壳体侧抽芯注塑模的设计【优秀】【word+21张CAD图纸全套】【注射塑料模具类】【毕业设计】

【带任务书+开题报告+评阅评语表+答辩资格审查表+工作中期检查表+指导教师评阅表+外文翻译】【55页@正文22000字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

Domestic and foreign car panel stamping die design Profiles.doc

任务书.doc

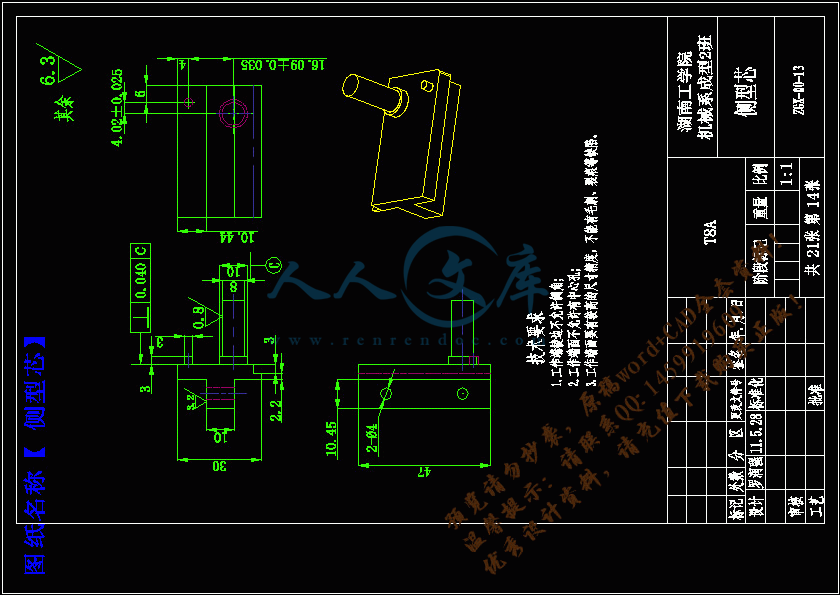

侧型芯.dwg

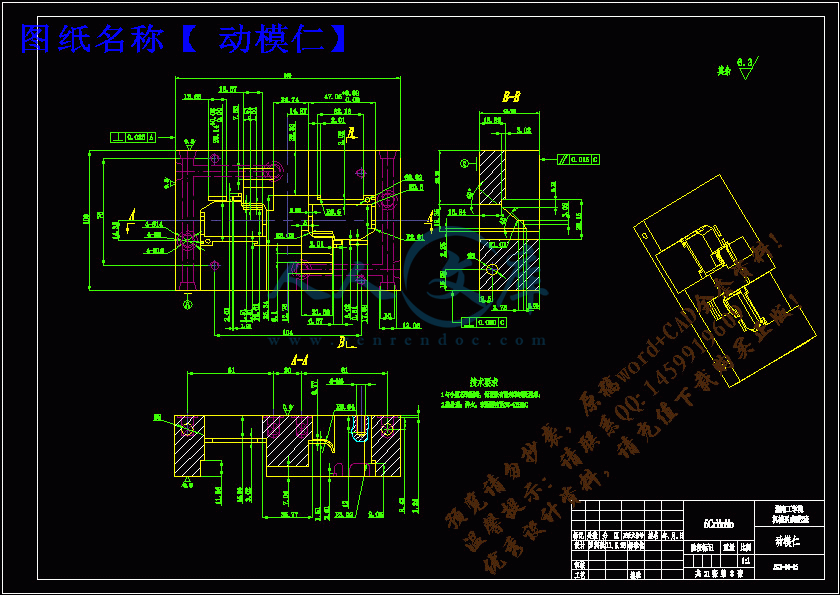

动模仁.dwg

动模座板.dwg

国内外轿车覆盖件冲压模具设计概况.doc

垫块.dwg

复位杆.dwg

定位圈.dwg

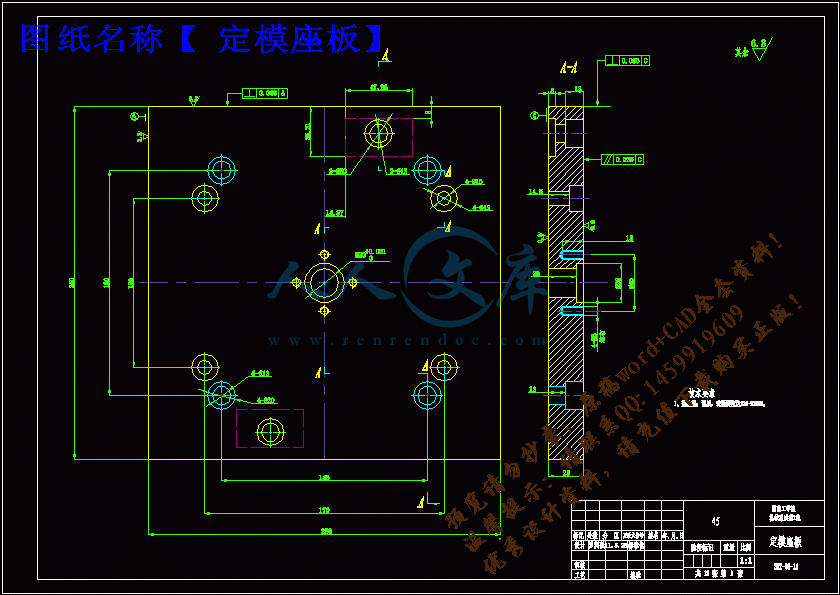

定模座板.dwg

导柱.dwg

封面.doc

工作中期检查表.doc

开题报告.doc

拉料杆.dwg

指导教师评阅表.doc

推杆.dwg

推板.dwg

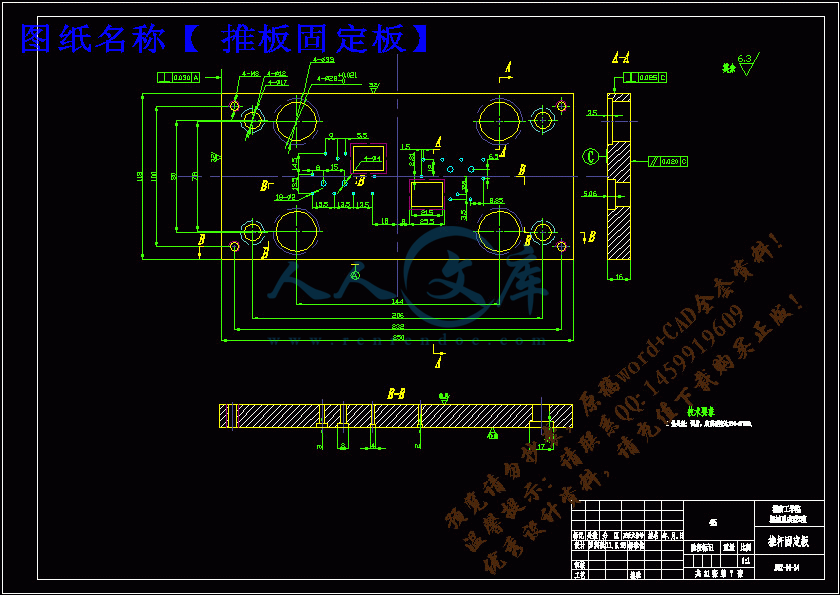

推板固定板.dwg

推板导柱.dwg

摘要.doc

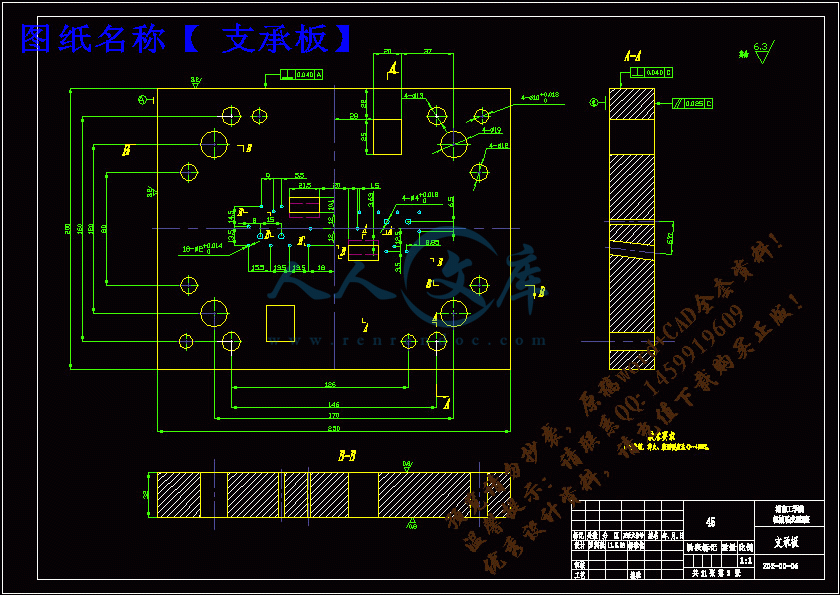

支承板.dwg

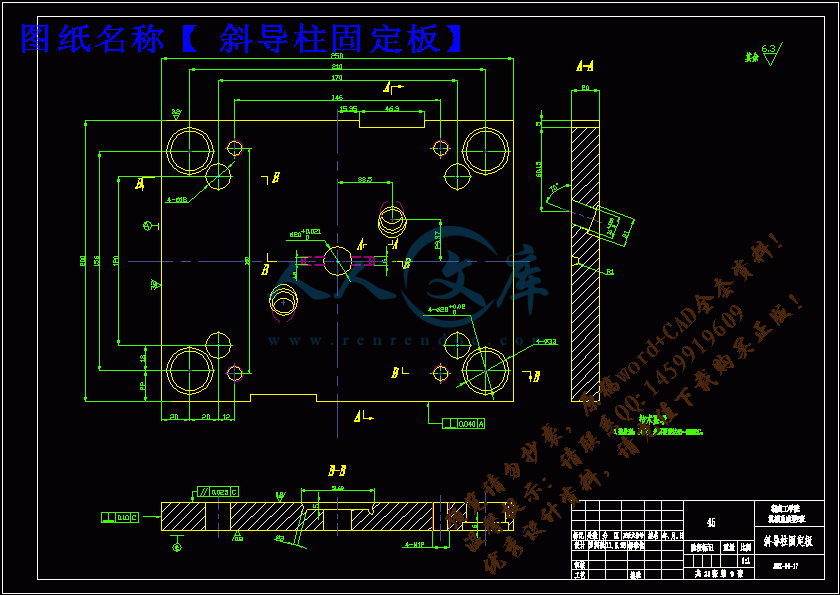

斜导柱固定板.dwg

斜滑杆.dwg

正文.doc

