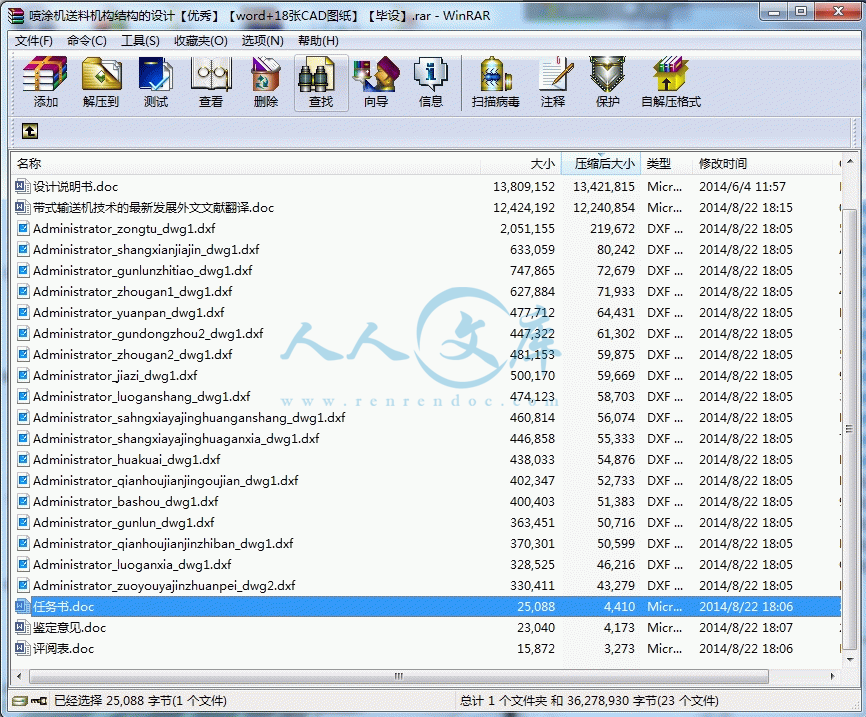

喷涂机送料机构结构的设计【优秀】【word+18张CAD图纸】【毕业设计】

【带任务书+评阅评语表+答辩资格审查表+工作中期检查表+指导教师评阅表+外文翻译+实习报告】【30页@正文11600字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】.bat

