复式耕整机设计

27页 10000字数+说明书+3张CAD图纸【详情如下】

CAXA图纸

复式耕整机设计说明书.doc

外文翻译--我国深松机械的研究现状和发展趋势.doc

机架.dwg

液压缸.dwg

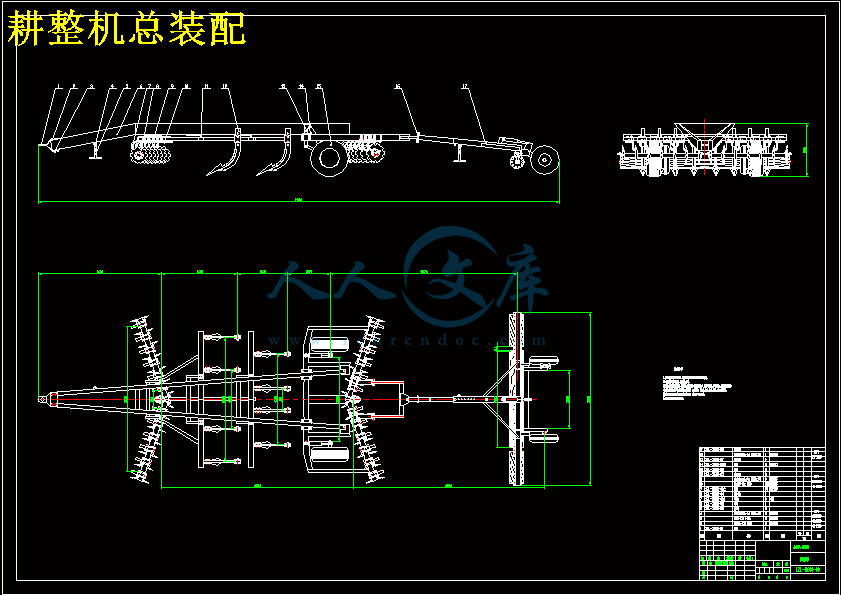

耕整机总装配.dwg

摘 要

为了解决传统整地机所不能完成的多项作业的问题,在研究分析传统整地机的基础上,研制出可与大马力拖拉机配套的新型复式耕整机。复式耕整机是一种多功能的土壤耕作机械,与大功率拖拉机配套作业时,首先对根茬进行粉碎还田,然后对垄顶位置进行深松,其后进行镇压等多项作业,从而可以打破犁底层,提高土壤透气、透水性能,提高土壤抵抗自然灾害能力,一次耕整地作业使田面达到待播状态,机具应用领域广泛。

关键词:复式耕整机;灭茬;深松;

Abstract

In order to solve a number of operations of traditional tillage machine can finish the problem, based on analysis of traditional tillage machine, developed a new type of compound can be matched with a large horsepower tractor tillage machine. Combined tillage machine is a multifunctional tillage machine, and operation supporting large power tractor, first on the stubble crushing returning, and then deep loosening of the ridge top position, followed by repression and many other operations, which can break the plow pan, improve soil permeability, water permeability, improve soil resistance natural disaster ability once the tillage and soil preparation, the surface reach to broadcast state, equipment widely used.

Keywords: multiple tillage machine; stubble; subsoiling;

目录

摘 要I

AbstractII

目录III

前言V

1开发复式耕整机的目的和意义1

2国内外复式耕整机的发展动态、存在问题及发展方向2

3总体方案的确定及主要参数的选择4

3.1总体结构设计4

3.2主要技术参数5

4主要结构部件设计6

4.1圆盘耙组件6

4.1.1圆盘耙片的结构形式7

4.1.2圆盘耙片的主要参数8

4.2深松部件10

4.2.1铲柄受力分析及校核12

4.2.2土壤比阻的确定13

4.2.3深松铲水平力和垂直力的测定13

4.2.4铲柄的校核14

4.3镇压碎土部件15

4.3.1镇压辊宽度的确定16

4.3.2镇压辊直径的确定17

4.4其他部件的设计18

4.4.1支撑轮的设计18

4.4.2机架的设计18

5结论19

参考文献20

致 谢21

附录22

复式耕整机是一种由多功能的土壤耕作机械。它的耕作部件为灭茬部件,圆盘耙的切土、碎土能力强,一次耕作能够达到一般犁耙作业几次的碎土效果,耕后地表平整、松软,能满足精耕细作要求,且缩短工序间隔,有利于抢农时抗旱保墒,减少拖拉机进地次数,减轻对土壤压实,减少能源消耗,降低作业成本,减少机具投资,提高机具利用率,加之近年来国内还田技术和免耕少耕技术的推广应用,复式耕整机得到了迅猛发展,已成为拖拉机的主要配套机具之一。

