超声波深孔钻床设计

超声深孔钻床的设计【优秀】【word+9张CAD图纸全套】【毕业设计】

【带任务书+鉴定意见评阅表+外文翻译】【带任务书+开题报告+评阅评语表+答辩资格审查表+工作中期检查表+指导教师评阅表+实习日记+外文翻译+实习报告】【31页@正文10490字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】.bat

A0-主轴箱.dwg

A0-机床总装配.dwg

A1-主轴.dwg

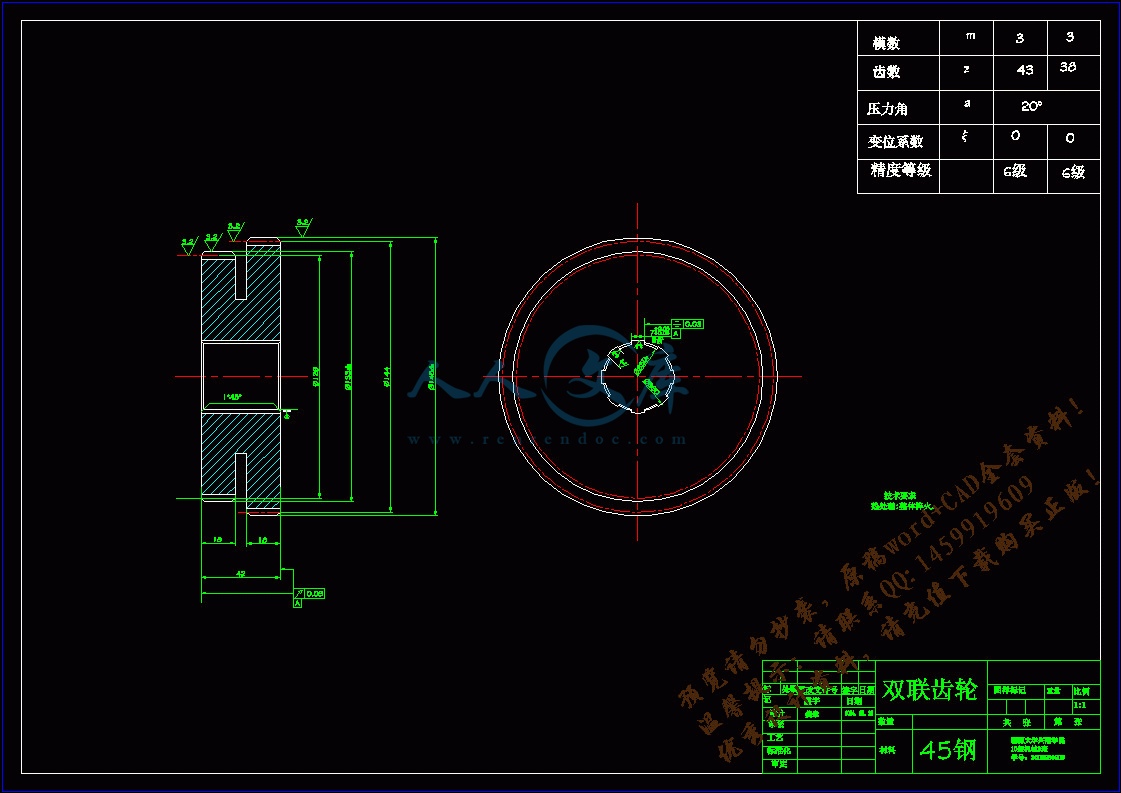

A2-双联齿轮.dwg

A2-双联齿轮2.dwg

A2-带轮.dwg

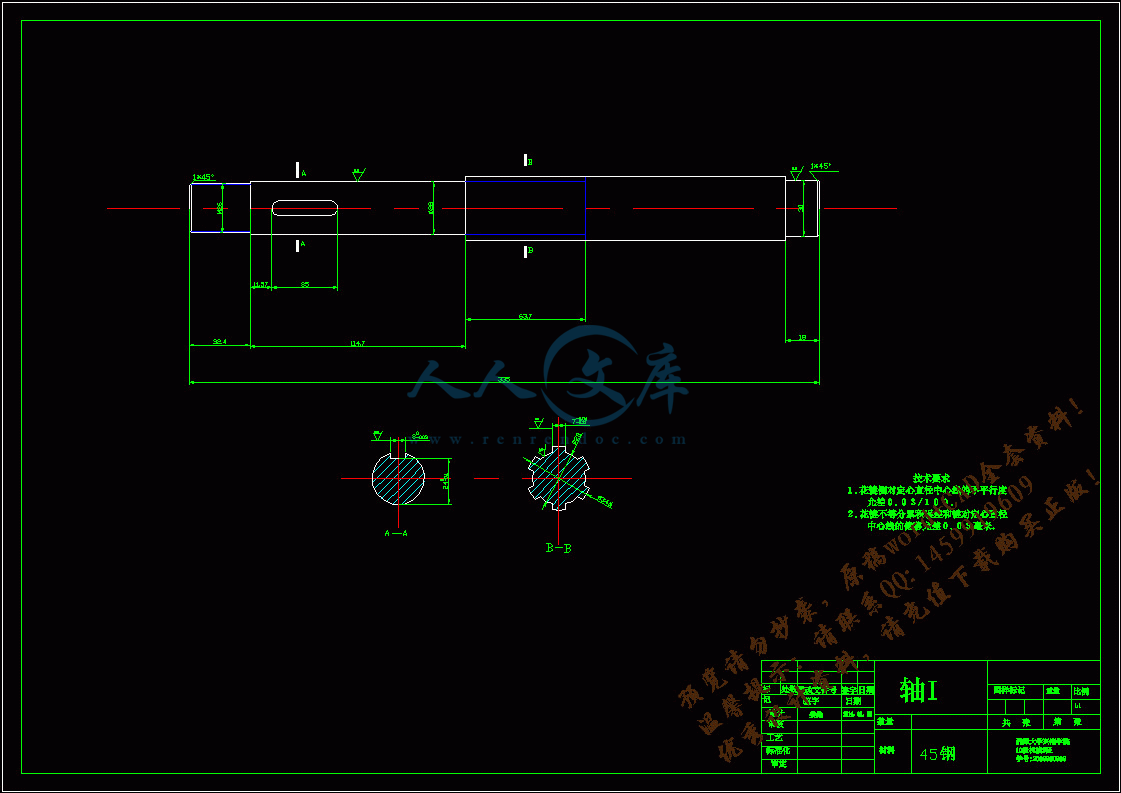

A2-轴I.dwg

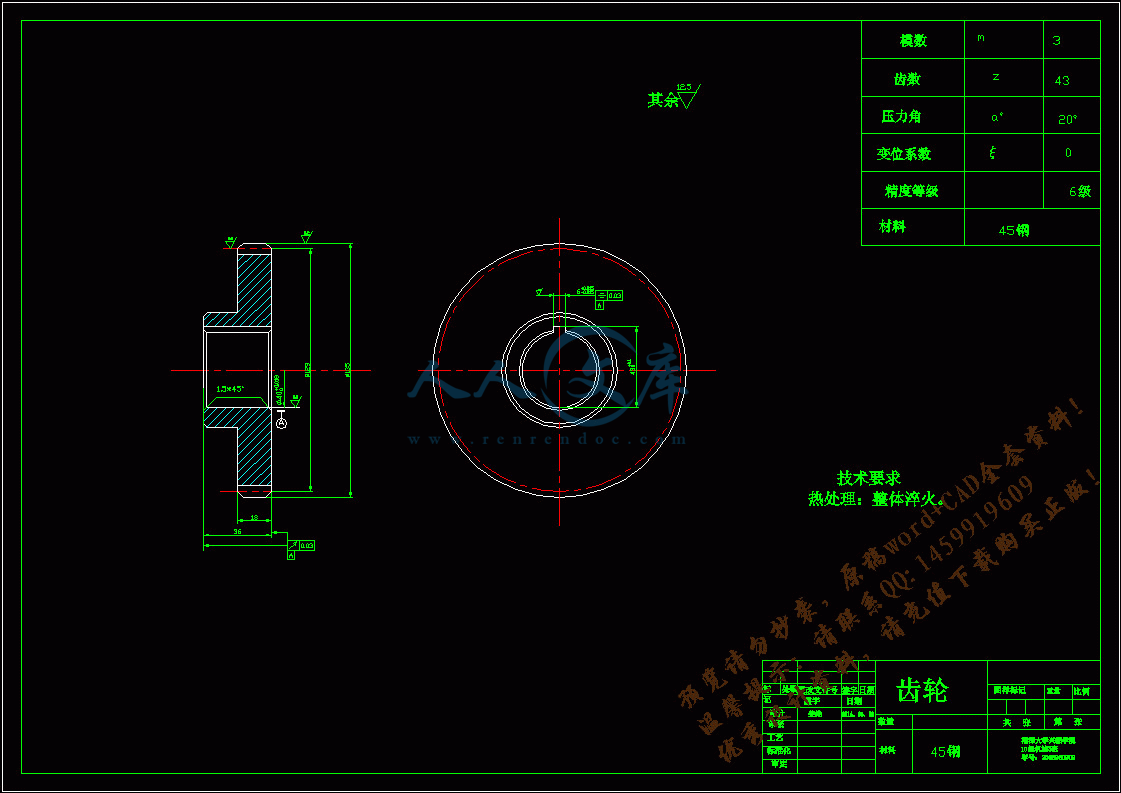

A2-齿轮.dwg

A2-齿轮2.dwg

任务书.doc

封面.doc

简介.txt

英文文献中文.doc

英文文献英文.pdf

评阅表.doc

说明书.doc

鉴定意见.doc

鉴定意见表.doc

湘潭大学兴湘学院

毕业论文(设计)任务书

论文(设计)题目 超声深孔钻床设计

一、主要内容及基本要求

对国内外振动钻削工艺与方法进行分析,探讨;对超声震动原理与振动力学进行研究;对超声振动钻削装置进行设计;利用AutoCAD等软件对设计的机床按国标要求绘制2D装配图及主要零部件的2D零件图; 对钻床主轴箱进行设计。

