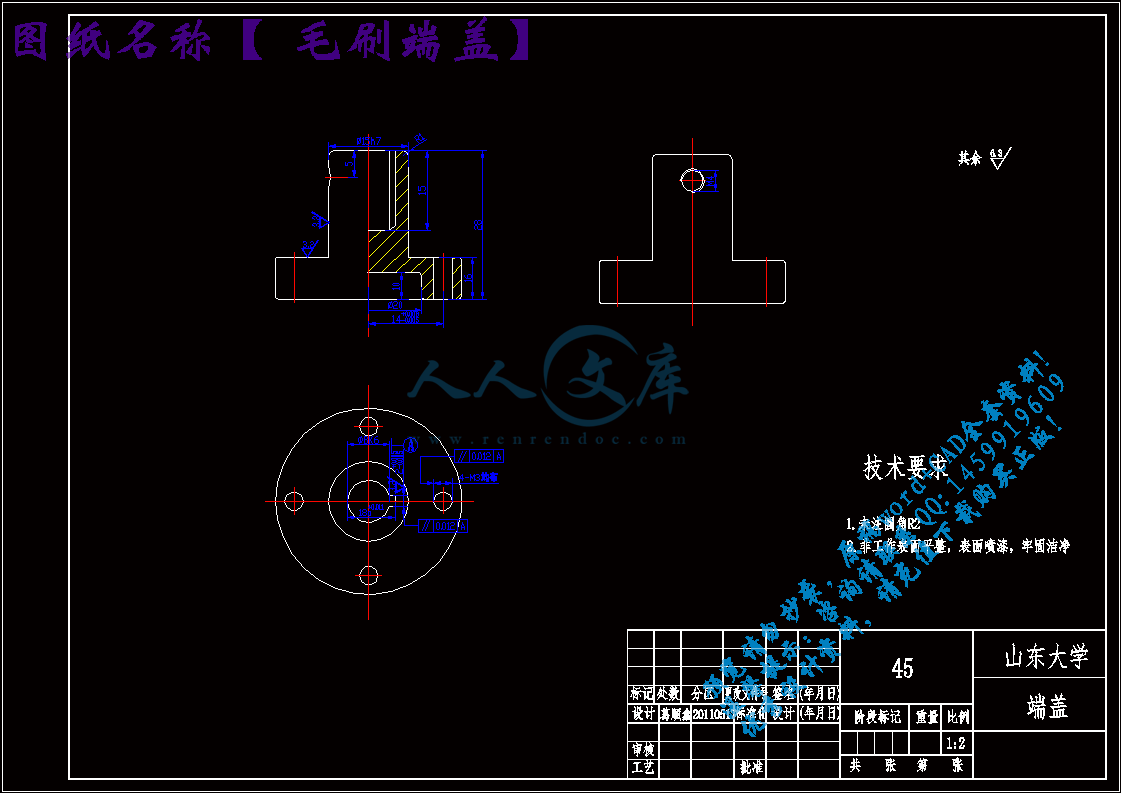

气体输送管道轮式机器人的设计【优秀】【word+17张CAD图纸】【毕业设计】

【带任务书+开题报告+外文翻译】【22页@正文10400字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