到目前为止,复式耕整机产品在理论上可以配套58.8-73.5kw的拖拉机,但实际上因受传动系统强度及结构尺寸、机架结构强度的限制,配套合理范围仅达有所减小;耕深亦局限在旱耕12-16cm。20世纪90年代以来,为适应市场需要,有些企业试图开发大型耕整机,但因水平有限,仅采用原有产品外延放大和堆砌材料的方法,没有着重结构的改进和参数的优化,因而走了弯路。因此,现有复式耕整机产品在品种上尚有大型和深耕型的空缺。随着水稻集约化、规模化生产的发展,水田耕整用宽幅高速型复式耕整机成为发展方向。水田土壤含水率高,抗剪切、抗压强度特别低,附着力、外摩擦力也接近为零,切土部件与土壤之间存在润滑水膜。因此,大块水田使用大型拖拉机旋耕机组水耕时,为充分发挥其功率,实现高效率、高效益,需要工作幅宽3m以上的宽幅旋耕机。但宽幅又受到道路行驶和入库停机不便的制约。解决途径有二:一是采用宽度伸缩或折叠式结构;二是采用适中的幅宽,提高作业速度,从现有的2-5km/h提高到4-8km/h。为满足以上要求,需要改进复式耕整机结构和参数,研制宽幅高速耕整机及灭茬、深松、镇压和深施化肥的复式作业机械。

大功率拖拉机以其强劲的功率,可以配套大型农机具,配套机具范围广,机动灵活强;性能可靠,低故障率;与履带拖拉机比较,具有油耗低、工作效率高的特点;标准化的耕整地作业质量,为培肥土壤创造了良好的基本条件,在农业生产机械化中扮演重要角色。预计到 2012 年,黑龙江省将新增大功率拖拉机 1 万台,保有量达到 2.73 万台。为大功率拖拉机研制配套的宽幅大型联合整地机,可以充分发挥大功率拖拉机的作业效率。因此,为了确保粮食生产安全,发挥大功率拖拉机的作用,尽快研发与大功率拖拉机配套的宽幅大型耕整地机具,提高农业机械化耕整地的作业效率迫在眉睫。

1开发复式耕整机的目的和意义

土壤耕作是种植业生产过程中的重要一环,对于农作物增产具有重要作用。因此,土壤耕作机械的发展一直受到人们的关注。由于土壤耕作是一项能耗很大的作业,传统的旋耕、灭茬等是由好几种机型来完成的,多次耕作会对土壤造成破坏,不利于水土保持,消耗较大。这样既增加了作业成本又增加了农民的负担。长期以来,人们一直在探讨新的工作制度,松土和局部松土,不耕和少耕。在这种形势下, 研究一种一次作业可完成灭茬、深松、镇压作业的新型联合作业机, 实现用一种机型解决深松、灭茬等几种机型的通用问题, 对于减轻农民购买机具的投资负担, 便于 使用与维修, 提高机具利用率, 都具有极其重要的意。于是复式耕整机械诞生了。这种机械之所以引人注目,一是强化土壤耕作过程,可以满足不同条件下的不同土壤类型;二是一次耕作可以联合作业;三是有动力驱动,质量好;四是作业时几乎不需要牵引功率,减少了功率的消耗。目前广泛使用的,应用前景最好的就是复式耕整机。耕机切土、碎土能力强,一次耕作能够达到一般犁耙作业几次的碎土效果,耕后地表平整、松软,能满足精耕细作要求,且缩短工序间隔,有利于抢农时抗旱保墒,减少拖拉机进地次数,减轻对土壤压实,减少能源消耗,降低作业成本,减少机具投资,提高机具利用率,加之近年来国内还田技术和免耕少耕技术的推广应用,复式耕整机得到了迅猛发展,已成为拖拉机的主要配套机具之一。

