ZL50装载机总体及变速箱设计(第二行星排)【优秀毕业设计】【word+5张CAD图纸全套】

【带开题报告+实习日记+外文翻译】【73页@正文32000字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

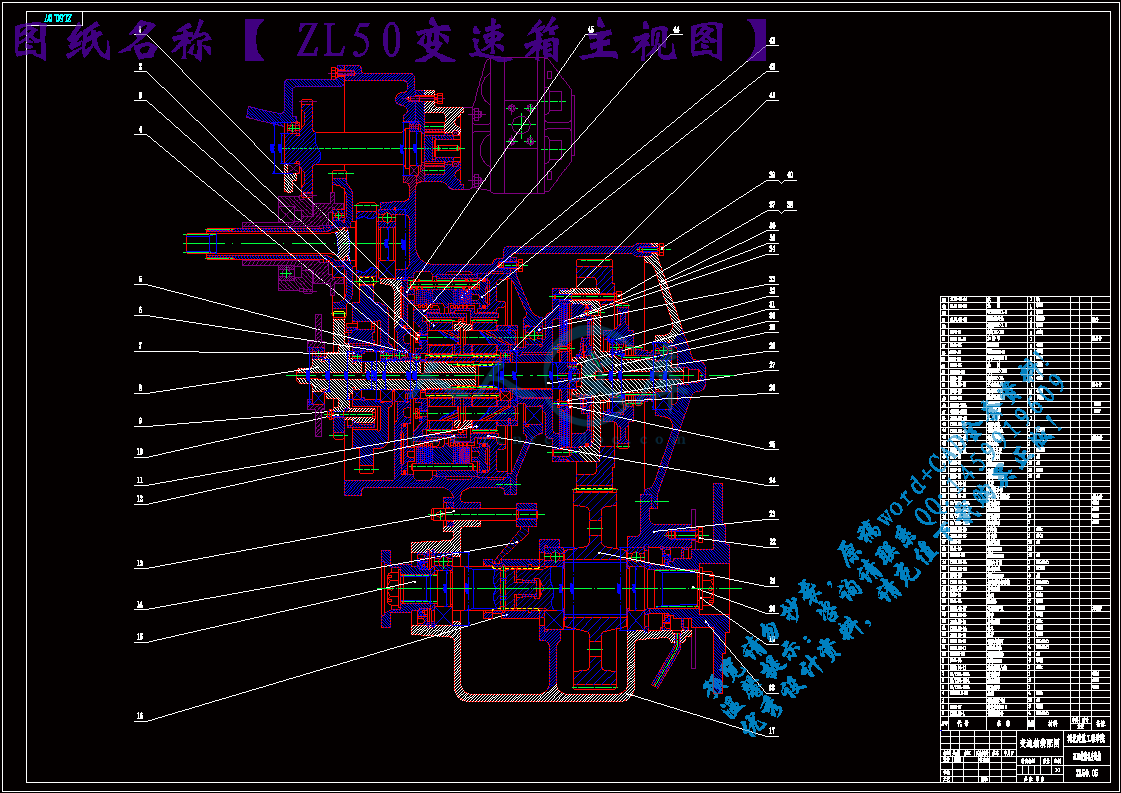

ZL50变速箱主视图.dwg

ZL50变速箱左视图.dwg

ZL50变速箱总成参考文献.pdf

外文翻译

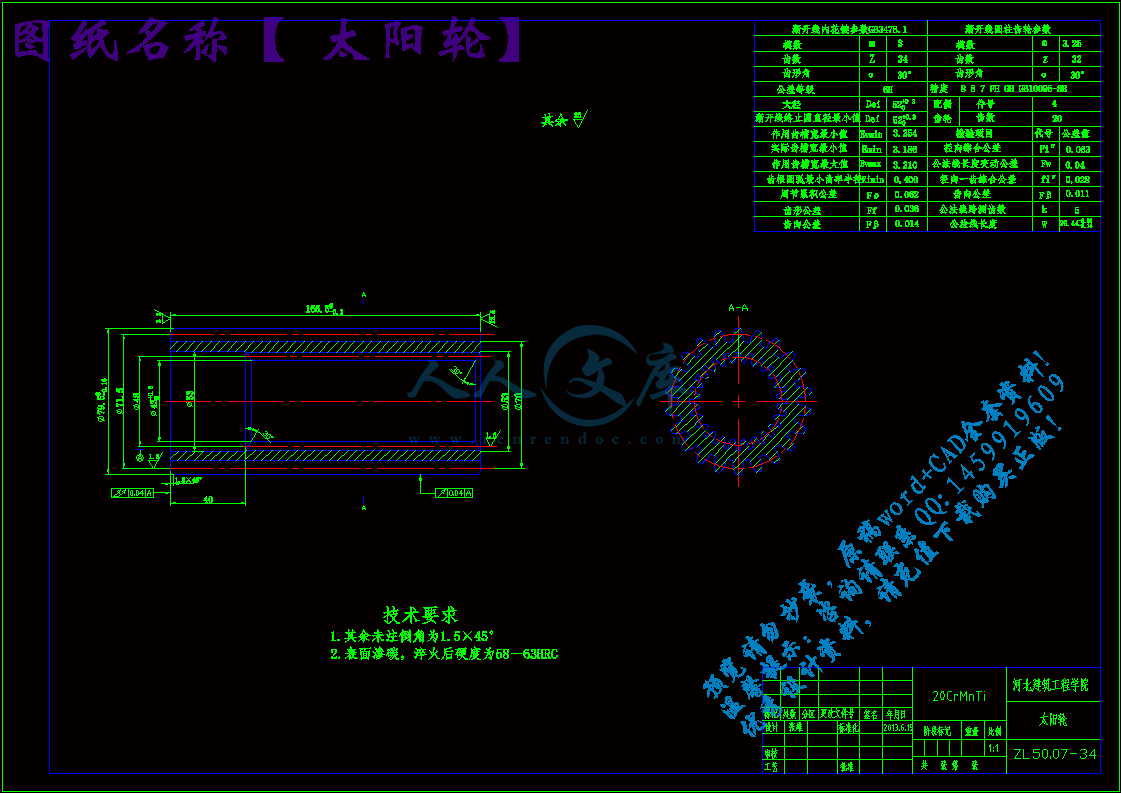

太阳轮.dwg

开题报告.doc

开题报告副本.doc

技术要求.doc

正文.doc

正文副本.doc

实习报告.doc

滚筒.dwg

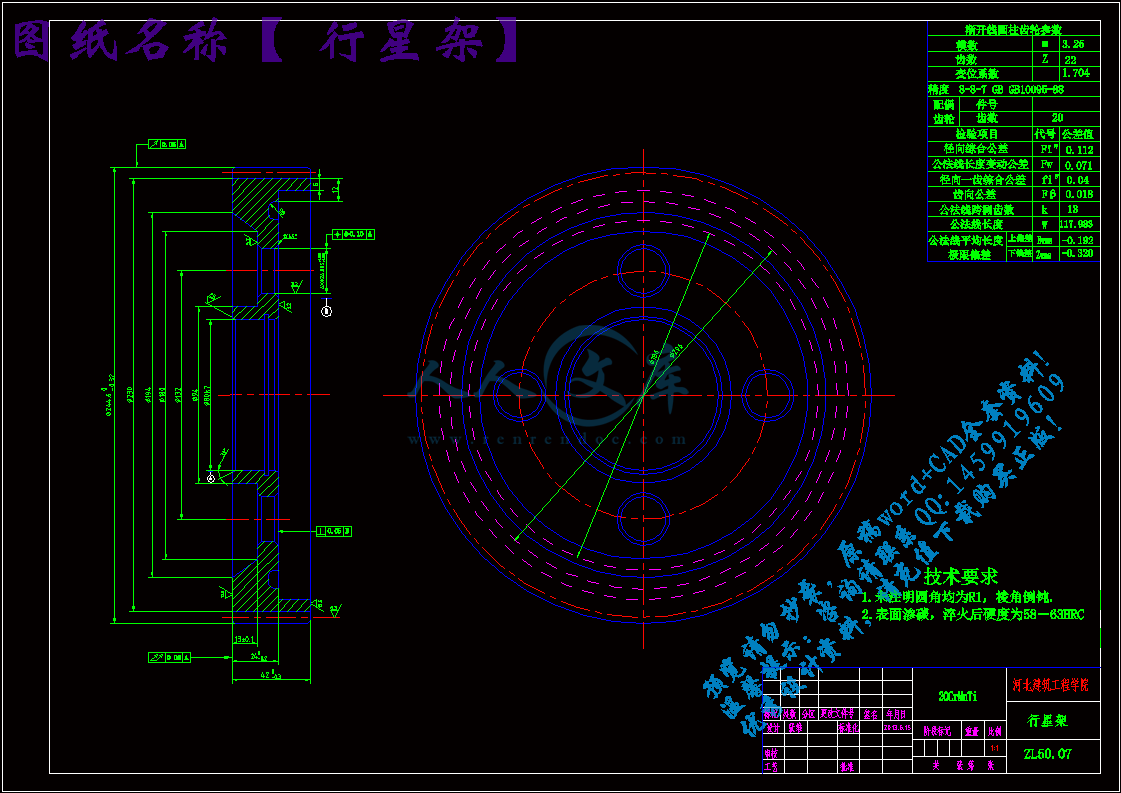

行星架.dwg

开题报告

名称ZL50装载机总体及变速箱设计(第二行星排)

课题来源导师课题课题类别工程设计

一、论文资料的准备

装载机是一种用途非常广泛得工程机械,它广泛应用于铲装、搬运、卸载、平整散装物料,也可以对岩石硬土等进行轻度得铲掘工作。因此,它被广泛应用于建筑、公路、铁路、水电、港口、矿山及国防等工程中。装载机对加快工程建设速度、减轻劳动强度、提高工程质量、降低工程成本具有重要作用。所以装载机在国内外不论是品种还是产量,都有飞速发展,并且成为工程机械的主要品种之一。

