JBT62轴流式通风机总体方案和通风机总体结构设计

轴流式通风机结构设计【优秀】【word+4张CAD图纸全套】【毕业设计】

【带开题报告+外文翻译+实习总结】【60页@正文16400字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

B9.Unsteady Flow Analysis in Hydraulic Turbomachinery.pdf

个人工作计划.doc

叶轮图a0.dwg

壳体a1.dwg

学生毕业实习总结.doc

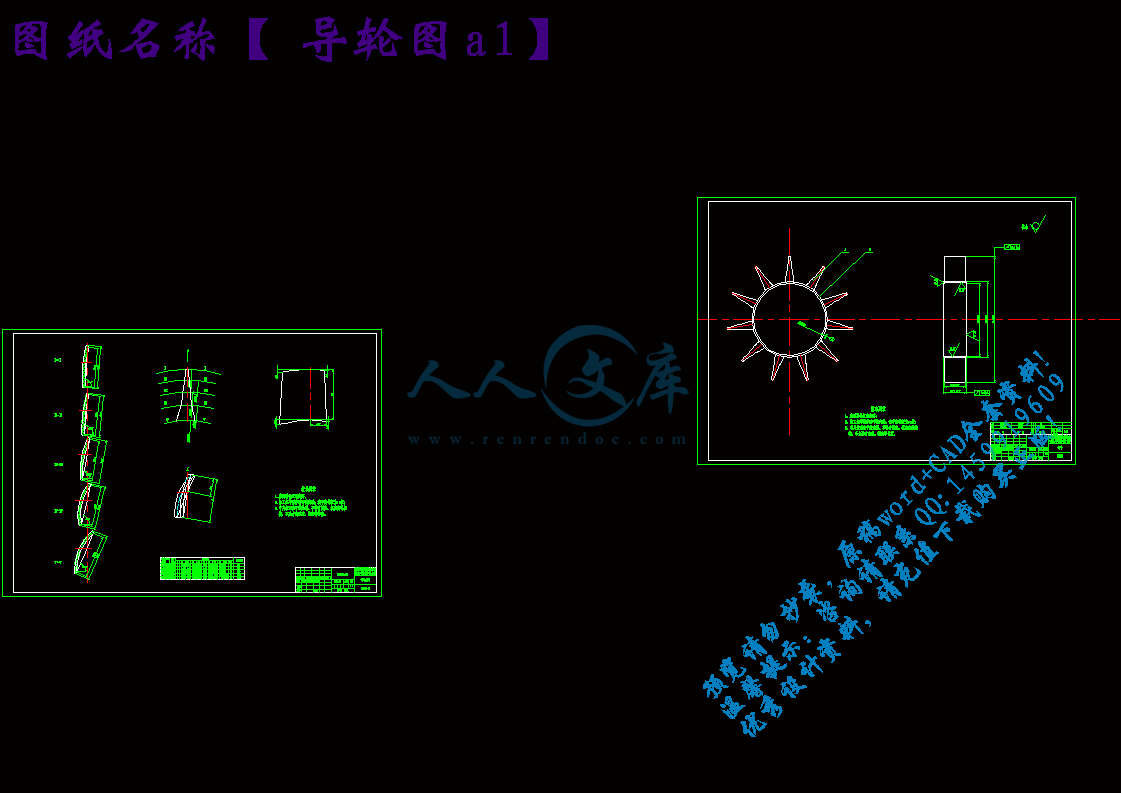

导轮图a1.dwg

开题报告.doc

总装图a0.dwg

摘 要.doc

译文.doc

说明书.doc

开题报告

1、研究目的和意义

在矿井生产过程中,为了准备新水平,新采区和采煤工作面,都必须掘进大量的巷道。在掘进巷道时,为了供给工作人员呼吸新鲜空气,稀释掘进工作面的瓦斯及产生的有害气体,矿尘,并创造良好的气候条件,必须对掘进工作面进行通风。

2、国内外发展情况

当前世界先进工业国家风机产品开发的主要特点是:1.以节能、节约资源为核心,提高单件效率和耐久性,进而提高整个系统的效率。2.加强系统的自动化、事故警报系统的研制,节省维护、监控方面的人力。3.为提高竞争能力,力求包括附属部件在内的产品标准化和组合化。4.进一步加强了对低噪声、低振动技术的研究。5.不断针对新的需要,开发新的产品。6.在工艺上引进柔性制造系统,最大限度地提高产品生产的自动化程度[12]。风机产品大多根据用户需要有不同特性要求,多属小批量生产,特别是一些大型风机产品甚至是单件小批生产,对工艺要求复杂。目前国内生产自动化程度很低,而国外通过研制和采用柔性制造系统,提高了生产的自动化程度。以美国为例,中小风机的生产已全部通过自动线完成,从工艺角度提高了产品质量,降低了产品成本[8]。