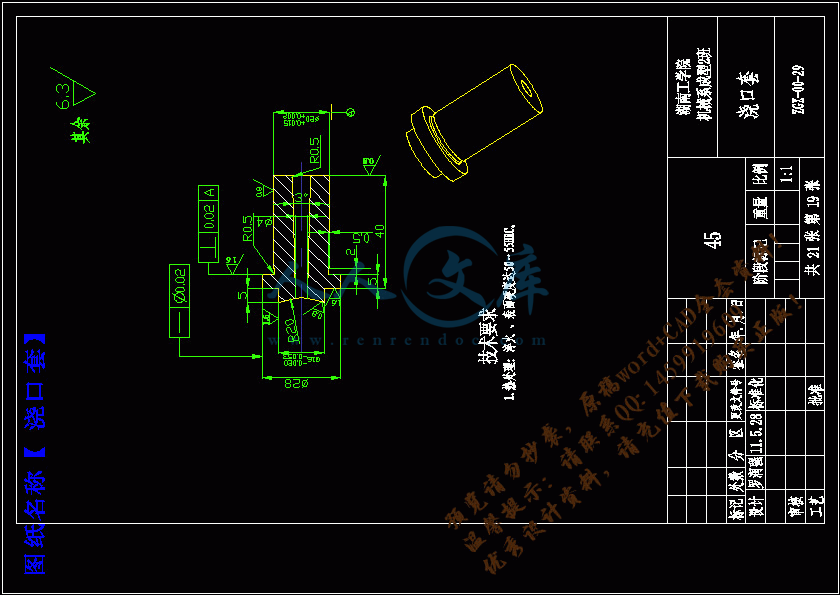

浇口套.dwg

脱浇板.dwg

表格.doc

装配图.dwg

评阅教师评阅表.doc

镶块1.dwg

零件图.dwg

任务书

内容及任务

设计题目: 壳体侧抽芯注塑模设计 材料: 丙烯腈-丁二烯-苯乙烯共聚物 (ABS)

具体尺寸见零件图纸

拟达到的要求或技术指标

1、设计相应模具结构,绘制模具装配图、零件图,总图纸量达3张0号图纸。

2、设计说明书资料充分,计算过程详细完整。公式的字母含义应标明,内容条理清楚,按步骤书写。

3、完成设计说明书,要求文字通顺,表达清楚,图标清晰合理,字数达20000万左右,按学校的相关要求排版并打印,同时上交电子文档。

进度安排起止日期工作内容备注

11.1.6~11.2.30

11.3.1~11.3.26

11.3.26~11.4.30

11.5.1~11.5.14

11.5.15~11.6.5

11.6.5~11.6.10

完成毕业选题

对设计相关资料收集整理,进行设计的初期准备

对零件的分析、尺寸计算,、注射机选择,设计绘装配图及各相关零件图。

写设计说明书

检查修改说明书,准备答辩。

答辩

主要参考资料

1 申开智主编 北京:中国轻工业出版社 2006

2 付宏生 刘京华编著 注塑制品与注塑模具设计 化学工业出版社 2003

3 伍先明 张蓉等编著 塑料模具设计指导 北京 国防工业出版社 2010

4《塑料模具技术手册》编委会编 塑料模具技术手册 北京 机械工业出版社 1997

5 唐志玉主编 塑料模具设计师指南 北京 国防工业出版社 1999

