CA6140车床法兰盘的加工工艺规程及钻 4—Φ9孔钻床夹具设计

CA6140车床法兰盘钻 4—Φ9孔钻床夹具设计

CA6140车床法兰盘工艺规程及夹具设计

CA6140车床法兰盘831004加工工艺及钻φ6孔夹具设计

CA6140车床法兰盘831004加工工艺及钻φ6孔工艺装备设计

CA6140车床法兰盘831004钻φ6孔夹具设计

CA6140车床法兰盘831004加工工艺规程及车大法兰端面和ф20孔夹具设计

法兰盘零件的工艺规程及车大法兰端面和ф20孔工艺装备设计

CA6140车床法兰盘831004钻Φ4孔夹具设计

CA6140车床法兰盘加工工艺规程及夹具设计

CA6140车床法兰盘831004的机械加工工艺规程及铣Φ90上下两侧平面夹具设计

法兰盘的夹具设计

CA6140车床法兰盘(831004型号)的加工工艺规程及夹具设计

CA6140车床法兰盘(831004)零件的机械加工工艺规程及专用夹具设计

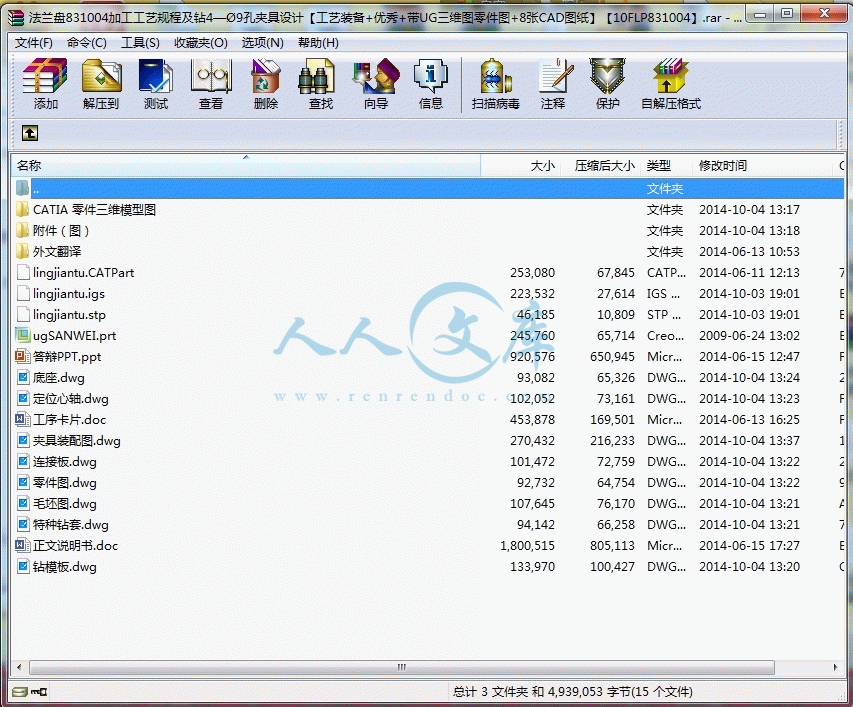

法兰盘831004加工工艺规程及钻4—?9孔夹具设计【工艺装备+优秀+带UG三维图零件图+8张CAD图纸】【10FLP831004】

【带任务书、答辩ppt、机械加工工艺过程、工序卡片全套】【word文档包含:42页@正文11700字】【详情如下】【需要咨询购买全套设计请加QQ1459919609】.bat