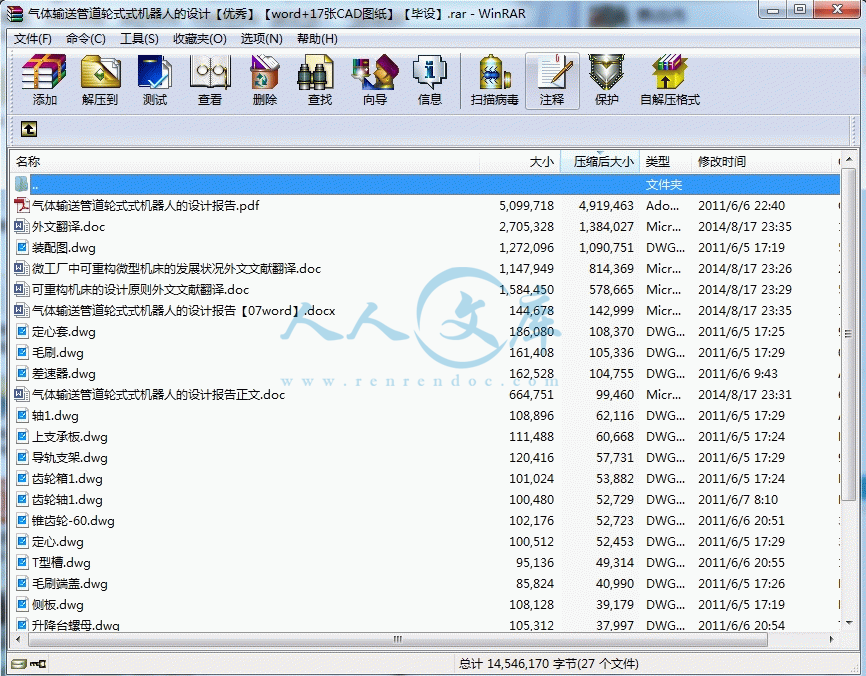

T型槽.dwg

上支承板.dwg

中期汇报表.doc

任务书.doc

侧板.dwg

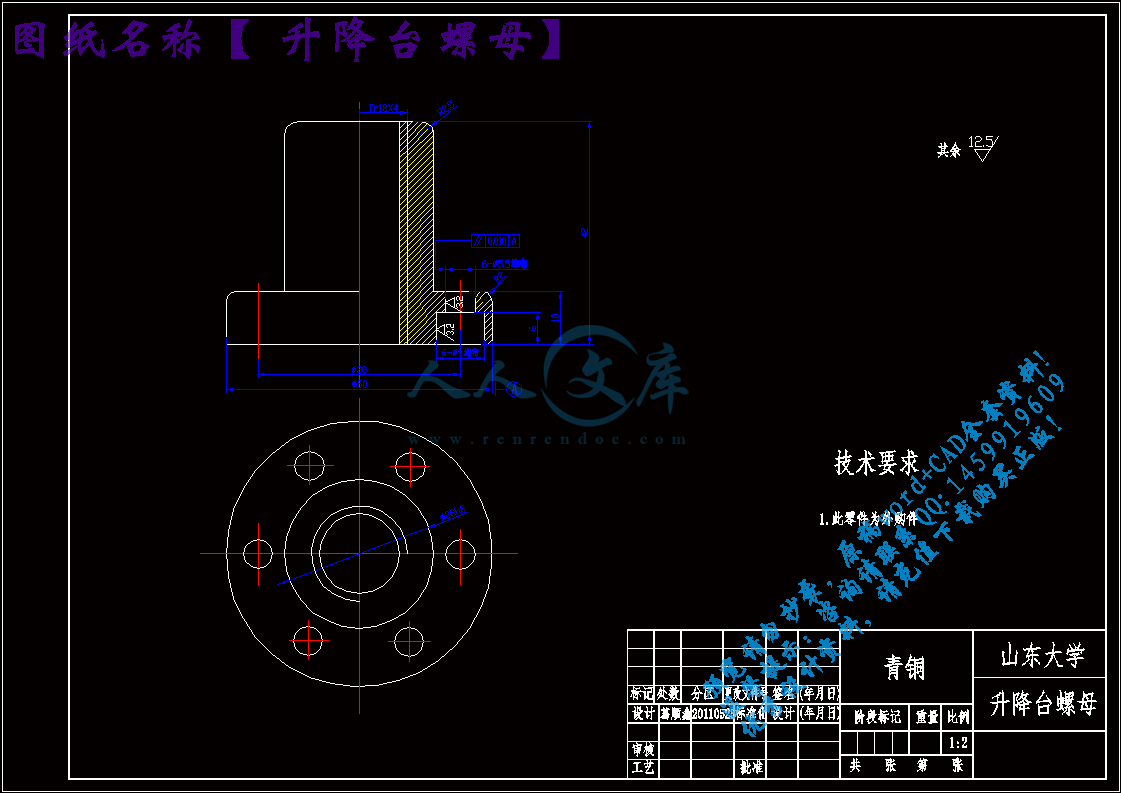

升降台螺母.dwg

可重构机床的设计原则外文文献翻译.doc

圆柱导轨.dwg

外文翻译.doc

定心.dwg

定心套.dwg

导轨支架.dwg

