【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘要

起重机械广泛应用于工矿企业、港口码头、车站仓库、建筑工地、海洋开发、宇宙航行等各个工业部门,可以说陆地、海洋、空中、民用、军用各个方面都有起重机械在进行着有效的工作。

起重机械与运输机械发展到现在,已经成为合理组织成批大量生产和机械化流水作业的基础,是现代化生产的重要标志之一。在我国四个现代化的发展和各个工业部门机械化水平、劳动生产率的提高中,起重机必将发挥更大的作用。

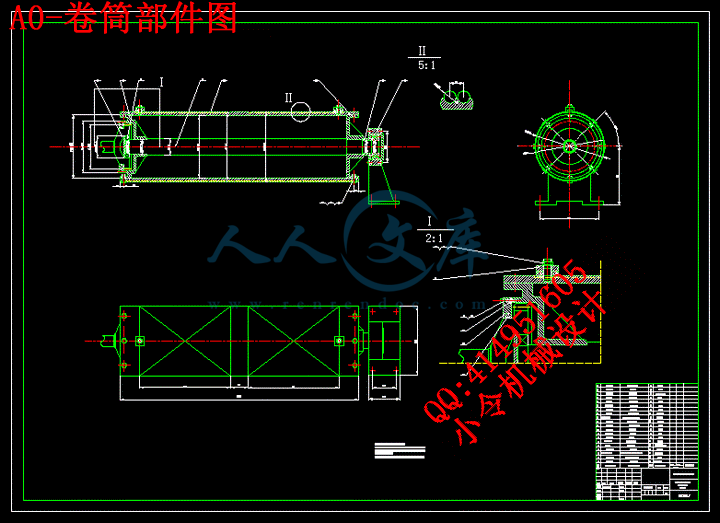

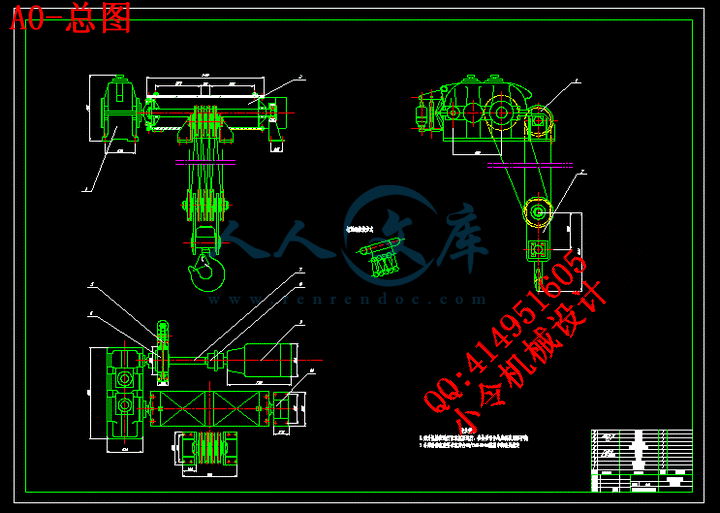

此次设计的起重机为50/10t双梁桥式起重机,主要用于各车间、分段生产线和钢材堆场等处。桥式起重机本身作横向移动,车架上的绞车作纵向移动,吊在绞车上的吊钩作垂向移动,三个方向的运动的合成才能使起重机起作用。为了防止桥式起重机在驾驶员看不清楚具体的吊钩运动方式,地面上一般配备有起重工进行指挥或夹、放吊钩。

