【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

秸秆粉碎机的设计

目录

1引言 1

1.1课题的意义 1

1.2秸秆粉碎机具的国内外研究 2

1.3课题的研究内容 5

2技术任务书(JR) 5

2.1设计依据 5

2.2产品用途及使用范围 5

2.3主要工作原理 6

2.4主要技术参数 6

2.5关键问题及解决方法 7

3设计计算说明书(SS) 7

3.1总体方案 7

3.2总体结构及工作原理 8

3.2.1结构组成 8

3.2.2主要技术参数 8

3.3主要零部件的设计计算 10

3.3.1配套动力计算 14

3.3.2变速箱设计 15

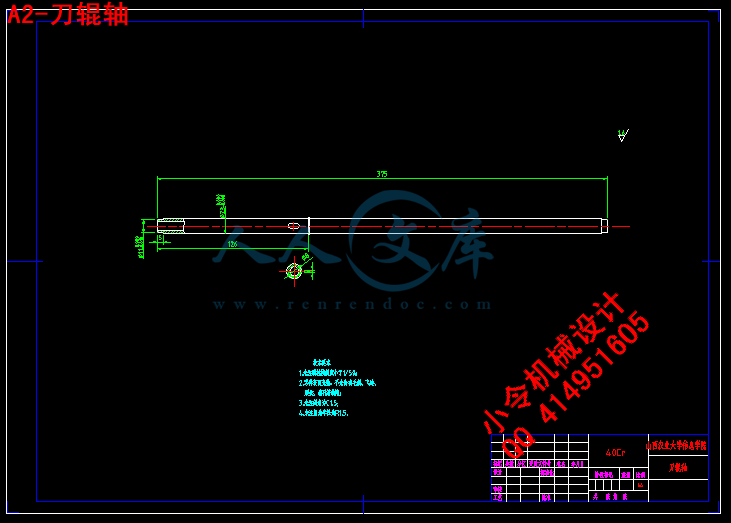

3.3.3主轴及粉碎部件的设计 16

3.4主要零件的强度校核 19

4使用说明书(SS) 23

4.1型号及名称 23

4.2结构及工作 26

4.3使用与保养 26

4.4安全注意事项 27

5技术条件(JT) 28

5.1检验规则 28

5.1.1检验的划分 28

5.1.2出厂检验 28

5.1.3型式检验 28

6结论 29

参考文献 31

致谢 33

毕业设计说明书中文摘要

秸秆粉碎机的设计

摘 要 保护性耕作是国际农业技术发展的重要趋势,秸秆还田技术是机械化 保护性耕作中关键的一项技术。使用机械化秸秆还田技术可以有效地解决农忙期间争农时、争劳力的矛盾,有力推动秸秆还田的农业全程机械化进程,避免由于焚烧秸秆产生的环境污染。本着一机多用、降低生产成本的原则,研制了既能满足玉米秸秆、又能单独实现旋耕作业的新型玉米秸秆还田机。

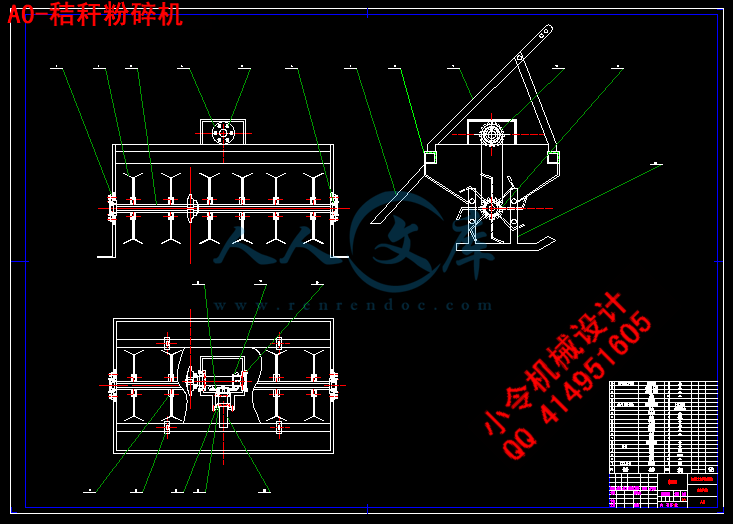

(1)在对秸秆粉碎及灭茬基本理论分析的基础上,提出多功能玉米秸秆还田机总体结构设计方案。采用卧式结构,主要由悬挂装置、变速箱、秸秆粉碎机构、等组成。拖拉机输出动力经万向节传递给变速箱,变速箱一轴经齿轮、链轮两级增速后,带动粉碎刀辊工作。