差速器.dwg

开题报告 .doc

微工厂中可重构微型机床的发展状况外文文献翻译.doc

成绩评定表.doc

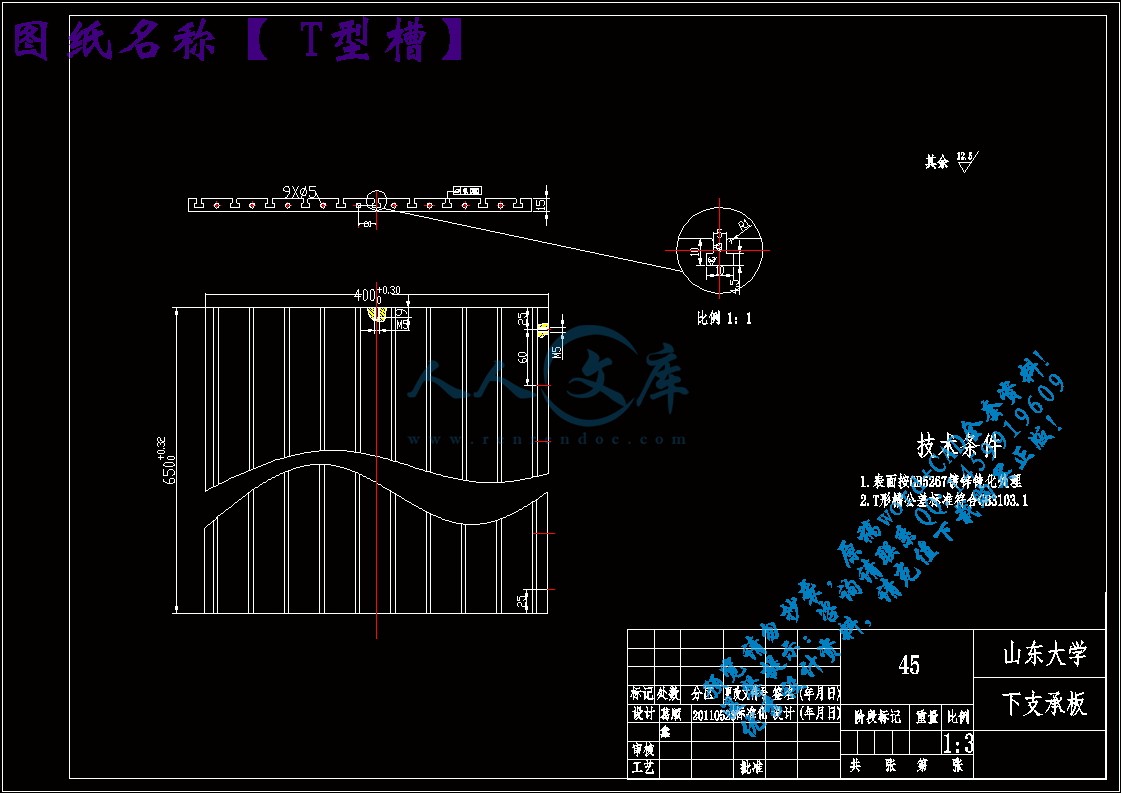

毛刷.dwg

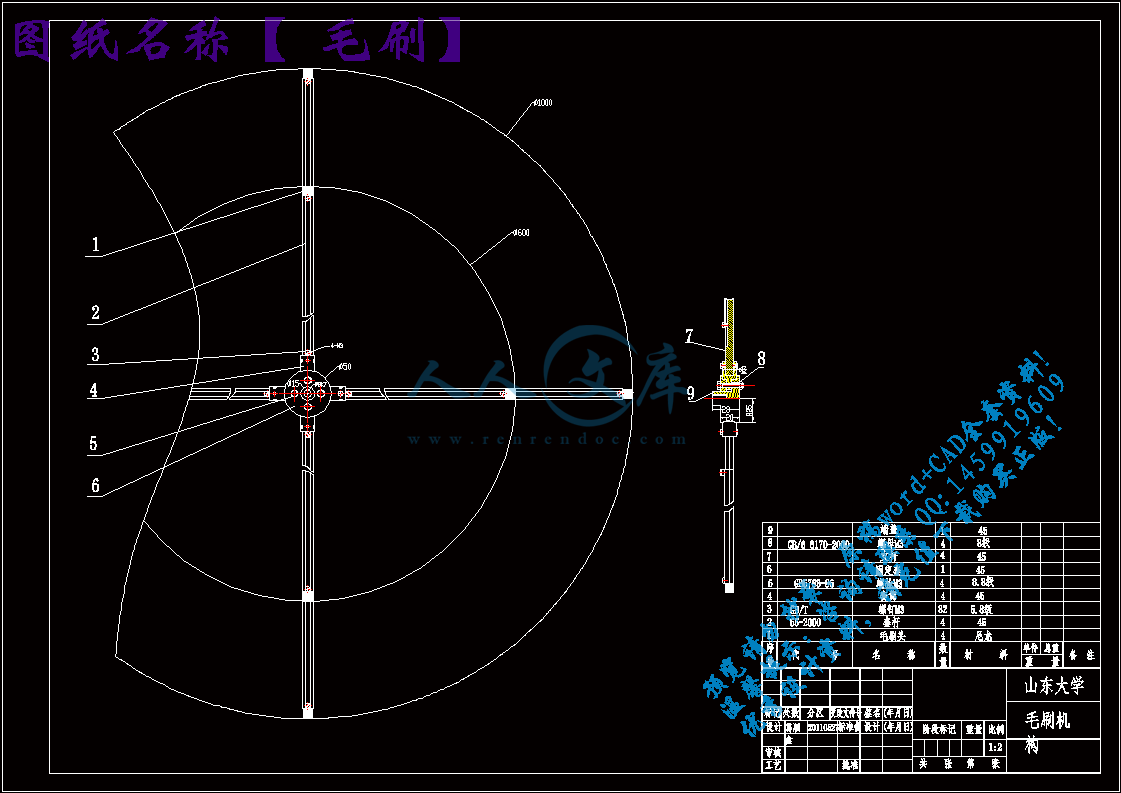

毛刷端盖.dwg

气体输送管道轮式式机器人的设计报告.pdf

气体输送管道轮式式机器人的设计报告【07word】.docx

