【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

科学技术的飞速发展,正在把人类推向信息时代。但是,面对着加工业70%—80%的中小批量生产的经济结构,如何达到自动化的目的,一直是工业界探索的课题。数控机床问世虽为这部分工厂自动化创造了条件,但实践证明,独立、分散的单机自动化解决不了传统批量生产所固有的生产率同生产柔性、加工批量同制造成本、生产同市场变化之间的矛盾,必须寻找更完善的自动生产体系。FMS就是在这种追求下诞生的。其优势在于把生产率同生产柔性、加工批量同制造成本、先进技术同科学管理高度统一起来。从而提高产品制造柔性,提高效率缩短生产周期,降低能耗及成本,节约设备占地面积。在柔性制造系统中采用全自动化生产,减少了认为的因素一次也提高了产品的精度。以上可见,柔性制造系统以上优点是如今制造业中非常需要的。

关键词:柔性制造;立体库;码垛机;流水线

Abstract

The rapid development of science and technology, human to the information age. But,Processing industry 70% -80% of the face of the economic structure of the small and medium volume, how to achieve the purpose of automation has been the industry to explore the subject.Although the advent of CNC machine tools to create the conditions for this part of the factory automation,but practice has proved that independent, decentralized stand-alone automation can not solve the productivity inherent in traditional mass production with the production of flexible processing the same batch manufacturing costs, the contradiction between production and market changes, we must find better automatic production system.FMS is born in this pursuit.The advantage of the productivity with flexible production, processing and batch manufacturing costs, with advanced technology with scientific management of highly unified.Thereby increasing manufacturing flexibility, improve efficiency, shorten the production cycle, reduce energy consumption and cost saving equipment footprint.Fully automated production, reducing the human factors and therefore improve the accuracy of the product in a flexible manufacturing system.Above that, the advantages of flexible manufacturing systems is much needed in the manufacturing industry today.

