【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

MG180/435-W型液压牵引采煤机主要用于中厚煤层的综采作业。它可以一次采全高,并且能适应煤层厚度变化和底板起伏不平的条件。该采煤机适应性好、功率大、采煤效率高、操作简单、检修方便。本设计主要针对采煤机的整机进行方案设计,对截割部进行结构及传动等相关设计。MG180/435-W型液压牵引采煤机采用弯摇臂截割部,截割电机横向布置在摇臂上,摇臂和机身连接没有动力传递,取消了螺旋伞齿轮和结构复杂的通轴。在截割部传动设计中,利用直齿轮和行星齿轮组成减速器是设计的一般原理,设计出适合截割部使用的减速器,并将它和矿用电动机直接联结,简化了截割部的传动布置。本设计的创新点:把截割部的减速器安装在摇臂里,使用了两个惰轮来增加中心距,这样也使齿轮的总个数减少,提高了传动效率。结构上将离合器安装在电机轴上,使制动变的方便安全。设计中对2K(Ⅰ)型行星减速器进行了优化配齿,采用高度变位,并做了相应的校核,在保证需要的传动比的情况下,使设计的2K(Ⅰ)型行星减速器体积最小。

关键词:采煤机 ;截割部 ;行星减速器 ;摇臂

ABSTRACT

The MG180/435-W type liquid presses to lead to shearer to mainly used for the medium thick coal seam to adopt homework. It can cuts the whole seam height in one trip, and accommodate the changing of seam thickness and floor undulation. Should the shearer adaptability like, the power is big and adopt a coal efficiency high, operate in brief and check to fix convenience. This design mainly carrieson a project design to the whole machine of the shearer, spreading to move to wait a related design towards the cutting drum to carry on structure. The MG180/435-W type liquid presses to lead to shearer curved the ranging arm of the cutting drum, and the electrical engineering horizontal arranges in the ranging arm. There is no motive delivering between ranging arm and gearhead conjunction and canceling spiral umbrella wheel gear and structure a complicated stalk. In the design of the cutting drum spread move , the exploitation keeps the general theory that wheel gear and planet wheel gear's constituting to decelerate a machine is a design. Designing to suit a deceleration machine which mows an usage, and will it and the mineral use electric motor to combine directly, simplifying to the cutting drum to spread to move a decoration. The creative of this design: Cut a deceleration machine of mowing the department to install in the ranging arm, used two round to increase center to be apart from, so as to make the total piece of wheel gear reduced, and raised to spread to move an efficiency. The structure full general clutch installs on the electrical engineering stalk, making the moving convenience and safety. In the Design medium to 2K(Ⅰ) type the planet decelerated a machine to carry on excellent turn to go together with teeth, adopt height to change, and did a homologous check. Be promising to need of spread under circumstance of moving the ratio, make the 2K(Ⅰ) of design type planet decelerate machine physical volume minimum.

