尾接杆零件的工艺规程和斜孔钻模设计

28页 12000字数+说明书+任务书+答辩稿+外文翻译+4张CAD图纸【详情如下】

任务书.doc

外文翻译--机械设计.doc

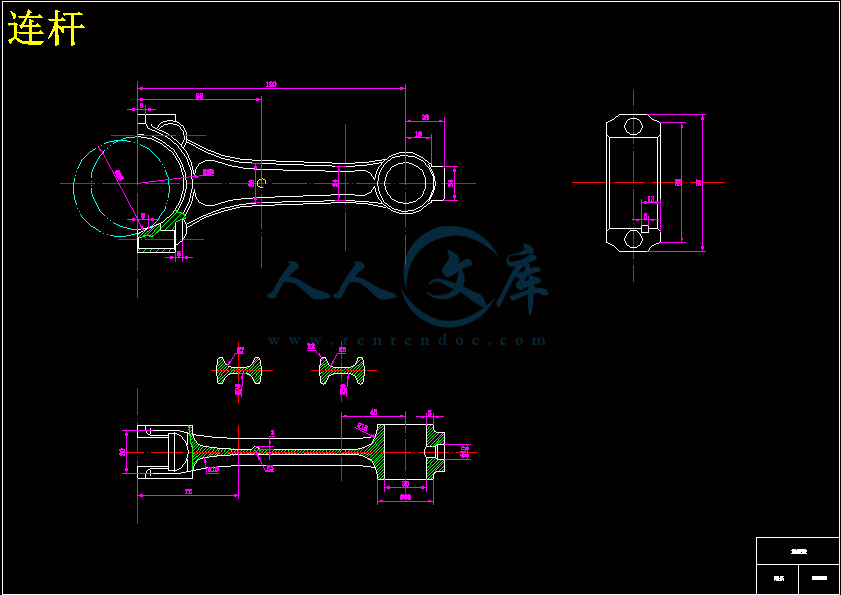

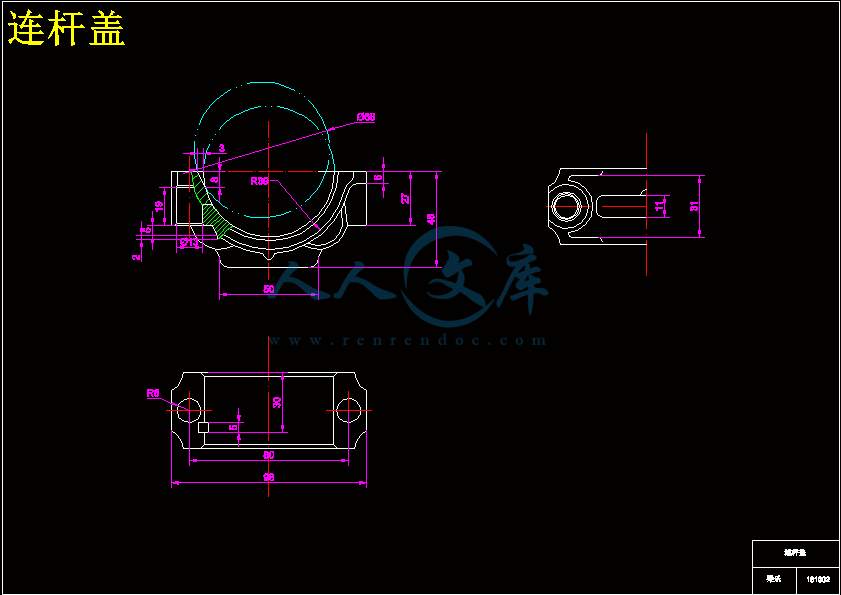

尾接杆毛坯图.dwg

尾接杆零件图.dwg

尾接杆零件的工艺规程和斜孔钻模设计答辩稿.ppt

尾接杆零件的工艺规程和斜孔钻模设计论文.doc

工序卡片.doc

工艺卡片.doc

斜孔钻模装配图.dwg

钻模板.dwg

一、题目

尾接杆零件的工艺规程和斜孔钻模设计

二、指导思想和目的要求

毕业设计(论文)是培养学生自学能力、综合应用能力、独立工作能力的重要教学实践环节。

通过毕业设计,学生对四年所学知识进行回顾和总结,培养自学能能力和独立工作能力,对本专业加深了解,为步入社会工作岗位做好理论和时间准备。学会理论联系实际,用严谨和认真的态度分析和解决遇到的问题,从而实现认识的深化。