从产品品种看,发达国家中小型通风机的生产数量和我国大致相当甚至低于我国,但离心、轴流风机的产量约为我国的2倍从85-94年的情况看,离心及轴流风机产量我国为537台,日本为2364台,日本是我国的5倍多,离心风机我国为9980台,而日本高达176911台,是我国的17.7倍。与95年情况对比,我国与之的差距在缩小[13]。

3、研究/设计的目标

设计流量Q=5.6m3/s ,全压H=3100pa,效率85%。适合煤矿掘进工作面用的轴流风机。

设计的主要内容:JBT62轴流式通风机总体方案设计,叶轮的设计,壳体、集流器、疏流罩、扩散器 、校核计算、外文翻译等。

4、设计方案(研究/设计方法、理论分析、计算、实验方法和步骤等)

为了适应掘进工作面和巷道狭窄的工况条件,应采用结构紧凑的轴流风机,为了便于拆卸、安装、应设计成多段壳体。风机采用一个电动机驱动二级叶轮的驱动方式,可以减小风机的体积,节约成本。

步骤如下:

1.电动机的选型,根据风量和全压计算出电动机功率选择电动机型号。

2.风机主要结构形式的确定,根据工况和通风要求选定风机结构。

3.风机叶轮、导轮的设计,采用相似原理设计风机叶轮。

4.风机集流器、扩散器、轴的设计,根据工作条件和强度要求设计主要部件。

5.主要零部件的强度校核,确定设计的合理性。

风机机构图如下:

方案简图

1-轴;2-壳体;3-中导轮;4-后导轮;5-扩散器;

6-叶片;7-叶轮;8集流器;9-流线题

5、方案的可行性分析

风机采用多段壳体设计,满足了采掘面狭小的工作条件,同时便于运输和安装,适合采掘工作面的变化,安装了消声装置,降低了对环境噪声的污染,采用防爆电机,提高了设备的安全性。

6、该设计的创新之处

风机是一个较强的噪声源。风机在运转中产生的噪声常常成为影响工人健康和干扰环境的祸源。特别是邻近生活区的风机,其进风口和出风口所辐射的空气动力性噪声,更是污染环境的主要因素,形成公害,风机噪音是近年来我国工业部门治理噪声污染的主要对象之一[6]。本设计在风机上安装了消声装置,有效的降低了风机的噪音,可以减少噪声对人们的听觉、视觉、神经系统、心血管系统、消化系统和内分泌系统的严重危害。

7、设计产品的主要用途和应用领域

轴流式风机风压一般在450N/平方米~4500N/平方米之间,是主要用来抽吸、输送、提高流体能量的一种机械,主要应用在矿井、隧道、船舰仓室的通风;纺织厂通风、工业作业场所的通风、降温;化工厂高温腐蚀气体的排放;热电厂锅炉的通风、引风;热电站、冶金、化工等冷却塔通风冷却;地下工程、地下发电厂通风;车间空调和原子防护设备的通风等方面。风机的应用非常广泛,简言之主要是用于辅助充分燃烧、通风、输送,几乎涉及国民经济各个领域[13]。

8、时间进程

第 1 周 在学校图书馆查找资料

第 2 周 在鹤岗南山矿实习

第 3 周 在鹤岗南山矿实习

第 4 周 整理资料,完成实习总结

第 5 周 筹备资料,完成开题报告

第 6 周 对轴流式通风机进行总体方案设计

第 7 周 主要零部件进行设计

第 8 周 主要零部件进行设计

第 9 周 对所设计个部分零件进行校核

第 10 周 画轴流式通风机总体装配图

第 11 周 画轴流式通风机总体装配图

第 12 周 画轴流式通风机各部分零件图

第 13 周 画轴流式通风机各部分零件图

第 14 周 进行外文参考文献的翻译

第 15 周 整理说明书和图纸

第 16 周 打印说明书和图纸

第 17 周 准备答辩

9、参考文献

1 黄清,陈焕新. 用MATLAB处理通风机性能试验数据.风机技术 , 2005,(02) .