The shearer ;The cutting drum ;The planet decelerates a machine ;The ranging arm

目录

1 绪论 1

1.1引言 1

1.2采煤机械概述 1

1.3采煤机械工作过程 2

2 总体 3

2.1概述 3

2.2主要用途及适用范围 3

2.3型号的组成及代表意义 4

2.4使用环境条件 4

2.5安全警示 4

3 截割部设计 7

3.1截割部概述 7

3.2截割部的传动系统 7

3.3传动系统的确定、运动学计算 9

3.3.1、确定总传动比并分配各级传动比 9

3.3.2计算传动装置的运动和动力参数 9

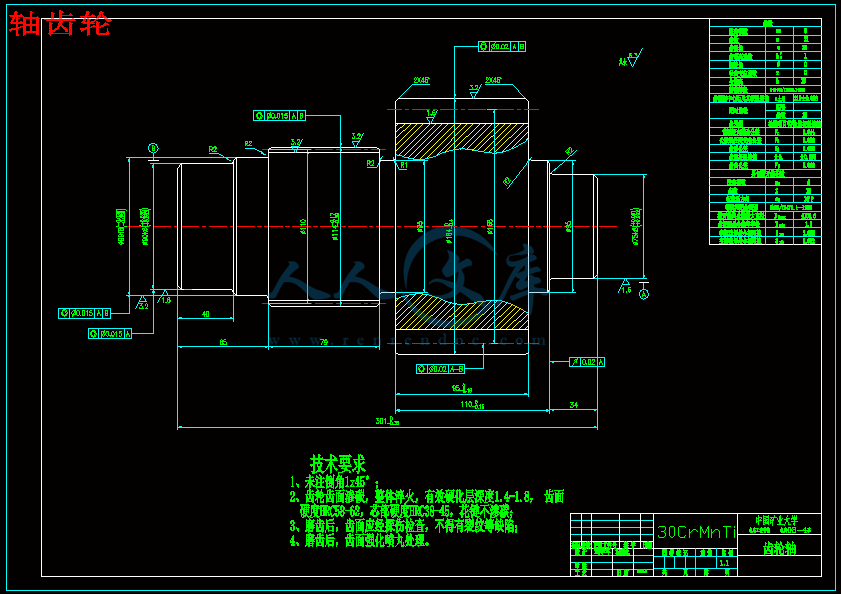

3.4齿轮传动的设计计算 12

3.4.1、第一传动组齿轮设计计算 12

3.4.2齿轮的校核 20

3.4.3、第二传动组齿轮设计计算 23

3.3.4、第三传动组齿轮设计计算 31

3.4.5齿轮的校核 39

3.4.6、渐开线行星齿轮组的设计计算 42

4 截割部传动系统辅助装置的校核计算 66

4.1截一轴花键设计计算 66

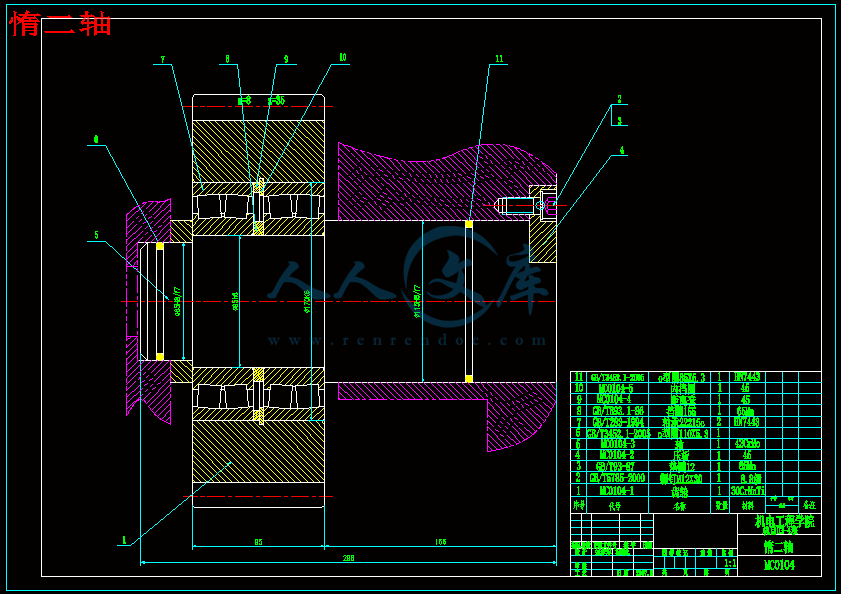

4.2截二轴设计 67

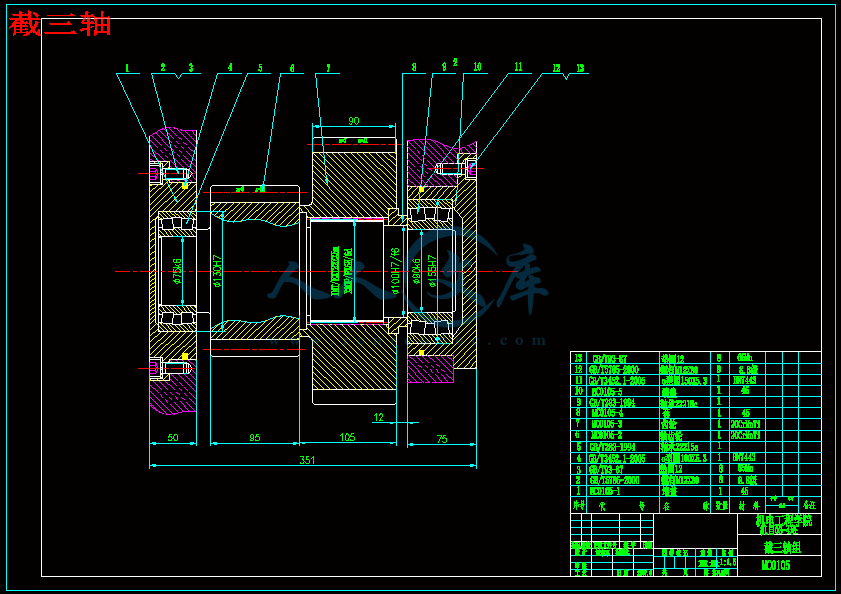

4.3截三轴设计 68

4.4截四轴设计 69

4.5输出轴花键设计计算 70

5 截割部传动系统各传动轴、轴承的校核 72

5.1截一轴及其轴承寿命验算: 72

5.1.1求轴上的载荷 72

5.1.2校核该轴得强度 73

5.2截二轴的详细校核: 73

5.2.1求轴上的载荷 73

5.2.2校核该轴得强度 75

5.3截三轴的详细校核: 76

5.3.1求轴上的载荷 76

5.3.2校核该轴得强度 77

5.3.3轴承寿命的验算 78

5.4惰一轴及其轴承的寿命校核 78

5.5惰二轴及其轴承的寿命校核 79

5.6截四轴及轴承的校核 79

5.6.1太阳轮轴的校核 79

5.6.2行星轮轴的校核及其轴承的寿命验算 80

6 MG180/435-W型采煤机其他部件及系统简介 81

6.1辅助液压系统 81

6.2 辅助装置 81

6.2.1滑靴组件 81

6.2.2拖缆装置 81

6.2.3喷雾冷却系统 81

6.2.4注意事项: 82

7 MG180/435-W型采煤机维护与检修 83

7.1井上检查与试运行 83

7.2采煤机的操作 83

7.3采煤机的注油 84

7.4采煤机的维护检修 84

7.4.1日检内容 84

7.4.2周检内容 84

7.4.3季检内容 85

总结 86

参考文献 87

附录1: 88

致谢辞 98

川公网安备: 51019002004831号

川公网安备: 51019002004831号