【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目录

1.引言 1

1.1我国塔式起重机行业发展概况 1

2设计任务书 5

2.1 产品设计的依据、目的及意义 5

2.2 产品的用途及适用范围 6

2.3 基本技术参数及性能指标 6

2.4 顶升机构工作原理 7

2.5 关键问题及其解决方案 7

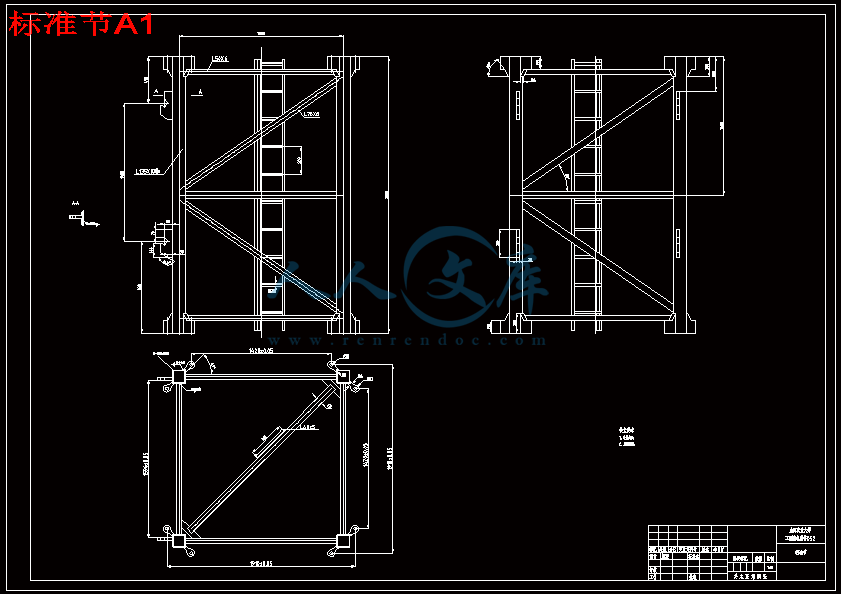

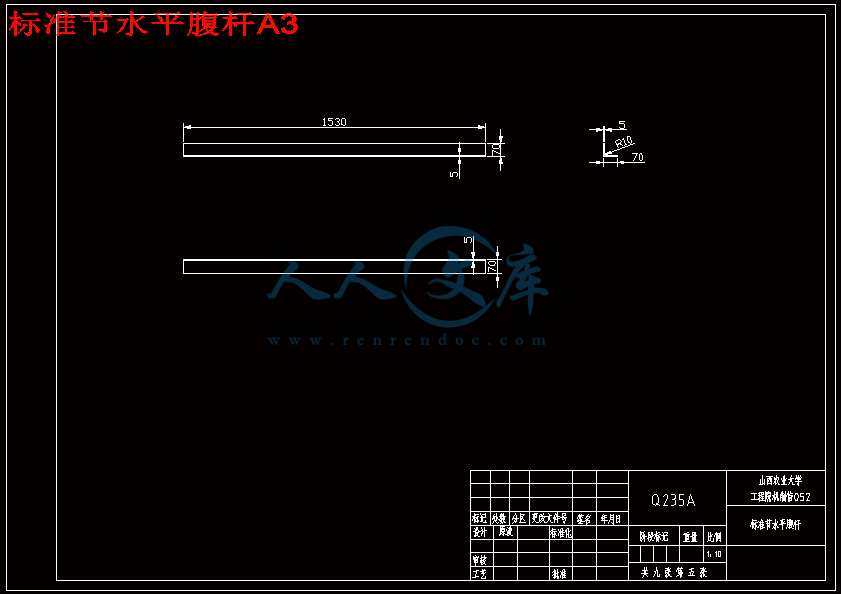

2.6 塔式起重机的构造 7

2.7工作机构 10

3.设计计算说明书 11

3.1顶升机构液压系统的确定 11

3.2塔式起重机顶升机构的设计 15

4.使用说明书 24

4.1顶升作业 24

4.2顶升过程的注意事项 25

4.3液压顶升系统的维护和保养 25

4.4一般说明 26

4.5 起重机的塔身升、降作业说明 26

4.6起重机的操作 27

5标准化审核报告 27

结论 28

参考文献 29

致谢 30

毕业设计说明书(论文)中文摘要

QTZ63型塔式起重机顶升机构的研究及设计

摘 要 塔式起重机在现代化建设中起到非常重要的地位,它是现代社会进步的一个标志,是人类建设不可缺少的重要设备。它的高效性、安全稳定性是塔机行业较普遍关心和注意的问题。本设计就塔式起重机的顶升机构的结构、受力分析、核心受力件材料等几个方面, 结合我国自行生产的QTZ63型塔式起重机为例,通过研究、分析踏步和顶升横梁的受力情况,明确踏步和顶升横梁的结构和尺寸的确定方法,以及对套架关键尺寸的确定。以及根据顶升载荷确定顶升机构的液压系统。确保塔式起重机能够安全、稳定的实行顶升加节过程,保证塔式起重机的安全施工。

