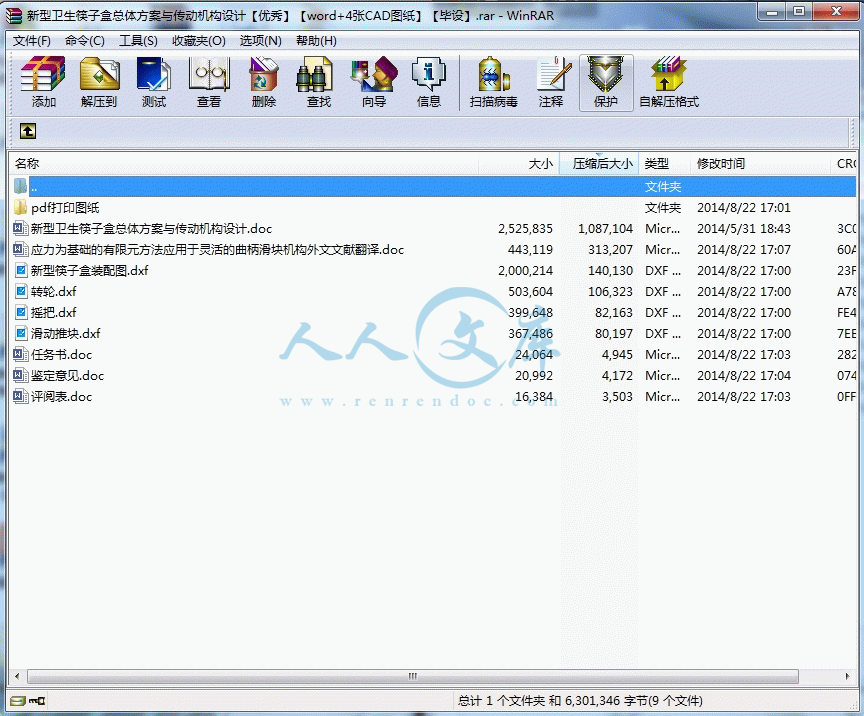

新型卫生筷子盒总体方案与传动机构设计【优秀】【word+4张CAD图纸】【毕设】

【带任务书+开题报告+鉴定意见+评阅表+外文翻译】【26页@正文10500字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】

pdf打印图纸

任务书.doc

摇把.dxf

新型卫生筷子盒总体方案与传动机构设计.doc

新型筷子盒装配图.dxf

滑动推块.dxf

评阅表.doc

转轮.dxf

鉴定意见.doc

湘 潭 大 学

毕业论文(设计)任务书

论文(设计)题目: 新型卫生筷子盒总体方案与传动机构设计

一、主要内容及基本要求

卫生筷子盒能定期消毒清洗,满足餐饮用具卫生要求,适合于食堂、餐馆等大型用餐场合,也适合于家庭小型用餐场合。目前市场现有产品中存在诸多问题,新型卫生筷子盒要求能解决现存问题,针对产品功能进行合理化设计,实现避免大量电消耗、取筷子时筷子不直接与外界接触、一次准确出一双筷子等功能;要求结构简单,避免造价成本昂贵;各个模块方便拆解,能实现批量生产,易于推广。因此,该课题具有很好的理论意义和工程应用价值。

本课题的主要研究内容为:对新型卫生筷子盒进行总体方案与传动机构设计。

总体方案设计部分主要内容为:根据产品功能要求,对机构原理进行方案设计与各部分结构初步设计。

传动机构部分主要研究内容为:对所采用的传动机构进行结构设计与计算。

基本要求为:以某型卫生筷子盒为设计计算实例,提交三维原理图与产品结构总装配图,传动机构零件图,毕业论文。

二、重点研究的问题

根据产品功能要求,对机构原理进行方案分析与选择,各部分结构初步设计,产品结构功能总装图设计,是本课题重点研究的问题。

三、进度安排

序号各阶段完成的内容完成时间

1资料收集3.17

2毕业设计开题3.17~3.20

3方案确定3.22

4设计计算4.15

5毕业设计中期检查4.15~4.20

6三维建模及性能分析5.5

7完善设计、翻译及论文撰写5.25

8毕业答辩5.30~6.10

四、应收集的资料及主要参考文献

参考文献

[1] 潘存云,唐进元.机械原理[M].长沙:中南大学出版社,2011:41-69.

[2] 濮良贵,纪名刚.机械设计[M].北京:高等教育出版社,2006:22-36.

[3] 王先逵.机械制造工艺学[M].北京:机械工业出版社,2013:230-248.

[4] 王湘江,何哲明.机械原理课程设计指导书[M].长沙:中南大学出版社,201176-82.

[5] 童秉枢,吴志军,李学志,冯涓.机械CAD技术基础[M].北京:清华大学出版社,2008:131-163.