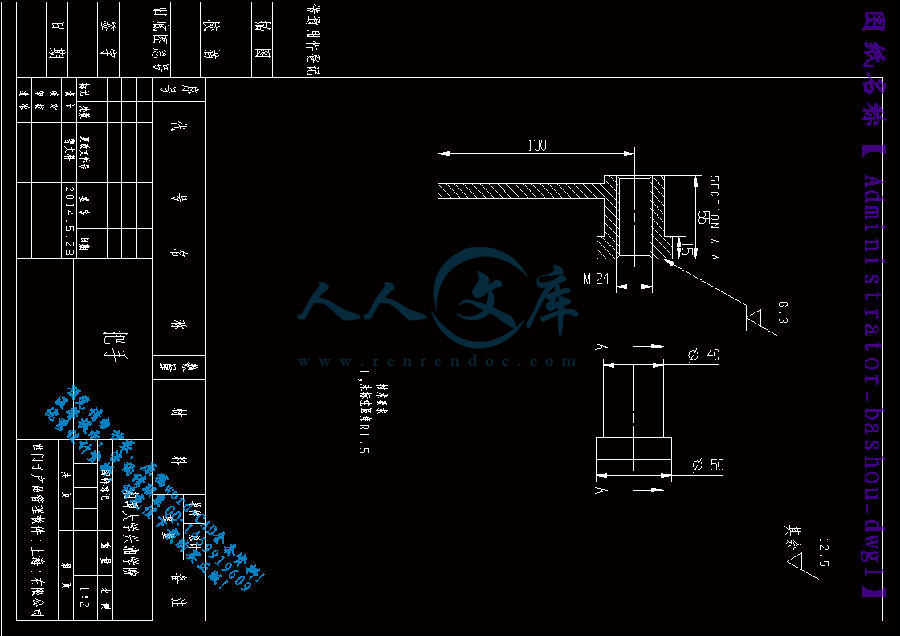

Administrator_bashou_dwg1.dxf

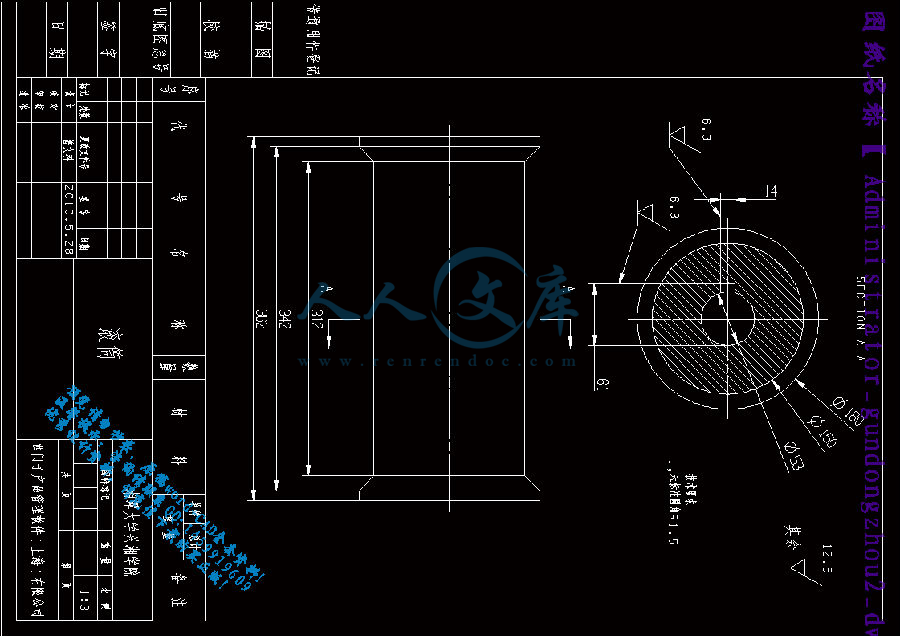

Administrator_gundongzhou2_dwg1.dxf

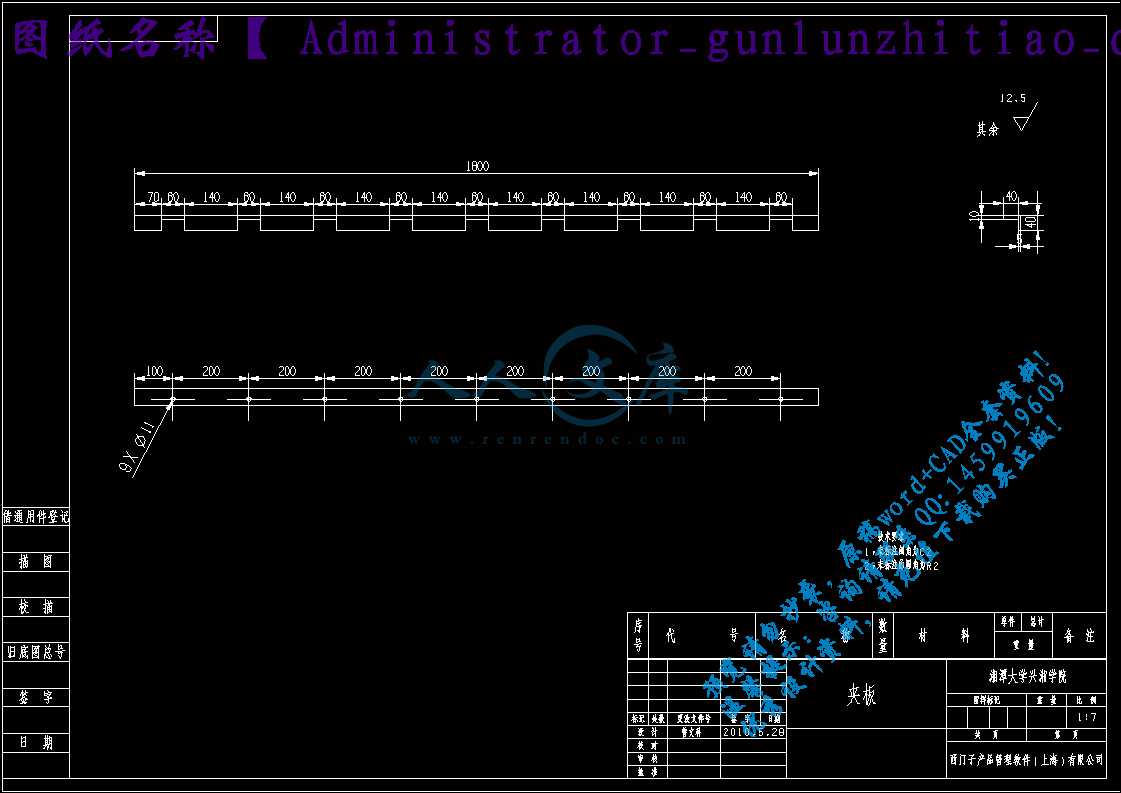

Administrator_gunlunzhitiao_dwg1.dxf

Administrator_gunlun_dwg1.dxf

Administrator_huakuai_dwg1.dxf

Administrator_jiazi_dwg1.dxf

Administrator_luoganshang_dwg1.dxf

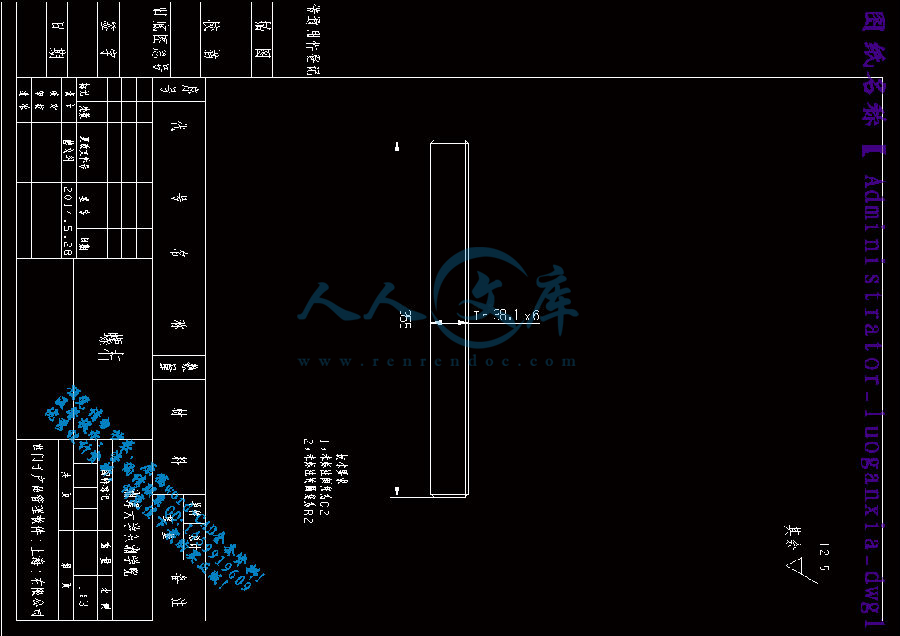

Administrator_luoganxia_dwg1.dxf

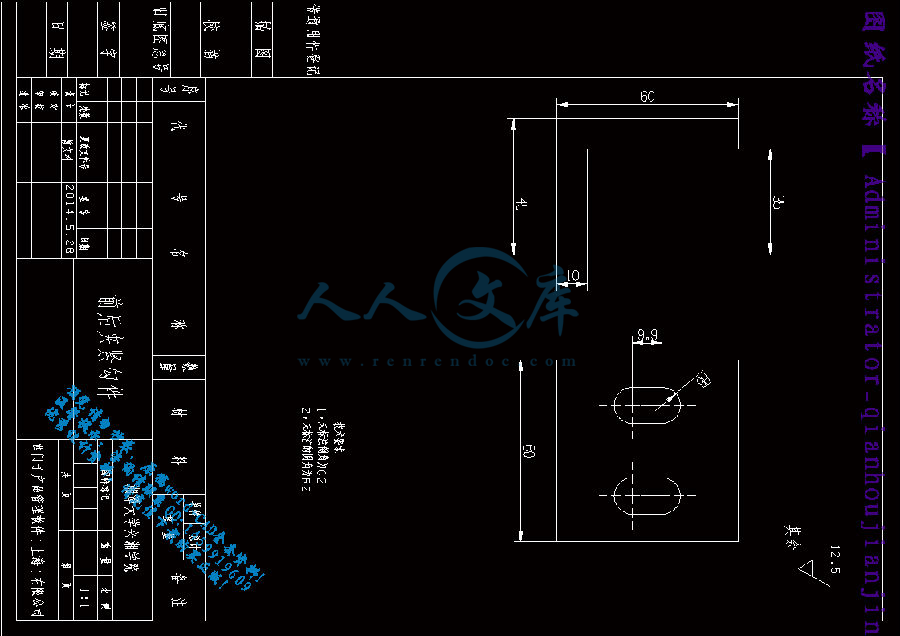