气体输送管道轮式式机器人的设计报告正文.doc

装配图.dwg

轴1.dwg

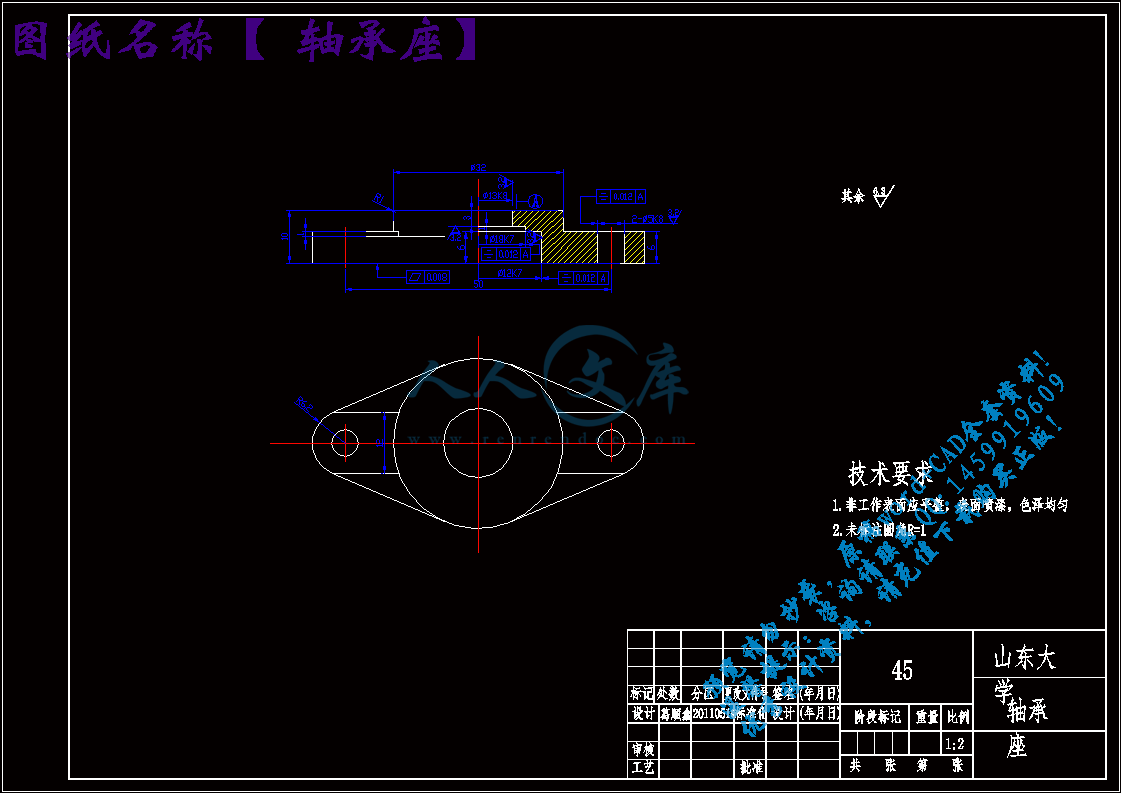

轴承座.dwg

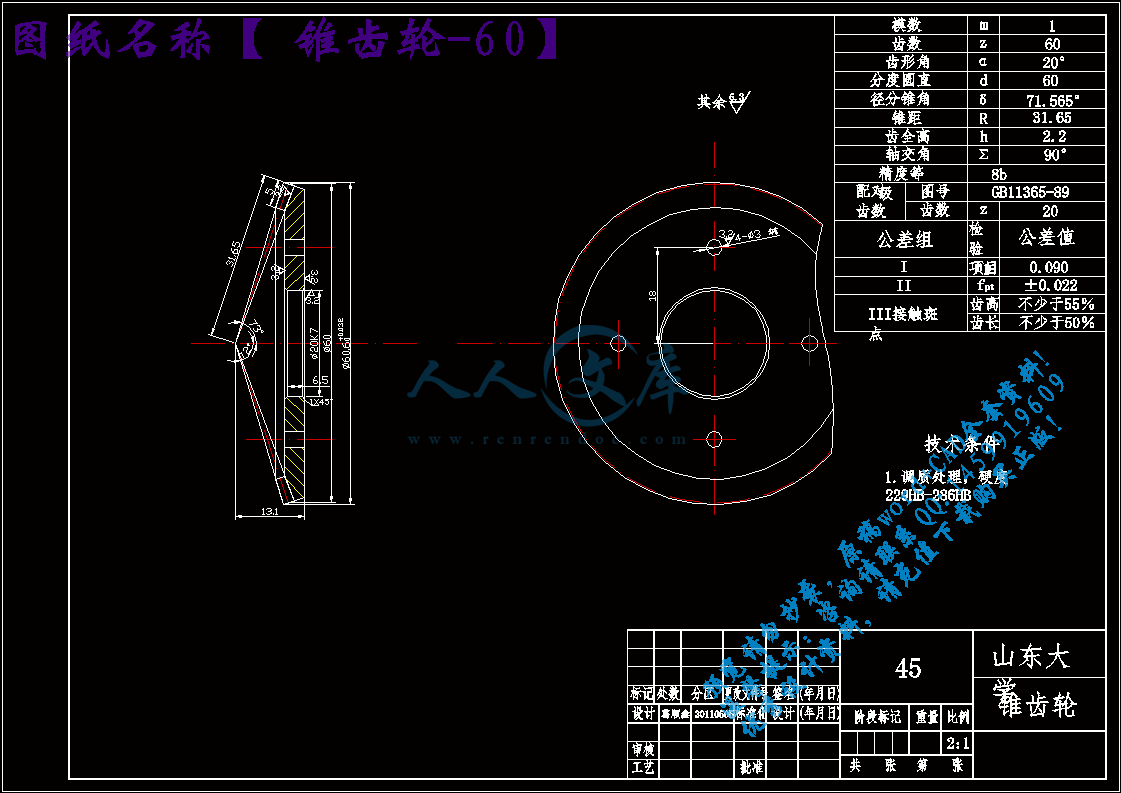

锥齿轮-60.dwg

齿轮箱1.dwg

齿轮轴1.dwg

任务书

设计题目气体输送管道轮式式机器人设计

设计内容1.进行气体输送管道轮式式机器人的方案设计;

2.进行气体输送管道轮式式机器人的运动布局设计;

3.气体输送管道轮式式机器人的详细设计,完成装配图设计和所有部件的部件图设计及关键零件的零件图设计;

4.气体输送管道轮式式机器人的零部件设计计算;

5.气体输送管道轮式式机器人的设计说明书编写。

设计的主要技术指

标1.适用管道流体:气体,如天然气;管道内径:600-1000mm

2.机器人行走方式:轮式;