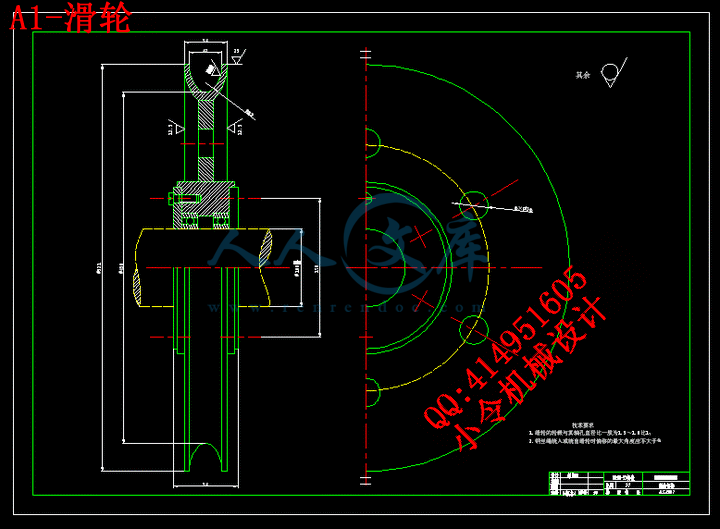

本课题主要对50/10t双梁桥式起重机的主起升机构进行总体设计,设计过程中查阅了大量国内外的相关资料,所做的设计运用了大量的专业课程。首先通过确定传动方案,选择滑轮组和吊钩组,选择合适的钢丝绳,计算滑轮的主要尺寸,确定卷筒尺寸并验算其强度,计算高速浮动轴,选择合适的电动机、减速器、制动器和联轴器。要求起重设备运行平稳, 定位准确, 安全可靠, 技术性能稳定。

关键词:起重机;桥式起重机;起升机构设计

Abstract

The hoisting machinery widely applies in the industrial and mining establishment, the harbor wharf, the station warehouse, the construction site, the ocean development, the astronautics and so on each industry sector, it may say that the land, the sea, airborne, civil, the military each aspect has the hoisting machinery to carry on the effective work.

The hoisting machinery and the transport machinery develops to the present, have already became the reasonable organization in groups mass productions and the mechanization streamlined production foundation, it is the one of modernized production important symbols. In our country four modernizations' development and each industry sector mechanization level, in labor productivity's enhancement, the hoist crane will certainly to play the major role.

This design of hoist crane is the 50/10t double beam bridge type hoist crane, mainly uses in various workshops, the partition production line and the steel products dump site and so on place. The bridge-type hoist crane itself makes the derailing, on frame's winch makes the longitudinal shift, hangs makes the vertical migration on winch's lift hook, three direction's movement's synthesis can cause the hoist crane to have an effect. In order to prevent the bridge-type hoist crane to look at not the clear concrete lift hook mode of motion in the pilot, as soon as in the ground is a match has the heavy industry to carry on the direction or to clamp, puts the lift hook.

This topic mainly carries on the system design to the 50/10t double beam bridge type hoist crane's host hoisting mechanism, designed in the process to consult the massive domestic and foreign correlation data, did the design has utilized the massive special courses. First through the definite transmission plan, the choice block and tackle and the lift hook group, chooses the appropriate steel wire, calculates pulley's main dimension, the definite reel size and checking calculation its intensity, the computation floats the moving axis high speed, chooses the appropriate electric motor, the reduction gear, the brake and the shaft coupling. The request hoisting equipment movement is steady, the localization is accurate, safe reliable, the technical performance is stable.