6 冯炳尧等主编 模具设计与制造简明手册 上海 上海科学技术出版社 1996

7 黄虹主编 塑性成型加工与模具。 北京:化学工业出版社 2002

8 陈锡栋等主编 实用模具技术手册。北京:机械工业出版社 2001

9 廖念钊等主编 互换性与技术测量 北京:中国计量出版社 2001

10章飞主编 型腔模具设计与制造 北京:化学工业出版社 2003

11陈万林等主编 实用塑料注射模设计与制造 北京:机械工业出版社 2000

12王爱珍主编 工程材料及成形技术 北京:机械工业出版社 2003

摘 要

本论文介绍了壳体的注射模设计过程。主要研究带有侧凹或侧孔结构的塑料制件如何分型和脱模的,本塑件侧面带有三个小孔,直接开模无法实现分型,这就涉及到斜导柱和斜滑杆的设计以及他们的工作原理,利用注塑机开合模的作用力进行侧抽芯,一方面减少了一些零件的使用,降低成本;另一方面省去一些零件的安装工序,节约时间,缩短生产周期,提高经济效益。本文还介绍了型腔数量和布局的确定、注射机选择、浇注系统设计、模板及其标准件的选用、脱模及抽芯机构的设计、成型部件的设计等。

关键词:注塑摸;斜滑杆;侧抽芯;壳体

ABSTRACT

This paper has introduced the design process of injection mould of the shell. The main research the plastic workpiece with side concave or side hole is how to divide structure and draw of patterns. Because the side of model has three eyelets, it is unable to realize by directly operating the mold, by designing the slanting leader pin and the lifter. We use the action of the injection molding machine to carry on core-pulling. The advantage of this design are reducing the use of some components, lowing the cost, omitting some component to install the working procedure, saving time, reducing the production cycle and enhancing the economic efficiency. This article also introduces die space quantity and the layout determination, the injection machine choice, the casting system design, the template and the standard part selection, the drawing of patterns and core-pulling organization design, the formation parts design etc.

