起重机一般由装有大车运行机构的桥架、装有起升机构和小车运行机构的起重小车、电气设备、司机室等几个大部分组成。外形像一个两端支撑在平行的两条架空轨道上平移运行的单跨平板桥。起升机构用来垂直升降物品,起重小车用来带着载荷作横向运动;桥架和大车运行机构用来将起重小车和物品作纵向移动,以达到在跨度内和规定高度内组成三维空间里作搬运和装卸货物用[3]。

桥式起重机是使用最广泛、拥有量最大的一种轨道运行式起重机,其额定起重量从几吨到几百吨。最基本形式是通用吊钩桥式起重机,其他形式的桥式起重机基本上都是在通用吊钩桥式的基础上派生发展出来的。

1.3实习地点及实习内容

毕业实习是在张家口市神力起重设备有限公司对QD16t/20t双梁桥式起重机小车进行了参观实习。

第2章 总体设计

2.1 概述

总体设计是机械设计中极为关键的环节,它是对机器本身总的设想。总体设计的成败关系到整部机器的经济技术指标,直接决定了机械设计的成败。

总体设计指导机构设计和零件设计的进行至关重要。在接受设计任务后进行细致的调查研究,收集国内外同类机械的有关资料了解国内外的使用、生产、设计和科研情况,并进行分析比较,制定总体设计原则。设计原则应当保证所设计的机型符合有关的方针、政策。在满足使用要求的前提下,力求结构合理,经济性好,寿命长,同时还应考虑到绿色环保和操作的舒适安全。

总体设计应遵循以下原则:

1.遵循“三化”原则:零件标准化,产品系列化,部件通用化。

2.采用“四新”原则:新技术,新工艺,新结构,新材料。

3.满足“三好”原则:好造,好用,好修。

好造,即具有良好的工艺性,制造简单;好用,即具有良好的使用性能,表现为生产率高,操作轻便,机动灵活,安全而且耐用可靠;好修,即一旦发生故障,易于拆卸,维修护理方便。

4.对部件设计和零件设计负责的原则。把各部件的设计制造特点作为部件和零件指导性文件,必须为零部件的设计人员创造方便条件,而零部件设计必须满足总体设计提出的工作条件、尺寸、性能参数等方面的要求。

制定设计总则以后,便可以编写设计任务书。在调研的基础上,运用所学的知识,从优选择,确定总体参数,保证设计的成功。

2.2 传动方案的确定

箱式双梁桥式起重机主要组成部分有小车(起升机构,小车运行机构和小车架),桥架(主梁,端梁,走台和护栏等),大车运行机构和司机室(操纵机构和电器设备等)等部分组成。

桥式起重机的运动,是由大车的纵向,小车的横向及吊钩的上下三种运动组成的。有时是单一的运动,有时是合成的动作。他们都有各自的传动机构来保证其运动形式的实现。

2.2.1起升机构的传动原理

起升机构的传动原理:起升机构的动力来源是由电动机产生,经齿轮联轴器,浮动轴,制动轮联轴器,将动力传递给减速器的高速轴端,经减速器把电动机的高转数降低到所需的转数之后,由减速器低速轴输出经卷筒上的齿轮联轴器把动力传递给卷筒组,再经过钢丝绳和滑轮组使吊钩进行升降,从而完成升降重物的目的。

2.2.2起重小车运行系统的传动原理

起重小车运行系统的传动原理动力由电动机产生,经制动轮联轴器,立式二级减速器的高速轴,并经立式二级减速器把电动机的高转数降低到所需要的转数之后,再由低速轴端输出,经半齿联轴器传到驱动轮,再有驱动轮的另一端经半齿联轴器通过浮动轴,半齿联轴器传到另一驱动轮。从而带动了小车驱动轮的旋转,完成小车的横向运送重物的目的。

2.2.3大车运行系统的传动原理

动力由电动机发出,经制动轮联轴器,补偿轴和半齿联轴器将动力传递给减速器的高速轴端,并经减速器把电动机的高转数降低到所需要的转数之后,由低速轴传出,又经全齿联轴器把动力传递给大车的主动车轮组,从而带动了大车主动车轮的旋转,完成桥架纵行吊运重物的目的。大车两端的驱动机构是一样的。

原有双梁桥式专用起重机的大车运行机构机构是由四个电机驱动的,电机较多,机构比较繁杂,这给安装和维修带来了许多不便,同时也提高了生产成本,改进后只在两梁的两侧分别安装一个电机,适当提高电机功率,由两对主、被动车轮组成。在不影响行走性能的前提下,精简了机构,减少了故障率,易于安装维修,电机的减少有效地降低了成本。

