【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目录

摘要 ····························································2

前言·····························································3

第一章 材料工艺分析

1.1 材料特性···············································4

1.2 模具设计方面需注意·····································4

1.3 注塑工艺条件···········································4

1.4 成型性能···············································4

第二章 制品结构及尺寸分析

2.1 制品结构分析···········································5

2.2 制品尺寸精度分析·······································5

第三章 模具结构设计

3.1 分型面的选择···········································6

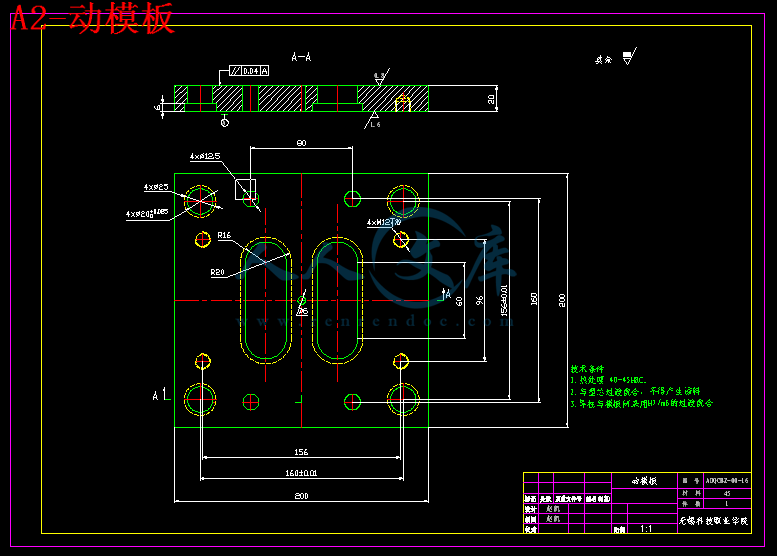

3.2 型腔布局···············································7

3.3 浇注系统的确定·········································8

3.4 注射机的选择···········································12

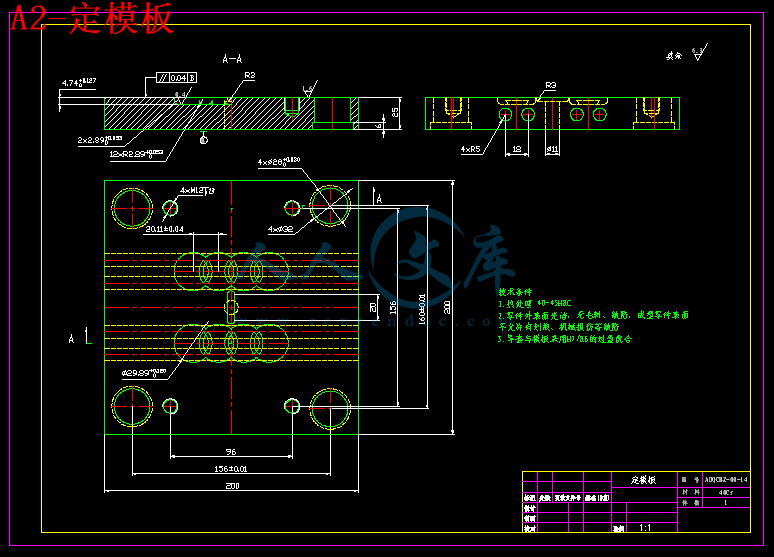

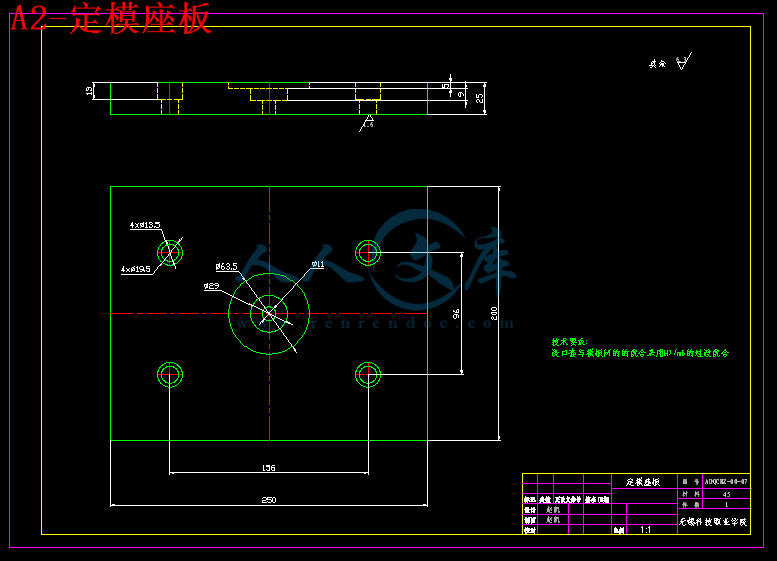

3.5 模架的选择·············································14

3.6 成型零部件设计·········································15

3.7 推出机构设计···········································17

3.8 排气系统设计···········································18

3.9 冷却系统设计···········································19

附 毕业设计小结···········································20

谢辞···················································21

参考文献···············································22

[摘 要]