Key words:injection mould; lifter; core-pulling; shell

目 录

1 前言1

2 绪论2

2.1概述2

2.2我国塑料模现状2

2.3 我国塑料模的发展趋势3

3 塑件成型工艺分析5

3.1 塑件图5

3.2 塑件工艺分析5

3.2.1 精度等级5

3.2.2 脱模斜度5

3.2.3 塑件圆角6

3.3 ABS塑料性能特性与工艺参数6

3.3.1 ABS化学与物理特性6

3.3.2 ABS塑料的成型条件7

4 拟定模具结构形式8

4.1 型腔数目的确定8

4.2 分型面的选择9

5注塑机型号的确定11

5.1 注塑容量的计算11

5.2锁模力的计算11

5.3 注塑机的选用12

5.4 有关参数的校核13

5.4.1由注塑机料筒速率校核模具的型腔数13

5.4.2 注射压力的校核13

5.4.3 锁模力的校核13

5.4.4 开模行程的校核14

6 浇注系统的设计14

6.1 主流道的设计15

6.2 分流道的设计17

6.3 冷料穴的设计19

6.4 浇口的设计20

6.4.1浇口类型的选择20

6.4.2 浇口尺寸的确定22

6.4.3 浇口剪切速率的校核23

6.5 排气系统的设计23

7 成型零件设计23

7.1 成型零件的结构设计24

7.2 成型零件钢材的选用25

7.3 成型零件工件尺寸的计算26

7.4 型腔壁厚和底板厚度的计算29

7.4.1 侧壁厚度计算29

7.4.2 底板厚度计算30

8 模架的确定32

9 导向机构的确定32

10 脱模机构的设计34

10.1 脱模力的计算34

10.2 脱模机构的结构设计35

11 侧向抽芯的设计37

11.1 抽芯距与抽芯力的计算37

11.2 斜导柱圆形截面直径的计算40

11.3 斜导柱圆长度的计算40

11.4 斜滑杆的设计41

12 模温调节系统的设计42

12.1 冷却系统的设计42

13 数控程序的编制47

14 设计小结49

参考文献50

致 谢51

1 前言

模具是工业生产的基础工艺装备,被称为工业之母。75%的粗加工工业产品零件、50%的精加工零件由模具成型,绝大部分塑料制品也由模具成型。作为国民经济的基础工业,模具涉及机械、汽车、轻工、电子、化工、冶金、建材等各个行业,应用范围十分广泛

模具技术水平已成为衡量一个国家制造业水平的重要指标。现代工业需要先进的模具设备和高技术人才。

目前国内模具技术人员短缺,要解决这样的问题,关键在于职业培训。我们作为踏入社会的当代学生,就应该掌握扎实的专业基础,现在学好理论基础。本设计是以适应企业技术的发展,能体现出在学校所学,能体现先进性和前瞻性,所涉及到的知识包括注塑成型基本原理、注塑工艺方案的确定、工艺规程编制、模具结构设计、模具材料的选择、压力机的选择、模具制造方法等。希望通过对这些知识的学习,能使自己掌握模具加工的核心技术,了解周边技术和跟踪前沿技术。希望能通过这次设计,能掌握模具设计的基本方法和基本理论。

本次设计得到了张蓉副教授的指导,同时也非常感谢湖南工学院的各位老师的教诲。

由于学生的理论学习和实践经验有限,设计中存在的不足之处和错误还肯请各位教授、专家批评指正。谢谢!