关键词 顶升机构 踏步 顶升横梁 安全 稳定

毕业设计说明书(论文)外文摘要

The Research and Design of How Tower Crane(QTZ63)rises

Abstract

The tower crane plays a very important role in modern construction. As an indispensable and important construction equipment, it is a marking of progress in modern society . In the crane area ,the crane’s high efficiently and safe stability is the key concern. With the example of tower crane QTZ63 made by China , this article introduces the rise structure of the tower crane, force analysis and the key component material. Through studying and analsing the force conditions of the tramper and top rising beam , make clear how to calculate and definite the dimensions and structure of top rising beam and tramper. So does the key size definition of frame. Make sure that tower crane can work safety , steady in its rising process, guarantee the safe construction of tower crane.

Keywords Rising mechanism Tramper Rising beam Safety stability

QTZ63型塔式起重机顶升机构的设计

1.引言

二次世界大战结束以后,由于许多国家夷为废墟,庞大而艰巨的家园重建工作,要求建筑施工实现机械化,以加快建设进度。作为建筑机械化主导机械,塔式起重机得以应运而迅猛发展。

1.1我国塔式起重机行业发展概况

我国塔式起重机行业于20世纪50年代开始起步,1953年由原民主德国引进建筑师-Ⅰ型塔式起重机(Baumeister Ⅰ),1954年抚顺试制成功第一台2-6t塔式起重机,仿建筑师-Ⅰ型。初名TQ2-6塔式起重机。首次在北京用于大型砌块民用建筑施工,并取得成功。1965年列入国家生产计划的沈阳建机厂开始批量生产红旗Ⅱ-16型塔式起重机。

20世纪80年代随着改革开放和国际技术交流增多,我国曾先后有原联邦德国.法国.意大利及丹麦引进了为数可观的塔式起重机产品,特别是1984年由法国POTAIN公司引进的三种机型(H3/36B.F0/23B.GTMR360B)的生产许可证,极大地促进了我国塔式起重机产品设计制造技术的进步。通过消化吸收国外先进技术,对基础部件,如电动机.电器.回转支承.传动机构及安全装置等进行定点生产,一些生产主机的专业大厂还进行了相应的技术改造,增设钢材预处理生产线,从而使国产塔式起重机的质量迅速提高,一些主要机种已达到或接近国外同类产品质量水平。

进入20世纪90年代以后,我国塔式起重机行业随着全国范围建筑任务的增加进入了一个新的兴盛时期,年产量连年猛增,全国塔式起重机总拥有约为10万台。塔式起重机出口业务曾一度极为兴旺。至此,无论从生产规模,应用范围和塔式起重机总量来衡量,我国均堪称世界首号塔式起重机大国。

改革开放以来,国民经济的腾飞和投资规模的扩大,促进了建筑机械行业的不断发展,为塔机行业提供了良好机遇和发展空间。

据有关方面提供的信息:我国西部开发建设、国家能源建设、煤炭基本建设、油田建设、住宅建设、城市地铁建设等众多项目,预计2001~2005年全社会固定资产投资规模约为60000亿元,用于购置建筑机械的费用每年约为700亿元左右,其中相当数额用于购置塔机。

近几年来,我国的塔式起重机制造行业发展速度很快。出现了一大批塔机制造厂家,开发了系列化塔机产品,实现了产品更新换代,积累了不少经验,市场竞争局面逐渐形成,特别是我国加入WTO以后,国际竞争更趋激烈。为了塔机企业在竞争中立于不败之地,必须生产出质优价廉的产品。但是我们的塔机企业与国外先进企业相比存在一些不足之处,如产品档次低,质量不够稳定,产品结构单一,更新换代速度慢,技术管理与生产管理落后等,因而难以有效地满足市场不断变化的需求,也制约了企业的进一步发展。

川公网安备: 51019002004831号

川公网安备: 51019002004831号