我国的轮式装载机是从20世纪70年代初期发展起来的,与其他机种工程机械相比,轮式装载机的桥、箱、泵、阀及缸等零部件产品配套相对成熟,已经形成了比较完整的配套体系。而且自90年代以来,国内外工程机械进入了一个新的发展时期。工程机械产品以信息技术为先导,在发动机燃料燃烧与电控、液压控制系统、自动操纵、可视化驾驶、精确定位与作业、故障诊断与监控、节能与环保等方面,有了长足的进步。设计人员开发出了许多新结构和新产品。ZL50型装载机作为主导产品,经过多年的发展,质量水平得到不断提高,已经形成独立的产品系列和行业门类。近年来,国内外装载机的发展趋向于采用新结构新技术,并向机电一体化、电子化方向发展。

然而,我国装载机在设计上存在很多问题,主要集中在可靠性、结构设计强度等方面。而变速箱对于装载机来说又是重中之重,所以变速箱的设计好坏直接影响到装载机的使用寿命以及工作效率。虽然现在市场上的装载机已经日趋成熟,但对其进行改进设计,尤其是对装载机的变速箱进行改进设计,仍有非常重要的意义。

ZL50装载机所采用的是行星式动力换挡变速箱:

首先,星行变速箱的主要优点是,可通过在行星排中设计多个行星轮,使载荷由几对齿共同传递,减轻了每对齿上的载荷,以便选用较小的模数,从而减小齿轮体积,因此行星变速箱在径向方向尺寸较紧凑。但轴向尺寸则与所采用的行星排数目有关,当行星排数较多时,则轴向尺寸较大。另外还可实现输入与输出轴同心转动。