2 绪论

模具是利用其特定形状去成型具有一定形状和尺寸的制品的工具。模具的类型很多,按照成形材料的不同可分为冲压模具、塑料模具、锻造模具、压铸模具、橡胶模具、粉末冶金模具、玻璃模具和陶瓷模具。模具生产技术水平的高低,已成为衡量一个国家产品制造水平高低的重要标志,因为模具在很大程度上决定着产品的质量、效益和新产品的开发能力。随着我国加入WTO,我国模具工业的发展将面临新的机遇和挑战。我国模具工业的发展,日益受到人们的重视和关注。“模具是工业生产的基础工艺装备”也已经取得了共识。注塑成型作为一种重要的成型加工方法,在家电行业、汽车工业、机械工业等都有广泛的应用,且生产的制件具有精度高、复杂度高、一致性高、生产效率高和消耗低的特点,有很大的市场需求和良好的发展前景。

2.1概述

塑料是以树脂为主要成分,添加一定数量和一定类型的添加剂。然而,塑料制品生产是一个既复杂又繁重的过程,其生产系统主要由成型、机械加工、修饰及装配四个连续过程组成。其中,成型是将各种形态的塑料(粉、粒、溶液或分散体)制成所需形状的制品或毛坯的过程。注塑模是一种用来生产塑料零件的模具。它被安装在塑料注射机上,由塑料注射机将塑料颗粒融化成为热熔体,经过合模、高压注射、保压冷却定型、开模、推出制件等工序,获取所需的塑料零件。塑料模具影响着塑料制品的质量。首先,模具型腔的形状、尺寸、表面粗糙度、分型面、浇口、和排气槽位置以及脱模方式等对制件的尺寸精度和形状精度以及制件的物理性能、机械性能、内应力大小、外观质量,表面粗糙度、气泡、凹痕、烧焦、银纹等都有十分重要的影响。其次,在塑料加工过程中,模具结构对操作难易程度影响很大。在大批量生产塑料制品时,应尽量减少开模、合模和取件过程中的手工劳动。当批量不大时,模具费用在制件成本中所占的比例将会很大,这时应尽可能地采用结构合理而简单的模具,以降低成本。

2.2我国塑料模现状

我国塑料模具的质量、技术和制造能力近年来确实发展很快,有些已达到或接近国际水平,尤其是随着改革开放政策的不断深入,“三资”企业蓬勃发展,对我国塑料模具设计制造水平的提高起到了非常大的作用。然而,由于我国模具制造基础薄弱,各地发展极不平衡,因此从总体上来看,与国际先进水平以及国内市场需求相比,差距还很大。这主要表现在以下方面:

塑料模具产品水平不高,与国外先进水平相差甚远;我国塑料模制造企业设备数控化率和CAD/CAM应用覆盖率比国外低很多,且设备不配套、利用率低的现象十分严重;开发能力低,在市场上处于被动地位,创造的经济效益方面,国内大多数是微利甚至亏损;国内外模具企业管理上的差距十分明显;我国塑料模具市场总体上供不应求,特别是大型、复杂、长寿命塑料模产需矛盾十分明显。

2.3 我国塑料模的发展趋势

CAD/CAM/CAE技术在塑料模的设计制造上应用已越来越普遍,特别是CAD/CAM技术的应用较为普遍,取得了很大成绩。使用计算机进行产品零件造型分析、模具主要结构及零件的设计、数控机床加工的编程已成为精密、大型塑料模具设计生产的主要手段。应用电子信息工程技术进一步提高了塑料模的设计制造水平。这不仅缩短了生产前的准备时间,而且还为扩大模具出口创造了良好的条件,也相应缩短了模具的设计和制造周期。此外,气体辅助注射成型技术的使用更趋成熟,热流道技术的应用更加广泛,精密、复杂、大型模具的制造水平有了很大提高,模具寿命及效率不断提高,同时还采用了先进的模具加工技术和设备。目前我国经济仍处于高速发展阶段,国际上经济全球化发展趋势日趋明显,这为我国模具工业高速发展提供了良好的条件和机遇。一方面,国内模具市场将继续高速发展,另一方面,模具制造也逐渐向我国转移以及跨国集团到我国进行模具采购趋向也十分明显。因此,放眼未来,国际、国内的模具市场总体发展趋势前景看好,预计中国模具将在良好的市场环境下得到高速发展,我国不但会成为模具大国,而且一定逐步向模具制造强国的行列迈进。“十一五”期间,中国模具工业水平不仅在量和质的方面有很大提高,而且行业结构、产品水平、开发创新能力、企业的体制与机制以及技术进步的方面也会取得较大发展。

