无负压供水方案设备设计

23页 11000字数+说明书+任务书+外文翻译+5张CAD图纸【详情如下】

任务书.doc

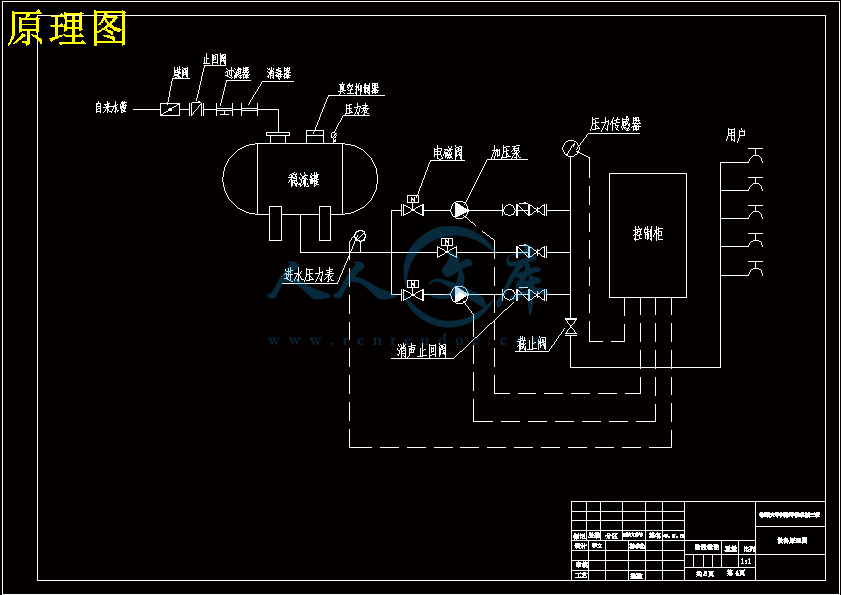

原理图.dwg

外文翻译--城市供水系统 中文版.doc

外文翻译--城市供水系统 英文版.pdf

无负压供水方案设备设计论文.doc

法兰.dwg

真空抑制器.dwg

稳流罐.dwg

装配图.dwg

目录

摘要

Abstract

第一章 绪论1

1.1 课题研究的目的和意义1

1.2 二次供水发展历史2

1.3国内外无负压供水研究现状4

1.4传统二次供水方式存在的问题5

1.5本课题的研究内容6

1.6本课题预计达到的目标6

1.7完成课题的方案和主要措施6

第二章 无负压供水方案简介7

2.1方案的工作原理7

2.2方案的工作流程7

2.3 方案的适用范围8

2.4 方案的核心技术——无负压技术8

第三章 设备的参数计算及设计10

3.1 稳流罐允许进水量的计算10

3.2 稳流罐调节容积计算12

3.3 稳流罐总容积的计算13

3.3 实例计算13

3.3.1工程概况13

3.3.2计算最大出水量14

3.3.3 确定水表特性系数14

3.3.4计算水泵扬程15

3.3.5水泵的选型15

3.3.6稳流罐容积的核算15

3.3.7 真空抑制器的设计16

总结17

无负压供水方案设备设计

摘要:近年来,随着科技的进步,二次供水设备作为一种新兴的二次供水产品,在节能和环保方面有独特的优势,无负压供水系统将市政供水管网和用户合并成为一个整体,在充分利用市政管网余压的情况下,进行变频无负压供水,即节水节电又可以防止二次污染。论文分析了无负压供水系统的组成、工作原理、工作流程、适用范围及其核心技术,即无负压技术。并对一高层住宅楼进行了实际的数据计算,根据所计算的数据设计选择不同型号的水泵和确定稳流罐的容积,并对稳流罐、真空抑制器等主要结构进行设计。

关键词:无负压、二次供水、节能、流量、扬程。

No negative pressure water equipment design program

Abstract: In recent years, with advances in technology, secondary water supply equipment as anew secondary water supply products, energy saving and environmental protection has unique advantages, no negative pressure water supply system will be municipal water supply network and user merged into a whole, in the case of full use of the residual pressure in the municipal pipe network, no negative pressure frequency conversion water supply, water saving that can also prevent secondary pollution. This paper analyzes the composition of non-negative pressure water supply system, working principle, workflow, scope and its core technologies, namely non-vacuum techniques. And a high-rise residential building were actual data calculations, select different types of pumps and determine the steady flow tank volume calculated based on data design, and the main structure of the steady flow tank, vacuum suppressors design.

