电火花线切割加工工艺设计及试验

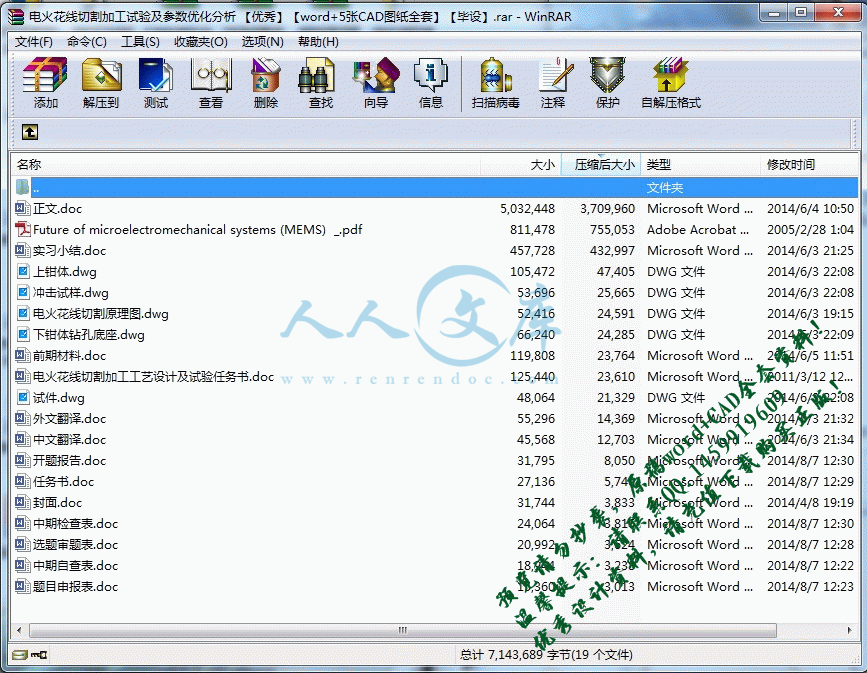

电火花线切割加工试验及参数优化分析 【优秀】【word+5张CAD图纸全套】【毕业设计】

【带任务书+开题报告+实习小结+题目申报表+中期自查表+外文翻译】【46页@正文19400字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

