TWLQ型气体涡轮流量计的设计与制造

30页 15000字数+外文翻译+说明书+5张CAD图纸【详情如下】

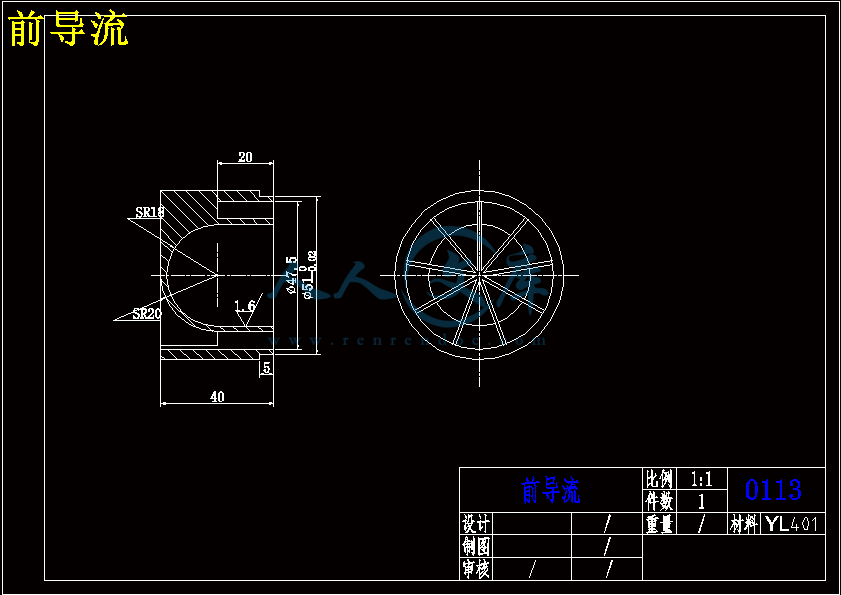

前导流.dwg

叶轮.dwg

后导流.dwg

气体涡轮流量计的设计与制造论文.doc

装配图.dwg

轴承.dwg

外文翻译--计算机辅助设计制造与应用.doc

目 录

1绪 论1

1.1 引言1

1.2 涡轮流量计的特点1

1.3气体涡轮流量计的应用场合3

1.4 发展前景6

2涡轮流量计的工作及结构原理7

2.1 TWLQ型气体涡轮流量计的工作原理7

2.2气体涡轮流量计的结构原理8

2.2.1 涡轮流量计的结构原理8

2.2.2 涡轮流量传感器的结构9

3气体涡轮流量计叶轮的改进21

3.1叶轮的叶型对加工的影响21

3.2叶轮叶型结构参数的确定22

4 导流器与传感器的改进26

4.1导流器的改进26

4.2传感器的改进29

4.2.1 传感器的分类29

4.2.2流体密度对传感器的影响30

5 TWLQ气体涡轮流量计中轴与轴承的改进34

5.1 涡轮轴的改进34

5.2 TWLQ气体涡轮流量计中轴承的结构改进35

6气体涡轮流量计的安装使用和维护38

6.1流量计的安装38

6.1.1传感器的安装38

6.1.2连接管道的安装39

6.2选用40

6.2.1传感器的选用40

6.2.2流量指示积算仪41

6.3使用注意事项41

6.4维护和故障处理42

结 论44

参考文献45

附录1:中英文翻译46

致 谢65

1绪 论

1.1 引言

数千年前,人们为适应农业灌溉和水利的需要,就已开始关注着流量测量问题,古埃及出现了堰的雏形,而我国都江堰在那时也已经知道利用宝瓶口岩壁上所刻的“水则”,来观察水位,以进行控制[1]。

到19世纪中叶,从节流式流量计开始,逐渐建立了近代流量计的理论基础。现代各类流量仪表也相继出现,如商用的水表,煤气表和文丘里管差压式流量计等。20世纪20-30年代,又出现了孔板和喷嘴差压式流量计,浮子流量计,融及时流量计以及宗法和稀释法等流量测量方法。20世纪50年代以后,随着电子技术,材料和加工技术的飞跃发展,以流程工业为先导的各工业部门和公用事业大量使用流量仪表,促使各种使用新颖的流量仪表相继问世和发展,如涡轮式,电磁式,超生式和涡街式流量计等。当代应用的流量仪表的主要品种,很多是这一阶段开发的。20世纪70年代后期又出现了科里奥利质量流量计。