2.2.4设计小车的基本原则和要求

箱形双梁桥式起重机由两根箱形主梁和两根横向端梁构成的双梁桥架,在桥架上运行起重小车,可起吊和水平搬运各类物件,其中主梁做横向移动,小车做纵向移动从而使起重机的工作范围扩展到一个立方形空间。

箱形双梁桥式起重机一般由起重小车、桥架运行机构、桥架金属结构组成。而起重小车主要由起升机构、小车运行机构和小车架以及限位安全装置等组成。

在设计桥式起重机小车时,必须力求满足以下几方面的要求:

1、整台起重机与厂房建筑物的配合以及小车与桥架的配合要适当。小车与桥架的互相配合,主要在 于小车轨距和桥架上的小车轨距应相同;其次,小车上的缓冲器与桥架上的挡铁位置要配合好,小车上的撞尺和桥架上的行程限位开关要配合恰当。小车的平面布置愈紧凑,小车到桥架的两端愈远,起重机工作范围也就愈大。小车的高度小,相应地可使起重机的高度减小,从而可降低厂房建筑物的高度。

2、小车上机构的布置及同一机构中各零部件间的配合要求适当。起升机构和小车运行机构在小车架平面上的布置要合理紧凑,但二者之间的距离不应太小,否则维修不便,或造成小车架难以设计。

3、小车车轮的轮压分布要求均匀。如能满足这个要求,则可以获得最小的车轮、轴承及轴承箱尺寸,并且使起重机桥架主梁受到均匀的轮压载荷。一般最大轮压不应超过平均轮压的20%。

4、小车架上的机构与小车架结构的配合要适当。为使小车上的起升、运行机构与小车架配合的好,要求二者之间的配合尺寸相符;联接零件要选择适当和安装方便。在设计原则上,要以机构为主,应尽量用小车架去配合机构;同时机构的布置也要尽量使钢结构的设计制造方便。因为小车架是用来安置与支撑起升机构和小车运行机构的,所以小车架要按照起升和运行机构的要求设计,但在不影响机构工作的条件下,机构的布置也应配合小车架的设计,使其构造简单、合理和便于制造。

5、尽量选用标准零部件,以提高设计与制造的工作效率,降低生产成本。

6、小车各部分的设计应考虑制造、安装和维护检修方便,要尽量在不需移动邻近部件的条件下,能将各部件拆下修理。

桥式起重机小车主要由起升机构、小车运行机构和小车架三部分组成。另外,还有一些安全防护装置。

我国制造的桥式起重机的小车具有下列特征;

1、起升和运行机构由独立的部件构成。这些部件之间用补偿联轴器联系起来。齿轮联轴器补偿了转轴中心线的偏移和歪斜,这些偏差和歪斜系因制造与安装不精确,以及小车架变形而产生部件间彼此位移所引起的。由于采用了分组的独立部件,因此,使小车上各机构的装拆方便。

2、在设计机构和小车时,遵循“三化”(标准化、通用化和系列化)的原则。这可使零部件的互换性得到保证,降低制造和使用维护起重机的费用,并使所需零部件的备品量减到最少。

3、小车架用钢板焊接而成。在车架上焊有底板。电动机、减速器、制动器和和可拆卸的轴承座等均安装在这种底板上。为了简化车架的加工,底座的加工面应尽量布置在同一水平面或垂直面上。

4、起升机构和运行机构采用减速器式传动装置。

起重机小车除有起升、运行机构和小车架外,还必须有必要的安全保护装置:如栏杆、排障板、撞尺、缓冲器、和限位开关等。其具体要求分述如下:

1、栏杆 栏杆设置在与小车轨道相垂直的小车台面边缘上。为了便于维修上下,在小车的另外两侧不设栏杆。栏杆可用角钢或钢管制作,高度不低于1米,并应设有间距为350㎜的水平横杆,底部应设有不小于70㎜高的围护板。

2、排障板 排障板装在小车架端梁两端的车轮外边,用于推开小车轨道上可能有的障碍物,以利于小车运行。

2、限位开关 用于限制吊钩和小车架的极限位置。在起升机构中,限位开关用于限制吊钩向上运行位置,使其不能碰到小车架。小车运行机构的行程限位开关,安装在起重机桥架主梁的两端,位于小车轨道外侧的主梁盖板上。在小车架相应的端梁外侧

固定着一根用角钢弯折的撞尺。当小车运行至极限位置时,撞尺压迫限位开关的摇柄转动30°,使开关盒内的触点断开,于是运行机构的电动机断电。由于接线关系,此时电动机只能作反向运行。

3、超载限制器 起升机构超载限制器应保证载荷不超过其额定值的10%,工作精度为2~3%。

起重机小车的设计主要是对起升机构、小车运行机构、小车架的设计以及包括栏杆、高度限位器、负载限制器和行程开关等在内的安全装置分析与计算,并在原有设计的基础上做出改进,并解决原来起重机上存在的影响工作性能的结构,并尽可能降低成本。