Future of microelectromechanical systems (MEMS) _.pdf

上钳体.dwg

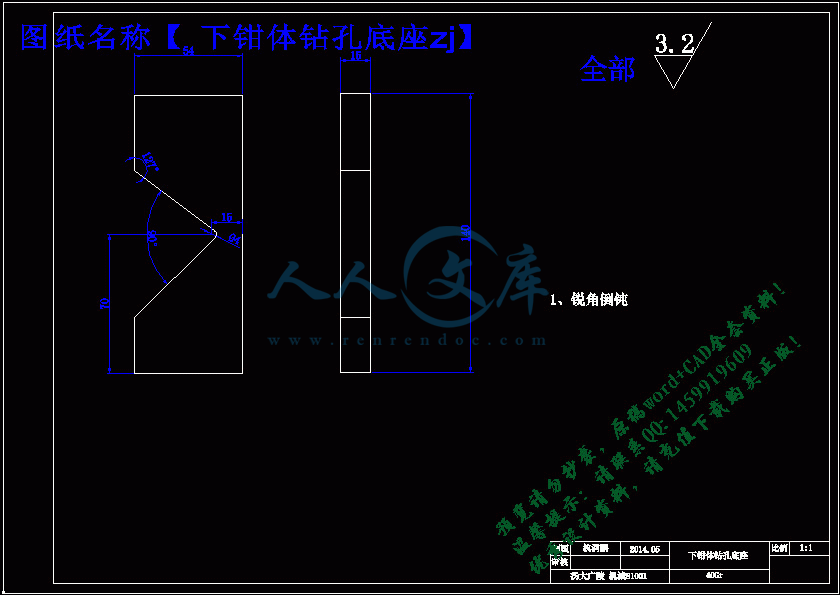

下钳体钻孔底座.dwg

中文翻译.doc

中期自查表.doc

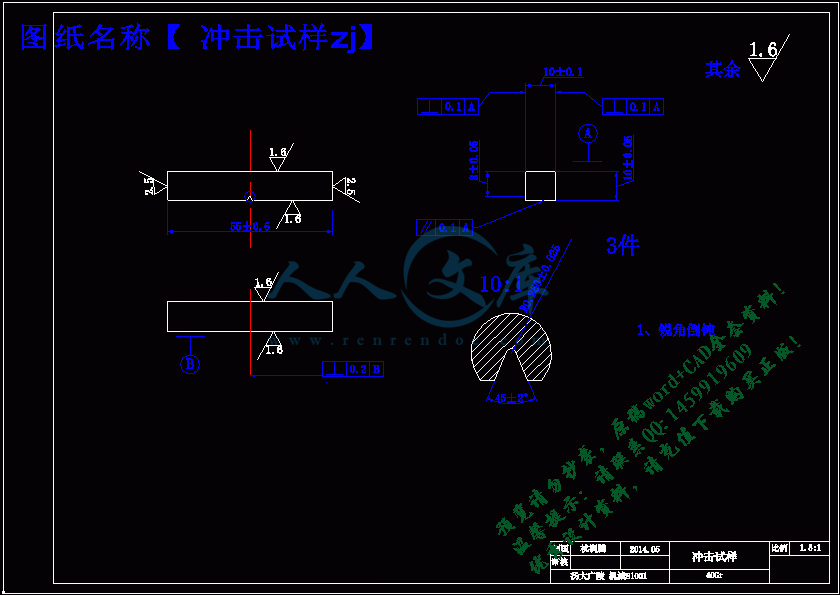

冲击试样.dwg

前期材料.doc

外文翻译.doc

实习小结.doc

封面.doc

开题报告.doc

正文.doc

电火花线切割加工工艺设计及试验任务书.doc

电火花线切割原理图.dwg

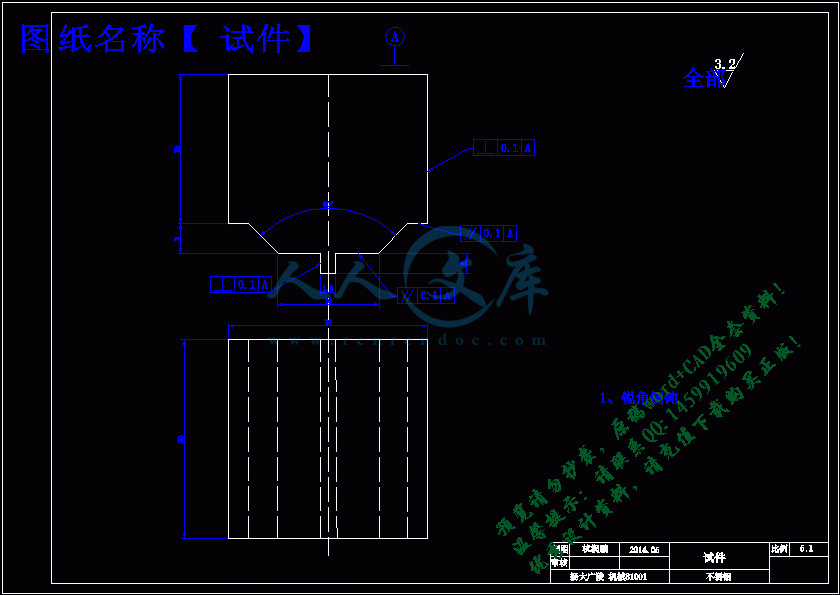

试件.dwg

题目申报表.doc

任务书

1.本毕业设计(论文)课题应达到的目的:

课题目的及意义:

随着科学技术的进步,具有复杂三维型面及难加工材料零件的应用越来越广泛,普通的机械加工难以满足要求,而特种加工中的电火花加工具有成形精度高,可加工三维曲面的任何导电材料的特性,在特种加工中具有重要地位,在现代制造业中有重要应用。

本毕业设计课题进行电火花线切割加工工艺设计及机理试验,熟悉其加工特性,进行加工参数优化,为其实际应用建立工艺基础。

2.本毕业设计(论文)课题任务的内容和要求(包括原始数据、技术要求、工作要求等):