Administrator_qianhoujianjingoujian_dwg1.dxf

Administrator_qianhoujianjinzhiban_dwg1.dxf

Administrator_sahngxiayajinghuanganshang_dwg1.dxf

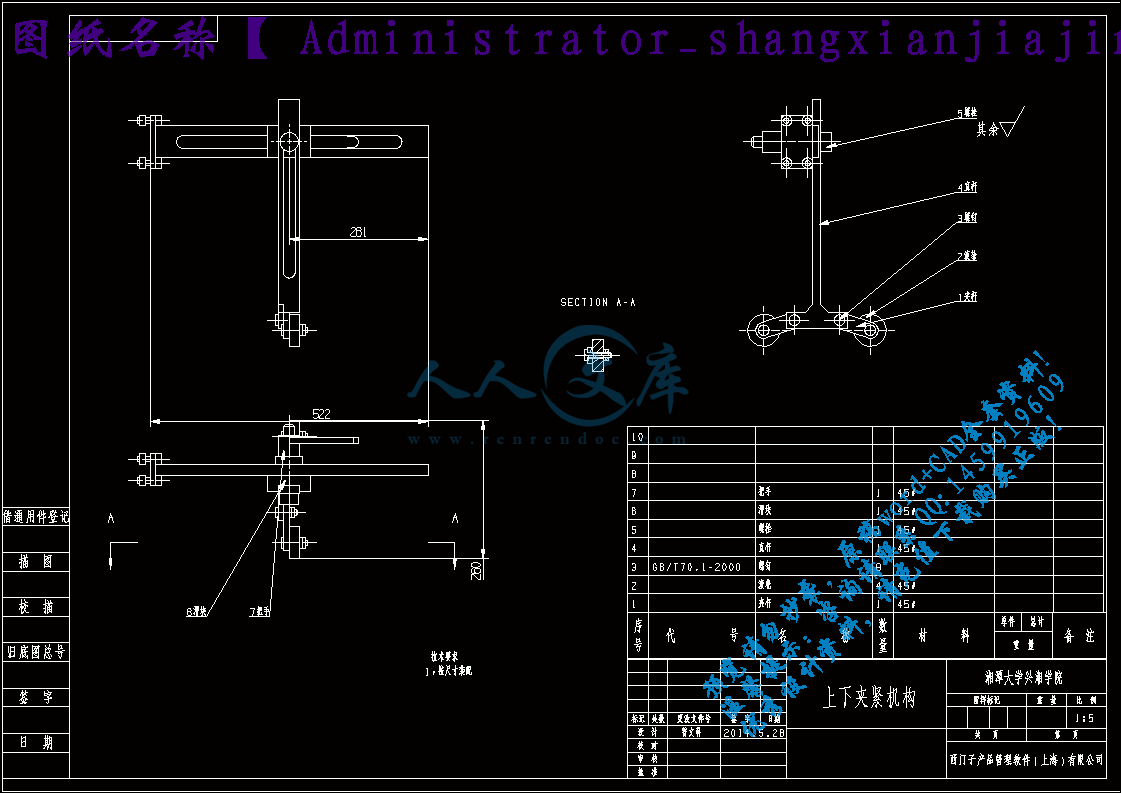

Administrator_shangxianjiajin_dwg1.dxf

Administrator_shangxiayajinghuaganxia_dwg1.dxf

Administrator_yuanpan_dwg1.dxf

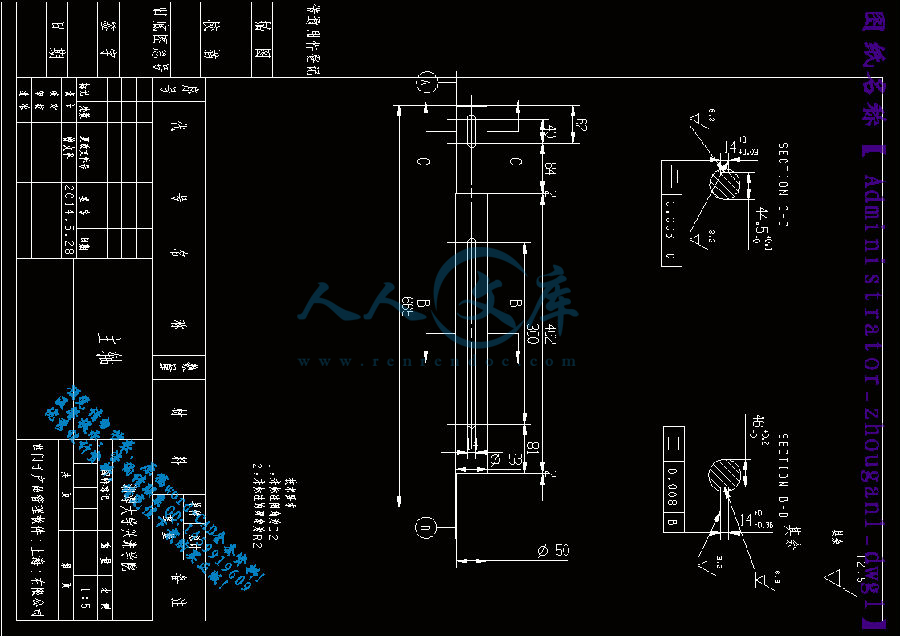

Administrator_zhougan1_dwg1.dxf

Administrator_zhougan2_dwg1.dxf

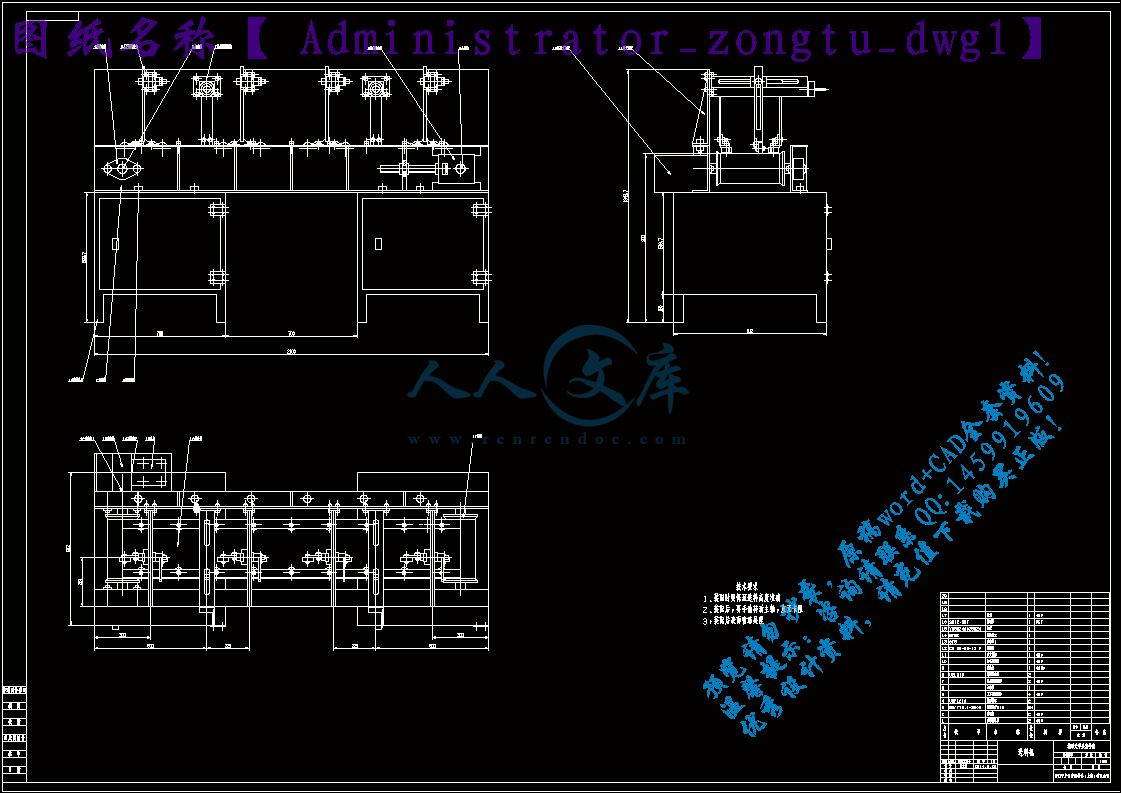

Administrator_zongtu_dwg1.dxf

Administrator_zuoyouyajinzhuanpei_dwg2.dxf

