【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目 录

摘 要 I

Abstract II

1绪论 1

1.1多功能封口机设计背景 1

1.2设计目的与意义 1

1.3设计内容 2

2方案设计 5

2.1方案设计方法 5

2.2任务要求键入章标题(第 2 级) 5

2.3多功能封口机工作原理 5

2.4方案选择 6

2.5 总体布置 7

3结构设计 8

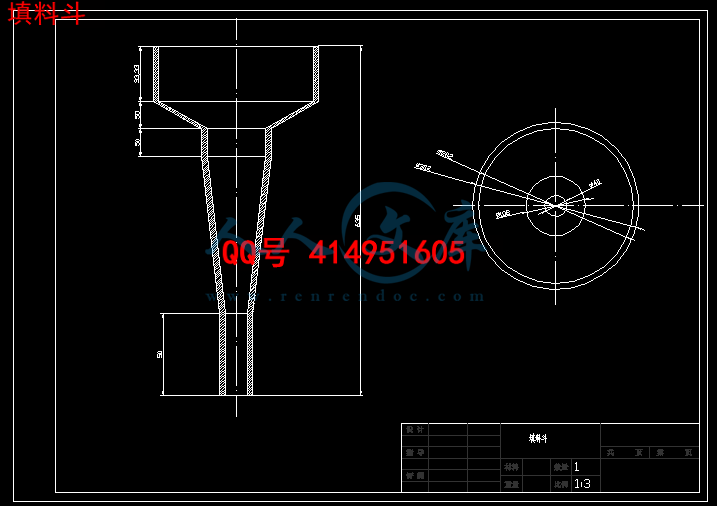

3.1成形器 8

3.1.1袋形选择 8

3.1.2成形器种类及选择 8

3.1.3成形器相关计算 9

3.2总体方案设计 11

3.2.1电机的选择 11

3.2.2运动参数计算 12

3.2.3各传动轴参数计算 12

3.2.4主轴最小直径 13

3.2.5功率分配 14

3.3链轮设计 14

3.4纵封辊 17

3.5横封辊 17

3.6齿轮设计 18

3.7切断装置 20

3.8导辊 21

4 结论 22

致谢 23

参考文献 24

文献综述 25

文献翻译 31

摘 要

本文是针对多功能封口机的设计以及说明。

多功能封口机,即多功能包装机,因为在一台机器上完成两个或两个以上的包装工序故称之为多功能包装机。其主要由引导成型部分、填料部分、封制部分以及切断部分组成。包装材料被安置在卷桶上,经由导辊引导至成型器处,在成型器作用下完成包装袋的基本成型,同时完成填料,此时由横封装置以及纵封装置完成对袋的封口工作,之后由切断装置切断,使之分离为完整的包装袋个体。

本文对多功能包装机的工作原理、结构等做了分析及说明,并在现有多功能封口机的基础上进行设计,设计出一套可行的方案并进行相关计算,使用制图软件画出其相应工程图。

本文使用Autocad2010对其进行绘图,Autocad2010是比较基础的工程制图软件,能够使机械的平面结构简单、清晰地表现出来,是当下十分常见与实用的制图软件之一。

关键词:多功能封口机 包装 Autocad

Abstract

This paper is aimed at the multifunctional sealing machine design and description.

Multifunctional sealing machine, the multifunction packing machine, because the completion of two or more than two of the packaging process is called multifunction packing machine in a machine. It is mainly composed of lead forming part, filling, sealing and cutting part part part. Packaging materials are placed in the roll barrel, through the guide roller guide to forming device, the completion of the basic molding packing bag in the shaper, at the same time, filler, this time by the sealing device and longitudinal sealing device to complete sealing of the bag, then cut by the cutting device, so that the separation for the complete package bag of individual.

This paper makes analysis and description of the working principle, multi function packaging machine structure, and machine design based on the existing multifunctional sealing, designed for the relevant calculation a set of feasible solutions and, using the mapping software to draw the corresponding engineering drawings.

In this paper, Autocad2010 drawing of engineering drawing software, Autocad2010 is the basis of comparison, can make the plane mechanical structure simple, clearly demonstrated, is now very common and practical drawing software.

Keywords: Multifunctional sealing machine sealing Autocad

川公网安备: 51019002004831号

川公网安备: 51019002004831号