其中简单行星排是由太阳轮、齿圈、行星架和行星轮组成。由于行星轮轴向旋转与外界连接困难,故在行星排中只有太阳轮、齿圈和行星架三个元件能与外界相连,并称为基本元件。在行星排传递运动过程中,行星轮只起到传递运动的惰轮作用,与传动比无直接关系。其中三个基本元件的传递中仅有两个是独立参数,这表示行星排具有两个自由度。当以某种方式固定某一个元件后,行星排变成了一自由度系统,即可由转速方程式确定另外两元件的转速比。这样,通过将行星排三个基本元件分别作为固定件、主动件或从动件,则可组成六种方案。

由于zl50装载机采用双涡轮变矩器和机械自动变速装置相结合,可以得到较大的变矩系数,且高效率范围宽,其作用相当于变矩器加上一个二档自动变速箱(随外负荷变化,不需人操纵,自动换挡)。因此他后面的行星变速箱档位数可以减少,ZL50型装载机的行星变速箱,有两个行星排组成,只有两个前进挡和一个倒档。输入轴和输入齿轮做成一体,与二级涡轮输出齿轮常啮合,二档输入轴与二档制动器摩擦片连成一体。前后行星排的太阳轮、行星轮、齿圈的齿数相同。两行星排的太阳轮制成一体,通过花键与输入轴、二档输入轴相连。前行星排齿圈与后行星排星架、二档离合器受压盘三者通过花键连成一体。前行星排行星架和后行星排齿圈分别设有倒档、一档制动器摩擦片。