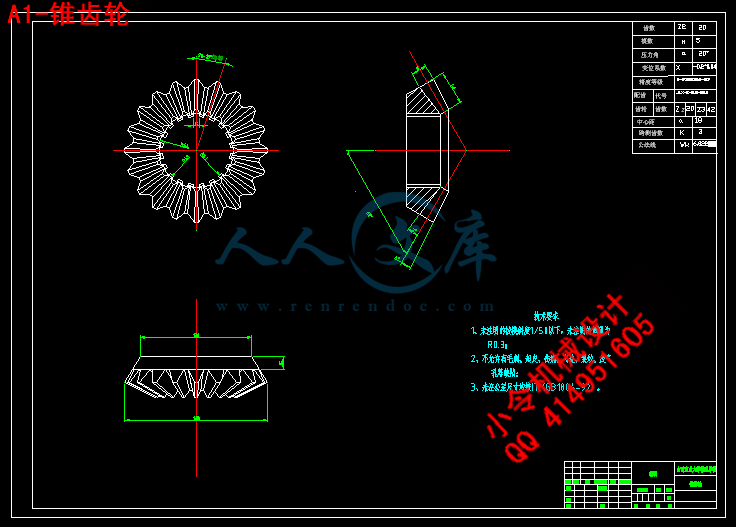

(2)设计了新型变速箱,实现了秸秆粉碎的作业,结构简单,一机多用。主要由锥齿轮传动等组成。利用从动齿轮的离合来实现粉碎、旋耕动力的分离与结合,从而分别完成秸秆粉碎与旋耕单项作业,实现一机多用之功能。

关键词 变速箱;秸秆粉碎机;甩刀;结构及工作原理

毕业设计说明书外文摘要

The hydraulic cylinder head drilling fixture design

Abstract

The protection cultivation is the most important international agriculturaltechnology development tendency.The smashed straw technology is one essential technology of the mechanized protection cultivation.Using smashed straw machines call effectively solve the problems that striving for time and labour during the busying farming time,and Can make the agricultural entire mechanization come幻truth.It also call avoid envkonment pollution caused by straw setting on fire.According to multi-function and reducing production COst,multi—function smashed straw machine WaS developed.It not only Can smash st“1w together with the stubble and put it back to the farmland to increase the nutrient once time but also Can according to Our practical necessityto choose rotary tilling single function.

(1)On the basic of studying the elementary theory of smaShing straw,the integral structure design plan ofmulti-functionmachine WaS introduced. The machine is mainly composed of hanng system,gearbox,belttransmission system,stalk-soil returning roller,rotary tiller roller,and depth limit roller.Power is transmitted from the tractor shaft to the power output gearbox.One shaft ofthe gearbox is acceleratedby both bevel gears and strap transmission.And then it drives the stalk—smashing knives revolving quickly. Another is moved by the bevel gears and strap wheel to drive the rotary tiller working.

(2)The innovativepoint is the design of new gearbox,which has realized

the composite work or sinsle work of smashing straw,stubble and rotary

tillage for the first time.It makes one machine has two uses.The gearbox is mainly composed ofbevel gears,poking fork,clutch,and bearings.Using the separation or union between the clutch and gears,the separation or union of the power canbe realized.So,the machine call choose smashed straw work or rotary tillage work.And the intension of bevel gears, belts,axes are checked.

After rotary tillage work,the farmland is smooth.It Can satisfy the agronomy request andcan carryOll the following sowing seedswork directly.

Keywords gearbox;smashed straw maehiFie;Structures and working mechanism;

1引言

1.1课题的意义

秸秆中含有的氮、磷、钾、镁、钙、硫等元素是农作物生长必需的主要营养元素,是我国重要的有机肥源之一。实践证明:秸秆还田后,土壤中氮、磷、钾养分都有所增加,尤其是速效钾的增加最明显。秸秆中有机质的含量平均为15%左右。据测定,湿玉米秸秆含氮量为0.61%,含磷量为0.27%,含钾量为2.28%,如果每亩地还田秸秆1000 kg,则可增加有机质150 kg。每亩地一年若还田鲜玉米秸秆1250 kg,则相当于4000 kg土杂肥的有机质含量,含氮、磷、钾相当于18.75 kg碳氨、lO埏过磷酸钙和7.65耗硫酸钾,同时还能补充其它多种营养元素。

秸秆还田还能改善土壤的团粒结构和理化性状。作物秸秆富含纤维素、木质素等富碳物质,它是形成土壤有机质的主要来源,因而秸秆还田有利于更新和增加土壤有机质。秸秆在耕翻入土之后,在分解过程中进行矿质化,释放养分,同时进行腐殖质化,使一些有机质化合物缩合脱水,形成更复杂的腐殖质,从而改善了土壤的结构及保水、吸水、粘结、透气、保温等性状,提高了土壤本身调

川公网安备: 51019002004831号

川公网安备: 51019002004831号