基本要求如下

1.绘制钻床装配图 1张

2.绘制钻床相关零件图 8套

3.编写设计说明书 1份

4.专业英语翻译 1份

二、重点研究的问题

(1)超声波振动钻床总体方案设计

(2)钻床主轴箱的设计。

(3)主执行机构设计(机构选型)及其结构设计。

三、进度安排

序号各阶段完成的内容起止时间

1收集资料第1-2周

2工艺分析,方案确定,绘制方案图第3周

3钻床结构设计,绘制总装图第4-8周

4绘制零件图第9-11周

5撰写设计说明书第12周

6外文翻译第13周

7毕业答辩第14周

四、 应收集的资料及主要参考文献

(1)曹凤国;《超声波加工技术》;化工工业出版社

(2)胡敏强,金龙,顾菊平;《超声波电机原理与设计》

(3)赵淳生;《超声电机技术与应用》

(4)超范国良, 陈传梁;《超声加工概况和未来展望》;1994年

(5)成大龙;《机械设计手册单行本机械振动/机架设计》;北京化学工业出版社 2004年

(6)成大龙;《机械设计手册单行本机构设计》;北京化学工业出版社2004年

(7)宁伟,许明翔,王耀俊;《固体间不同厚度界面层超声反射声学技术》;1995年

(8)王亚非, 袁敬闳, 曾宏亮;《分层媒质中声波传输规律的研究压电与声光》;2000年

(9)吴宗泽 罗圣国主编 《机械设计手册》高等教育出版社,2012年5月

(10)张雄 焦峰 论文《超声加工技术的应用及其发展趋势》,2012年6月

目录

摘 要1

前言2

第一章.超声和深孔加工技术的发展趋势4

1.1 超声振动加工技术发展趋势4

1.2 深孔加工发展状况5

第二章.机床主要参数的确定6

2.1 电机功率的确定6

2.2 主运动参数的确定6

2.3 标准公比值和标准转速数列7

第三章.确定结构式和绘制转速图9

3.1 求级数z9

3.2 确定结构式9

3.3 绘制转速图10

第四章.确定各级传动副齿轮的齿数12

4.1 确定齿轮的齿数12

4.2 验算传动比13

4.3 各轴及齿轮的计算转速的确定14

第五章.传动零件的初步计算16

5.1 传动轴直径初定16

5.2 主轴主要结构参数的确定16

5.3 齿轮模数计算和齿轮中心距的计算17

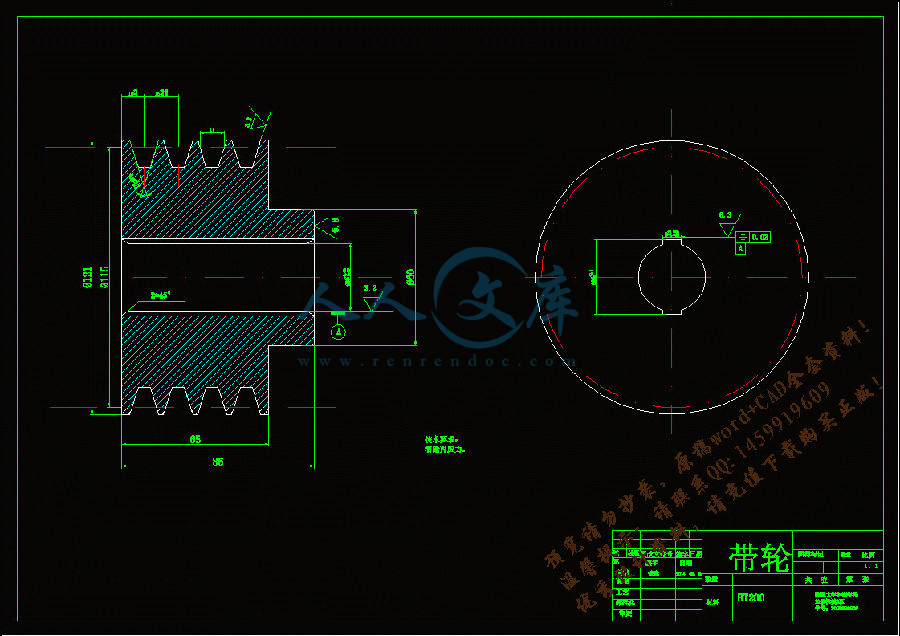

5.4 皮带的相关计算18

第六章.主要零件的验算21

6.1 齿轮的强度验算21

6.2 主轴的验算22

6.3 花键的验算26

致 谢28

参考文献29

英文文献30

摘 要

该设计是设计一超声深孔钻床,利用超声震动加工深孔。振动钻削,即在钻头(或工件)正常工作进给的同时,对钻头(或工件)施加某种有规律的振动,使钻头在振动中切削,形成脉冲式的切削力波形,使切削用量按某种规律变化,以达到改善切削效能的目的。根据实际加工的需要,适当选择振动参数(频率v,振幅A以及频率v与工件转速n的比例关系),可以控制切屑的大小和形状,得到满意的切屑,避免切屑堵塞。可提高生产效率几倍到十几倍,提高加工精度1—2级,且加工表面质量也有较大改善。

超声振动深孔加工钻床是利用超声振动系统对钻头施加振动,使钻头在振动中切削,使切削用两按规律变化,从而达到改善切削效能的目的。

关键词:超声振动,深孔加工,枪钻车床。

Abstract

This design is designs a supersonic deep hole drilling machine, the use supersonic vibration processes the deep hole. The vibration drills truncates, namely while the drill bit (or work piece) normal work to feed, (or work piece) exerts some kind of orderly vibration to the drill bit, causes the drill bit to cut in the vibration, forms the pulse -like cutting force profile, causes the cutting specifications according to some kind of rule change, achieves the improvement cutting potency the goal。According to the actual processing need, chooses the vibration parameter suitably (frequency v, oscillation amplitude A as well as frequency v with the work piece rotational speed n proportional relationship), may control the scrap the size and the shape, obtains satisfaction scrap, avoids the scrap jamming. May enhance production efficiency several times to several times, enhances the processing precision 1-2 level, also the processing surface quality also has improves greatly.

