【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目录

前 言 1

第一章 概 论 2

1.1 塑料模具的特点与发展趋势 2

1.1.1塑料模具的重要性 2

1.1.2塑料模具的特点 2

1.1.3塑料成型技术的发展趋势 3

1.2注射模设计要求与程序 4

1.2.1基本要求与注意事项 4

1.2.2设计程序 4

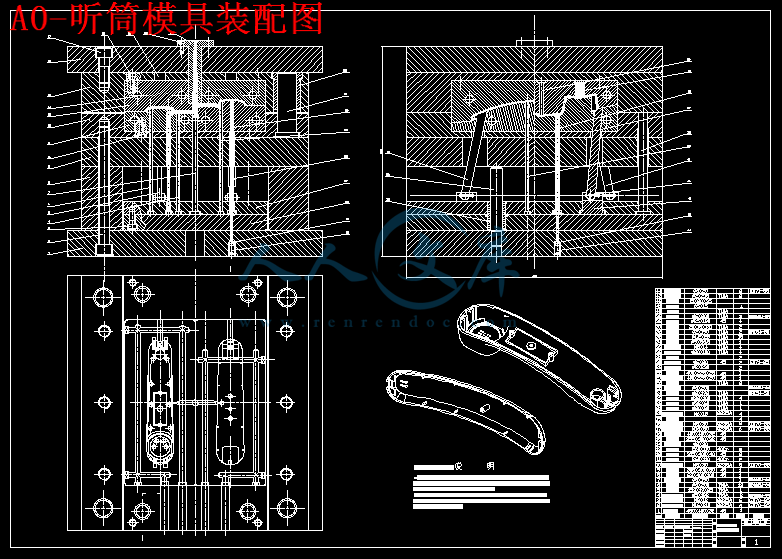

第二章 听筒注射模具设计过程 8

2.1塑件分析 8

2.2塑件材料的成型特性与工艺参数 10

2.2.1ABS基本特性 10

2.2.2 ABS主要用途 10

2.2.3 ABS成型特点 10

2.3成型设备的选择 11

2.3.1型腔数量及排列方式 12

2.3.2注射容量的的估计计算 12

2.3.3注射机的选定及其技术参数 12

2.4分型面和排气槽的设计 13

2.4.1分型面的设计 13

2.4.2排气槽设计 14

2.5浇注系统的设计 14

2.5.1主流道的设计 15

2.5.2分流道的设计 15

2.5.3浇口的设计 16

2.5.4冷料穴的设计 18

2.6成型零部件的设计与计算 18

2.6.1成型零件的结构设计 19

2.6.2成型零件的工作尺寸计算 19

2.6.3模具型腔侧壁和底板厚度的计算 24

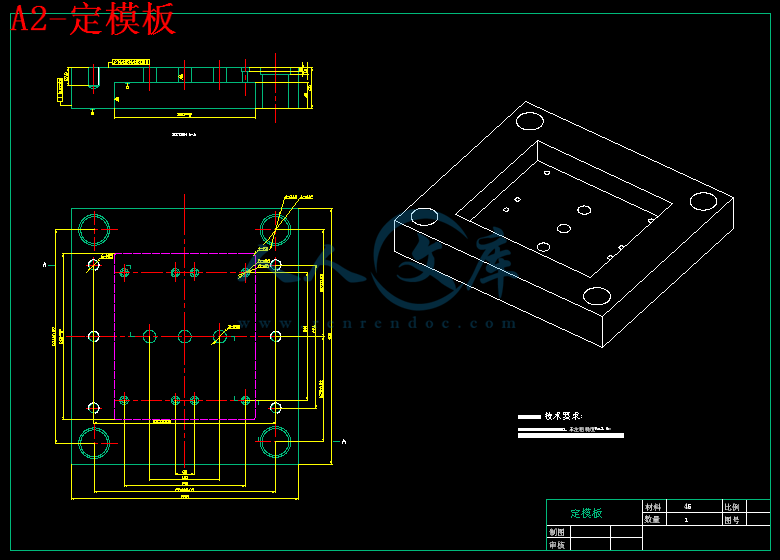

2.6.4模架的选取 26

2.7合模导向机构的设计 27

2.8侧向分型与抽芯机构的设计 28

2.8.1确定抽芯形式与结构 28

2.8.2确定抽芯机构的结构尺寸 29

2.9脱模机构的设计 30

2.9.1脱模力的计算 30

2.9.2脱模机构的结构形式 31

2.9.3脱模机构的导向与复位 32

2.10温度调节系统的设计与计算 32

2.10.1冷却水道回路的布置 32

2.10.2冷却时间的计算 33

2.11注射机的校核 33

2.11.1工艺参数的校核 33

2.11.2安装参数校核 34

总 结 35

致 谢 36

参考文献 37

在目前激烈的市场竞争中,产品投入市场的迟早往往是成败的关键。模具是高质量、高效率的产品生产工具,模具开发周期占整个产品开发周期的主要部分。因此,如何在保证质量、控制成本的前提下缩短模具开发周期是值得认真考虑的问题。

模具开发周期包括模具设计、制造、装配与试模等阶段。所阶段出现的问题都会对整个开发周期都有直接的影响,但有些因素的作用是根本的、全局性的。人的因素及设计质量就是这样的因素。

缩短设计周期并提高设计质量是缩短整个模具开发周期的关键之一。模块化设计就是利用产品零部件在结构及功能上的相似性,而实现产品的标准化与组合化。大量实践表明,模块化设计能有效减少产品设计时间并提高设计质量。因此本文探索在模具设计中运用模块化设计方法。

某些模具零件(如凸凹模)的形状和尺寸由产品决定因而无法在模块设计时预见到,所以只能按常见形状设计模块(如圆形或矩形的冲头),适用面窄;某些模具零件(如冲压模的工件定位零件)虽然互相配合执行某一功能,但它们的空间布置难寻规律与共性,因此即使按功能划分也不能产生模块。

本文介绍了注射模具的特点及发展趋势,叙述了电话机听筒注射模具设计与计算的详细过程,介绍了该塑件成型工艺、注射模具的结构特点与工作过程, 阐述了在有斜滑块抽芯的注射模设计中应注意的事项

关键词:听筒,注射模;斜滑块;侧抽芯

Abstract

Launching a new product in time is the key to success in the current fierce market competition. Mold as the tool which is used to ensure the high-quality and high-efficiency production, its development circle takes up the main part of the entire development circle of the product.

Thus, it is necessary to consider how to shorten the entire development circle of model on the premise that the quality can be ensured and the cost can be cut.