PDF打印图

任务书.doc

设计说明书.doc

评阅表.doc

鉴定意见.doc

任务书

论文(设计)题目: 喷涂机送料机构结构设计

一、主要内容及基本要求

1、完成喷涂机送料机构的结构设计、尺寸设计和工作台设计;

2、喷涂速度5-30m/min可调;喷涂工件为铝型材;

3、工件最大尺寸为200×200mm;送料轨道长度范围1.6—2.0m高度与喷涂室配套;

4、装配图A0#1张、零件图总量不少于A0#1张;

5、编写设计计算说明书一份。

6、英文文献翻译,不少于3000Words。

二、重点研究的问题

1、上下、左右压紧机构设计;

2、送料机构设计。

三、进度安排

各阶段完成的内容起止时间

1熟悉课题与基础资料第1周

2调研、收集资料第2周

3送料机构总体方案设计与论证第3~4周

4送料机构总体布局设计第5~6周

5送料机构总装图设计第7~9周

6送料机构工程图设计第10周

7撰写设计说明书第11周

8英文文献翻译第12周

9答辩第12周

四、应收集的资料及主要参考文献

[1] 上海市标准化协会. 机械精度设计手册[M].中国标准出版社,1992

[2] 徐鸿本. 机床夹具设计手册[M].辽宁科学技术出版社,2003

[3] 苗磊,陶晓杰. 精密喷涂机的工作平台设计[J].电子测量与仪器学报,2009年增刊:132-135

目 录

中文题目:油漆喷涂机送料机构结构设计1

Subject:Structural design of the spray chamber of the sprayer2

第1章 概述3

1.1. 送料机构简介3

1.2. 送料机构国内基本情况4

1.3. 送料机构国外基本情况5

1.4. 设计任务和技术要求6

第2章 方案的比较和选择8

2.1. 夹紧机构方案比较8

2.2. 压紧机构方案选择10

2.3. 输送机构方案比较12

2.4. 输送机构方案选择15

第3章 减速电机和联轴器、轴承选择数据计算18

3.1. 减速电机的选择18

3.2. 减速器的选择18

3.3. 联轴器与轴承的选择19

第4章 压紧机构设计23

4.1. 上下压紧机构设计23

4.2. 左右压紧机构设计26

第5章 总结28

参考文献29