The ultrasonic vibration deep hole processing drilling machine is the use ultrasonic vibration system to the drill bit infliction vibration, causes the drill bit to cut in the vibration, causes the cutting with two according to the rule change, thus achieves the improvement cutting potency the goal.

Key words: The ultrasonic vibration, the deep hole processing, butts the lathe.

前言

毕业设计是学生学完大学教学计划所规定的全部基础课和专业课后,综合运用所学的知识,与实践相结合的重要实践性教学环节。它是大学生活最后一个里程碑,是四年大学学习的一个总结,是我们结束学生时代,踏入社会,走上工作岗位的必由之路,是对我们工作能力的一次综合性检验。

1.毕业设计的目的

通过本次毕业设计,使达到以下几个效果:

(1)巩固、扩大、深化学生以前所学的基础和专业知识;

(2)培养学生综合分析、理论联系实际的能力;

(3)培养学生调查研究、正确熟练运用国家标准、规范、手册等工具书的能力;

(4)锻炼进行设计计算、数据处理、编写技术文件、绘图等独立工作能力。

总之,通过毕业设计使学生建立正确的设计思想,初步掌握解决本专业工程技术问题的方法和手段,从而使学生受到一次工程师的基本训练。

2、毕业设计的主要内容和要求

本次毕业设计的主要内容是设计超声深孔钻床的主轴箱。具体设计内容和要求如下:

a)调查使用部门对机床的具体要求,现在使用的加工方法;收集并分析国内外同类型机床的先进技术、发展趋势以及有关的科技动向;调查制造长的设备、技术能力和生产经验等。

b)超声深孔钻床主轴箱的设计主要是设计主轴、传动轴及传动齿轮,确定各部分的相互关系;拟订总体设计方案,根据总体设计方案,选择通用部件,并绘制装配图和各零件的零件图;

c)进行运动计算和动力计算,绘制转速图;

d)其他零部件的设计和选择;

e)设计并选择皮带的型号和根数及带轮;

f)编制设计技术说明书一份。

3、程序和时间安排

毕业设计是实践性的教学环节,由于时间的限制,本次毕业设计不可能按工厂的设计程序来进行,具体的说,可以分以下几个阶段:

g)实习阶段,通过毕业实习实地调查、研究、收集有关资料,掌握深孔加工技术和超声加工技术,了解机床的结构、工作原理和设计的基本要求,花两周时间;

h)制定方案、总体设计阶段,花两周时间;

i)计算和技术设计阶段,绘制图纸,整理设计说明书,花四周时间;

j)答辩阶段,自述设计内容,回答问题,花半周时间。

第一章.超声和深孔加工技术的发展趋势

1.1 超声振动加工技术发展趋势

超声加工是利用超声振动工具在有磨料的液体介质或干磨料中产生磨料的冲击、抛磨、液压冲击及由此产生的气蚀作用来去除材料,或给工具或工件沿一定方向施加超声频振动进行振动加工,或利用超声振动使工件相互结合的加工方法。超声加工技术在几十年里得到了迅速的发展,在超声振动切削、磨削加工、光整加工、塑性加工及其他方面的加工都有着广泛的研究与应用,尤其是在难加工材料领域解决了许多关键的工艺问题,取得了良好的效果。难加工材料促进了超声加工技术的发展,从而进一步促进了新材料的发展,可以预测,超声加工技术的应用会越来越广泛。