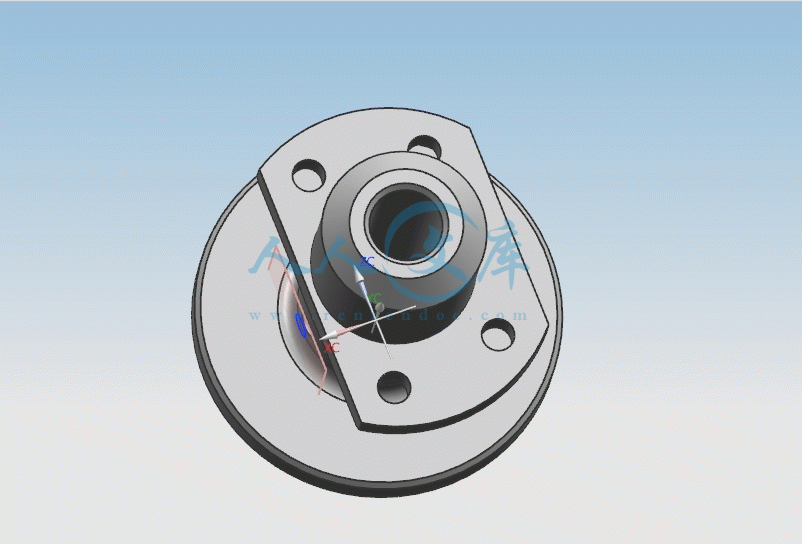

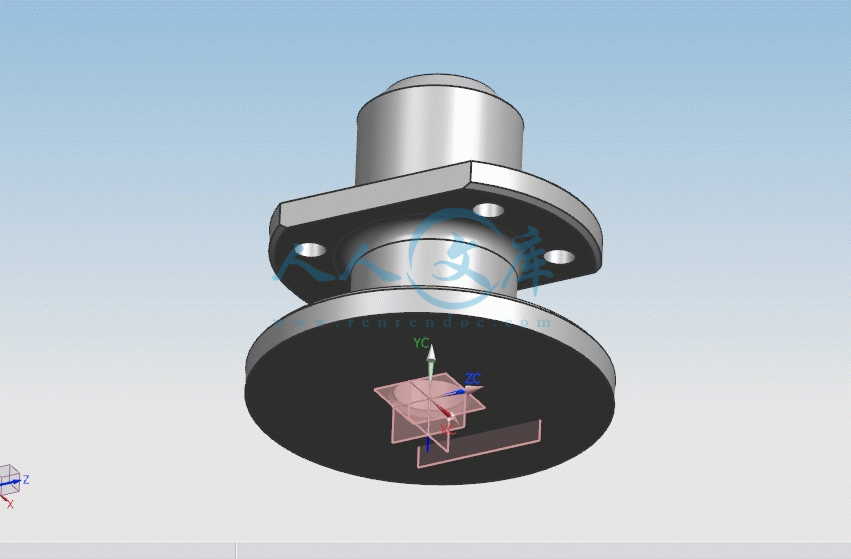

CATIA 零件三维模型图

lingjiantu.CATPart

lingjiantu.igs

lingjiantu.stp

ugSANWEI.prt

外文翻译