最终设计出优化产品。

2.3 基本参数

1.额定起重量(Q)

起重机正常工作时允许一次起升的最大重量称为额定起重量,单位为吨(t)或千克,常用符号Q、P或CP等表示。桥式起重机的额定起重量是定值。当额定起重量不只一个时,通常称额定起重量为最大起重量,或简称起重量。

额定起重量:Q=10t

2.起升高度(H)

起升高度是指从地面至取物装置最高位置的铅垂距离(吊钩的钩环中心),单位为米。

起升高度:H=12m

3.跨度(L)与轨距(l)

桥式起重机大车运行轨道中心线之间的水平距离称为跨度(L),小车运行轨道中心线之间的水平距离称为轨距。

跨度为:L=31.5 m

轨距为:l=2 m

4.工作级别

确定起重机的工作级别是为了对起重机金属结构和结构设计提供合理的基础,为和客户进行协商时提供一个参考范围,它能使起重机胜任它需要完成的工作任务。由利用等级和载荷状态两个因素来确定起重机的工作级别。

工作级别为A5

5.起重机利用等级

起重机在有效寿命期间有一定的总工作循环数。起重机作业的工作循环是从准备起吊物品开始,到下一次起吊物品为止的整个作业过程。工作循环总数表征起重机的利用程度,它是起重机分级的基本参数之一。

起重机利用等级为U5

6.工作速度

起重机机构工作速度根据作业要求而定。

主起升速度:V1=13.3m/min

小车运行速度:V3=43.8m/min

大车运行速度:V2=112.5m/min

第3章 起升机构的设计计算

由已知条件:工作级别A5,起重机利用等级U5,主钩额定起重量10t。

参考文献【1】P7表1-8得起重机为中级工作类型,JC%=25

参考文献【1】P50表4-3得安全系数K=5.5,=25(固定式)

参考文献【1】P65表4-14得选双联滑轮组X=2,倍率m=3

参考文献【3】表2-1得滑轮组的效率=0.985

参考文献【2】P230查附表8选图号为G15吊钩组,得其重量=219kg,两动滑轮间距A=185mm

参考文献【1】P50式4-4换算系数=0.85(6×19)=0.82(6×37)

1.选择钢丝绳

计算钢丝绳最的大静拉为

钢丝绳破断拉力为:

=5.5×17.29=95.1KN

查参考文献【2】P224附表1选用瓦林吞型纤维芯钢丝绳6×19W+FC,钢丝公称抗拉强度1670MPa,光面钢丝,左右互捻,直径d=14mm,钢丝绳最小破断拉力[]=108KN,标记如下:

钢丝绳14NAT6×19W+FC1770ZS108GB8918-88

滑轮的许用最小直径

图3-1起升钢丝绳缠绕简图

=14(25-1)=336mm

参考文献

【1】华玉洁 主编. 起重机械与吊装. 北京. 北京工业出版社

【2】陈道南. 起重机课程设计. 北京科技大学:冶金工业出版社,1993.10

【3】陈道南等编. 起重运输机械. 冶金工业出版社,1988

【4】起重机设计手册编写组编. 起重机设计手册. 机械工业出版社:1979

【5】陈国璋编. 起重机计算实例. 北京. 中国铁道出版社

【6】起重机计算实例. 中国标准出版社,1984

【7】GB6067-85 起重机械安全规程.

【8】GB/T14405-93 通用桥式起重机. 北京:中国标准出版社,

【9】GB3811-83 起重机设计规范.

【10】JB/T6392.2-92 起重机车轮技术条件.

【11】董刚等主编.机械设计—3版.北京:机械工业出版社,1998

【12】机械设计手册编委会主编.机械设计手册(第二卷).北京:机械工业出版社,2004

【13】成大先主编.机械设计手册.单行本.轴及其联接.北京:化学工业出版社,2004

【14】成大先主编.机械设计图册(第一卷 上册).北京:化学工业出版社,1997

【15】成大先主编.机械设计图册(第一卷 下册).北京:化学工业出版社,1997

【16】陆玉,何在洲,佟延伟编.机械设计课程设计.北京:机械工业出版社,2003

【17】(日)坂本种芳,长谷川政弘著,池成渊译,傅东明校,桥式起重机设计计算.北京:中国铁道出版社,1987

【18】余厚极编著.起重机吊装安全技术.北京:中国建材工业出版社,1998.11

【19】华玉溪主编.起重机械与吊装.北京:化学工业出版社,2005.8

川公网安备: 51019002004831号

川公网安备: 51019002004831号