三、主要技术指标

绘制零件图;

设计与绘制毛坯图

制定工艺路线

编制全部工艺规程

设计钻模

编写论文

四、进度和要求

1、分析并绘制零件图 1周

2、绘制毛坯图 1周

3、设计工艺路线及编制工艺规程 4周

4、设计工艺装备 3周

5、编写说明书(论文) 2周

五、主要参考书及参考资料

[1] 阎光明,侯忠滨.现代制造工艺基础.西安:西北工业大学出版社,2007.

[2] 王长春,孙步功.互换性与测量技术基础.北京:北京大学出版社,2010.摘要

本设计的题目是尾接杆工艺规程及斜孔钻模设计。内容可分为机械加工工艺规程编制和斜孔钻模夹具设计两个部分。

首先,运用机械制造技术及相关的课程知识,解决工件在加工过程中的定位、加紧以及工艺路线的安排等方面的相关问题,确定相关的工艺尺寸及选择合适的机床和刀具。其次,通过分析尾接杆,了解尾接杆的作用。然后,依据毛坯件和生产纲领的要求,制定出切实可行的铣夹具加工工艺规程路线,确定加工方案。最后,根据被加工零件的加工要求,参考机床夹具设计手册及相关方面的书籍,设计出高效、经济、合理并且能保证加工质量的夹具。

随着社会的进步和科技的发展,机床夹具的通用性也直接影响其经济性。机床夹具的高精、高效、通用、经济等性质的良好发展将在我国的现代化工业建设和发展过程中起着至关重要的作用。

关键词: 夹具设计,机械加工,工艺,工装

ABSTRACT

This design topic is The tail rod and inclined hole jig process design. Content can be divided into the machining process planning design and the machine tool's fixture design two parts.

First, with mechanical manufacturing technology and related course knowledge and solve workpiece position in the process, which belong to the process route arrangement and the related aspects related technology problem, determine the size and choose appropriate machine and tools. Secondly, through the analysis the tail rod, understand the tail rod. Then, on the basis and milling fixture blank piece and production program requirements, formulate feasible milling machining procedure line, fixture to determine processing plan. Finally, according to the requirements of the processing of processed spares, reference the machine tool's fixture design manual and related books, design the efficient, economy, reasonable and can ensure the process quality fixture.

Along with the progress of the society and the development of science and technology, the machine tool's fixture commonality also directly affects its economy. The machine tool's fixture with high precision, high efficiency, gm, economic and other properties of the good development will be in the modernization of our country in the process of the development of industrial construction and plays a vital role.