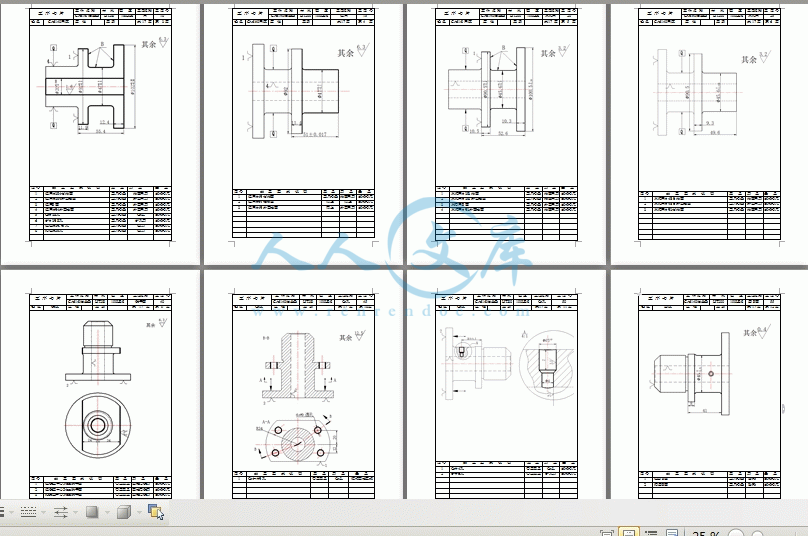

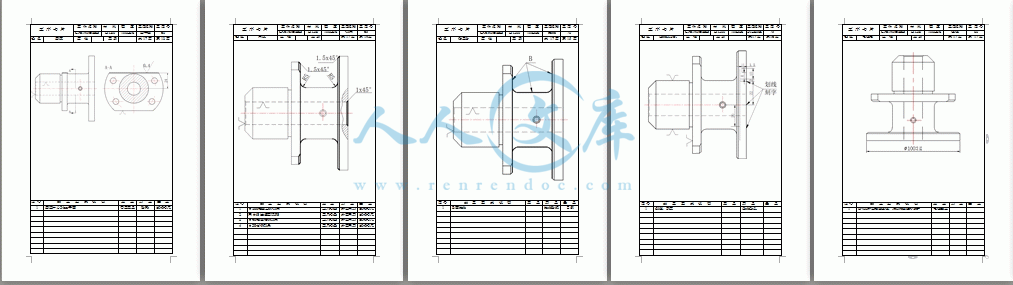

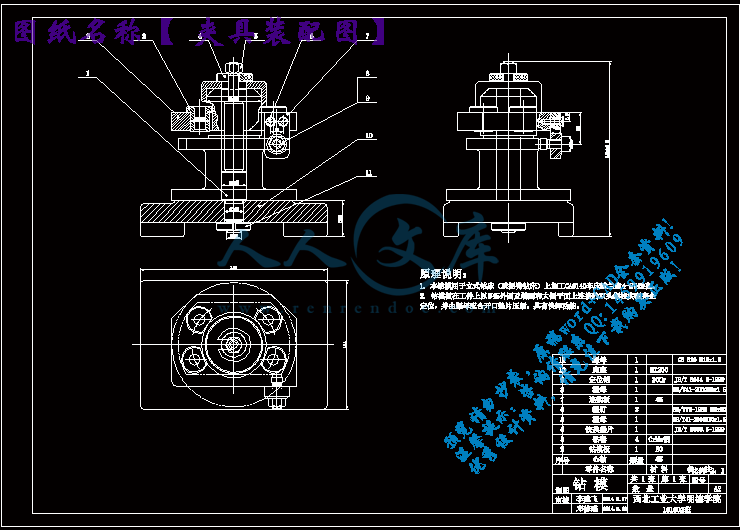

夹具装配图.dwg

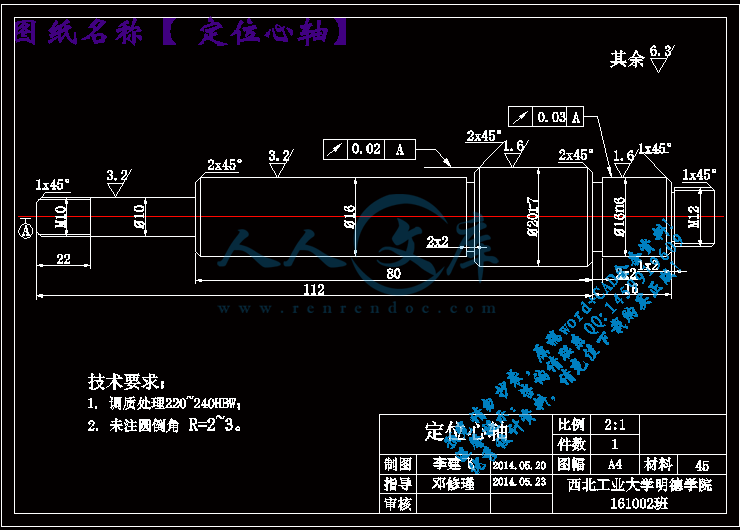

