【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

文档包括:

说明书一份,59页,23000字左右.

任务书一份.

实习报告一份.

PPT答辩稿一份.

图纸共11张:

A0-整体图.dwg

A0-装配图.dwg

A1-凹模.dwg

A1-支撑板.dwg

A2-定模座板.dwg

A2-动模座板.dwg

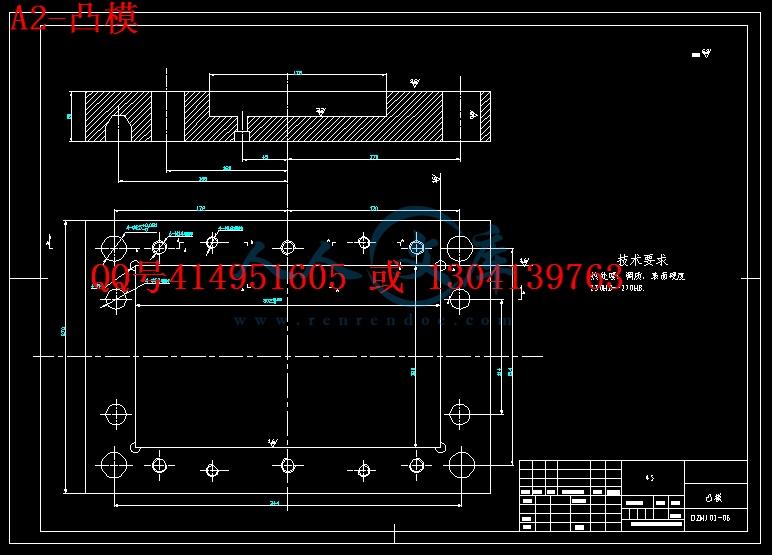

A2-凸模.dwg

A2-型芯.dwg

A3-充电器外形.dwg

A4-定位圈.dwg

A4-浇口套.dwg

摘 要

摘 要

分析了手机充电器外壳的工艺特点,介绍了手机充电器外壳上盖注射模结构及模具的工作过程。重点介绍了手机充电器外壳注射模结构的设计

方法。分析和阐述了模具型芯零件及各标准件的选材、热处理工艺,手机充电器外壳的塑件的结构要素,塑件的尺寸公差和精度的选择,塑件

的体积和质量的计算方法以及注射机的选择和校核。此手机充电器外壳注射模设计的结构特点是点浇口形式的单分型面的注射模。该模具结构

设计巧妙,操作方便,使用寿命长,塑件达到技术要求。

关键词:手机充电器外壳;注射模;型芯;型腔

Abstract

Has analyzed the handset battery charger outer covering craft characteristic, introduced the handset battery charger outer

covering top head injection mold structure and the mold work process. Introduced the handset battery charger outer covering

injection mold structure design method with emphasis. Analyzed and elaborated the mold core components selection, the heat

treatment craft, the handset battery charger outer covering model the member, model the size common difference and the

precision choice, model a volume and the quality computational method. This handset battery charger outer covering injection

mold designs the unique feature is the runner form three minute profiles injection molds, is lateral pulls out the core

injection mold. After production confirmation, this mold structural design ingenious, the ease of operation, the service life

is long, models to achieve the specification.

Key words: handset battery charger outer;covering injection mold;slide;core.

目 录

第1章 绪 论 - 1 -

1.1 模具工业在国民经济中的地位 - 1 -

2.2 国模具技术的现状及发展趋势 - 1 -

第2章 塑件工艺分析 - 3 -

2.1 塑件的结构要素 - 3 -

2.1.1 ABS的使用性能 - 3 -

2.1.2 ABS材料的成形特点 - 3 -

2.1.3 ABS的成型工艺 - 4 -

2.2 注射成型工艺 - 4 -

第3章 塑件几何形状的设计 - 6 -

3.1 塑件几何形状的设计 - 6 -

3.1.1 脱模斜度 - 6 -

3.1.2 加强筋 - 6 -

3.1.3 塑件的圆角 - 7 -

3.1.4 塑件的壁厚 - 7 -

3.1.5 孔 - 7 -

3.1.6 支承面 - 7 -

3.2 塑件尺寸公差与精度 - 7 -

第4章 分型面及型腔数目的确定 - 9 -

4.1 型腔分型面及型腔数目 - 9 -

4.2 型腔、型芯的结构 - 9 -

4.2.1 型腔的结构设计 - 10 -

4.2.2 型芯的结构设计 - 10 -

第5章 注射机的选取和校核 - 11 -

5.1 根据型腔数选择注射机 - 11 -

5.1.1 根据塑件形状估算其体积和重量 - 11 -

5.1.2 选择注射机 - 11 -

5.2 校核注射机有关工艺参数 - 12 -

5.2.1 注射量的校核 - 12 -

5.2.2 锁模力的校核 - 12 -

5.2.3 开模行程的校核 - 13 -

第6章 成型零件的设计 - 13 -

6.1 成型零件的结构设计 - 13 -

6.1.1 凹模的结构设计 - 14 -

6.1.2凸模和型芯的结构设计 - 14 -

6.2 成型零件工作尺寸的计算 - 14 -

6.2.1凹模与凸模工作尺寸 - 15 -

6.2.2凹模与凸模尺寸计算 - 15 -

6.2.3型腔的强度设计 - 16 -

第7章 浇注系统的设计 - 17 -

7.1 主浇道的设计 - 17 -

7.2 分浇道的设计 - 17 -

7.3 浇口的设计 - 18 -

7.4 冷料穴的设计 - 18 -

第8章 结构零件的设计 - 19 -

8.1 脱模机构的设计 - 19 -

8.1.1 机构的设计原则 - 19 -

8.1.2 脱模机构分类 - 19 -

8.2 脱模机构的导向与复位 - 20 -

8.2.1导向零件 - 20 -

8.2.2 复位零件 - 20 -

第9章 塑料模具钢的选用 - 21 -

9.1 塑料模具材料应具有的性能 - 21 -

9.2 模具选材原则 - 21 -

第10章 模具结构及其工作过程 - 24 -

9.1 模架的选择 - 24 -

9.2 模具工作过程 - 24 -

结 论 - 26 -

致 谢 - 27 -

参 考 文 献 - 28 -

川公网安备: 51019002004831号

川公网安备: 51019002004831号