Key words: Flexible manufacturing; stereo storage; palletizer; pipeline

目 录

摘 要

Abstract

第一章 绪 论 1

1.1 柔性制造背景 1

1.2 柔性制造的工作流程 1

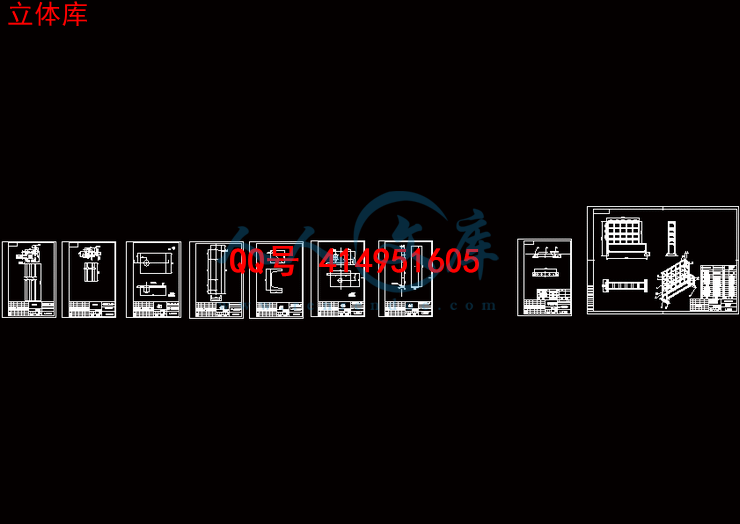

第二章 立体库的设计 3

2.1 立体库优点及功能 3

2.2 国内立体库发展趋势 3

2.3立体库的外形 3

2.4 立体库各部分材料选择 4

2.4.1 底座材料选择与外形设计 4

2.4.2 立体库主体设计 6

2.4.3 托盘设计 8

2.5 立体库储存能力及主要设备 9

2.5.1 立体库储存能力计算 9

2.5.2 主要设备 9

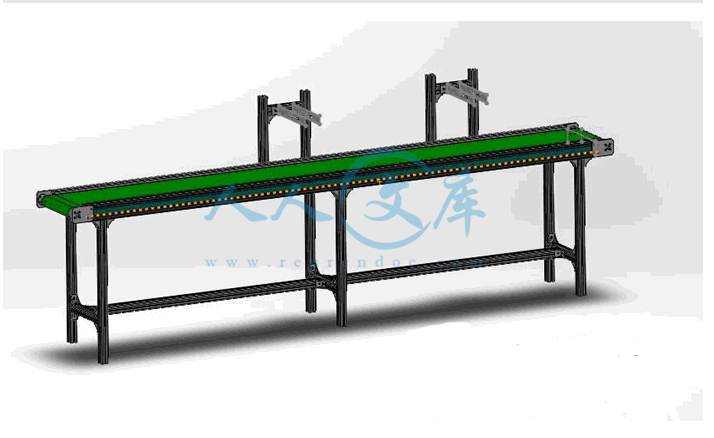

第三章 流水线的设计 10

3.1 流水线的工作原理 10

3.1.1 流水线的工作原理及流程图 10

3.2 电路中主要元器件的介绍 11

3.2.1 对射开关的原理及应用 11

3.2.2 CCD颜色尺寸检测单元工作原理及应用 11

3.2.3 PLC及其扩展单元 12

3.3 流水线系统控制 13

3.3.1 流水线电机正反转控制 13

3.3.2 流水线电机启动/停止控制 13

3.4 流水线设计 13

3.4.1 流水线技术参数 13

3.4.2 CCD检测单元支架设计 14

3.4.3 对射开关 16

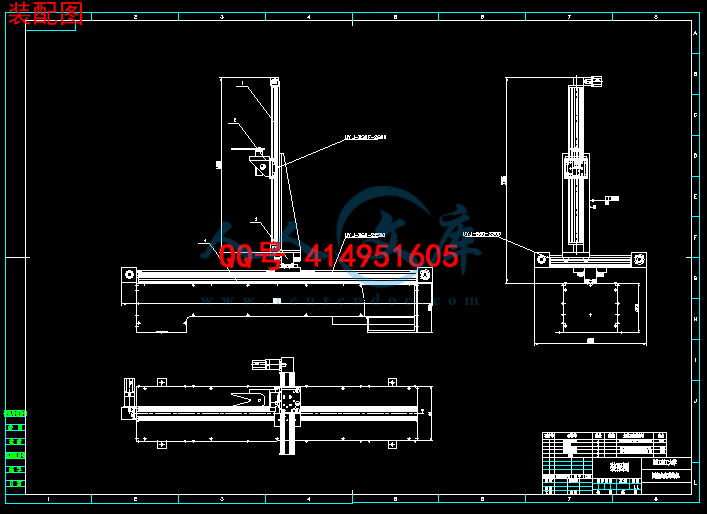

第四章 四自由度码垛机 21

4.1 码垛机简介 21

4.1.1 码垛机性能参数 21

4.1.2 四自由度的实现 21

4.1.3 线性滑台简介 22

4.2 码垛机各部分设计安装 23

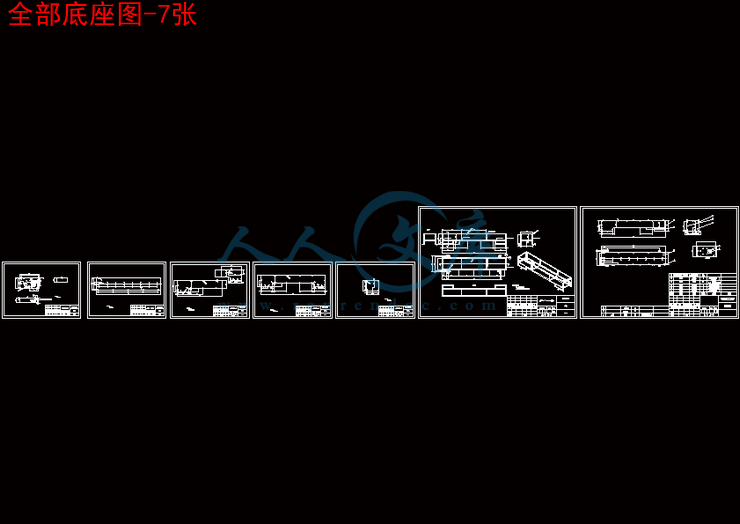

4.2.1 底座设计 23

4.2.2 底座高度尺寸计算 24

4.2.3 底座设计方案与材料选择 25

4.3 码垛机控制箱的设计 28

4.3.1 码垛机控制箱位置摆放 28

4.3.2 控制箱内电器元件 28

4.3.3 控制箱外形设计及材料选择 29

4.4 机械爪的设计 29

4.4 主要电器元件介绍 35

第五章 外部控制系统 36

第六章 结束语 38

参考文献 39

致 谢 40

第一章 绪 论

1.1 柔性制造系统的背景

随着科学技术的迅速发展,新产品不断涌现,产品的复杂程度也随之增加,而产品的市场寿命日益缩短,更新换代加速,中、小批量生产占有越来越重要的地位。面临这—新的局面,必须大幅度提高制造柔性和生产效率,缩短生产周期,保证产品质量,降低能耗,从而降低生产成本,以获得更好的经济效益。柔性制造系统正是在这种形势下应运而生的。从机械制造行业来看现在FMS不仅能完成机械加工而且还能完成钣金加工、锻造、焊接、装配、铸造和激光、电火花等特种加工以及喷漆、热处理、注塑和橡胶模制等工作。FMS相对于传统加工有以下优点:

川公网安备: 51019002004831号

川公网安备: 51019002004831号