主要内容:熟悉电火花线切割加工机的组成部分、功能、工作原理及操作方法。掌握电火花线切割加工加工的基本原理,对不同材料进行电火花加工试验,对电参数进行在线测试,对加工结果进行对比分析,讨论工艺参数对加工速度、加工精度以及表面粗糙度等工艺指标的影响规律。

要求:

1、掌握电火花线切割加工加工的基本原理、特性;

2、电火花线切割加工试件及工具电极丝的预备,并进行各种参数电火花线切割加工工艺试验;

3、对实验数据进行分析、数据处理,形成可指导实际应用的工艺文件;

毕业设计(论文)任务书

3.对本毕业设计(论文)课题成果的要求(包括毕业设计论文、图表、实物样品等):

1.完成外文专业资料的翻译;

2.电火花线切割加工原理示意图;

3.电火花线切割加工试验结果;

4.电火花线切割加工特性分析;

5.毕业实习报告;

6.毕业论文;

4.主要参考文献:

[1].李明辉.电火花加工理论基础.国防工业出版社,1889

[2].刘晋春,赵家齐. 特种加工. 北京:机械工业出版社,1995

[3].曹风国. 电火花加工技术. 化学工业出版社.2005

[4].苑伟政,马炳和. 微机械与微细加工技术 . 西北工业大学出版社,2000.

[5].朱荻. 纳米制造技术与特种加工. 2001年中国机械工程年会特种加工技术论文集.北京:机械工业出版社,2001

[6].赵万生. 电火花加工技术.哈尔滨工业大学出版社. 2000

[7].袁哲俊,王先逵. 精密和超精密加工技术. 北京: 机械工业出版社,1999.7 .

[8].胡传炘主编.夏志东副主编. 特种加工手册. 北京工业出版社, 2001

[9].余承业. 特种加工新技术. 国防工业出版社.1995

[10].孔庆华. 特种加工.同济大学出版社.1997.5

[11].刘振辉,杨嘉揩.特种加工.重庆大学出版社.1991.5

[12].胡传稀.特种加工手册.北京工业大学出版社.2001

[13].赵万生. 电火花加工技术. 哈尔滨: 哈尔滨工业大学出版社, 2000. 5.

[14].赵万生, 敦永丰, 耿春明. 国外电火花最新加工. 2001 年中国机械工程学会年会暨第九届全国特种加工学术年会, 2001

查阅资料,熟悉课题要求,熟悉电火花加工的基本原理;

摘要

随着科学技术的进步,具有复杂三维型面及难加工材料零件的应用越来越广泛,普通的机械加工难以满足要求,而特种加工中的电火花加工具有成形精度高,可加工三维曲面的任何导电材料的特性,在特种加工中具有重要地位,在现代制造业中有重要应用。

本毕业设计课题在熟悉电火花线切割加工机的组成部分、功能、工作原理及操作方法基础上,进行电火花线切割加工工艺设计及机理试验,熟悉其加工特性,进行加工参数优化,为其实际应用建立工艺基础。对不同电参数进行加工试验,对加工结果进行对比分析,讨论工艺参数对加工速度、加工精度以及表面粗糙度等工艺指标的影响规律。

关键词:电火花线切割 基本原理 参数优化 工艺设计

Abstract

With the progress of science and technology,?application and?has a?complex three-dimensional surface?and difficult to machine materials,?parts of the?more extensive,?general?difficult to satisfy the requirements of?machining,?and themachining?of?WEDM?with?high forming precision,?characteristic of?any conductive material?can be processed?3D surface,?has an important position in theconstruction?process,?there are?an important application?in modern manufacturing industry.

The graduation project in the familiar WEDM wire cutting machine component, function, working principle and method of operation, based on the conduct WEDM process design and testing mechanism, familiar with its processing characteristics, processing parameters optimized for the practical application of the process to establish the foundation. Different electrical parameters for processing test, the results of a comparative analysis of the process, discuss the impact of the law of process parameters on processing speed, precision and surface roughness technology indicators.