KEY WORDS: fixture design, Mechanical processing, Craft,Fixtures

目 录

第一章 绪论7

1.1 课题背景及发展趋势7

1.2 夹具的基本结构及夹具设计的内容8

第二章 尾接杆工艺规程编制9

2. 1 零件的分析9

2.1.1 零件的作用9

2.1.2零件的工艺分析9

2.2 确定毛坯11

2.2.1选择毛坯11

2.2.2设计尾接杆毛坯图12

2.3 工艺规程设计14

2.3.1 定位基准的选择14

2.3.2 工艺路线的制定15

第三章 夹具设计的基本知识18

3.1机床夹具的概述18

3.1.1机床夹具的定义18

3.1.2机床夹具的功用18

3.1.3机床夹具的组成18

3.1.4机床夹具的分类19

3.2 机床夹具的设计特点和要求20

3.2.1 机床夹具的设计特点20

3.2.2 机床夹具的设计要求20

3.3 机床夹具总图设计20

3.3.1总图设计的步骤20

3.3.2总体设计的几点要求21

第四章 尾接杆斜孔钻模设计22

4.1夹具设计方法及步骤22

4.2拟订定位方法与对定位元件23

4.2.1 定位方案分析23

4.4 钻床夹具的设计24

4.5 绘制尾接杆夹具装配图25

前 言

设计是有关尾接杆零件的加工工艺步骤的说明和斜孔钻模设计的具体阐述。工艺设计是在学习机械制造技术及机床夹具设计后,在生产实习的基础上,综合运用所学相关知识对零件进行加工工艺规程的设计和机床夹具的设计,根据零件加工要求制定出可行的工艺路线和合理的夹具方案,以确保零件的加工质量。

制造工艺是指加工制造产品或零件所使用的路线、设备及加工方法的总称。工艺可以是多样化的,它对成本和效率都会产生影响。应用机床夹具,有利于保证工件的加工精度、稳定产品质量;有利于提高劳动生产率和降低成本;有利于改善工人劳动条件,保证安全生产;有利于扩大机床工艺范围,实现“一机多用”。

为了提高机床在生产过程的生产效率,双面、四面和多件装夹的夹具产品越来越多。为了减少工件的安装时间,各种自动定心夹紧、精密平口钳、杠杆夹紧、凸轮夹紧、气动和液压夹紧等,快速夹紧功能部件不断地推陈出新。随着社会的进步和科技的发展,机床夹具的通用性也直接影响其经济性。所以只有改进研发更高效率的夹具,以适应现代化工厂机床生产要求。

就我个人而言,我希望能通过这次毕业设计,了解并认识一般机器零件的生产工艺过程,巩固和加深已学过的知识,理论联系实际,对自己未来将从事的工作进行一次适应性训练,从中锻炼自己分析问题、解决问题的能力,为今后的工作打下一个良好的基础。由于个人能力所限,设计尚有许多不足之处,恳请各位老师给予指导。加工工艺及夹具毕业设计是对所学专业知识的一次巩固,是在进行社会实践之前对所学各课程的一次深入的综合性的总复习,也是理论联系实际的训练。

机床夹具已成为机械加工中的重要装备,同时是机械加工不可缺少的部件,在机床技术向高速、高效、精密、复合、智能、环保方向发展的带动下,夹具技术正朝着高精、高效、模块、组合、通用、经济方向发展。机床夹具的设计和使用是促进生产发展的重要工艺措施之一。随着我国机械工业生产的不断发展,机床夹具的改进和创造已成为广大机械工人和技术人员在技术革新中的一项重要任务。

1.1 课题背景及发展趋势

材料、结构、工艺是产品设计的物质技术基础,一方面,技术制约着设计;另一方面,技术也推动着设计。技术是产品形态发展的先导,新材料,新工艺的出现,必然给产品带来新的结构,新的形态和新的造型风格。材料,加工工艺,结构,产品形象有机地联系在一起的,某个环节的变革,便会引起整个机体的变化。随着机床加工精度的提高,为了降低定位误差,提高加工精度对夹具的制造精度要求更高精度夹具的定位孔距精度也随着提高,机床夹具的精度已提高到微米级,世界知名的夹具制造公司都是精密机械制造企业。诚然,为了适应不同行业的需求和经济性,夹具有不同的型号,以及不同档次的精度标准供选择。

工业的模块、组合夹具元件模块化是实现组合化的基础。利用模块化设计的系列化、标准化夹具元件,快速组装成各种夹具,已成为夹具技术开发的基点。省工、省时,节材、节能,体现在各种先进夹具系统的创新之中。模块化设计为夹具的计算机辅助设计与组装打下基础,应用CAD技术,可建立元件库、典型夹具库、标准和用户使用档案库,进行夹具优化设计,为用户三维实体组装夹具。模拟仿真刀具的切削过程,既能为用户提供正确、合理的夹具与元件配套方案,又能积累使用经验,了解市场需求,不断地改进和完善夹具系统。组合夹具分会与华中科技大学合作,正在着手创建夹具专业技术网站,为夹具行业提供信息交流、夹具产品咨询与开发的公共平台,争取实现夹具设计与服务的通用化、远程信息化和经营电子商务化。迅速发展对产品的品种和生产率提出了愈来愈高的要求,使多品种,对中小批生产作为机械生产的主流,为了适应机械生产的这种发展趋势,必然对机床夹具提出更高的要求。