2 盛赛斌. 轴流式风机防堵转控制系统. 华东电力 , 1997,(06)

3 付怀波, 王秉恒. 提高对旋轴流式风机轴承寿命的探讨. 防爆电机 , 2004,(03)

4 杨红军. 风机紧固件的失效和控制措施. 风机技术 , 2005,(02)

5 刘敏. 矿用轴流通风机现场测试技术的研究. 流体机械 , 1996,(12)

6 张弛. 煤矿轴流式风机风井噪声控制方案探讨. 噪声与振动控制 , 1999,(04)

7 吴华淼. 动叶角度可调轴流式风机平衡重块的平衡原理. 华东电力 , 1982,(07)

8 赵艳志, 杜付.风机应用与节能分析. 发电设备 , 2006,(01)

9 苗继军. 变频器在轴流式风机中的应用. 山西煤炭 , 2006,(01)

10吕文灿. 轴流式风机空间流型分析与研究.工程热物理学报 , 1993,(02)

11 陈佐一,叶大均. 叶轮机械内部真实流动研究的某些进展.中国科学基金 , 1996,(02)

12 赵日春, 杨佳仁. 矿井通风机的现场技术改造. 风机技术 , 1997,(04)

13 昌泽舟.轴流式通风机实用技术.机械工业出版社,2005

14 J.P.Van Doormal,G.G.Raithby. Enhancement of the SIMPLEmethod for predicting incompressible fluid flows.NumericalHeat Transfer, 1984, (7) :147-163

15 Korakianitis, T.P. On the Prediction of Unsteady Forces on Gas-Turbine Blades .Part 2:Viscous-Wake-Interaction and Axial-Gap Effects. ASME Paper 88-GT-90, June, 1988

16 Marizo Piller, Enrico Nobile, Thomas J. DNS study of turbulent transport at low Prandtl numbers in a channel flow .Journal of Fluid Mechanics, (458):419-441, 2002

指导教师意见

摘 要

在矿井掘进巷道时,为了供给工作人员呼吸新鲜空气,稀释掘进工作面的瓦斯及产生的有害气体,矿尘,创造良好工作条件,必须对掘进工作面进行通风。目前对掘进工作面进行通风的主要设备为JBT系列轴流式通风机。

本次设计的内容是对JBT62轴流式通风机总体方案和通风机总体结构设计,机械传动部分设计,对轴流风机工作原理,主要工况参数的意义的掌握。具体内容包括:通风方式的选择,总体结构方案的确定,轴的设计和校核计算,叶轮的设计和校核计算,导叶的设计计算,疏流罩、扩散器和集流器的设计和选择,壳体的设计,通风机消声装置的设计,电机的选择和固定方式的设计,联轴器、键和法兰等零件的选型校核。

关键词 轴流风机? 局部通风设备? 机械设计

Abstract

When mine pit tunneling tunnel, breathes the fresh air for the supplies staff, the noxious gas which the dilution tunneling working surface's gas and produces, the mine dust, the creation good working condition, must carry on to the tunneling working surface ventilates. At present carries on the well ventilated major installation to the tunneling working surface is the JBT series axial flow type ventilator.

This design's content is to the JBT62 axial fans flow type ventilator overall concept and the ventilator gross structure design, mechanical drive part design, to axial-flow fan principle of work, main operating mode parameter significance grasping. The actual content includes: Ventilates the way the choice, the gross structure plan determination, the axis design and the examination computation, impeller's design examines and examines the computation, guide vane's design calculation, sparse class cover, diffuser and current collector design and choice, shell's design, ventilator muffler design, electrical machinery's choice and fixed way design, components and so on shaft coupling, key and flange shaping examinations.

