【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

矿用半挂车分动器设计

摘 要

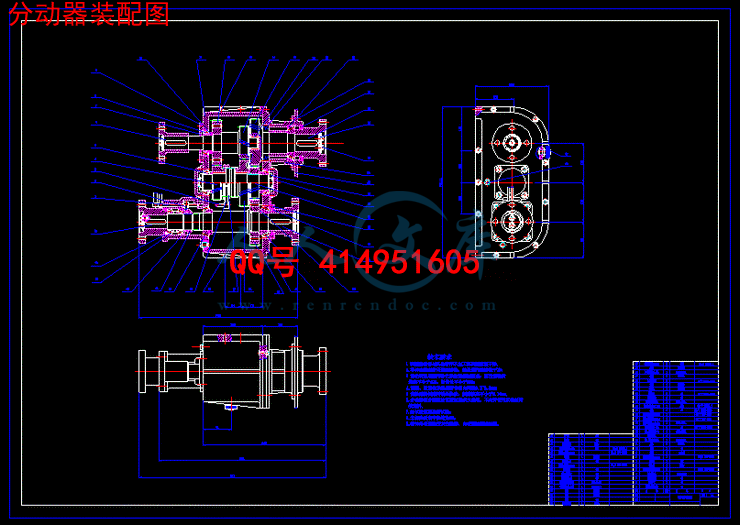

本设计主要了解矿用半挂车,以及矿用半挂车的载重,常见矿用半挂车的分动器基本原理和基本结构的型式,矿用半挂车属于非公路运输用的重型和超重型自卸挂车主要承担大型矿山、工程等运输任务,工程方面,比一般载重车更耐用,工作环境恶劣、负载重、劳动强度高。分动器的功用就是将分动器输出的动力分配到各驱动桥,并且进一步增大扭矩。分动器也是一个齿轮传动系统,它单独固定在车架上,其输入轴与分动器的输出轴用万向传动装置连接,分动器的输出轴有若干根,分别经万向传动装置与各驱动桥相连。本设计主要说明了分动器的设计计算过程。设计部分较详细的叙述了分动器的设计过程,选择结构方案、主要参数、齿轮设计、轴设计、计算校核、其他结构部件的设计。

关键词:矿用半挂车分动器;齿轮;轴

Design of Power Transfer Case for the mine Semi-trailer

Abstract

This design mainly know mine semi-trailer, and mine semi-trailer truck, common mining semi-trailer transfer basic principle and basic structure of the model, mining semi-trailer belongs to the highway transportation of heavy and super-heavy dump trailer mainly bear the transportation tasks such as large-scale mining, engineering, engineering, the truck is more durable than normal, work environment bad, negative load, high labor intensity. Transfer function is to transfer the output of the power allocated to each drive axle, and further increase torque. Transfer box is a gear transmission system, it separately fixed on the frame, its input shaft connected to the transfer box output shaft with a universal transmission device, there are a few root transfer box output shaft, respectively by the universal driving device connected with the drive axle. This design mainly illustrates the design and calculation of transfer process. Design part in detail describes the transfer of the design process, choose the structure scheme, the main parameter, design of gear, shaft structure design, calculation and checking, other parts of the design

Keywords: mine semi-trailer; gear;shaft

目 录

1绪论…………………………………………………………………………………1

1.1概述.....................................................................................................................…1

1.2分动器简介..................…..…………………………………………………….....1

1.2.1带轴间差速器的分动器…………....................................................................1

1.2.2不带轴间差速器的分动器…………................................................................2

1.2.3装有超越离合器的分动器…………................................................................2

1.3分动器的构造及原理....................................................................................…2

1.4分动器的轮型..................…..………………………………..……………...…....2

1.4.1分时四驱............................................................................................................2

1.4.2全时四驱............................................................................................................2

1.4.3适时驱动............................................................................................................3

1.5分动器结构方案的选择.........................................................................................3

1.6完成本课题的工作方案及进度计划(按周次填写)…..……………………...5

1.7毕业设计的工作量要求…..………………………………...……………………5

2分动器主要参数的选择………………………………………………………6

2.1档数及传动比……………………………………………………………………6

2.2中心距.................…………………………………………………………… …7

2.3齿轮参数.................…………………………………………………… ……7

2.3.1齿轮模数...........................................................................................................7

2.3.2齿形、压力角、螺旋角β和齿宽................................. .............................8

2.4高低档传动比及其齿数的确定……… ………………………………………9

2.4.1确定抵挡齿轮的齿数........................................................................................9

2.4.2确定高挡齿轮的齿数........................................................................................9

3分动器齿轮强度计算及材料选择…………………………………………11

3.1齿轮失效形式与原因…………………………………………………………11

3.2齿轮强度计算与校核…………………………………………………………11

3.2.1斜齿轮弯曲应力..............................................................................................11

3.2.2齿轮接触应力..................................................................................................12

4轴的计算与校核………………………………………………………………14

4.1轴的失效形式及设计准则……………………………………………………14

4.2轴的计算..............……………………………………………………………14

4.2.1输入轴的初选及校核......................................................................................14

4.2.2输出轴的初选及校核......................................................................................15

4.3分动器轴承的选择………………………………………………...............……15

4.3.1轴的结构设计..................................................................................................15

4.4键的计算...............................................................................................................18

5同步器……………………………………………………………………………20

5.1同步器的结构类型…………………………………………………………20

5.2锁环式同步器的工作原理……………………………………………………20

5.3惯性锁止式同步器的主要结构参数…………………………………………22

5.3.1摩擦锥面的半锥角和摩擦系数f………………………………………....22

5.3.2摩擦锥面的平均半径和同步锥环的镜像厚度.....................................22

5.3.3摩擦锥面的工作面宽..................................................................................22

5.3.4锁止角β...........................................................................................................23

5.3.5同步时间与轴向推力.............................................................................23

5.3.6同步器摩擦副的材料......................................................................................23

6工艺分析................................................................................................................24

6.1壳体加工工艺.......................................................................................................24

6.2拨叉加工工艺.......................................................................................................25

6.3齿轮加工工艺.......................................................................................................25

6.4轴的加工工艺.......................................................................................................25

6.5总成的装配...........................................................................................................26

7总结…………………………………………………………………......…………28

参考文献………………………………………………………………………...…29

致谢……………………………………………………………………………….....30

毕业设计(论文)知识产权声明…………………………………………….....31

毕业设计(论文)独创性声明………………………………………………….....….32

1 绪论

1.1概述

本课题主要研究矿用半挂车分动器设计,在多轴驱动的汽车上,为了将变速器输出的动力分配到各驱动桥,通常装有分动器。矿用半挂车的牵引车是在矿车底盘基础上改进设计的双后桥驱动结构,针对桥驱动结构设计中的关键设备—专用分动器,通过分析双后桥驱动原理以及分动器的原理和功能,根据动力分配、底盘结构、传递扭矩及传动方式的要求,确定出分动器的设计方案和整体结构特点[1]。在近百年中,汽车设计技术也经历了由经验设计发展到以科

川公网安备: 51019002004831号

川公网安备: 51019002004831号