随着国民经济总量和工业产品技术的不断发展,各行各业对模具的需求量越来越大,技术要求也越来越高。虽然模具种类繁多,但其发展重点应该是既能满足大量需要,又有较高 技术含量,特别是目前国内尚不能自给,需大量进口的模具和能代表发展方向的大型、精密、复杂、长寿命模具。模具标准件的种类、数量、水平、生产集中度等对整个模具行业的发展 有重大影响。因此,一些重要的模具标准件也必须重点发展,而且其发展速度应快于模具的 发展速度,这样才能不断提高我国模具标准化水平,从而提高模具质量,缩短模具生产周期,降低成本。由于我国的模具产品在国际市场上占有较大的价格优势,因此对于出口前景好的模具产品也应作为重点来发展。根据上述需要量大、技术含量高、代表发展方向、出口前景 好的原则选择重点发展产品,而且所选产品必须目前已有一定技术基础,属于有条件、有可 能发展起来的产品。

随着经济的发展,各行各业对各类模具的需求不断增加,所需品种也越来越细化. 据预测,国内模具发展的趋势:

(1)模具日趋大型化;模具的精度将越来越高;多功能复合模具将进一步发展;

(2)热流道模具在塑料模具中的比重将逐渐提高;

(3)随着塑料成形工艺的不断改进与发展,气辅模具及适应高压注射成型等工艺的模具将随之发展;

(4)标准件的应用将日渐广泛;

(5)快速经济模具的发展前景十分广阔;

(6)以塑代钢、以塑代木的进程进一步加快,塑料模具的比例将不断增大;

(7)模具技术含量将不断提高,中、高档模具比例将不断增大。

参考文献

[1] 许发樾主编.实用模具设计与制造手册[M].北京:机械工业出版社,2001.2

[2] 四川大学等编.塑料成型模具[M].北京:中国轻工业出版社,1982.6

[3] 李建军,李德群.模具设计基础及模具CAD[M].北京:机械工业出版社,2005.7

[4] 叶久新,王群.塑料制品成型模具及模具设计[M].长沙:湖南科学技术出版社.2005.8

[5] 黄毅宏,李明辉.模具制造工艺[M]. 北京:机械工业出版社,2003.7

[6] 付宏生,刘京华.注塑制品与注塑模具设计[M]. 北京:化学工业出版社,2003.6

[7] 卜建新主编.塑料模具设计[M]. 北京:中国轻工业出版社,2005.2

[8] 杜智敏等著.Pro/ENGINEER野火版塑料注射模具设计实例[M]. 北京:机械工业出版社,2005.2

[9] 周凤云.工程材料及应用(第二版)[M].武汉:华中科技大学出版社,2002.11

[10] 沈其文.材料成型工艺基础(第三版)[M].武汉:华中科技大学出版社,2003.9

[11] 大连理工大学工程画教研室编[M].机械制图(第四版).北京:高等教育出版社,1993.5

[12] 王永平编.注塑模具设计经验点评[M]. 北京:高等教育出版社,2004.7

[13] 伍先明等编著.塑料模具设计指导[M].北京:国防工业出版社,2006.5

[14] 周建安. 彩电前壳注射模设计[J].模具制造.2005,12

[15] 阳湘安. 注射模冷却系统的设计及分析[J].模具制造.2004,8.

[16] 李孝宽.对国内模具发展建议性探讨[J] .数控机床市场.2005,8

[17] 任紫亭,郭晓婷.热处理工艺对楔块模具使用寿命的影响[J].机械管理开发.2005,1

[18] 许发樾等. 试论制造业与模具市场[J].模具制造.2004,12

[19] 许荔珉等.注塑成型质量缺陷分析[J].模具技术.2005,2

[20] 付宏生,刘京华.注塑制品与注塑模具设计[J].化学工业出版社.2003.5

[21] 伍先明,张蓉.塑料模具设计指导[J].国防工业出版社.2010.8

川公网安备: 51019002004831号

川公网安备: 51019002004831号