变速箱后部是一个分动箱,输出齿轮用螺栓和二档油缸、二档离合器受压盘连成一体,同变速箱输出齿轮组成常啮齿轮副,后者用花键和前桥输出轴连接。后桥输出轴前端用滑动轴承支撑在前桥输出轴后面中心孔内;后端则以滚动轴承支撑在壳体上。前、后桥离合套用花键和前、后桥输出轴相连,并可由拨叉波动,当离合套移向前面时,前后轮同时驱动;当离合套移向后面时,则只有前桥驱动。离合套通过拉杆、拨叉来操纵,并有锁定机构。

相比液力机械传动系统的装载机不能拖启动;当柴油机熄火后,便不能转向;不能利用柴油机进行排气制动。ZL50装载机的传动系统中设有“三合一”机构,可以解决这些问题。

此构件由以下零件组成,空转齿轮通过一个滚动轴承支撑在闭锁离合器被动鼓轴上,滑动啮合套与闭锁离合器被动鼓周通过花键连接。中间传动轴,其上固定着齿轮1,此齿轮与另一齿轮2啮合,齿轮3通过滚珠轴承和自由轮支撑在中间传动轴上。齿轮3与油泵齿轮相啮合,而油泵齿轮变矩器泵轮齿圈相啮合。

当发动机启动后,发动机由被动变为主动,它要反过来通过这条传动路线来驱动车轮。由于自由轮只能单向传动,反向传动时,它自动把动力切断,这样,防止有可能发动机通过两条传动路线来驱动车轮,发生干涉,使“三合一”机构受损。三合一机构存有一个缺点,当发动机突然熄火时,要想利用发动机制动和保持动力转向,需将啮合套迅速连接上,但往往难于结合上。

基于上述内容,此设计主要是改进变速箱,设计过程:变速箱行星机构进行运动学和动力学分析,行星变速箱传动方案简图设计,齿轮传动部分设计,换挡制动器和闭锁离合器设计,行星变速箱结构分析。跟紧装载机行业向高档、高技术含量和智能化方向发展的趋势,开发和生产具有自主知识产权、适合我国国情的重型车用变速器。

二、本课题的目的(重点及拟解决的关键问题)

轮式装载机总体设计,是机械设计制造及其自动化专业学习的一个重要的环节。通过设计提高我们对机构的分析能力,机械构造设计的能力,机电一体化系统设计能力,掌握实践生产过程自动化的设计方法,并锻炼机械类学生的综合素质。通过设计,我们将有关课程(如机械原理,机械设计,理论力学,材料力学,液压与气压传动,工程材料,材料成型,自动控制理论,电气控制,测试技术,数控技术,微型计算机原理及应用等)中所获得的理论知识在实际中综合地加以运用,并使这些知识得到巩固和发展,并使理论知识和生产密切的结合起来。

关键问题:了解装载机的发展状况和结构类型,确定装载机总体参数、总体布置;分析行星机构的运动学和动力学,其中包括运动分析、力矩分析、功率分析;分析行星齿轮变速箱,其包括行星变速箱组成、自由度和档位数分析,行星变速箱转速分析,行星变速箱力矩分析;设计行星变速箱传动方案简图;设计齿轮传动部分,包括基本参数的确定、配齿计算、齿轮的几何计算;分析行星变速箱结构,包括行星变速箱中不转动部分的支撑和定位、旋转零件的支撑和定位。编写符合要求的设计说明书,并正确绘制机械与液压工程图纸,独立撰写一分毕业论文,并绘制有关图表。

三、主要内容、研究方法、研究思路

(1)设计任务:

①装载机的发展状况和结构类别

②装载机总体参数的确定

③装载机的总体布置

④装载机变速箱传动特性分析

(2)装载机变速箱的设计和计算

①变速箱结构形式的选择

②变速箱行星排运动和受力分析

③行星变速箱传动方案简图设计

通过对资料的调查、收集、加工与整理,综合运用多学科的理论、知识与技能,分析解决变速箱设计中的问题。并且经过实习,了解变速箱的实际工作状况,在对变速箱设计过程中有所帮助外,还能使自己的设计更加接近实际。

四、总体安排和进度(包括阶段性工作内容及完成日期)

2013.3.29-2013.4.11 熟悉整理资料

2013.4.12-2013.4.25 方案选择及总体设计

2013.4.26-2013.5.9 绘制总图

2013.5.10-2013.5.23 变速箱传统系统分析

2013.5.24-2013.6.13 行星排设计及受力分析计算

2013.6.14-2013.6.22 绘制零件图纸

2013.6.23-2013.6.27 准备论文及答辩

五、主要参考文献

[1]吴永平等.工程机械设计机 北京 化学工业出版社 2007.