本课题是江苏省普通高等院校模具设计与制造专业,专题综合实践项目之一。是对模具专业学生的一次综合考察。

设计者需通过课题的CAD二维工程图纸,进行模具设计。其中包括:产品材料、工艺、结构、尺寸精度分析,成型零件尺寸计算,合理选择注塑机及标准模架。并用CAD2006完成模具总装图及成型零件图的绘制,完成成型零件的加工工艺卡编写等。

本设计主用软件CAD2006,通过CAD2006完成相关元件的二维工程图纸。并结合Pro/ENGINEER4.0进行辅助设计。经过反复修改,最终完成课题设计。

关键词:模具 标准模架 CAD2006

Abstract

This topic is ordinary colleges and universities in Jiangsu Province mold design and manufacturing expertise, special comprehensive practice items.Is to mold a comprehensive survey of students.

Designers have passed the two-dimensional capacitance Block CAD engineering drawings, for mold design.These include: product materials, processes, structure, size precision analysis, forming part size calculation, a reasonable choice and standard mold injection molding machine.And use CAD2006 complete the mold assembly diagram and forming part drawing of the drawing, forming part of the processing technology to complete the preparation of such cards.

The design of the main software CAD2006, with the completion of related components over CAD2006 two-dimensional engineering drawings.Carried out in conjunction with Pro/ENGINEER4.0-aided design.After repeated changes to the final completion of the design issues.

Keywords:Mold Standard Mold CAD2006

前言

模具制造是我国经济建设中的一项重要产业,起着振兴和发展我国模具工业的重要作用,正日益受到人们的重视和关注。“模具是工业生产的基础工艺装备”也已经成为广大业内人士的共识。在电子、汽车、电机、电器、仪器、仪表、家电和通信等产品中,60%~80%的零部件都要依靠模具成形。用模具生产制件,具备高精度、高复杂程度、高一致性、高生产率和低消耗,是其他加工制造方法所不能比拟的。模具又是“效益放大器”,用模具生产的最终产品的价值,往往是模具自身价值的几十倍、上百倍,尤其是在冲压技术相对落后的中国,制造出优质的模具以及生产出高质量的产品势在必行。

经过本次的课题研究主要掌握模具设计的方法及工序,巩固和加深对机械二维、三维的制图能力。设计过程中锻炼查阅文献和资料、自我设计的能力,培养和提升自己的创新能力,增强独立思考问题和解决问题的能力。在对模具设备的结构设计和理论计算上,掌握模具设备的主要结构与性能、工艺适应性与技术参数。从而能根据成型的生产要求、模具结构等因素,经济、有效的使用设备,合理的选择工艺,正确的设计模具,保证成型生产能够经济、合理的进行,提高自身在成型工艺和模具方面的综合着机水平,提高自身解决实际问题的能力。

在这次毕业设计过程中,我得到了袁小江老师的指导,他给了我很多意见和建议,使我的设计更加完善,在此特别的感谢他。同时也感谢那些曾经授课的老师,他们使我学习、获得了专业知识,对设计起了重要作用。也要感谢那些帮过我的同学,他们给我提了很多好的建议。

第一章 材料工艺分析

1.1材料特性

ABS无色、无味、呈微黄色。密度为1.02~1.05g/cm³(注射注射级密度为1.05g/cm ³)。具有优越的综合性能:强度高、刚性好,硬度、耐冲击性、制品表面光泽性好,耐磨性好。具有有良的成型加工性,尺寸稳定性好,着色性能、电镀性好。

1.2在模具设计方面需注意:

⑴需要采用较高的料温与模温,浇注系统的流动阻力要小。

⑵注意选择浇口位置,避免浇口与熔接痕位于影响制品外观的部位。

⑶合理设计顶出脱模结构,推出力过大时,制品表面易“发白”、“变混”(顶白)。

川公网安备: 51019002004831号

川公网安备: 51019002004831号