Key words crane bridge crane lifting mechanism design

目 录

1绪论 1

1.1起重机概述 1

1.2起重机的分类 1

1.3起升机构介绍 2

2起重机的国内外发展状况 4

2.1起重机的国外发展状况 4

2.2起重机的国内发展状况 6

3桥式起重机的主要技术参数与工作级别 8

3.1桥式起重机的主要技术参数 8

3.2桥式起重机的工作级别 10

4传动方案的选择 11

4.1驱动装置的布置方式 11

4.1.1电动起升机构 11

4.1.2液压起升机构 11

5钢丝绳的选择 13

5.1钢丝绳的特性 13

5.2钢丝绳的种类 13

5.2.1根据钢丝绳的捻绕次数分类 13

5.2.2按钢丝绳的捻向分类 13

5.2.3根据股的形状分类 14

5.2.4根据股的构造分类 14

5.2.5根据钢丝表面处理分类 15

5.2.6根据钢丝绳股数的数目分类 15

5.2.7根据绳芯分类 15

5.3钢丝绳的选择 15

6滑轮、卷筒的计算 17

6.1卷筒的构造与类型 17

6.1.1按钢丝绳在卷筒上的卷绕层数分类 17

6.1.2按卷筒的表面不同分类 17

6.1.3.按卷筒的制作方法分类 18

6.2卷筒、滑轮的设计计算 18

6.2.1滑轮、卷筒最小直径的确定 18

6.2.2卷筒长度和厚度的计算 18

6.2.3卷筒转速 19

6.2.4卷筒压应力验算 20

6.2.5卷筒强度验算 20

6.3钢丝绳在卷筒上的固定方法 21

7初选电动机和减速器的选择 22

7.1初选电动机 22

7.2减速器的选择 22

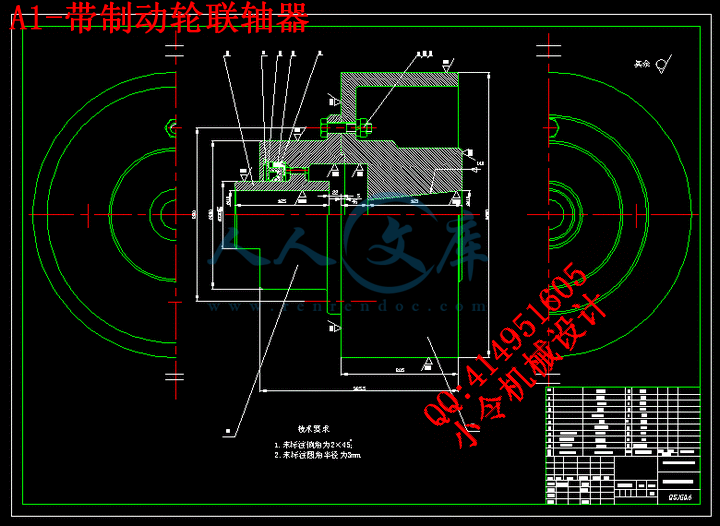

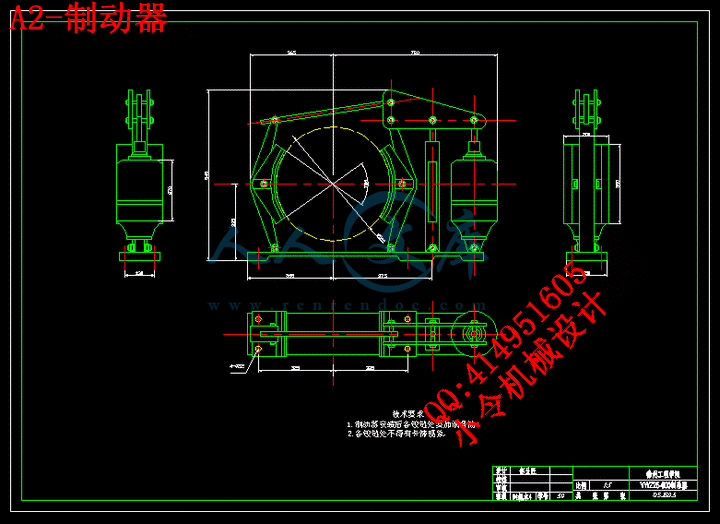

8制动器的选择 24

8.1概述 24

8.2制动装置的分类 24

8.2.1按制动器的结构形式分类 24

8.2.2按制动器工作状态分类 25

8.2.3按制动器的驱动方式分类 25

8.3块式制动器 25

8.4块式制动器的设计 27

8.5起动时间与起动加速度的验算 29

8.6电动机起动可靠性的验算 29

9.联轴器的选择和高速浮动轴验算 31

9.1联轴器选择 31

9.2高速浮动轴的验算 32

结论 33

致谢 34

参考文献 35

附录 36

附录1 36

川公网安备: 51019002004831号

川公网安备: 51019002004831号