The development of model includes designing, producing, assembling and examining steps etc. the problems which appear in every step can influence the whole developing process directly. There are many factors influence the development process, some of them influence it radically, entirely, such as the designer and the quality of design.

Shortening the period and enhancing the quality of design are the keys to shorten to entire development circle of model. Modular design refers to utilize the similarity in construction and function between the components to achieve the standardization and assibilation of products. Practices show that modular design is an effective way to reduce the time and enhance the quality of products .This paper mainly explores the method of applying the modular design in model design.

Shape and size of some model spares, such as convex and cave mold are decided by certain product, as the result, they can not be foresaw in the

model piece design, people only can design the model according to the common shapes such as the blunt head of circular or rectangle. Meanwhile, although some model spares such as blunt press the fixed position spare can work in coordination to carry out certain function, it is hard to find the regulation and similarity in their spaces arrangement, so it also cannot produce a model piece even according to their function.

The characteristics and developments of injection mould will be introduced in this paper. The designing and calculating of injection mould of microphone will be stated in detail. The forming process of the product and the structure characteristics as well as working process of the injection mould will be introduced .The attention should be paid in the design of the injection mould for the part with lifters also will be stated.

Key words: microphone, injection mould; lifter; core pulling

川公网安备: 51019002004831号

川公网安备: 51019002004831号