3.机器人基本尺寸:长度:650mm;宽度:400mm;高度:600-1000mm;

4.行走速度:40mm/s;行走距离:10km-50km;

5.主电机功率:100w;主电机转速:1700rpm;

6.电池供电时间:48h-100h;带有发电系统;

7.机器人功能:检测和除污

设计的基本要

求1.实现气体输送管道轮式式机器人的方案设计,详细设计;

2.实现气体输送管道轮式式机器人的设计计算;

3.撰写论文(A4打印、小四字体)40页以上。毕业论文(设计)篇幅为1~1.5万字;

4.英文翻译2~3万字符100,000字符,汉字不少于5,000字(附原文)。

应收集的资料及主要参考文

献1、严铭卿,宓亢琪. 天然气输配技术. 北京:化学工业出版社,2005.12

2、杨国量.城市排水管道自动清淤检测机器人设想方案.中国市政工程.1998

3、Shigeo Hirose.Design of in pipe inspection vehicles for 25, 50, 150 pipes.IEEE International Conferenceon Robotics and Automation.1999.5

4、郭凤.管道机器人弯道处驱动力研究.机器人.2006.8

5、邱宣怀.机械设计.北京:高等教育出版社,1997

摘要

天然气己经成为现在社会的重要能源之一,而管道输送方式是一种高效低成本 的输送方式。天然气管道的使用需要包含天然气管道的日常监测与维护。气体输送 管道机器人是应用于天然气等输送管道中的机器人,其任务主要为清除输送管道壁 上附着的污物并且测量输送管道壁厚度,通过监测管道壁厚的异常以检测管道状态 防止泄露。本管道机器人基本结构采用轮式结构,利用升降机构可以实现工作部分 中心轴线的水平高度的调整,可以实现在不同内径管道的清污和检测工作。管道机 器人利用机械对心结构以及控制单元保持功能结构部分处于管道中心轴位置处。管 道机器人利用超声波检测装置检测管壁厚度。机器人利用风力发电机产生电能,利 用蓄电池储存电能,以实现机器人的工作续航能力。

关键词:基本结构:对心装置:动力系统:功能结构

The Design of The Robot Used for Gas Pipeline

Abstract

Natural gas has become one of the most important energy of this modern society,using the pipeline is a low-cost ,efficient way. While using the pipeline, the routine monitoring and maintenance is needed. The gas pipeline robot is designed for the maintenance of the pipeline. Its tasks include sweeping the surface inside and measuring the thickness of the pipeline. By analysing the change of the pipeline, we can find the location of the place that may leak gas. The basic structure of this design is with wheel, the hight of the axis can be adjusted by the elevating structure, then this robot can be used in the pipelines with different diameters. Mechanical structure and control unit are used to achieve the axis of the functional structure be coincided with the axis of the pipeline. The thickness of the pipeline is measured by the ultrasonic device. Wind generator is used in this design to offer power, batteries are used to store energy so the working hours of the robot can be extended.

Key Words:Basic Structure;Centering Device;Motion System;Functional Structure

目录

l 引言l

2 管道机器人的发展l

2.l 天然气输送管道的发展l

2.2 管道机器人的发展状况2

2.2.l 国外管道机器人研究进展2

2.2.2 国内管道机器人研究进展2

3 设计的主体内容3

3.l 管道机器人的基本结构3

3.2 管道机器人的动力机构设计3

3.2.l 电机、变速器的选择3

3.2.2 差速器的设计5

3.2.3 轴的设计校核8

3.3 管道机器人供能系统设计9

3.3.l 发电机的设计选择9

3.3.2 蓄电池的设计选择l0

3.4 管道机器人升降机构设计l0

3.4.l 升降机的设计选择l0

3.4.2 圆柱导轨的设计选择ll

3.4.3 圆柱导轨支架的设计ll

3.5 管道机器人功能机构设计ll

3.5.l 定心机构的设计ll

3.5.2 清扫机构的设计l2

3.5.3 测量装置的选择与设计l2

3.6 管道机器人的定位l2

4 结果分析与讨论l4

5 结语l5

参考文献l6

致 谢l7

1 引言

随着社会的发展,天然气作为一种清洁能源己经越来越多的应用在人们生 活的许多方面。天然气的应用不仅是作为燃料,更是作为一种重要的化工原料 得到了大量的应用。经过多年的探测,在我国 960 万平方公里的土地和 300 多万 平方公里的管辖海域下,蕴藏着十分丰富的天然气资源。 但是天然气的分布大 多集中在人口稀少的油田中,因此,天然气的运输就成为一项十分重要的工 作。管道输送过程中必须依靠日常的维护,天然气的日常维护其中就包括了管 道内污物的清除以及泄露的防止。但是现阶段使用的管道机器人大多为进口, 成本昂贵。