Keywords Axial fans Local ventilation equipment Mechanical design

目录

摘 要I

AbstractII

第1章 绪论1

1.1选题的意义1

1.2主要设计内容1

1.3国内外同类设备发展状况2

1.4轴流通风机的工作原理2

1.5轴流通风机主要工作参数3

1.5.1风量3

1.5.2风压3

1.5.3功率3

1.5.4效率4

1.5.5转速4

1.5.6无因次的流量系数4

第2章 轴流通风机总体结构方案设计6

2.1通风方式的确定6

2.1.1压入式通风6

2.1.2抽出式通风7

2.2结构方案型式8

2.2.1叶轮9

2.2.2导叶9

2.2.3进风口(集流器和整流罩)10

2.2.4扩散器10

2.2.5外壳10

2.2.6轴11

2.3通风机结构形式的确定11

2.3.1确定通风机的转速n11

2.3.2确定通风机的级型式11

2.3.3确定通风机各级风压比11

2.3.4叶顶圆周速度ut和叶轮直径D 的选择计算12

2.4计算电动机功率并选择电机型号13

第3章 主要部件的设计计算15

3.1叶轮参数的设计计算15

3.1.1流量系数和全压系数的确定15

3.1.2轮毂比和轮毂直径的确定15

3.1.3轮毂比检验16

3.1.4叶片翼型参数的计算18

3.2叶片翼型的选择21

3.2.1 LS翼型坐标22

3.2.2叶片的绘制22

3.3导轮参数的设计计算23

3.3.1导轮参数的计算23

3.3.2导流器叶片几何尺寸的计算25

3.4导叶翼型的选择25

3.4.1 圆弧板翼型25

3.4.2叶片的绘制26

第4章 结构部件的设计计算27

4.1集流器的设计27

4.2流线罩的设计27

4.3扩散器的设计28

4.4轴流通风机轴向间隙的确定30

4.5轴流通风机径向间隙的确定31

4.6轴承的选择32

4.7联轴器的选择33

4.8风筒的选择34

4.8.1风筒选用要求34

4.8.2局部通风机的风筒选型34

4.9噪音的处理34

第5章 主要零部件强度计算36

5.1叶轮强度计算36

5.2键的校核38

5.2.1 键的基本尺寸38

5.2.2 键的校核38

5.3轴的校核39

第6章 通风机的安装维护和保养41

6.1通风机安装方法41

6.2通风机的拆卸41

6.3通风机的维护41

6.3.1叶轮的检修42

6.3.2主轴的检修42

6.3.3转子的检查43

6.3.4机壳漏气的检修43

6.3.5轴承的检修43

结论45

致谢46

参考文献47

附录149

附录252

第1章 绪论

1.1选题的意义

瓦斯事故历来是煤矿的主要安全事故,因此矿井要防止瓦斯事故的发生。中国矿山安全条例与安全规程规定:向井下供给新鲜风量一般每人不得少于4m3/min,在采掘工作面进风风流中氧气按体积计算不得低于,二氧化碳不得超过。矿井新建、扩建或生产时,都要掘进巷道,在掘进过程中,为了供给工作人员呼吸新鲜空气,稀释和排出自煤(岩)体涌出的有害气体、爆破产生的炮烟和矿尘,以及创造良好的气候条件,必须对掘进工作面进行通风。矿井采掘面通风可以保证人身安全和矿井的安全生产,因此矿井通风有着非常重要的意义。

1.2主要设计内容

本次设计的内容及工作量是确定JBT62轴流式通风机总体方案设计,总体结构及其组成,掌握轴流风机工作原理,主要工况参数的意义。完成主要机械部分设计。JBT62轴流式通风机过流部件由集流器,叶轮,导叶,扩散器等几部分组成。具体设计内容包括:拟定总体结构方案的确定,轴的设计计算,叶轮的设计计算,导叶的设计计算,疏流罩的设计计算,扩散器的设计计算,集流器的设计计算,壳体的设计,联轴器、法兰等零件的选型校核。保证设计参数流量达到Q=5.6m3/s、全压达到H=3100Pa、效率在以上。此外还包括设计说明书的编写,外文资料的翻译工作。图纸的绘制工作。包括:总体装配图 1张;叶轮零件图 1张;导叶零件图1张;壳体零件图1张;轴零件图1张。

1.3国内外同类设备发展状况

风机已有悠久的历史。中国在公元前许多年就已制造出简单的木制砻谷风车,它的作用原理与现代离心风机基本相同。1862年,英国的圭贝尔发明离心风机,其叶轮、机壳为同心圆型,机壳用砖制,木制叶轮采用后向直叶片,效率仅为40%左右,主要用于矿山通风。1935年,德国首先采用轴流等压风机为锅炉通风和引风;1948年,丹麦制成运行中动叶可调的轴流风机;旋轴流风机、子午加速轴流风机、斜流风机和横流风机也都获得了发展。未来风机发展将进一步提高风机的气动效率、装置效率和使用效率,以降低电能消耗;用动叶可调的轴流风机代替大型离心风机;降低风机噪声;提高排烟、排尘风机叶轮和机壳的耐磨性;实现变转速调节和自动化调节。随着科学技术的不断发展,人们对风机使用的要求也愈来愈高,就目前国外风机技术发展趋势而言,将朝着风机容量不断增大、高效化、高速小型化和低噪音方向发展。高速小型化。各类风机采用三元流动叶轮后,在提高效率的同时,压力也可提高。所以在同等条件下,叶轮外径可减少10%~30%,这样就取得缩小体积和减轻重量的明显效果。提高转速也是风机小型化的重要途径之一。 低噪声化。风机的噪声是工业生产中噪声污染源最主要来源之一。风机大型化和高速化使噪声问题更加突出。对低频噪声,风机主要通过改进风机结构设计,降低本体噪声,若达不到要求,可采取加装消声器等措施。综上所述,这些技术既是国外风机未来发展趋势,也是国内风机行业在技术方面的努力方向。