复式耕整机用于未耕或已耕地上的耕整作业,一次进地可完成深松、灭茬、镇压等多项作业。其中深松作业要求深松的范围一般在250mm-350mm之间。具有蓄水保墒、改善土壤结构、优化土壤成分、提高作物产量,实现耕地的可持续利用的作用。旋耕灭茬部分全幅旋耕作业一般用于平作地,耕深要求一般为 100-160mm。其次对于复式耕整机的开发主要以在满足农业要求的前提下尽可能的选取简单轻便的结构,在原有的结构上要有创新和改进。

2国内外复式耕整机的发展动态、存在问题及发展方向

目前,水平轴旋耕部件与地轮转向一致的耕整机,在国内外在实际生产中得到广泛的应用,并且旋耕工作部件结构相当完善。复式耕整机的保有量也增加的很快,为了适应当前的生产规模,为不同机型拖拉机配套,生产了作业幅:为1.25m-2.8m多种型号的复式耕整机。如南昌旋耕机厂的IGN系列多种型号复式耕整机,连云港旋耕机集团公司生产的IGE2—210型复式耕整机,1C-N-250S型复式耕整机等。在黑龙江省农业生产中,使用的机型还有1GHL一280型松旋起垄机、1GSZ-210/280型组合式旋耕多用机、1GZJ一210型旋耕灭茬联合整地机、1GLT-4型松旋灭茬起垄通用机等。

对于北方旱田垄作地区气温低,春秋整地时间短,多采用单一灭茬或旋耕和灭茬旋耕联合整地为主,机具的耕作幅宽一般在 1.4~2.1 m,配套拖拉机多以中小功率拖拉机为主。随着我国的经济状况的不断提高,支农的力度不断加大,农村拖拉机的整体水平也由中小型向大型转变,进口拖拉机也进行了大量引进,拖拉机的整体水平得到了显著提高,但是与之配套的大型机具还很缺少,急需加大力度研制和开发。宽幅灭茬、旋耕联合整地机就是专为 88.2kW 以上的大型拖拉机配套使用的,因此,从近几年国产的旋耕机配套推广应用情况来看,存在一些问题:(1)、拖拉机动力输出轴容易损坏:(2)、十字万向传动轴使用寿命短:(3)、旋耕作业性能不稳定和容易缠草的问题;(4)、缺少与大功率拖拉机配套的复式耕整机;(5)、作业性能满足不了当今的农艺要求;这些问题的解决有待于进行更深入的研究。

机具通过实际生产应用,其作业效率明显优于其它小型联合整地机,提高工作效率在 20%以上,为农业生产赢得农时。深松装置可以打破多年来因用小型机具整地形成的犁地层,改良土壤、增强土壤活力,提高土壤抵抗自然灾害的能力。拖拉机一次进地就可以使田面达到待播状态,节约作业环节,减少成本投入,节约能源消耗随着农业机械化程度的增强,工作效率和效益的提高,现有的复式耕整机的弊端日益突出,已满足不了农艺要求和生产规模扩大的需要。故对复式耕整机的研究有了进一步的深化,出现如下几个方向的发展趋势:(1)、向宽幅,高速型复式耕整机发展;(2)、向联合作业机组方向发展;(3)、向多功能机方向发展;(4)、向可持续发展战略型发展;(5)、大型复式耕整机需求量有所增加。由牵引架和主机架组成主机框架,用于整机各部件的联接。圆盘耙架与牵引架铰接,用液压油缸调整耙架的上下位置, 圆盘耙组件安装于圆盘耙架上,利用液压油缸调整耙架实现圆盘耙组件的入土深度,以满足不同耕深的农艺要求。地轮组件安装于主机架上,两个液压油缸用于升降地轮,完成整机的升起和降落,运输时整机升起,作业时利用地轮陷深,实现整机各工作部件的工作深度要求。深松部件安装于主机架上,完成深松作业。镇压轮采用牵引的形式与主机架铰接,用于镇压和碎土。镇压强度用安装于镇压顺梁上的弹簧调节。是将三角形牵引架、X形圆盘耙架、深松机架、和门形镇压器梁架按工艺程序要求进行合理组配, 实现各种工作部件的最佳配置, 同时既可以根据不同的土壤条件进行整机耕深液压调节, 又可以进行不同工作部件 根据机具的总体结构配置需要,并保证各组件之间保持足够间隔距离和各工作部件前后距离,保证机具的通过性能。因此,本机设计了框架式和三角形机架结构。