定位心轴.dwg

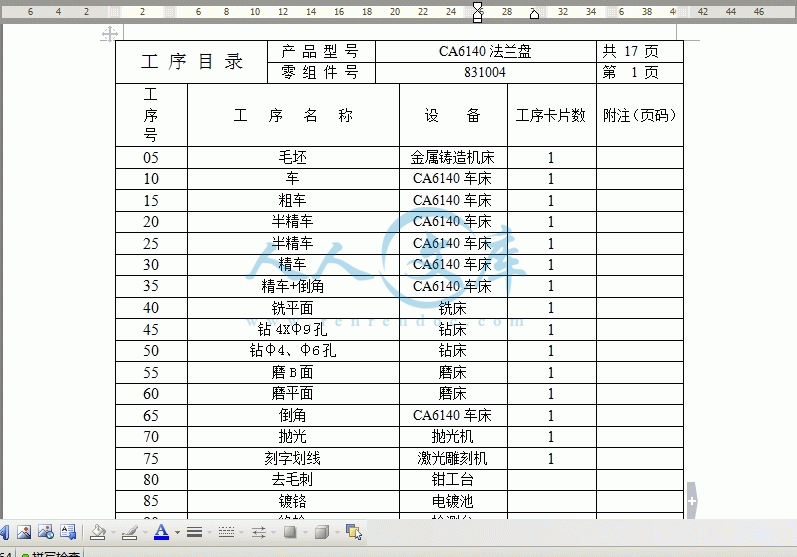

工序卡片.doc

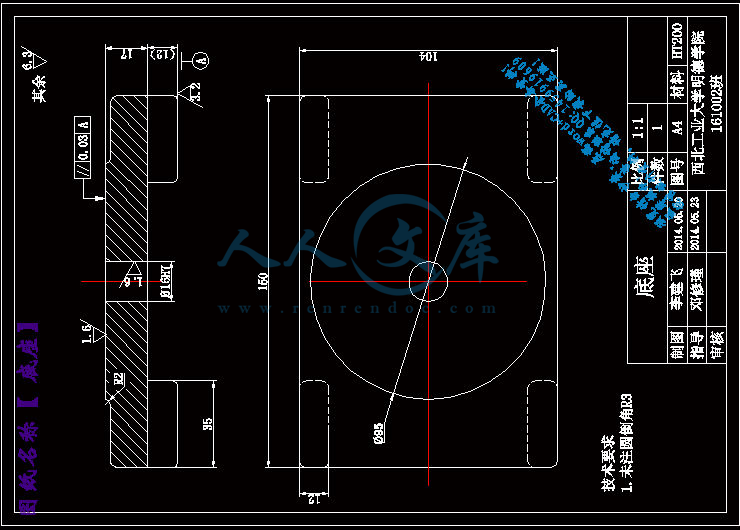

底座.dwg

正文说明书.doc

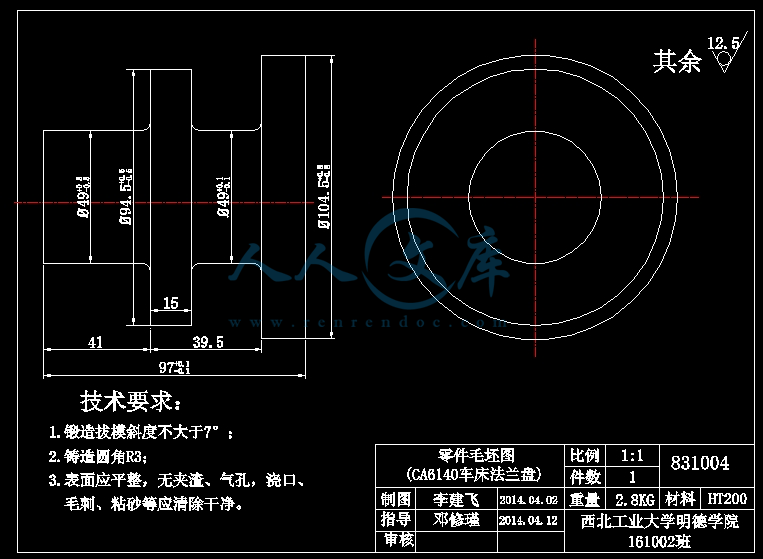

毛坯图.dwg