Keywords: No negative pressure、 Secondary water supply、Energy、Flow、Head

第一章 绪论

1.1 课题研究的目的和意义

水是自然界一切生命赖以生存的不可替代的物质,又是社会发展不可缺少的重要资源。目前,世界上 80 个国家或占全球 40%的人口严重缺水。据预测,今后 30 年内全球55%以上的人口将面临水荒。就我国而言,水资源不足尤其是人均占有量低已经成为我国的基本国情。而近年来,随着经济的快速增长,城市化建设的不断加快,人口的不断增加,土地需求日益紧张,高层建筑层出不穷。为满足建筑内部用水点对水量、水压和水质的要求,必须对自来水进行二次加压,因此,选择一种既能节水节能,又能保障供水安全的供水方式,这对降低建筑耗能、提高供水安全可靠性具有重要的意义。

建筑内部给水系统是将城镇供水管网或自备水源的水引入室内,经配水管送至生活、生产和消防用水设备,并满足用水点对水量、水压和水质要求的冷水供应系统。从上世纪末开始,随着城市规模的不断扩大,城市建筑业得到突飞猛进的发展,10 层和10 层以上的住宅或建筑高度超过 24 米的其他民用建筑等高层建筑越来越多,使得城市的总用水量中,建筑内部用水占据的比例逐年增加,二次供水得到了更为广泛的应用。目前,我国城市自来水管网的压力在非用水高峰时,一般在 0.2MPa~0.35Mpa,此压力2值只能满足低层和多层建筑的供水需求,所以为了弥补市政供水管网压力的不足,高层建筑内部供水系统须使用二次加压设施以满足需求。

现有通常的供水方式都是将自来水放入蓄水池,然后由水泵将水从水池抽至屋顶的高位水箱,再由高位水箱向用户供水。这种供水方式存在严重的能量浪费问题:第一,将原本有压力能的水放到水池中变成了无压力能和势能的水,使得二次加压供水时需要更多的能量;第二,由于用水量是随时间变化的,大多数水泵并未在高效区运行,水泵低效率运行会浪费更多的电能。另外这种供水方式还存在严重的水质二次污染问题,据调查,各地二次供水主要水质指标都存在不同程度的超标。例如,深圳市对 274 个二次供水贮水池水质进行调查,合格率更低,经水池后余氯合格率不大于 30%,大体积水池的合格率只有 10.6%。兰州市目前使用二次供水的人口占全市总人口的近 70%,全市二次供水单位约 1200 家,二次供水设施约 1400 多个。2010 年,通过对兰州市 356 家单位的二次供水水质的调查发现,水样检测合格率为 68.35%,其中,游离性余氯合格率最低,仅为 57.31%,其次是细菌总数和总大肠菌群,合格率均低于 60%。迄今为止,发现至少有 10 余种传染病可以通过水传播,如伤寒、痢疾、霍乱等,一些病毒引起的病症也可以通过水进行传播。另外,水污染导致微量元素过多,容易引起身体器官的功能改变,严重的甚至会引起中毒。例如,l 998 年湖南省地税局办公楼工作人员集体腹泻,后被证实问题就是出在二次供水的水质上,而且是由细菌总数超标以及大肠菌群所致。长春市某生活小区不断有居民发生消化道疾病,经查,原来是屋顶水箱多

1.4 传统二次供水方式存在的问题

总结以往的供水经验和实际工程,二次供水存在以下几个问题:

1.投资大。传统二次供水都要修建水池,有的还要设置水箱,这就需要一定的成本。修建水池和水箱需占用一定的建筑面积,在如今土地价格高涨的今天,这又是个投资负担。此外,水池和水箱一般都有一些水质处理设施,从而加大了设备总投资,而且使用中要定期清洗,也增加了日常开支。

2.水质二次污染严重。据调查,大部分水池和水箱由于管理不善,和其结构本身的原因,里面的贮水水质没有符合饮用水标准,水质污染相当严重,这将直接危害到人们的身体健康,因此饮用水卫生问题已成为急需解决的大问题。

3.能量浪费严重。传统的二次供水是将自来水放入水池中,再从水池抽水至用水点,但是市政管网中的水具有一定的能量,也就是说这部分能量没有得到充分利用。

4.水资源浪费严重。大多数水池采用混凝土结构,因此存在不同程度的渗水、跑水、漏水、蒸发等问题,造成水资源浪费。此外,水池、水箱要进行定期的清洗,这就又成一部分浪费。

1.5 本课题的研究内容

无负压供水设备由智能型变频控制柜、稳流罐、真空抑制器、水泵机组、仪表阀门及管路、基座等组成。本次课题研究的主要内容是供水方案的设备设计,其中包括稳流罐的设计,真空抑制器的设计,水泵的选型已经设备的整体结构设计。

1.6 本课题预计达到的目标

能够顺利完成课题所需要完成的任务,设备达到无水池,不用消毒,体积小,占地少,安装方便的要求。设备应具有无负压供水能力,整套设备全封闭无污染。

1.7 完成课题的方案和主要措施

1、同老师讨论合适的方案和机体结构,讨论其可行性。

2、在图书馆和网上查找相关资料。

3、从网上实体照片中形成设备的基本模型。

4、按照老师布置的任务按时完成计划,画出装配图及主要零件图。

5、主要参数的计算和设备的选型。

6、设计说明书的编写。

7、后期工作。 第二章 无负压供水方案简介

.1 方案的工作原理

1.市政管网自来水进入调节罐,罐内的空气从负压消除器内排出,待水充满后,负压消除器自动关闭。当市政管网的压力满足用水点的要求时,即管网压力大于或等于设定压力时,设备通过旁通阀门直接向用户供水。