Keywords: WEDM Fundamental Parameter optimization Process Design

目录

摘要II

AbstractIII

第一章 引言1

1.1 电火花线切割的发展1

1.2 电火花线切割机床的分类2

1.3 电火花线切割的加工环境3

1.4 本章小结4

第二章 电火花线切割加工的机理及应用5

2.1电火花线切割加工原理5

2.2电火花线切割加工物理过程7

2.3电火花线切割加工的特点10

2.4电火花线切割加工的局限性13

2.5电火花线切割加工的应用13

2.6本章小结14

第三章 电火花加工设备15

3.1机床传动系统16

3.2机床操作步骤17

3.3机床控制系统19

3.4 本章小结21

第四章 加工试验及分析22

4.1试验简介22

4.2电极工具头制作33

4.3本章小结36

第五章 试验总结 体会及前景37

5.1实验总结37

5.2体会38

5.3前景39

5.4 本章小结39

致 谢40

参考文献41

第一章 引言

1.1.电火花线切割的发展

电火花线切割机(Wire?cut?Electrical?Discharge?Machining简称WEDM),属电加工范畴,是由前苏联拉扎林科夫妇研究开关触点受火花放电腐蚀损坏的现象和原因时,发现电火花的瞬时高温可以使局部的金属熔化、氧化而被腐蚀掉,从而开创和发明了电火花加工方法。线切割机也于1960年发明于前苏联,我国是第一个用于工业生产的国家。

目前电火花线切割加工技术的研究与发展趋势主要表现在以下几个方面:

1.新型走私系统

2.油基工作液

3.自动化,人工智能技术

4.微细电火花线切割加工

5.多次切屑工艺

今后的趋势是将在以下几个方面进行深人开发研究:

1)开发和完善开放式的数控系统。目前高速走丝电火花线切割机所用的数控软件是在DOS基础上开发的,有很大的局限性,难于进一步扩充其功能。现在应加速向以pc机为基础的开放式、多任务管理与控制系统发展,以便充分开发PC机的资源,扩充数控系统功能。

2)继续完善数控电火花线切割加工的计算机绘图、自动编程、加工规机控制及其缩放等功能,扩充自动定位、自动找中心、低速走丝及自动穿丝、高速走丝及自动紧缩等功能,提高电火花线切割加工的自动化程度。

3)研究放电间隙状态数值检测技术,建立伺服控制模型,开发加工过程伺服进给自适应控制系统。为了提高加工精度,还应对传动系统的丝距误差及传动间隙进行精确检测,并利用PC机进行自动补偿。

4)开发和完善数值脉冲电源,并在工艺试验基础上建立工艺数据库,开发加工参数优化选取系统,以帮助操作者根据不同的加工条件和要求合理选用加工参数,充分发挥机床潜力。

5)深人研究电火花线切割加工工艺规律,建立加工参数的控制模型,开发加工参数自适应控制系统,提高加工稳定性。

6)进一步开发有自主版权的电火花线切割—和人工智能软件。

积极采用现代技术,促进电火花线切割技术发展今后的电火花线切割技术开发研究将会涉及到:用激光测量技术来分析研究机床零部件的制造质量;用有限元技术来分析机床结构的力学性能和热稳定性;用陶瓷等新材料来制造机床的关键零部件及其工夹具;用模糊控制技术来开发伺服进给和加工参数控制系统;用人工神经网络技术来研究各种复杂系统的输入量与输出量之间的关系,并建立相关的神经网络模型;用数值模拟(计算机仿真)技术上的各种疑难问题,并预测其结果;用专家系统或人工智能系统来控制加工过程等。

1.2 电火花线切割机床的分类

1.2.1电火花线切割机床根据电极丝的运行方向和速度

电火花线切割机场通常风味两大类:一类是往复高速走丝电火花线切割机床,一般走丝速度为8-10m/s,这是我国生产和使用的主要机种,也是我国独创的电火花线切割加工模式;另一类是单向低速走丝电火花线切割机床,一般走丝速度低于0.2m/s,这是国外生产和使用的主要机种。

1.2.2 按电极丝运动轨迹的控制形式分

(一)靠模仿形控制电火花线切割机床

靠模仿形电火花线切割机床,其在进行线切割加工前,预先制造出与工件形状相同的靠模,加工时把工件毛坯和靠模同时装夹在机床工作台上,在切割过程中电极丝紧紧的贴着靠模边缘作轨迹运动,从而切割出与靠模形状和精度相同的工件。