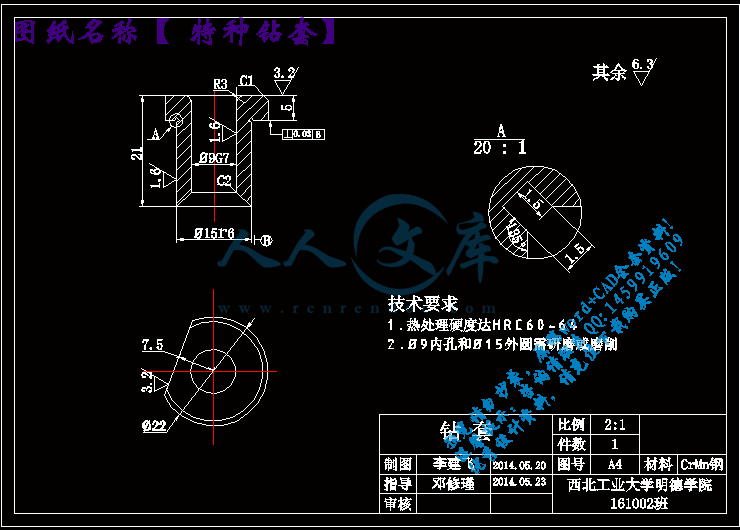

特种钻套.dwg

答辩PPT.ppt

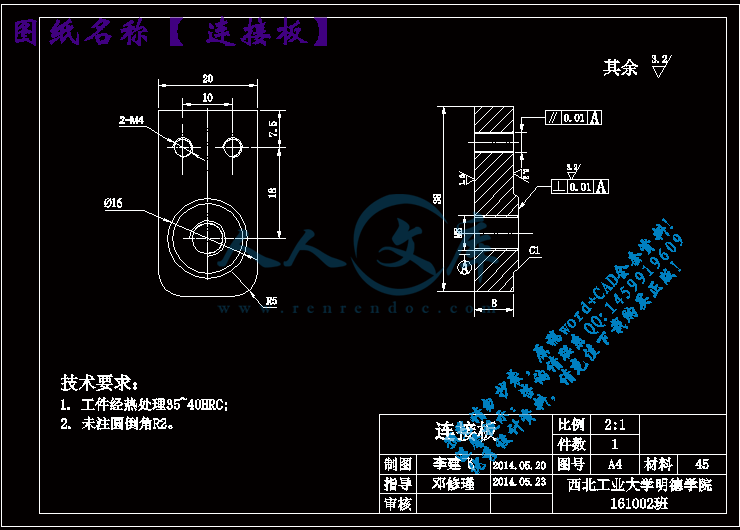

连接板.dwg

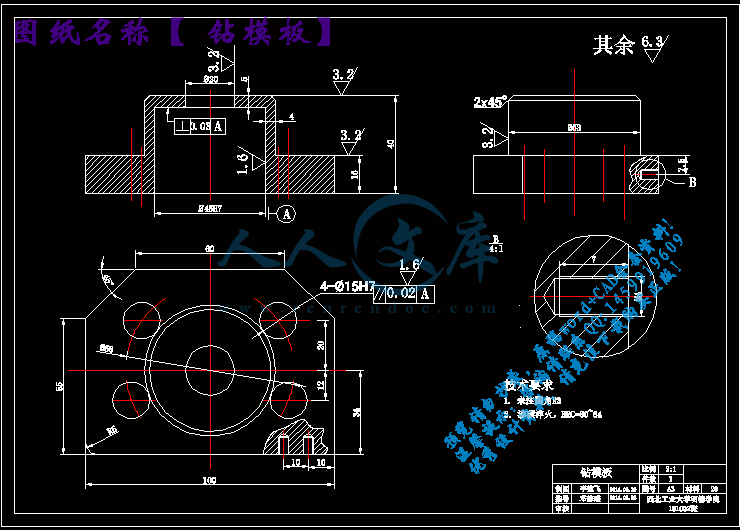

钻模板.dwg

附件(图)