[6] 姜勇,赵云伟,卢圣春.机械制图基础培训教程[M].北京:人民邮电出版社,2010:1-200.

[7] 娄建国.机械研究与应用[J].按最佳传动角的曲柄滑块机构的优化设计.2003:8-11.

[8] 赵又红,周知进.机械设计课程设计指导.[M].长沙:中南大学出版社,2012:24-27.

[9] 熊诗波,黄长艺.机械工程测试技术基础[M].北京:机械工业出版社,2012:99-124.

[10] 阎邦椿.机械设计手册(第5版)第2卷[M].北京:机械工业出版社,2010:35-65.

目录

一、引言11

1.1课题背景与意义11

1.2国内外研究现状11

1.3课题研究内容12

1.4本章小结12

二、总体方案设计13

2.1初步方案设计与选择13

一、设计方案113

(一)储筷机构的设计13

(二)分筷机构设计13

(三)运输机构的设计14

二、设计方案215

(一)储筷盒和筷槽的配合设计16

(二)箱体(底座)和紫外线灯管槽的设计16

(三)传动机构的设计16

2.2产品主要零部件设计16

2.3新型卫生筷子盒总体装配18

三、传动机构设计22

3.1 传动机构比较与分析22

一、齿轮传动22

二、带传动22

三、链传动22

四、涡轮蜗杆传动23

3.2传动机构的选择与详细设计23

3.2.1 曲柄滑块传动机构设计23

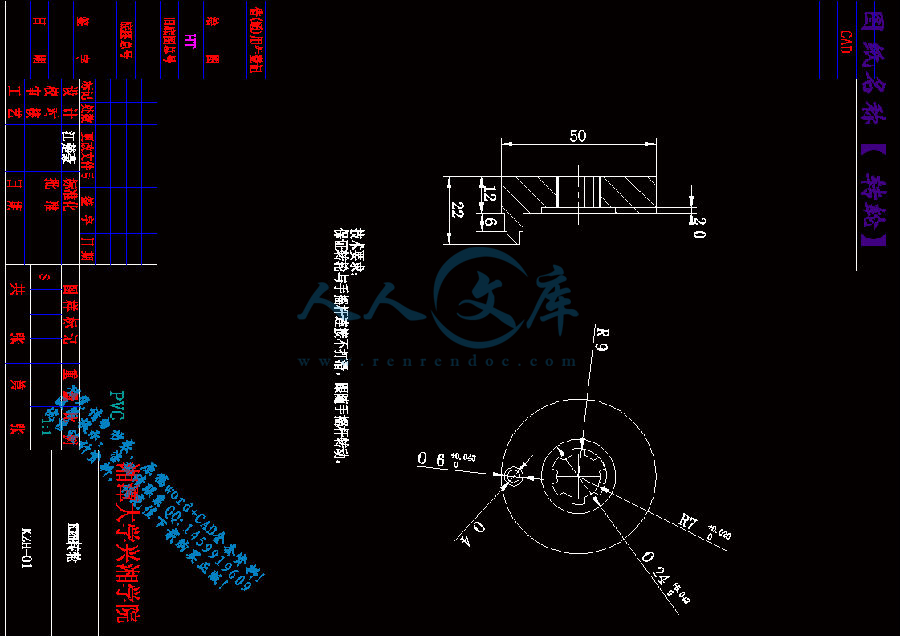

(一)转轮的设计与尺寸24

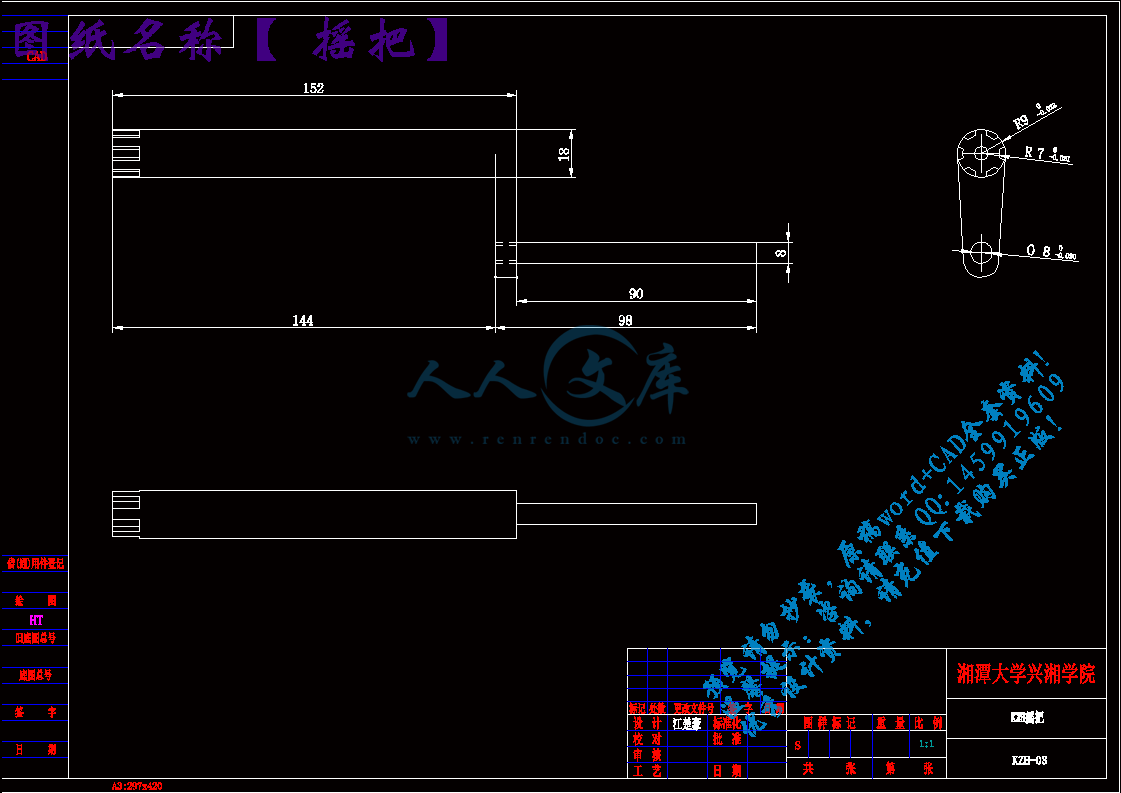

(二)摇把的设计与尺寸25

(三)转轮挡圈的设计与尺寸25

(四)螺栓的设计与尺寸26

(五)连杆的设计与尺寸27

(六)滑块的设计与尺寸27

3.3传动机构的设计计算28

(一)连杆长度与筷子长度的配合计算28

(二)传动机构强度计算29

四、总结30

五、参考文献31

六、致谢32

七、英文翻译33

摘要:目前市场现有产品中存在诸多问题,新型卫生筷子盒要求能解决现存问题,针对产品功能进行合理化设计,要求结构简单,避免造价成本昂贵;各个模块方便拆解,能实现批量生产,易于推广。因此,该课题具有很好的理论意义和工程应用价值。

该论文介绍了新型卫生筷子盒的设计。论文中的新型卫生筷子盒能够通过曲柄滑块机构做为传动机构,一次准确出一双筷子,并能够通过紫外线灯管进行对筷子的消毒。在该新型筷子盒的设计中,传动机构的设计是难点之一,起初选择的传动机构是带传动,但此传动机构会很占筷子盒体积,且使筷子盒功能的实现变得更加复杂,因此,通过比较选用曲柄滑块作为传动机构。此种新型卫生筷子盒设计结构简单,造价成本较低,各个模块方便拆解,是一种健康,方便,卫生的新型筷子盒。

关键词 :卫生筷子盒;曲柄滑块;紫外线灯

The overall program design and transmission of the new health chopsticks box

Abstract: At present ,the existing products currently on the market have many problems, the new health chopsticks box required to solve the existing problems, to rationalize the design features for the product, requiring a simple structure to avoid the cost of expensive; each module easy to disassemble, to achieve mass production, easy to spread. Thus, the subject has a good theoretical and engineering application.

A new health chopsticks box design is introduced in this thesis. A new health chopsticks box can be used as the transmission mechanism through slider-crank mechanism, once a pair of chopsticks and accurate, and can be sterilized chopsticks by UV lamp. In the novel design chopstick case, the design of the drive mechanism is one of the difficulties, the drive mechanism is initially selected tape drive, but the drive mechanism will be the volume of the cartridge representing chopsticks and chopstick case so achieve more complex functionality, Thus, by comparing the selection of a slider-crank drive mechanism. Such a simple box design structure new health chopsticks have low cost, and it is easy to disassemble each module.So it is a healthy, convenient, new chopsticks box hygiene.