附录Ⅰ 英文文献翻译30

中文题目:油漆喷涂机送料机构结构设计

摘要

喷涂机是一种将涂料分散成雾状喷涂于被涂物表面的专用涂装设备,其工作机构主要包括有喷头的喷涂室、传送带、干燥系统、清洁机构和回收系统等。由于喷涂机具有喷涂效率高、喷涂均匀、油漆利用率高、易于操作等优点,所以被广泛应用于工业生产中。

本次毕业设计的课题是油漆喷涂机送料机构结构设计,其中设计内容主要包括:1、送料机构的整体外形和尺寸设计。2、设计夹紧机构的结构,并对比各种方案,选择最优方案。3、输送带的设计。4、夹紧机构的强度设计。5、设计送料机构的工作台。

本次毕业设计旨在设计出一个能够对工件进行自动送料的送料机构。压紧机构作为送料机构的主要部件,它不仅要能控制工件的左右位置,还要能控制工件的上下位置,因此,压紧机构的结构设计是最重要的部分。在设计过程中,要根据压紧机构的原理设计出几种压紧机构的机构简图,并对不同的方案进行对比。在本文中选出了三种不同的方案进行对比选择,最后选择出最优的方案,再对其进行尺寸设计。除了夹紧机构的设计外,工作台的设计也是其中的一个重点。由于工件的大小可能不一,所以要求夹紧机构能够上下左右移动。