1.2 夹具的基本结构及夹具设计的内容

与此同时夹具的通用性直接影响其经济性。采用模块、组合式的夹具系统,一次性投资比较大,只有夹具系统的可重组性、可重构性及可扩展性功能强,应用范围广,通用性好,夹具利用率高,收回投资快,才能体现出经济性好。因此,我认为加快用高新技术改造和提升夹具技术水平的步伐,创建夹具专业技术网站,充分利用现代信息和网络技术,与时俱进地创新和发展夹具技术。主动与国外夹具厂商联系,争取合资与合作,引进技术,这是改造和发展我国组合夹具行业较为行之有效的途径。

按在夹具中的作用,地位结构特点,组成夹具的元件可以划分为以下几类:

(1)定位元件及定位装臵;

夹紧元件及定位装臵(或者称夹紧机构);

(3)夹具体;

(4)对刀,引导元件及装臵(包括刀具导向元件,对刀装臵及靠模装臵等);

(5)动力装臵;

(6)分度,对定装臵;

(7)其它的元件及装臵(包括夹具各部分相互连接用的以及夹具与机床相连接用的紧固螺钉,销钉,键和各种手柄等);

每个夹具不一定所有的各类元件都具备,如手动夹具就没有动力装臵,一般的车床夹具不一定有刀具导向元件及分度装臵。反之,按照加工等方面的要求,有些夹具上还需要设有其它装臵及机构,例如在有的自动化夹具中必须有上下料装臵。 零件是飞机液压助力器执行机构中的主要部件之一。从整体上来看,飞机液压助力器是安装在飞机副翼操纵机构中或方向舵操纵系统中,用于不可逆的液压助力器操纵。当飞机液压系统损坏或压力下降时,液压助力器外筒左右两腔沟通,即助力器当一拉杆使用,以实现人力应急操纵。每架飞机上装有两台液压助力器。分别操纵左右副翼或方向舵。

尾接杆零件在产品中一端与液压助力器外筒组件连接,另一端通过关节轴承与飞机的副翼连接,其作用是带动飞机操纵系统的摇臂和拉杆,而使飞机的副翼偏转,在工作时能够传递3800公斤以上的力,是一个能承受复杂力的受力件。

2.1.2零件的工艺分析

零件的材质为30CrMnSiA,属中碳调质钢,强度高,焊接性能较差。30CrMnSiA调质后有很高的强度和足够的韧性,淬透性也好。调质后该材料做砂轮轴,齿轮,链轮都可以。30CrMnSiA具有良好的加工性,加工变形微小,抗疲劳性能相当好。用于轴类、活塞类零配件等。用于汽车、飞机各种特殊耐磨零配件等。

参考文献

[1]孙桓,陈作模,葛文杰. 《机械原理》第七版. 北京:高等教育出版社

[2]濮良贵,纪名刚.《机械设计》第八版.北京:高等教育出版社

[3]吴宗泽,罗圣果. 《械设计课程设计手册》 北京:化学工业出版社

[4]马兰, 《机械制图》.北京:机械工业出版社

[5]刘守勇等.《械制造工艺与机床夹具》. 机械工业出版社

[6]白成轩.《机床夹具设计新原理》.机械工业出版社

[7]融亦鸣 《计算机辅助夹具设计》.机械出版社

[8]肖继德、陈宁平.《机床夹具设计》第2版.机械工业出版社

川公网安备: 51019002004831号

川公网安备: 51019002004831号