1) 牵引架的设计。牵引架承担整机前进方向的力量,因此要求牵引架有足够强度和刚度。本机采用200×100×6、150×100×6(210型)的矩形管、摇臂、牵引板焊合而成的三角形机架结构。

2) 深松铲机架的设计。深松铲机架联接深松铲,并承担着联接后面各个组件,因此要求此架有足够的强度和刚度。本机采用150×100×6的矩形管与18mm 钢板焊合而成的框架式结构。 该机具与大功率拖拉机配套作业时,首先对根茬进行粉碎还田,然后对垄顶位置进行深松,其后进行镇压等多项作业,一次耕整地作业使田面达到待播状态。该机具应用领域广泛, 适宜在东北三省旱田垄作地区的耕整地作业。深松装置可以打破多年来因使用小型机具整地形成的犁地层,改良土壤、增强土壤活力,提高土壤抵抗自然灾害的能力。拖拉机一次进地就可以使田面达到待播状态,节约作业环节,减少成本投入,节约能源消耗。

该机具为大功率拖拉机提供了一种新型的配套机具,机具适宜在各种地块作业,提高耕整地作业效率,缩短作业周期,用较少的作业时间,使田面达到待播状态。减少了机车对土壤的压实程度,提高作业质量,减少了生产成本的投入,具有明显的综合技术经济效益。

参考文献

[1]国农业机械化科学研究所.农业机械设计手册[M].北京: 中国工业出版社1988,23-89

[2]濮良贵,纪名刚.机械设计[M].(第七版),北京:高等教育出版社, 2001,13-193

[3]吴宗泽, 罗圣国. 机械设计课程设计手册[M].(第二版),北京:高等教育出版社, 1999,11-247

[4]董国耀, 机械制图[M]. 北京:北京理工大学出版社, 1998,1-50

[5]孔令德, 张认成. 旋耕刀的研究现状与展望[J]. 江苏理工大学学报, 1997.18(3):88-92.

[6]叶新跃, 对我国复式耕整机机研究现状及发展方向的探讨[J]. 山东农机, 1995.7(5):12—13.

[7] Ping-Kun Chang,Yaw-Nan Peng. Influence of mixing techniques on propertiesof high performance concrete. [J] Cement and Concrete Research. 2001

[8]王伯平,互换性与测量技术基础[M]. 北京:机械工业出版社,2008,23-56.

[9]Zhu Y, Zhang S, Rong y. Experimental Study on Stiffness of T-Slot Based Modular Fixure[M]. Transaction of NAM-RI/SME, Volumn X XI,1993.

[10]涂建平, 秸杆还田机刀片优化排列软件的开发研究[J]. 江西农业大学学报(自然科学版), 2002, 24(4): 556-558.

[11]贾洪雷,东北垄作蓄水保墒耕作体系与配套机具[J]. 农业机械学报, 2006, 36(7): 32-37.

[12]贾洪雷, 陈忠亮, 刘昭辰, 孙裕晶, 王长生. 耕整联合作业工艺及配套机具的研究[J]. 农业机械学报, 2001, 32(5): 40-43.

[13]桑正中.,农业机械学(上册)[M]. 北京: 机械工业出版社, 1987,114-136.

[14]周建来, 李源知, 焦巧凤. 国内外旋耕机的技术状况[J]. 农机化研究,2000(2): 49-51.

川公网安备: 51019002004831号

川公网安备: 51019002004831号