本文除了设计过程的阐述外,还对喷涂机进行了简单的介绍,并且就喷涂机的国内外发展情况进行了介绍和分析。

关键词:喷涂机、压紧机构、输送带、工作台

Subject:Structural design of the spray chamber of the sprayer

Abstract

The sprayer is a paint dispersed into a mist sprayed on the surface to be painted a special painting equipment, its agencies including the nozzle of the spray booths, conveyors, drying system, clean bodies, and recycling systems, etc. Spraying machine has the advantages of high efficiency spray, spray evenly, paint utilization, ease of operation, it is widely used in industrial production.

The subject of this graduation project is a paint spraying machine feed mechanism structural design, including design and content including: 1, the feed mechanism as a whole shape and size of the design. 2, the design structure of the clamping mechanism, and compare the various options and choose the best program. 3, the design of the conveyor belt. 4, the strength design of the clamping mechanism. Design table feed mechanism.

The graduation project is to design an automatic feed of the workpiece feed mechanism. Pressed institutions as the main components of the feeding mechanism, it must not only be able to control the left and right position of the workpiece, but also be able to control the upper and lower positions of the workpiece, therefore, the structural design of the compression bodies is the most important part. According to the principle of compression bodies in the design process, design the institutions of several compression diagram, and compare the different options. Elected three different scenarios in this paper were compared to select the final choice of the optimal solution, its size design. In addition to the clamping mechanism design, bench design is a key. As the size of the workpiece may vary, so the clamping mechanism can up and down and move around.

In addition to the design process elaboration on the sprayer a brief introduction, and spraying machine at home and abroad, the development of presentations and analysis.

Key words:spraying machine, pressed institutions, conveyor belt, bench,

第1章 概述

1.1.送料机构简介

为了提高油漆喷涂的质量和其工作效率,特设计出送料机构来代替传统的人工送料。

送料机的作用就是在材料加工的过程中提供输送材料的作用,目前送料机已经遍布轻工业和重工业,是日常生产中不可或缺的机械设备。传统的送料机是通过简单的机器运动带动材料的运送,随着科技的发展,近代的送料机的形式更加丰富,结构更加复杂,开始将超声波、高压空气等先进技术使用到送料技术当中,现今自动化较高的送料设备有:激光送料机,由电脑控制的动头式送料机、高压气压和电脑送料机等。另外,国外的公司生产一种投影送料机,在这种机器上,送料机上安装有感应器和观察装置,用于对材料形状的扫描,从而对材料的引导输送。

1.1.1.喷涂机送料机构工作原理

在送料机器中,不同类型种类的送料机是有差别的,但整体的工作原理差不多,就拿带式送料机来说,其由压紧机构、传送机构、动力系统、控制电路等四部分组成,工作时由传送带支撑带动材料,压紧机构约束材料进行输送,在压紧机构中采用滚轮接触材料方式减少摩擦,从而使输送顺畅,减少工作噪音。

1.1.2.送料机种类

a.埋刮板送料机 埋刮板送料机由封闭的壳体、刮板链条、驱动装置及张紧装置等部件组成。埋刮板送料机工作时,物料经进料口进入机壳承载段,受到刮板的推力,与刮板链条形成整体一同向前运动,达料槽的卸料口自行排出,刮板链条沿机壳的空载段返回。因其在工作时刮板链条被埋没在物料中与物料一起向前移动,故称为“埋刮板送料机”。

b.带式送料机 带式送料机的一般结构主要由输送带、滚筒、支承装置、驱动装置、张紧装置、卸料装置、清扫装置和机架等部件组成。带式送料机是一种连续送料机械,用一根环绕于前、后两个滚筒上的输送带作为牵引及承载构件,驱动滚筒依靠摩擦力驱动输送带运动,并带动物料一起运行,从而实现输送物料的目的。