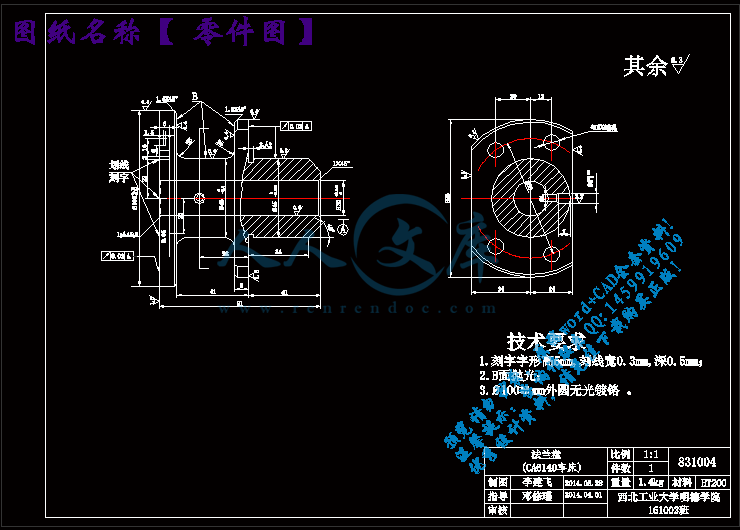

零件图.dwg

任务书

一、题目

�CA6140车床法兰盘的工艺规程和夹具设计

二、指导思想和目的要求

毕业设计(论文)是培养学生自学能力、综合应用能力、独立工作能力的重要教学实践环节。

在毕业设计中,学生应独立承担一部分比较完整的工程技术设计任务。要求学生发挥主观能动性,积极性和创造性,在毕业设计中着重培养独立工作能力和分析解决问题的能力,严谨踏实的工作作风,理论联系实际,以严谨认真的科学态度,进行有创造性的工作,认真、按时完成任务。

三、主要技术指标

1. 零件图一张;

2. 毛坯图一张;

3. 工艺规程一本;

4. 工艺装备(夹具1-2套);

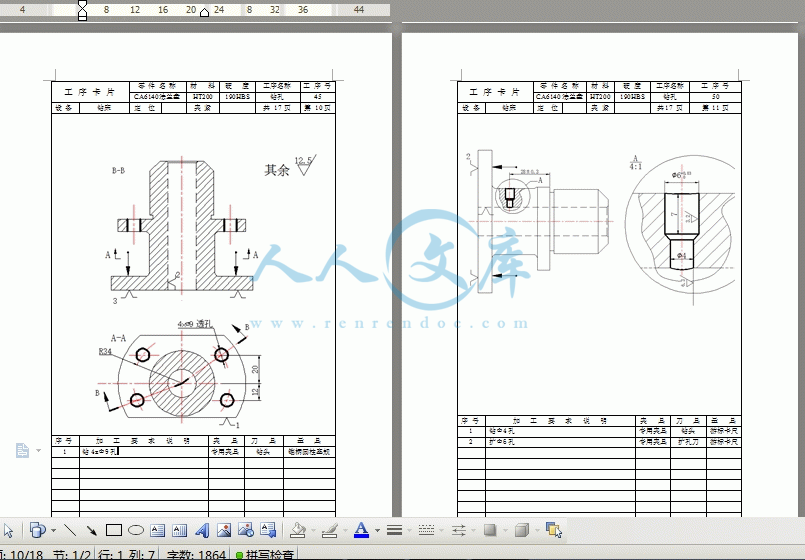

5. 说明书一份

四、进度和要求

1. 分析并绘制零件图 2周

2. 绘制毛坯图 1周

3. 设计工艺路线及编制工艺规程 5周

4. 设计工艺装备 4周

5. 编写说明书(论文) 2周

五、主要参考书及参考资料

[1] 王先逵编著.机械制造工艺学[M].北京:清华大学出版社,1989

[2] 杨叔子.机械加工工艺师手册[M].北京:机械工业出版社,2001

[3] 朱耀祥,蒲林祥.现代夹具手册[M].北京:机械工业出版社,2010

摘 要

本次毕业设计的题目是�CA6140车床法兰盘的工艺规程和夹具设计,主要内容如下:

首先,对零件进行分析,主要是零件作用的分析和工艺性分析,通过零件分析可以了解零件的基本情况,而工艺分析可以知道零件的加工表面和加工要求。根据零件图提出的加工要求,确定毛坯的制造形式和尺寸。

