【温馨提示】 购买原稿文件请充值后自助下载。

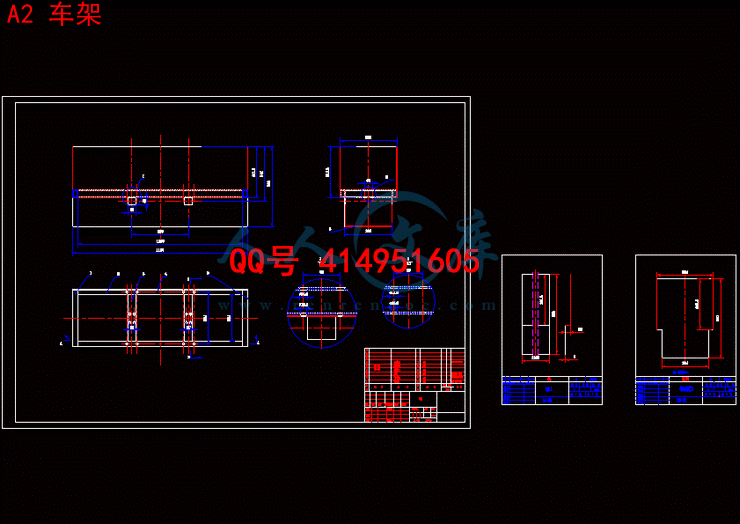

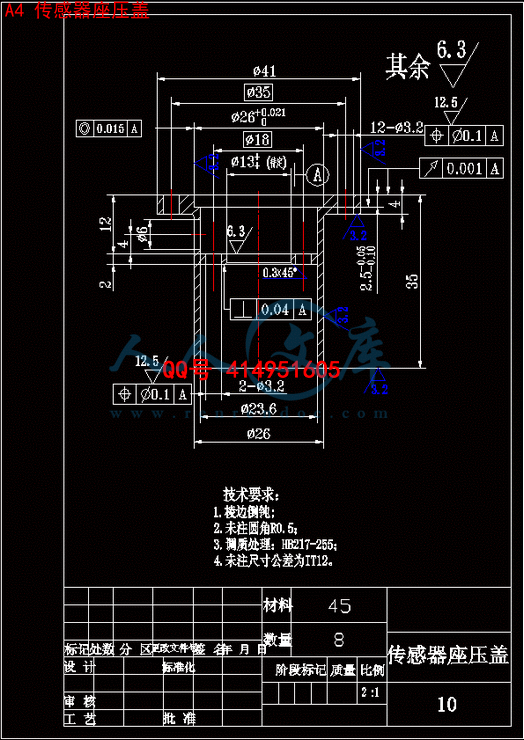

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

星球车移动系统作为星球面探测的媒介,其关键技术的研究对于完善探索太空工程具有重要意义。本文主要进行八轮星球探测车可展开移动系统的设计。

为实现星球车折叠比及相应的功能要求,分别对组成移动系统的悬架部件、车轮部件进行设计。通过准静力学分析,分析了各结构参数对星球车越障通过性的影响。为确保八轮星球探测车越障能力满足设计要求,求解后确定了其整体结构尺寸。

根据所确定的结构尺寸,对八轮星球探测车可展开移动系统进行设计,包括车轮部件、悬架部件。根据车轮部件独立驱动、独立转向的功能要求,进行驱动传动装置及转向装置的设计,同时采用可展开车轮新构型设计了相应的轮辐结构。根据可展开悬架新构型,对悬架部件进行了总体结构设计。

关键词 八轮星球探测车;可展开移动系统;结构设计;建模

Abstract

Locomotion system of lunar rover is the medium of lunar exploration, the research of the locomotion system key technologies of lunar rover has important meaning for perfecting project of lunar exploration. The key technologies on deployable locomotion system of the eight-wheel with torsion-bar and rocker structure lunar rover are researched.

To meet the demand that the volume of lunar rover is least at folded station, and to realize the relevant function, the suspensions and wheels, which make up of the locomotion system, were designed. By the quasi-static analysis, the performance parameter expression of climbing obstacle with structure parameters was determined. The influence that each design parameter acts on the lunar rover performance of climbing obstacle is analyzed. In order to guarantee the climbing ability of eight-wheel with torsion-bar and rocker structure lunar rover to satisfy the design request, after solving the model, the structure dimension of the eight-wheel with torsion-bar and rocker structure lunar rover is made sure.

According to the structure dimension, the deployable locomotion system of the eight-wheel with torsion-bar and rocker structure lunar rover was designed, involving the wheels, the suspensions and the power for deploying the suspensions. According to the characteristic each wheel is driven and veered alone, the driving and turning devices of deployable wheel have been designed. Using the new framework of deployable wheel spoke, its structure has been designed. According to the new framework of deployable suspension, the whole structure of the deployable suspension parts has been designed.

Keyboard lunar rover, deployable motion system, physical design, modeling,

目 录

摘 要

Abstract

第1章 绪论 1

1.1 课题背景及研究意义 1

1.2 行星车移动系统概述 2

1.2.1 不可展轮式移动系统研究现状 2

1.2.2 可展开轮式移动系统研究现状 5

1.3 本文主要研究内容 8

第2章 可展开移动系统结构设计 9

2.1 引言 9

2.2 移动系统结构的基本型式 9

2.3 可展开悬架结构 10

2.3.1 可展开悬架结构特点分析 10

2.3.2 可展开悬架展开方案确定 10

2.4 可展开车轮结构设计 12

2.5 本章小结 13

第3章 可展开移动系统的参数设计 14

3.1 引言 14

3.2 由结构参数表征的地形通过条件 14

3.2.1 通过崎岖地形临界条件 15

3.2.2 通过坡状地形失效条件 15

3.3 由结构参数表征的越垂直障碍条件 18

3.3.1 两个前车轮同时越障 18

3.3.2 两个中前轮同时越障 19

3.3.3 各轮越过垂直障碍能力评价 21

3.3.4 越过壕沟的能力 21

3.3.5 移动系统的主要参数确定 21

3.4 本章小结 22

第4章 可展开移动系统车轮部件设计 23

4.1 引言 23

4.2 可展开移动系统概述 23

4.3 车轮部件及其驱动 23

4.3.1 驱动方案确定 24

4.3.2 可展开车轮结构设计 25

4.4 本章小结 26

第5章 可展开移动系统三维建模 27

5.1 三维建模软件简介 27

5.1 可展开移动系统三维建模 27

5.3 本章小结 28

第6章 结论 29

参考文献

致 谢

第1章 绪论

1.1 课题背景及研究意义

月球是距离地球最近的自然天体,蕴藏大量的矿产资源,是人类飞离地球进行深空探测的第一站,也是理想的天然空间中转站。月球所具有的巨大经济、政治和军事价值使得月球探测成为人类一直关注的焦点。在经历了第一次美苏探月高潮以后,月球探测沉寂了20年,1986年美国提出的“重返月球、建立月球基地”设想,揭开了新一轮探月高潮的序幕。俄罗斯、日本、欧洲空间局、印度等国家和组织也纷纷宣布要进行月球探测。作为一个航天大国, 2000年11月22日中国发布了《中国的航天》白皮书,明确提出未来10年将开展深空探测研究,重点开展月球探测。2004年中国正式启动了探月“嫦娥工程” [1]。

川公网安备: 51019002004831号

川公网安备: 51019002004831号