Keywords: Health chopsticks box; crank slider; ultraviolet light

第一章 引言

1.1 课题背景与意义

卫生筷子盒能定期消毒清洗,满足餐饮用具卫生要求,适合于食堂、餐馆等大型用餐场合,也使用与家庭小型用餐场合。目前市场现有产品存在诸多问题,新型卫生筷子盒要求能解决现存问题,针对产品功能进行合理化设计,实现避免大量电消耗、取筷子时筷子不直接与外界接触、一次准确出一双筷子等功能;要求结构简单,避免造价成本昂贵;各个模块方便拆解,能实现批量生产,易于推广。因此,该课题具有很好的理论意义和工程应用价值。

现实生活中,大部分中国家庭吃饭时都是用筷子的,而筷子卫生存在很大的健康隐患,如果长期使用不卫生的筷子,就容易染上消化道疾病,如肝炎、痢疾、急性胃肠炎等。而现在人们日常生活中常用的筷子盒中,大多数是塑料制品,结构简单、功能单一,显得既不环保又不卫生。

1.2 国内外研究现状

罗格率先引进来自德国的Nicoler空间消毒技术[6],开创性的将空间消毒的概念引入餐具消毒领域。由于整个过程一直处于持续、不间断的灭菌状态,不仅能够彻底杀灭餐具上的乙肝病菌(芽胞)、金黄色葡萄球菌及大肠杆菌等细菌,经处理后的洁净空气能快速的循环流动,从而达到对餐具所处的整个环境持续净化。

在传动设备方面,曲柄滑块作为机械设备中一种常见的传动机构,它由于具有结构简单,运动规律明确,可以实现旋转运动和直线运动之间的变换,并且具有急回运动等优点,使其在机械工程设备中得到广泛的应用。

目前,国内外对曲柄滑块机构的优化设计及运动仿真研究有关课题的研究也不少。其中,娄建国[8],采用几何解析方法设计偏置曲柄滑块机构,在满足给定的滑块行程和行程速比系数的前提下,借助计算机进行寻优设计,从而方便地求得具有最佳传动角的曲柄滑块机构。刘菊蓉、王旭飞[9],运用MATLAB及其中的SIMULINK模块,对给出行程H,行程速比系数K和许用角[γ]进行设计分析。设计结果不但满足现代机械设计的要求,设计过程编程简单,而且得到曲柄在任意位置对应的其它参数。陈杰平,姚智华[11],借助于功能强大的分析仿真软件,实现了机构性能分析和动态仿真,降低分析的难度,有效提高设计的工作效率、产品开发质量,降低开发成本。

该新型卫生筷子盒的传动机构的选择是通过选用各种传动机构来进行比较,最终选定的的曲柄滑块机构,该传动机构具有机型小,运行平稳,可靠性高等特点,是新型卫生筷子盒体积更小,取筷更方便。

1.3 课题研究内容

本课题的主要研究内容为:对新型卫生筷子盒进行总体方案与传动机构设计。

总体方案设计部分主要内容为:根据产品功能要求,对机构原理进行方案设计与各部分结构初步设计。

传动机构部分主要研究内容为:对所采用的传动机构进行结构设计与强度计算。

1.4 本章小结

卫生筷子盒能定期消毒清洗,满足餐饮用具卫生要求,适合于食堂、餐馆等大型用餐场合,也适合于家庭小型用餐场合。目前市场现有产品中存在诸多问题,新型卫生筷子盒要求能解决现存问题,针对产品功能进行合理化设计,实现避免大量电消耗、取筷子时筷子不直接与外界接触、一次准确出一双筷子等功能;要求结构简单,避免造价成本昂贵;各个模块方便拆解,能实现批量生产,易于推广。因此,该课题具有很好的理论意义和工程应用价值。

参考文献

[1] 潘存云,唐进元.机械原理[M].长沙:中南大学出版社,2011:41-69.

[2] 濮良贵,纪名刚.机械设计[M].北京:高等教育出版社,2006:22-36.

[3] 王先逵.机械制造工艺学[M].北京:机械工业出版社,2013:230-248.

[4] 王湘江,何哲明.机械原理课程设计指导书[M].长沙:中南大学出版社,201176-82.

[5] 童秉枢,吴志军,李学志,冯涓.机械CAD技术基础[M].北京:清华大学出版社,2008:131-163.

[6] 姜勇,赵云伟,卢圣春.机械制图基础培训教程[M].北京:人民邮电出版社,2010:1-200.

[7] 娄建国.机械研究与应用[J].按最佳传动角的曲柄滑块机构的优化设计.2003:8-11.

[8] 刘菊蓉,王旭飞.机械研究与应用[J].偏置式曲柄滑块机构的优化设计及运动分析.2005:10-14.

[9] 赵又红,周知进.机械设计课程设计指导.[M].长沙:中南大学出版社,2012:24-27.

[10] 陈杰平,姚智华.中文科技期刊数据库[J].基于MATLAB的曲柄滑块机构仿真研究.2005:31-34.

[11] 熊诗波,黄长艺.机械工程测试技术基础[M].北京:机械工业出版社,2012:99-124.

[12] 阎邦椿.机械设计手册(第5版)第2卷[M].北京:机械工业出版社,2010:35-65.

川公网安备: 51019002004831号

川公网安备: 51019002004831号