1.1.1 超声加工技术发展概况

因超声加工技术在硬脆等难加工材料加工方面有较大的优势, 同时这些硬脆材料具有普通材料无法比拟的特点, 使其在工程上有着越来越广泛的应用, 国内外学者纷纷对超声加工技术的理论和工艺进行深入研究, 不断扬弃传统超声加工过程中所出现的缺点, 使超声加工这一技术的优点更为突出。

沈阳航空工业学院进行了精密深小孔的深入研究, 分别进 行了超 声镗孔、钻 孔和铰孔研究试验。张建中教授等人提出采用超声激振双刃镗削可较好弥补单刀镗削的缺陷与不足0, 提高系统的刚性, 进一步提高了精密深孔加工精度, 加工表面粗糙度为 Ra0. 1 Lm; 在铰孔试验中发现, 积屑瘤和磷次消失, 切削温度保持室温, 孔的圆度可达0. 004 mm, 圆柱度为0. 005 mm, 表面粗糙度为Ra0. 17 Lm; 超声钻孔的相关工艺实验表明, 这种钻削工艺减少了切削力, 降低了切削温度, 提高了零件的加工质量。

天津大学做了超声磨削加工工程陶瓷小孔的实验, 电镀金刚石的工具以超声频率和一定的振幅振动, 并加以高速旋转, 通过磨削液中的磨粒和工具对工件进行高速撞击、超声空化和砂轮磨粒的磨削, 达到材料去除的目的。结果表明, 超声磨削加工可明显提高陶瓷加工效率, 能明显减少普通磨削产生的表面裂纹和凹坑, 是陶瓷深孔精密高效加工的有效方法。

1.1.2 超声加工技术发展趋势和未来展望

超声加工技术已经涉及到许多领域,在各行各业发挥了突出的作用,但有关工艺与设备的相关技术有待于进一步研究开发。

(1)超声振动切削技术

随着传统加工技术和高新技术的发展,超声振动切削技术的应用日益广泛,振动切削研究日趋深入,主要表现在以下几个方面。

1研制和采用新的刀具材料。在现代产品中,难加工材料所占的比例越来越大,对机械零件加工质量的要求越来越高。

2对振动切削机理深入研究。

3超声椭圆振动切削的研究与推广。

a超声铣削加丁技术。基于分层去除技术思想的超声铣削加工技术正在被更多的学者所关注。

b超声复合加工技术

目前,超声电火花机械三元复合加工技术已经得到较快的发展。哈尔滨工业大学利用超声电火花磨料三元复合加工技术对不锈铜进行加工,解决了电火花小孔加工中生产率和表面质量不能兼顾的矛盾,具合较好的应用前景。

c微细超声加工技术

随着以微机械为代表的工业制品的日益小型化及微细化,特别是随着晶体硅、光学玻璃、工程陶瓷等硬脆材料在微机械中的广泛应用,硬脆材料的高精度三维微细加工技术己成为世界各国制造业的一个重要价究课题。

同其他特种加工技术一样,起声加工技术在不断完善之中.正向着高精度、微细化发展,微细超声加丁技术合理成为微电子机械系统(MEM5)技术的有力补充。

参考文献:

[1] 冯辛安主编《机械制造装备设计》机械工业出版社出版,2003年6月

[2]濮良贵 纪名刚主编《机械设计》高等教育出版社出版,2001年4月

[3]王世清主编《深孔加工技术》西北工业大学出版社出版,2003年10月

[4]李洪主编《实用机床设计手册》辽宁科学技术出版社出版,1999年1月

[5]黄鹤汀主编《金属切削机床》下册 机械工业出版社出版,1998年5月

[6]赵世华主编《金属切削机床》航空工业出版社出版,1996

[7]曹凤国主编《超声加工技术》化学工业出版社出版,2004年8月

[8]孙桓 陈作模主编《机械原理》(第六版高等教育出版社出版,2002年8月

[9]吴宗泽 罗圣国主编 《机械设计手册》高等教育出版社,2012年5月

[10]张雄 焦峰 论文《超声加工技术的应用及其发展趋势》,2012年6月

川公网安备: 51019002004831号

川公网安备: 51019002004831号