1.2 涡轮流量计的特点

流量计是一种速度式流量仪表。它是以动量守恒原理为基础的,流体冲击涡轮叶片,使涡轮旋转,涡轮的旋转速度随流量而变化,最后从涡轮的转数求出流量值。在二次仪表进行计数和显示,可反映出瞬时流量和累积流量(或称总量),也可以转换成标准信号进行远传。通常将涡轮流量计的感知流体留宿的涡轮及组合(包括前后导流架,轴承,客体即前置放大器)统称为涡轮流量传感器,而将涡轮转速检出后的信号处理,转换部分称为二次仪表或显示仪表。

涡轮流量计之所以能够广泛地应用于石油工业领域。是因为涡轮流量计比其他形式的流量计,如容积式流量计有更突出的优点,如涡轮流量计具有流量范围宽、结构紧凑、简单、使用寿命长等优点,更重要的是,涡轮流量计能够经受严重的脉动而引起的超出流量上限的流量,以及流量计不会因为液体中所夹带的固体物从而导致管路系统的阻塞,一般小颗粒物质经过流量计时也不会引起损坏。但是,容积式流量计就不能容忍液体中夹带固体颗粒,这不仅会使流量计发生故障,更严重的是,一旦流量计卡死不转,将导致液体的阻塞而引起系统过压的现象,因此我们相信,涡轮流量计将会在石油工业领域,以及其他领域得到越来越广泛的应用,到如今占据全球领先位置。我国开展内近代流量测量技术方面的工作比较晚,20世纪60年代才开始有了国产流量计,发展到现在已经形成了一个相当规模从事流量测量技术和仪表研究开发和生产的产业,以逐步跻身世界领先水平。

对于气体涡轮流量计的测量精度一般为0.25%R~1.5%R,对于液体涡轮流量计,它的测量精度一般为0.25%R~0.5%R,高精度型可达到0.15%R,特殊专用型为0.5% R~1% R。涡轮流量计的短期冲度型可达0.5%~0.2%。由于具有良好的重复性,因此其在贸易结算中被优先选用。 涡轮流量计的输出信号为脉冲频率,因此适用于总量及瞬时流量的计量与控制,且易于远传。信号的抗干扰能力也较强。但是涡轮流量计难以长期保持校准,需要定期校验。流体的密度,黏度等物理性质对仪表特性有较大影响,来流的速度分布和旋转来流对流量计的特性也有较大影响。

智能化气体涡轮流量计是集流量,温度,压力检测功能于一体,并能进行温度,压力,压缩因子自动补偿的新一代流量计广泛应用于企业生产和家庭生活中。

最贴近人民生活的家用燃气表和家用水表大多是采用涡轮结构的流量计,涡轮流量计是石油,化工,电力,冶金,工业锅炉等工业,行业的燃气计量和城市天然气,燃气调压站及燃气贸易计量的理想仪表。

涡轮流量计,是速度式流量计中的主要种类,它采用多叶片的转子(涡轮)感受流体平均流速,从而推导出流量或总量的仪表。一般它由传感器和显示仪两部分组成,也可做成整体式。涡轮流量计和容积式流量计、科里奥利质量流量计称为流量计中三类重复性、精度最佳的产品,作为十大类型流量计之一,其产品已发展为多品种、多系列批量生产的规模。

气体涡轮流量计的优点[2]:

(1)高精度,在所有流量计中,属于最精确的流量计;

(2)重复性好;

1.3气体涡轮流量计的应用场合[3]