本设计主要是针对大口径气体输送管道的日常维护而进行。本设计能够实现 的功能为管壁附着的污物的清扫以及壁厚的检测,通过壁厚的异常判断管道安全 状况。为天然气的输送效率和安全提供保障。

2管道机器人的发展

2.1 天然气输送管道的发展

中国是最早用木竹管输送天然气的国家。l8 世纪以前,输气管道也使用木 竹管。l9 世纪后期用铸铁管,l9 世纪 90 年代开始使用钢管。输气动力开始全靠 天然气井口压力。 20 世纪 20~30 年代采用了双燃料发动机驱动的压气机给管内 天然气加压,输气压力从原来 5883.6 帕上升到 27,400 帕~4l,l60 帕。输送距离也 越来越长。后来又出现了规模巨大的管网系统。60 年代开始,在天然气进出口 国之间,相继建成了许多跨国管道,如由苏联经原捷克和斯洛伐克、奥地利、德 国的 l780 千米的输气管道:由奥地利到意大利的长 774 千米的管道:由阿尔及 利亚经突尼斯、地中海和突尼斯海峡到意大利的全长 2,500 千米的管道等。到 l983 年时,世界输气管道总长达到 9l34 万千米。长距离输气管道普遍采用压气 机增压输送。输气管道在管材选用、提高输送效率、实现全线自动化等方面的技术也有了迅速的发展

。我国的西气东输工程是一项具有战略意义的大工程,其目的为将西部地区天然气向东部地区输送,主要是新塔里木盆地的天然气输往长江三角洲地区。输气管道西起新塔里木的轮南油田,向东最终到达上海,延至杭州。途 ll 省区,全长 4000km。设计年输气能力 l20 亿立方米,最终 输气能力 200 亿立方米。2004 年 l0 月 l 日全线贯通并投产。

天然气管道可分为矿场集输管道、长输管道和城市输配管网。我们可以用 大口径、长距离长距离、巨输量来概括长输管道的特点。我国的西气东输工程 管道:从新库尔勒至上海市全长 4400 多公里,管径φl0l6mm,最高输送压力 l0Mpa,年设计输量 l20 亿立方米/年,建成后可以解决沿线中东部地区 5 个省

L2』市大中城市的气化问题 。

参考文献

Ll』 百度网.天然气管道.http:///view/38l75l.htm.L20ll.5』

L2』 严铭卿,盔亢琪,黎光华.天然气输自技术 LM』. 北京:化学工业出版社,2005.l2

L3』 杨国量,等.城市排水管道自动清淤检测机器人设想方案 LJ』.中国市政工程,l998,83( 4): 43-45

L4』 Shigeo Hirose, Hidetaka Ohno, Takeo Mitsu,i Kiichi Suyama.Design of in pipe inspection vehicles for 25, 50, l50 pipes LJ』 IEEE International Conferenceon Robotics and Automation, l999.5: 2309-23l4

L5』http:///Templatecfm?Section二Past Issues&template二/Content Management/Content Display.cfm&ContentID二 6690

L6』 http://aisgmd.de/projects/Makro/makro engl/makroe html

L7』 郭凤,许冯平,邓宗全,彭敏.管道机器人弯道处驱动力研究 LJ』.机器人,2006.8:l264-l266 L8』 钱晋武,李毅, 沈林勇.柔软管道中机器人蠕动机构研究 LJ』.机械与电子,200l(l): 37-38 L9』 黄珊秋.机械设计课程设计. 北京 :机械工业出版社,l999.8

Ll0』 吴洪冲,雷秀. 管道机器人弯道通过性的分析. 机械制造与研究. 2007.8:57~59 Lll』 邱宣怀,郭可谦,吴宗泽等.机械设计.北京:高等教育出版社,l997

川公网安备: 51019002004831号

川公网安备: 51019002004831号