其次,进行基面的选择,确定加工过程中的粗基准和精基准。根据选好的基准,制订工艺路线,通常制订两种以上的工艺路线,通过工艺方案的比较与分析,再选择可以使零件的几何形状、尺寸精度及位置精度等技术要求得到合理的保证的一种较佳工序路线。

然后,根据已经选定的工序路线,确定每一步的切削用量及基本工时,并选择合适的机床和刀具和量具。

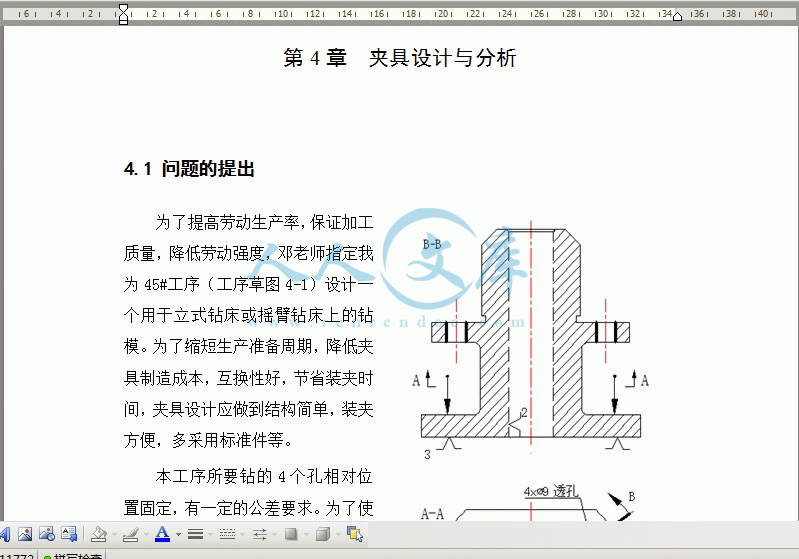

最后,设计钻法兰盘4-?9孔的钻床夹具。设计钻床夹具,首先要仔细分析被加工零件的技术要求,运用夹具设计的基本原理和方法,拟定夹具设计方案;在满足加工精度的条件下,合理的进行安装、定位、夹紧;在完成夹具草图后,进一步考虑零件间的连接关系和螺钉、螺母、定位销等的固定方式,设计合理的结构实现各零部件间的相对运动;根据各零件的使用要求,选择相应的材料。

完成钻床夹具的所有设计后,用AutoCAD进行二维图形的绘制,首先画装配图,然后从装配图上拆画零件图,标注相关尺寸及技术要求;再用CATIA画出三维模型图,最后进行论文的撰写、整理、修改完成该毕业设计。

关键词: 机械,法兰盘,加工工艺,夹具设计

ABSTRACT

The subject of this graduation project is that CA6140 lathe ring flange processing technology rules and special-purpose jig of a certain process are designed, the main content is as follows:

First of all, analyse , it is mainly analysis of the function of the part and craft analysis to the part , through part analyse can find out about basic situation of part, and craft analyse may know the processing surface of the part and is it require to process. The processing demand put forward according to the part picture, confirm the manufacture form. of the blank and sureness of the size.

The second step, carry on the choice the base , confirm thick datum and precise datum in the processing course. According to the datum chosen , make the craft route , usually make the craft route of more than two kinds, with analysing through the comparison of the craft scheme, and then choosing be able to make such specification requirements as the precision of geometry form. size of the part and precision of position ,etc. get a kind of process of the rational assurance s.

The third step, according to the already selected process route, confirm for every steps of cutting consumption and basic man-hour , choose suitable lathe and cutter. To rough machining , will check the power of the lathe .

Finally , design the jig getting into the hole of the ring flange. Designed drilling fixture, the first careful analysis is the technical requirements for processing components, fixture design using the basic principles and methods.Prepared the fixture design scheme ;Meet the conditions of precision ,then reasonable installation, positioning, clamping;After the completion of draft fixture, and further consider the connection relation between parts and screws, nuts, pins and other fixed means,designing the reasonable structure to achieve relative motion between the various components;Requirements of the various components, select the appropriate materials.

