【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

第 1 章 .绪论 ............................................................................................................................... 1

1.1 前言 ................................................................................................................................... 1

1.2 宽窄行分插机构的发展状况 ............................................................................................ 1

1.3 课题研究内容 ................................................................................................................... 4

1.4 本章小结 ........................................................................................................................... 5

第 2 章 .宽窄行分插机构设计的分析 .................................................................................. 6

2.1 宽窄行插秧达到的效果和机构工作原理 ........................................................................ 6

2.1.1 宽窄行分插机构达到的效果 ............................................................................... 6

2.1.2 分插机构的工作原理 ........................................................................................... 6

2.2 宽窄行分插机构的运动要求 ............................................................................................ 8

2.3 分插机构的数学建模及参数确定 ................................................................................... 9

2.3.1 非圆锥齿轮齿轮节曲线表示 ................................................................................ 9

2.3.2 求解共轭非圆锥齿轮节曲线 .............................................................................. 10

2.3.3 分插机构空间轨迹模型构建 .............................................................................. 11

2.3.4 分插机构参数分析及优化 .................................................................................. 13

2.4 本章小结 ......................................................................................................................... 19

第 3 章. 分插机构行星轮系的建模与仿真分析.............................................................. 20

3.1 不完全非圆锥齿轮的齿廓设计及三维造型 .................................................................. 20

3.2 分插机构不完全非圆锥齿轮行星系的建模 ................................................................. 21

3.3 不完全非圆锥齿轮行星轮系的仿真分析 ...................................................................... 22

第 4 章. 插秧机分插机构的三维建模及二维图纸设计 ................................................ 23

4.1 箱体的结构设计 ............................................................................................................. 24

4.2 栽植臂机构设计 ............................................................................................................. 25

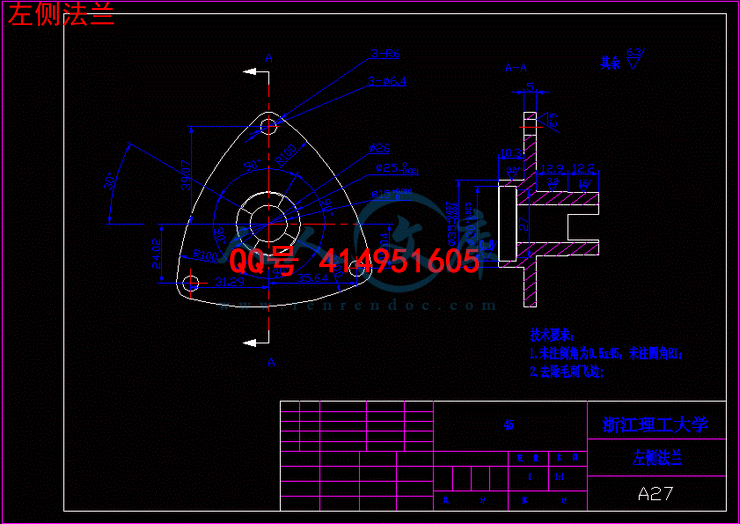

4.3 各零部件的二维图纸生成 ............................................................................................. 26

4.4 分插机构零件设计的注意问题 ..................................................................................... 28

第 5 章. 论文总结 .................................................................................................................... 29

5.1 论文总结 ......................................................................................................................... 29

5.2 插秧机分插机构的发展前景 ......................................................................................... 29

参考文献 ................................................................................................................................... 30

致谢 .............................................................................................................................................. 32

第 1 章 .绪论

1.1 前言

浙江理工大学毕业论文

中国是一个农业大国,而水稻是我国主要的粮食作物。要实现农业现代化必

须要实现农业机械化。中国目前的农业机械化水平还不高,目前只有 48.8%,中

国的农业装备制造业只有持续稳定快速发展,产品国际竞争力与科技创新能力才

会逐步跨入世界先进行列。节能减排和低碳经济发展模式成为提升物质装备和改

变发展方式的优先战略。《“十二五”中国农业机械化发展形势分析》中提到农作

物耕种收综合机械化水平将要稳步提升 2—3 个百分点,到 2015 年达到 60%以上。

水稻栽植、收获机机械化,玉米收获机械化进入提速发展期。其中水稻种植的机

械化必须要大力发展,水稻合理的栽植能够有效地提高水稻产量[1-2]。

水稻机械化中最重要的是水稻插秧机,水稻插秧的机械化能够提高生产效率。

现如今大多数的农村青壮年劳动力都离开农村到城市务工,农村劳动力数量和水

平都持续下降,所以提高水稻插秧的机械化水平尤为重要,因此插秧机的发展是

目前发展的重点。而水稻插秧机中的分插机构决定了插秧机的性能。目前世界范

围内的分插机构均为均匀行插秧,由于均匀行插秧容易导致秧苗的通风效果差,

容易造成水稻的病虫害,还有由于均匀插秧造成的光照不充足的问题,都会大大

影响水稻的产量。

因此宽窄行插秧的种植方法在我国显得尤为重要,利用插秧行距不同来改善

通风减少病虫害,提高粮食产量。同时有助于减少农药的使用,对环境的保护会

起到很大的作用。

1.2 宽窄行分插机构的发展状况

浙江理工大学的赵匀教授领导课题组研究开发了一系列宽窄行分插机构。

1.步行式偏心-变位齿轮行星轮系宽窄行分插机构,如图 1.1[3]所示:

偏心-变位齿轮行星轮系后插式分插机构其主要结构是偏心变位齿轮传动结

构只对中间齿轮变位,太阳轮和行星轮为偏心圆齿轮。该偏心-变位齿轮行星轮

系由两个全等偏心圆齿轮、一个与其共轭的偏心变位齿轮和一个行星架构成。由

1

异形非圆锥齿轮行星轮系水稻宽窄行分插机构设计

于偏心齿轮和共轭偏心变位齿轮啮合,引起传动比的非匀速变化,从而使得行星

轮相对行星架作非匀速转动。行星轮随着行星架绕回转中心作圆周运动,同时相

对行星架作非匀速转动,行星轮的绝对运动是这两种运动的复合运动。通过键、

行星轮轴与行星轮固结的一对栽植臂和行星轮作相同的复合运动。插秧机由传动

**箱 1、齿轮箱 15、16

全部文件包含以下内容

川公网安备: 51019002004831号

川公网安备: 51019002004831号