[2]杨占敏 轮式装载机 北京 化学工业出版社,2007.

[3]吴庆鸣 何小新 工程机械设计 武汉 武汉大学出版社 2006.

[4]杨国平 现代工程机械技术 北京 机械工业出版社 2006.

[5]杨晋升 轮式装载机设计 北京 机械工业出版社 1986

[6]张光裕 工程机械底盘构造与设计 1986

[7]同济大学主编 铲土运输机械 北京 中国建筑工业出版社,1987.

[8]吉林工业大学编. 轮式装载机设计 北京 中国建筑工业出版社,1989.

[9]同济大学主编. 工程机械底盘构造与设计 北京 中国建筑工业出版社,1987.

[10]诸文农编. 底盘设计(上、下) 北京 机械工业出版社.

[11]许镇宇、邱宣怀主编. 机械零件 北京 人民教育出版社.

[12]机械零件课程设计.贵州:贵州人民出版社.

[13]吉林工业大学主编. 工程机械液压与液力传动 北京 机械工业出版社.

[14]东北工学院编.机械零件设计手册. 北京:冶金工业出版社.

[15]成大先主编 机械设计手册 北京 化学工业出版社,2004.

[16]《机械工程标准手册》编委会编 机械工程标准手册 北京 中国标准出版社,2002.

[17]黄宗益、薛瑞祺、阎以诵编著 工程机械CAD 上海 同济大学出版设,1990.

[18] 闻邦椿.机械设计手册(第五版)北京 机械工业出版社,2010.

指导教师意见:

摘要

Zl50装载机是我国轮式装载机系列中的中型产品,该机是一种较大型的以装卸散状物料为主的工程机械,广泛应用于矿山、基建、道路修筑、港口、货场、煤场等地进行装载、推土、铲挖、起重、牵引等作业。

本设计的步骤简单如下:1.对装载机的总体进行分析,确定总体参数;2.牵引计算,确定出各档及各档传动比;3.对装载机进行整体布置,并绘出总体布置图;4.变速箱的设计,这是本设计中最主要的部分,确定传动比,设计传动简图,配齿计算,得出齿圈、行星轮、太阳轮的齿数,并验算其合理性。然后进行齿轮设计;5.对离合器,轴、轴承的设计及选择。

此设计中,主要任务是设计变速箱及第二行星排,设计中采用了行星式动力换挡变速箱,它具有3个离合器和3根轴,且轴安装在壳体内,使变速箱结构简单、便于维修。变速箱具有两个前进挡和一个后退档,可以产生三个速度。

关键词: 装载机 液力机械传动系统 行星式动力换挡变速箱

ABSTRACT

The loader ZL50 iswheel type and it is more bigger among the series made in our country.It is suitable for loading discharging materials and it applies for mine、capital contuction、road builing 、port、field、coalfield and carries loading 、pushing dust 、diging rising weight

The design of the simple steps are as follows: 1.the overall loader analysis , to determine the overall parameters; 2. traction calculation, determine the gear and the gear ratio; 3 .to loader for the overall layout, and draw the overall layout; 4.design of gearbox ,and it is the design of the main parts determination of design, transmission ratio, transmission diagram, gear tooth number calculation, the ring gear, a planet wheel, sun wheel, and check the rationality. Then the design of the clutch gear; 5. design and selection of shaft, bearing.