2.当市政供水管网压力不能满足用水点要求时,供水系统利用压力传感器(或压力控制器、电接点压表)发出启泵信号,水泵进入运行状态,向用户持续供水。

3.在用水高峰期,供水管网压力下降,当降至低于设定压力时,压力传感器发信号给控制柜,升高变频器频率,使水泵机组转速增加,出水量和压力也随之上升,直至用水点实际压力等于设定压力。

4.在用水低谷期,供水管网压力上升,当高于设定压力时,压力传感器发信号给控制柜,降低变频器频率,使水泵机组转速降低,直至供水管网实际压力等于设定压力。若用水量变小甚至无流量时,水泵处于空转状态,则水泵机组自动停止工作,自来水通过旁通管直接供给用户。

5.若市政管网流量大于或等于水泵的进水量,负压消除器使得稳流补偿器与外界隔绝,系统正常供水。若市政管网流量小于水泵流量时,空气由负压消除器进入稳流补偿器,消除了市政管网的负压,保证市政管网的正常供水,同时罐内的水作为补充水源仍正常供水,待用水高峰期过后,系统恢复正常状态。

6.当市政供水管网停水时,利用稳流补偿器内的部分存水,水泵仍可继续工作一段时间,当稳流补偿器内水位下降至一定水位时,自动停机以保护水泵;来水后随着水位的上升而自动开机。

7.停电时,水泵不工作,自来水通过旁通管直接到达低层用户,保证低层部分用户的用水,来电时水泵机组自动开机,恢复所有用户的正常供水。

2.2 方案的工作流程

无负压供水技术综合利用负压处理技术、变频调速技术和全自动智能化控制技术,实现从市政管网直接加压向用户持续和稳定地供水,达到用户用水要求,其工作流程如图2-2所示:

图2-2 无负压供水方案工作流程图

2.3 方案的适应范围

无负压供水系统适用于市政供水管网压力不足地区的二次加压供水,包括:新建、改建或扩建的住宅小区、办公楼、宾馆、学校等民用建筑的生活给水工程,工矿企业的生活、生产用水,各种循环用水系统,原有传统二次供水的改造工程,低层供水压力不能满足要求的消防用水等。

无负压供水系统不适用的场所:市政管网可利用水头过低的区域;供水可靠性要求高的地区;市政管网供水流量和压力波动大的区域;用户用水量非常集中的区域;可能会对公共供水管网造成有毒污染的相关行业(医院、医药、化工、核工业等)。

2.4 方案的核心技术 —— 无负压技术

无负压供水技术中所提到的无负压中负压的概念,并非物理学所指负压概念,即低于常压(通常为一个大气压)的压力状态。这里的负压是在此基础上的演绎而来的说法,是指以各地区规定的最低市政管网服务压力值为界限,低于这一压力即为负压。无负压供水系统必须要保证直接抽水时市政管网的压力不低于最低服务压力值,同时由此产生的压降也要控制在一定的范围内,符合当地管理部门的有关规定。

负压消除器,也叫真空抑制器,是该设备的核心,它和稳流补偿器联合工作以消除管网中的负压,从而避免对周围用户的影响,保证市政管网与设备安全可靠地供水。其原理如下:它根据稳流补偿器内的水量、水压、液位、真空度等信号,进行实时反馈、处理和控制,在满水时关闭阀门,在容器内产生负压会水位下降时打开阀门,从而调节稳流补偿器吸气和排气,保证内部压力平衡,同时消除容器内的负压。该装置的控制方式主要有水力机械式、电动式(利用电接点真空表或容器内水位接点控制电磁阀的启闭)。 参考文献

[1]姚福来.?无负压供水设备的现状与发展态势[J].建设科技,2005,(22)

[2]濮良贵. 纪名刚. 机械设计[M]. 北京:高等教育出版社,2006.

[3]尤百琴.?新型供水设备问世[J].船艇,1992,(0).

[4]邵军.?无负压变频恒压供水[J].大众科学(科学研究与实践),2007,(08).

[5]张凤英.?论无负压供水设备的优点[J].安装,2006,(02)

[6]会议论文?北京地区无负压加压供水设备的管理现状及存在问题?2010’建筑二次供水技术推广与管理经验交流会 – 2010

[7]会议论文?NFWG无负压变频供水设备?中国水协设备材料委第二届二次供水设备选型与应用技术交流研讨会 – 2009

[8]会议论文?浅谈箱式无负压供水设备?2010’建筑二次供水技术推广与管理经验交流会 – 2010

川公网安备: 51019002004831号

川公网安备: 51019002004831号