Completion of all drilling fixture design, using the AutoCAD drawing two-dimensional graphics,first draw assembly drawing, and then removed from the part drawing on the painting Parts,marking the related to size and technical requirements,finally, write a thesis, organize, edit, complete the graduation project.

KEY WORDS: machine, flange, process the craft, the tongs design

目 录

第1章 绪 论7

第2章 零件的结构工艺性分析8

2.1 零件的作用8

2.2 零件的工艺性分析8

第3章 工艺规程设计10

3.1 确定毛坯的制造形式10

3.2 基准的选择10

3.2.1粗基准的选择10

3.2.2精基准的选择11

3.3 工艺路线的拟定11

3.3.1 选择加工方法11

3.3.2 划分加工阶段12

3.3.3 安排加工顺序12

3.4 机械加工余量、工序尺寸及毛坯尺寸的确定14

3.5 确定切削用量及基本工时18

第4章 夹具设计与分析24

4.1 问题的提出24

4.2 夹具设计24

4.2.1 夹具结构和类型的选取24

4.2.2 夹具定位元件的选择26

4.2.3 钻套的设计27

4.2.4 钻模板设计28

4.2.5 夹具体(底座)的设计29

4.2.6 其他装置30

4.2.7 夹紧装置的设计计算31

4.2.8 切削力计算33

4.2.9 机床夹具精度校核34

4.2.10 绘制夹具总图37

4.2.11 拆分夹具零件图37

第5章 全文总结39

参考文献40

致 谢41

毕业设计小结42

第1章 绪论

法兰盘类零件是在一个类似盘状的金属体的周边开上几个固定用的孔用于连接其它东西,此类零件在机械行业拥有非常重要的地位,其加工质量和精度直接影响一台机器的运作。因此,进行法兰盘类零件加工工艺的研究,对于整个机械行业而言,有着举足轻重的地位。

在提高工件加工质量的基础上同时提高生产效率是大部分机械零件工艺设计的准则,法兰盘类零件也是如此。一个合格的零件工艺规程,应该首先要求保证零件设计的尺寸和精度,其次要尽量合理地运用现有的工作条件,尽量减少辅助时间,提高生产效率。夹具的设计需要注意其精度对被加工工件精度的影响,务必确保使用夹具能够保证设计精度。本设计均以上述各原则为基准进行。

由于专业知识有限,设计尚有许多不足之处,恳请各位老师、同学给予指出。

第2章 零件的结构工艺性分析

2.1 零件的作用

CA6140卧式车床上的法兰盘,为盘类零件,用于卧式车床上。车床的变速箱固定在主轴箱上,靠法兰盘定心。法兰盘内孔与主轴的中间轴承外圆相配,外圆与变速箱体孔相配,以保证主轴三个轴承孔同心,使齿轮正确啮合。主要作用是标明刻度,实现纵向进给。

参考文献

[1] 阎光明,侯忠滨,张云鹏.现代制造工艺基础.西安:西北工业大学出版社,2007

[2] 王先逵.机械加工工艺手册,北京:机械工业出版社,第二版,2003

[3] 邓文英.宋力宏.金属工艺学.北京:高等教育出版社,第五版,2008

[4] 吴 拓.简明机床夹具设计手册,北京:化学工业出版社,2010

[5] 陈宏钧.机械加工工艺设计员手册. 北京:机械工业出版社,2009

[6] 陈宏钧.实用机械加工工艺手册. 北京:机械工业出版社,2003

[7] 陈宏钧.金属切削工艺技术手册. 北京:机械工业出版社,2013.4

[8] 王权民.机床夹具设计,第1版,北京:科学出版社,2011

[9] 赵家齐.机械制造工艺学课程设计指导书,北京:机械工业出版社,1994

[10]卢秉恒.机械制造技术基础,第三版,西安:机械工业出版社,2007

[11]朱耀祥,蒲林祥.现代夹具设计手册.北京:机械工业出版社,2011

[12]钱云峰.殷锐,互换性与技术测量. 北京:电子工业出版社,2011.4

[13]李名望.机床夹具设计实例教程. 北京:化学工业出版社,2009

川公网安备: 51019002004831号

川公网安备: 51019002004831号