(二)光电跟踪控制电火花线切割机床

光电跟踪控制电火花线切割机床,其在进行线切割前,先根据零件图样按一定比例描绘出一张光电跟踪图,加工时将图样置于机床的光电跟踪台上,跟踪台上的光点头始终追随墨线图形的轨迹运动,再借助于电气、机械的联动,控制机床工作台连同工件相对电极丝做相似形的运动,从而切割出与图样形状相同的工件。

(三)数字程序控制电火花线切割机床

数字程序控制电火花线切割机床,采用先进的数字化自动控制技术,驱动机床按照加工前根据工件几何形状参数预先编制好的数控加工程序自动完成加工,不需要制作靠模样板也无需绘制放大图,比前面两种控制形式具有更高的加工精度和广阔的应用范围,目前国内外95%以上的电火花线切割人机床都以采用数字化。

1.2.3按加工尺寸范围分类

按加工尺寸范围可分为大,中,小型,还可以分为普通型于专用型等。目前国内外的线切割机床采用不同水平的微机数控系统,从单片机,单板机到卫星计算机系统,一般都还具有自动编程的功能。

1.3电火花线切割的加工环境

环境的选择与线切割电放电加工设备及其操作人员有直接关系,环境选择的好坏有以下影响:其一,损坏设备性能及精度,使其机床寿命缩短;其二,影响工件加工精度,造成品质不良;其三,对操作者的安全及身体健康也有危害。故而,在环境场所的选择应考虑以下事项:

1.满足线切割机床所要求的空间尺寸

2.选择能承受机床重量的场所

3.选择没有振动和冲击传入的场所。

线切割放电机床是高精度加工设备,如果所放置的地方有振动和冲击,将会对机台造成严重的损伤,从而严重影响其加工精度,缩短其使用寿命,甚至导致机器报废。

4.选择没有粉尘的场所,避免流众多的通道旁边。

(1) 线切割放电机器之本身特性,其空气中有灰尘存在,将会使机器的丝杆受到严重磨损,从而影响使用寿命。

(2) 线切割放电机器属于计算机控制,计算计所使用的磁盘对空气中灰尘的要求相当严格的,当磁盘内有灰尘进入时,磁盘就会被损坏,同时也损坏硬盘。

(3) 线切割放电机本身发出大量热,所以电器柜内需要经常换气,若空气中灰尘太多,则会在换气过程中附积到各个电器组件上,造成电器组件散热不良,从而导致电路板被烧坏掉。因此,机台防尘网要经常清洁。

5.选择温度变化小的场所,避免阳光通过窗户和顶窗玻璃直射及靠近热流的地方。

参考文献

[1].刘晋春,赵家齐. 特种加工. 北京:机械工业出版社,1995

[2].苑伟政,马炳和. 微机械与微细加工技术 . 西北工业大学出版社,2000.

[3].朱荻. 纳米制造技术与特种加工. 2001年中国机械工程年会特种加工技术论文集.北京:机械工业出版社,2001

[4].袁哲俊,王先逵. 精密和超精密加工技术. 北京: 机械工业出版社,1999.7 .

[5] 胡传炘主编.夏志东副主编. 特种加工手册. 北京工业出版社, 2001

[6] 王建业,徐加文,电解加工原理及应用,国防工业出版社,2001

[7] 曹凤国主编 电火花加工技术 ,化学工业出版社,2005

[8] 王瑞金主编 特种加工技术 北京:机械工业出版社,2001

[9] 王至尧主编 特种加工成形手册 北京:化学工业出版社,2009.6

[10] 曹凤国主编 特种加工手册 北京:机械工业出版社,2010.12

[11].余承业. 特种加工新技术. 国防工业出版社.1995

[12].孔庆华. 特种加工.同济大学出版社.1997.5

[13].刘振辉,杨嘉揩.特种加工.重庆大学出版社.1991.5

[14].胡传稀.特种加工手册.北京工业大学出版社.2001

[15].赵万生. 电火花加工技术. 哈尔滨: 哈尔滨工业大学出版社, 2000. 5.

[16].赵万生, 敦永丰, 耿春明. 国外电火花最新加工. 2001 年中国机械工程学会年会暨第九届全国特种加工学术年会, 2001

川公网安备: 51019002004831号

川公网安备: 51019002004831号