In my design, I adopt counter shaft power shift transmission’s construction is simple and maincenance is easy .the transmission has two forward and one reverse gear ,it can provide three speeds

KEY WORDS: lorder liquid engine driving system

Hydraulic torque conventer power shift gearbox

目录

第1章 前言1

第2章 总体设计2

2.1 概述2

2.2 选择确定总体参数2

2.3 装载机底盘部件型式设计11

第3章 牵引计算22

3.1 柴油机与变矩器联合工作的输入与输出特性曲线22

3.2 确定档位及各档传动比 28

3.3 运输工况牵引特性曲线 31

3.4 求出各档最高车速并分析牵引特性 33

第4章 总体布置35

4.1 总体布置草图的基准 35

4.2 各组成部件的位置 35

4.3 计算平衡重 39

4.4 桥荷的分配 40

4.5 验算轮胎载荷 42

4.6 总体布置图 43

第5章 行星式动力换挡变速箱设计 43

5.1 传动比的确定 44

5.2 传动简图设计 45

5.3 配齿计算 47

5.4 离合器设计53

5.5 齿轮设计56

5.6 轴的设计 59

5.7 轴承的选择计算 64

第6章 毕业设计小节 66

参考文献68

毕业实习报告 69

第1章前言

ZL50轮式装载机是一种较大型的以装卸散状物料为主的工程机械,因其具有作业速度快、效率高、机动性好、操作轻便等优点,所以对于加快工程建设速度,减轻劳动强度,提高工程质量,降低工程成本都发挥着重要的作用,是现代机械化施工中不可缺少的装备之一。

ZL50轮式装载机是高效率、用途广泛的工程机械,广泛应用于建筑、矿山、道路、水电和国防建设等国民经济各个部门,不仅对松散的堆积物料可以进行装、运、卸等作业,还可以对岩石、硬土进行轻度挖掘工作。

ZL50轮式装载机属于ZL系列,采用轮式行走系,液力机械传动系,铰接式车架工作装置采用液压操纵。此类装载机具有机动性好、转向灵活、生产率高、操纵轻便等特点,一般后桥布置为摆动桥,增加了整机的稳定性,所以该机的安全性好。

ZL50轮式装载机为四轮驱动装载机,作业时以全轮驱动,空车运输时,为防止寄生功率,仅用前轮驱动,因此后桥的传动可以用啮合套脱开。ZL50装载机采用液压与液力机械传动,具有变速平稳、传动比大、作业效率高和无级变速等特点,应用十分广泛。其变速器采用行星齿轮变速器,换档操纵为液压式。ZL50装载机的主要特点:采用双涡轮变矩器、具有两个前进档一个倒退档的双行星传动动力换档变速器,以及能实现脱起动,内燃机熄火转向,排气制动的“三合一”机构。

第2章 总体设计

2.1 概述

总体设计是极为关键的环节,是对所设计的机械的总设想。总体设计的成败关系到整部机械的经济技术指标,直接决定了机械设计的成败。

总体设计指导机构设计和部件设计的进行,在接受设计任务以后,应进行深入细致的调查研究。收集国内外同类机械的有关资料。了解当前国内外装载机的使用、生产、设计和科研情况,并进行分析比较,制定总的设计原则。设计原则应当保证保证所设计机型符合的方针、政策。在满足使用要求的基础上,力求结构合理,技术先进,经济性好,寿命长。制定总则之后,便可以编制设计任务书,在调研的基础上,运用所学知识,从优选择总体方案,以确保设计的成功。

装载机总体参数的选择就是对装载机主要性能提出总体的要求,作为整机和总体设计的依据。

总的设计原则:

1.遵守“三化”:零件标准化、产品系列化、部件

2.采用“四新”:新技术、新结构、新材料、新工艺。

3.满足“三好”:好制造、好使用、好维修。

装载机总体参数主要包括:发动机功率,载重量,装载机自重,车速,牵引力,铲起力,轴距,轮距,最大卸载高度,最小转向半径,轮胎尺寸,整机外形尺寸。

2.2选择确定总体参数

目前,装载机的总体设计中有计算法、类比法及综合运用计算等三种设计方法,限于我们的条件,我们的设计采用计算法和类比法综合运用的方法,比较法就是参考国内外已有的同类型机种的参考尺寸,结合我们要设计的机型的具体要求,参照确定其参数尺寸。

总体参数的确定包括以下内容:

2.2.1确定轴距和轮距

1.轴距是装载机总体设计中的主要尺寸,一般是用比较法初步选取,然后通过绘制总布置,才能准确地选定轴距。轴距L的主要影响以下三个方面的性能:

(1)轴距增大,有利于提高整车的纵向稳定性。轴距增加还可以减少装载机在行驶中之前后颠覆,提高行驶平稳性,减少司机疲劳。

(2)轴距增长如其它条件不变时,最小转弯半径增加。

(3)轴距增长,相应的车架、传动轴等都要增长,所以装载机自重增加。

此外,轴距的改变,还会影响车架受力和整机的通过性。

2.大部分装载机前后轮距相同,且前后轮用相同的轮胎。

(1)轮距增加,可提高整机横向稳定性,但最小转弯半径将增加,影响机动性。

(2)轮距增加会造成铲斗斗宽的增加。因为在作业中要保护轮胎不被碰伤,一般铲斗要比轮胎宽50――100mm(单侧),所以轮距增加,铲斗宽度相应加宽,这样就降低单位斗刃长度上的插入力。

综上所述,参考同类产品初选:

轴距 3300mm 轮距 2200mm

2.2.2初选轮胎:

装载机多在松软、潮湿或干硬不平的地面上工作,为了降低接地比压,增加轮胎支承面积,改善附着性能和缓冲性能,多采用低压宽基轮胎。在国外,宽基轮胎多采用无内胎轮胎,它工作安全,散热性好,寿命较长。必要时其内部还可注入氯化钙溶液,以增加装载机作业时的稳定性和附着性能。轮式装载机的轮胎费用占整机费的10%—15%,占装载机使用费用的25%—50%,因此,正确的选择轮胎,延长轮胎的使用寿命,对降低生产成本,具有重要的意义。

装载机的轮胎应根据轮胎所受负荷,作业场地情况和运输距离来选择。它除了满足一定的承载能力外,还需要有很好的耐磨、抗穿刺性、牵引性、散热性和缓冲性能。对于常在松软地面上作业的装载机,为了发挥其牵引力,要求轮胎有较好附着性能,应采用牵引型轮胎,其特点是轮胎表面沟槽宽度大于凸起花纹的宽度(二倍以上),能使花纹压入软土中,产生比较大的抓土能力。花纹呈“八”字形或“人”字型,具有较好的自动排除沟槽中泥土的能力,它的橡胶层薄,散热快,因此可在较高的速度下运转。

轮式装载机在矿山、碎石厂作业时,轮胎外侧最易受损伤,为了保护轮胎,或将外部胎肩部分加厚,或将外侧半个胎面作成光胎面,采用耐切割的胶料,以提高抗切割性能。对于用在矿山碎石硬路面作业的装载机,要求轮胎具有耐磨和抗穿刺的能力,应采用岩石型轮胎,其特点是凸起花纹的宽度大于槽宽,橡胶层厚,花纹深,不易被尖刀刺穿或切割,使其在岩石等硬地面作业时使用寿命长。但其散热差,不宜作长距离或高速行使。

参考文献

[Ⅰ]吴永平等.工程机械设计机 北京 化学工业出版社 2007.

[Ⅱ]杨占敏 轮式装载机 北京 化学工业出版社,2007.

[Ⅲ]吴庆鸣 何小新 工程机械设计 武汉 武汉大学出版社 2006.

[Ⅳ]杨国平 现代工程机械技术 北京 机械工业出版社 2006.

[Ⅴ]杨晋升 轮式装载机设计 北京 机械工业出版社 1986

[Ⅵ]张光裕 工程机械底盘构造与设计 1986

[Ⅶ]同济大学主编 铲土运输机械 北京 中国建筑工业出版社,1987.

[Ⅷ]吉林工业大学编. 轮式装载机设计 北京 中国建筑工业出版社,1989.

[Ⅸ]同济大学主编. 工程机械底盘构造与设计 北京 中国建筑工业出版社,1987.

[Ⅹ]诸文农编. 底盘设计(上、下) 北京 机械工业出版社.

[ⅱ]许镇宇、邱宣怀主编. 机械零件 北京 人民教育出版社.

[ⅲ]机械零件课程设计.贵州:贵州人民出版社.

[ⅳ]吉林工业大学主编. 工程机械液压与液力传动 北京 机械工业出版社.

[ⅴ]东北工学院编.机械零件设计手册. 北京:冶金工业出版社.

[ⅵ]成大先主编 机械设计手册 北京 化学工业出版社,2004.

[ⅶ]《机械工程标准手册》编委会编 机械工程标准手册 北京 中国标准出版社,2002.

[ⅷ]黄宗益、薛瑞祺、阎以诵编著 工程机械CAD 上海 同济大学出版设,1990.

[ⅸ] 闻邦椿.机械设计手册(第五版)北京 机械工业出版社,2010.

川公网安备: 51019002004831号

川公网安备: 51019002004831号