1.4轴流通风机的工作原理

轴流风机又叫局部通风机,是工矿企业常用的一种风机,安不同于一般的风机它的电机和风叶都在一个圆筒里,外形就是一个筒形,用于局部通风,安装方便,通风换气效果明显,使用安全,可以接风筒把风送到指定的区域。轴流,就是与风叶的轴同方向的气流(即风的流向和轴平行),如电风扇,空调外机风扇就是轴流方式。风流从集风器沿轴向进入,通过原动机驱动叶轮旋转,使风流获得能量后流入导叶。由于导叶是静止的,其作用是改变风流方向.并使风流的部分动能转换为压能。最后,风流通过扩散风筒进一步降低流速,将轴向风流的动能转换为静压能沿轴向排出。

1.5轴流通风机主要工作参数

风机的性能参数主要有流量、压力、功率,效率和转速。另外,噪声和振动的大小也是主要的风机设计指标。

1.5.1风量

风量指通风机在单位时间内所输送的气体体积。风机说明书中的风量与风压, 一般均指标准气态下(即大气压力为760mmHg, 温度为, 湿度为, 密度为1.2kg/m3)的数值。风量单位常用的有m3/s, m3/min, m3/h。

1.5.2风压

风机风压系指全压H, 单位为Pa, 它是单位体积的气体流过风机叶轮时所获得的能量增量。它等于风机的静压与动压之和。一般通风机在较高效率范围内工作时, 其动压约占全压的10~20% 左右。

1.5.3功率

功率是指单位时间内所做的功, 单位 kW(千瓦)。风机的功率可分为:

全压有效功率─指单位时间内通过风机的空气所获得的实际能量, 它是风机的输出功率, 也称为空气功率。

静压有效功率─指单位时间内通过风机的空气所获得的静压能量。它是全压有效功率的一部分。

轴功率─电动机传递给风机转轴上的功率。也就是风机的输入功率。

电机功率─考虑了传动机械效率和电机容量安全系数后, 电动机的功率。

1.5.4效率

效率: 表明风机将输入功率转化为输出功率的程度。分为全压效率(也称为空气效率或总效率)和静压效率。

1.5.5转速

转速系指风机叶轮每分钟的转数, 单位为rad/min。风机转速改变时, 风机的流量、风压和轴功率都将随之改变。

参考文献

1 黄清,陈焕新. 用MATLAB处理通风机性能试验数据.风机技术 , 2005,(02) .

2 盛赛斌. 轴流式风机防堵转控制系统. 华东电力 , 1997,(06)

3 付怀波, 王秉恒. 提高对旋轴流式风机轴承寿命的探讨. 防爆电机 , 2004,(03)

4 杨红军. 风机紧固件的失效和控制措施. 风机技术 , 2005,(02)

5 刘敏. 矿用轴流通风机现场测试技术的研究. 流体机械 , 1996,(12)

6 张弛. 煤矿轴流式风机风井噪声控制方案探讨. 噪声与振动控制 , 1999,(04)

7 吴华淼. 动叶角度可调轴流式风机平衡重块的平衡原理. 华东电力 , 1982,(07)

8 赵艳志, 杜付.风机应用与节能分析. 发电设备 , 2006,(01)

9 苗继军. 变频器在轴流式风机中的应用. 山西煤炭 , 2006,(01)

10吕文灿. 轴流式风机空间流型分析与研究.工程热物理学报 , 1993,(02)

11 陈佐一,叶大均. 叶轮机械内部真实流动研究的某些进展.中国科学基金 , 1996,(02)

12 赵日春, 杨佳仁. 矿井通风机的现场技术改造. 风机技术 , 1997,(04)

13 昌泽舟.轴流式通风机实用技术.机械工业出版社,2005

川公网安备: 51019002004831号

川公网安备: 51019002004831号