涡轮流量计在以下一些测量对象上获得广泛应用:石油、有机液体、无机液、液化气、天然气和低温流体统在欧洲和美国,涡轮流量计在用量上是仅次于孔板流量计的天然计量仪表,仅荷兰在天然气管线上就采用了2600多台各种尺寸,压力从0.8~6.5MPa的气体涡轮流量计,它们已成为优良的天然气计量仪表。

涡轮流量计是一种速度式仪表,它具有压力损失小,准确度高,起步流量低,抗震与抗脉动流性能好,范围度宽等容易维修的特点。

气体涡轮流量计因其结构简单、线性好、精度高等特点而得以广泛应用。实际涡轮流量计在使用过程中受其结构参数及被测流体特性的影响,输入输出关系即特性曲线并非是理想直线,如图1-1所示(横坐标Q是体积流量;纵坐标K是流量系数)。 小流量区普遍存在着“驼峰”状非线性区,使涡轮流量计在小流量区测量误差较大。研究表明:涡轮流量计特性的影响因素很多,主要有被测流体介质粘性,涡轮流量计结构参数及来流速度分布等。对于来流速度分布的影响,实际应用中可控制流量计在安装管道中的位置(前后保持一定距离的直管道等措施),使来流速度分布相对均匀,因而本文引用理论计算与实际测量结果吻合较好的理论模型着重就流体介质粘性与流量计结构参数的综合影响进行探讨。

天津第五机床厂生产的TWLQ型气体涡轮流量计,口径Ф50~Ф150mm,始动流量 3.0m3/h,流量范围10~150m3/h,介质温度-30℃~+60℃,工况压力小于1.6 Mpa ,准确度为1.5级,外形如下图1-2所示。图1-3 无锡求新公司生产的LWGQ气体涡轮传感器

浙江苍南仪表有限公司LWQ型气体涡轮流量计其特点及结构参数如下:

特点: (1)测量范围宽,下限流速低于0.5m/s,压力损失小,叶轮抗冲击能力强。 (2)具有较高的抗电磁干扰和抗振动能力,采用全密封隔离保护自润滑轴承, 性能可靠工作寿命长。 (3)采用先进的超低功耗单片微机技术,整机功能强,功耗低,性能优越。具有非线性精度补偿功能的智能流量显示器。

(4)仪表系数可由按键在线设置,并可显示在LCD屏上,LCD屏直观清晰,可靠性高。 (5)采用EEPROM对累积流量、仪表系数进行掉电保护,保护时间大于10年。 (6)可在被测气体稳定的压力状态下进行压力补偿。 气体涡轮流量计是一种速度式仪表,它具有精度高,重复性好,结构简单,运动部件少,耐高压,测量范围宽,体积小,重量轻,压力损失小,流通能力大(同样口径可通过的流量大),维修方便等优点,且可适应高温,高压和低温流体的测量需要,用于封闭管道中测量低粘度气体的体积流量和总量。在城市天然气计量,输配气管网天然气计量,石油、化工、电力工业和民用等锅炉燃气计量,燃气调压站计量中得到了广泛的应用。

2涡轮流量计的工作及结构原理

2.1 TWLQ型气体涡轮流量计的工作原理[3]

气体涡轮流量计是将涡轮置于被测流体中,当气体进入流量计时,在特殊结构整流器的作用下得到整流并加速,在一定流量范围内涡轮的角速度和流量成正比。利用电磁感应原理感应出与流体体积流量成正比的脉冲信号,该信号经前置放大器放大,整形后将得到实际流量,并显示在LCD屏上;如果同温度压力传感器检测到的信号一起输入智能流量积算仪进行运算处理,将得到标准状况下的流量,并显示于LCD屏上。如下图2-1所示