c.斗式送料机 斗式送料机主要由牵引构件(橡胶带或链条)承载构件(料斗)头轮和底轮、驱动装置、张紧装置、机壳等组成。闭合的牵引构件环绕于头轮和底轮上,并被张紧装置张紧。牵引构件的全长上,每个一定距离装置一个料斗。为防止物料的抛撒和灰尘飞扬,这些运动的部件用机壳封闭。工作时,外部的驱动装置通过头轮带动牵引构件和料斗运行。物料从机座的进料口进入机座底部,被运动着的料斗挖起并向上提升。达机头后,物料再重力和离心力的作用下脱离料斗,从卸料口排出。

d.振动送料机 振动送料机主要由输送槽、激振器、主振弹簧、导向杆、隔振弹簧、平衡底架、进料装置和卸料装置组成。振动送料机是利用某一形式的激振器使槽体沿某一倾斜方向产生振动,从而将物料由某一位置运送至另外一个位置。

e.螺旋送料机 螺旋送料机主要由料槽、螺旋叶片和转动轴组成的螺旋体、两端轴承、中间悬挂轴承及驱动装置所组成。当螺旋体转动时,进入机槽的物料受到旋转叶片的法向推力,该推力的径向分量和叶片对物料的摩擦力将使物料绕轴转动;而物料的重力和机槽对物料的摩擦力又阻止物料绕轴转动。当螺旋叶片对物料法向推力的轴向分量克服了机槽对物料的摩擦力及法向推力的径向分量,物料和睦螺旋一起旋转,只沿料槽向前远移。

1.2.送料机构国内基本情况

我国送料机工业历史较短,技术水平和生产能力低,但近年来随着我国工业的发展,在巨大的市场需求下,并随着国外先进技术的引进,发展速度很快,在技术上有明显提高,该工业逐渐成为国民经济中非常重要新兴行业。与国外送料机厂家相比,国内送料机生产起步要晚很多,虽然后期发展迅速,但很多技术和经验相比有很大差距,使得目前国内整体送料机行业处在多而不精,大而不强的一个状态,一方面是国外送料机品牌向国内迈进,国内企业为抢占市场打起价格战,为缩小成本,没能在科研和新品开发方面取得突破,另一方面,制造行业不景气,是市场需求有很大的下降,导致国内很多企业属于停滞状态,产品档次低,技术,质量,效率,安全等方面都不够高。所以还需进一步提高各方面水平。

1.2.1.新型夹式送料机特性

a.适用于要求高速加工、且需要高精度送料的冲制品。(每分钟送料最高可达1200次)

b.机械运转时,安静无声,不造成工作场所的噪音。

c.材料表面不会留下任何压痕,可使冲制电镀材料合金、不锈钢、铜或二次工程厂商、得到最完美的冲制成品。

d.所有调整均采用刻书式,操作简单,稳定性佳。任何人员均可操作它本体为一体成型,可避免冲压时所产生的共振,而影响送料精度。

参考文献

1、上海市标准化协会. 机械精度设计手册.中国标准出版社,1992

2、徐鸿本. 机床夹具设计手册.辽宁科学技术出版社,2003

3、苗磊,陶晓杰. 精密喷涂机的工作平台设计.电子测量与仪器学报,2009年增刊:132-135

4、成大先,机械设计手册.北京:化学工业出版社,2004;

5、机械设计手册编委会,机械设计手册(第四卷).机械工业出版社,2005;

6、上海市标准化协会,机械精度设计手册.中国标准出版社,1992;

7、徐鸿本,机床夹具设计手册.辽宁科学技术出版社,2003;

8、王少怀,机械设计师手册(上册).电子工业出版社,2006;

9、机械设计手册(第四版)第2卷;成大先编;北京;化学工业出版社,2002;

10、机床设计手册编写组,机床设计手册.北京:机械工业出版社,1986;

11、王启平,机床夹具设计.哈尔滨工业大学出版社,2005;

12、詹启贤,自动机械设计.北京:中国轻工业出版社,1994;

13、吕仲文,机械创新设计.北京:机械工业出版社,2004;

14、孟宪源,现代机构手册.北京:机械工业出版社,1994;

15、周明衡,联轴器选用手册.北京:化学工业出版社工业装备与信息工程出版中心,2001

川公网安备: 51019002004831号

川公网安备: 51019002004831号