2.2气体涡轮流量计的结构原理

叶轮式流量计是一种速度式流量计,主要有涡轮流量计、分流旋翼流量计、水表和叶轮风速计等。涡轮流量计时叶轮式流量计的主要品种,在国际上已有近半个世纪的工业应用历史,我国从60年代开始生产,已形成全系列化仪表。它利用置于流体中的叶轮的旋转角速度与流体流速成比例关系,通过测量叶轮的转速来反映通过管道的体积流量大小,是目前流量仪表中比较成熟的高精度仪表。涡轮流量计有涡轮流量传感器和流量显示仪表组成,可实现瞬时流量和累积流量的计量。传感器输出与流量成正比的脉冲频率信号,该信号通过传输线路远离传送仪表,便于累计和显示。此外传感器输出的脉冲频率信号可以单独与计算机配套使用,有计算机代替流量显示仪表实现密度或温度、压力补偿,显示质量流量或气体体积流量。本类仪表适用于流体总量的测量。如今,涡轮流量计已在石油、化工、科研、国防和计量等各部门中获得广泛应用。

2.2.1 涡轮流量计的结构原理[4]

气体涡轮流量传感器的结构如下图2—2所示。它主要由仪表壳体1,前后导向架组件2和4,叶轮组件3和信号检测放大器6组成。当被测流体通过涡轮流量传感器时,流体通过导流器冲击涡轮叶片,由于涡轮的叶片与流体流向间有一倾角,流体的冲击力对涡轮产生转动力矩,使涡轮克服机械摩擦阻力矩和流动阻力矩而转动。实践表明,在一定的流量范围内,对于一定的流体介质粘度,涡轮的旋转角速度与通过涡轮的流量成正比。所以,可以通过测量涡轮的旋转角速度来测量流量。

涡轮的旋转角速度一般都是通过安装在传感器壳体外面的信号检测放大器用磁电感应的原理来测量转换的。当涡轮转动时,涡轮上由YL401制成的螺旋形叶片依次接近和离开处于管壁外的磁电感应线圈,周期性地改变感应线圈磁回路的磁阻,是通过线圈的磁通量发生周期性的变化而产生与流量成正比的脉冲电信号。此脉冲信号经信号检测放大器放大整形后送至显示仪表(或计算机)显示流体流量或总量。

在某一流量范围和一定粘度范围内,涡轮流量及输出的信号脉冲频率f与通过涡轮流量计的体积流量成正比。即: 本文对TWLQ型气体涡轮流量计的工作原理进行了详细的介绍,并着重对口径为Ф50系列的气体涡轮流量计内部结构进行了分析,其中包括了对流量计中涡轮轴,支撑轴承,叶轮,后导流器进行了结构的分析及重新设计。针对原产品在燃气市场中使用时存在的问题,其最大特点在于特性曲线与温度压力有关,气体压力损失在550-1400pa之间不等,不确定度可达1%-2%。针对这些不足之处,本文在产品的工作与结构原理中,通过特性分析了解到引起上述不足的因素,为后文对该产品的结构进行重新设计打下铺垫。其总结如下:

1、叶轮的叶形是由机械中最难加工的复杂曲面组成的,要根据流体性质,流量范围,使用要求等设计,选择合适的叶片参数有利于流量计性能的更好发挥。

2、在原有的结构基础之上重新选择密度更小的且摩擦系数更小的材料20Cr,使叶轮在转动过程中受的摩擦阻力矩降到最小。

本次结构改进后存在的问题:

1、改进后TWLQ系列气体涡轮流量计的内部零件,目前只是停留在理论的设计计

算阶段,还没有应用到实际的场合中去.

2、改进后的产品结构所选用的材料在性能上有很大的提高,但是不太符合经济

性要求。

3、下一步将通过与五机床技术人员的共同合作,进行该系列流量计内部零件的

实际加工并组装成产品,经过反复试验,投入到燃气市场中。

参考文献

[1]蔡武昌 应启嘎 编著 新型流量检测仪表 北京:化学工业出版社 2006年1月

[2]杨根生 林辉喻 编著 流量测量仪表 北京:机械工业出版社 1986年9月

[3]天津仪表集团有限公司 无锡求信集团有限公司 浙江苍南仪表有限公司等的涡轮流量计使用说明书

[4]梁国伟 蔡武昌主编 流量测量技术及仪表 北京:机械工业出版社2002年6月

[5]方沂主编 数控机床编程与操作 北京:国防工业出版社 2006年8月

川公网安备: 51019002004831号

川公网安备: 51019002004831号