LS型螺旋输送机设计【10张CAD图纸+毕业论文】【矿山输送机械】

收藏

资源目录

压缩包内文档预览:(预览前20页/共40页)

编号:349632

类型:共享资源

大小:2.45MB

格式:RAR

上传时间:2014-10-31

上传人:好资料QQ****51605

认证信息

个人认证

孙**(实名认证)

江苏

IP属地:江苏

45

积分

- 关 键 词:

-

ls

螺旋

输送

设计

cad

图纸

毕业论文

矿山

机械

- 资源描述:

-

【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

目 录

1. 引言…………………………………………………………………………………1

2. 螺旋输送机主要构件的设计和选用………………………………………1

2.1 螺旋输送机的一般结构…………………………………………………………1

2.1.1 螺旋输送机的类型………………………………………………………………2

2.1.2 螺旋输送机的特点………………………………………………………………3

2.2 螺旋输送机的主要构件…………………………………………………………4

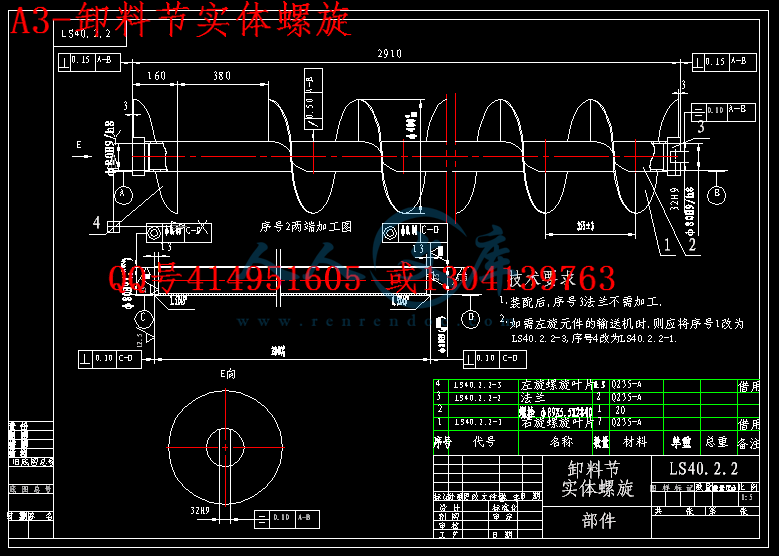

2.2.1 螺旋体……………………………………………………………………………4

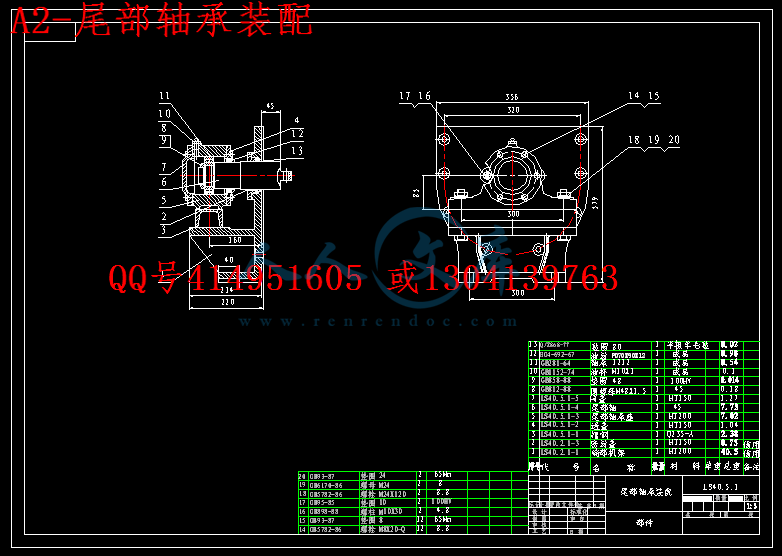

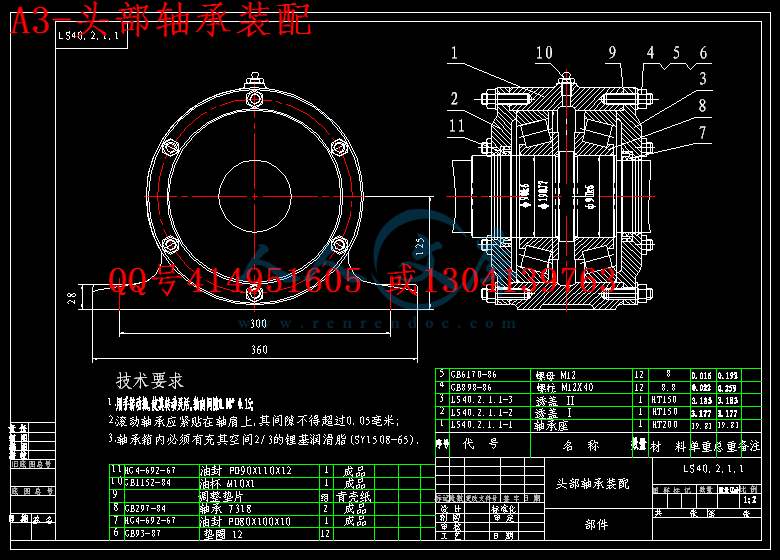

2.2.2 轴承………………………………………………………………………………9

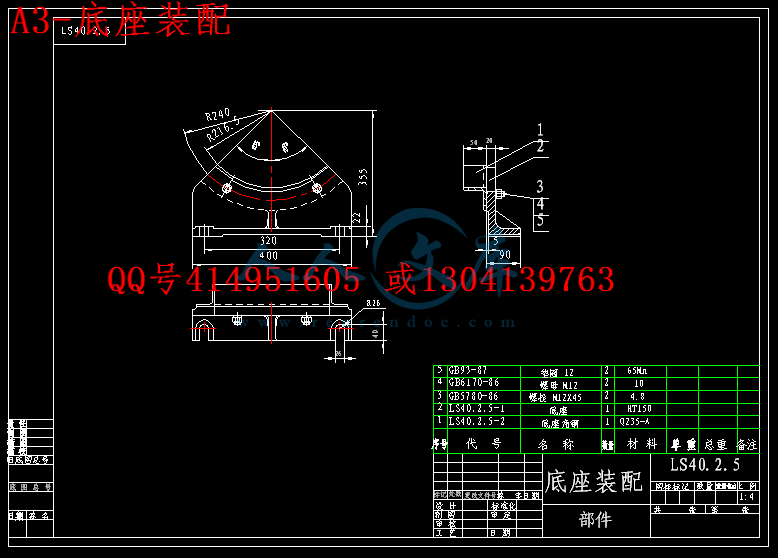

2.2.3 机槽………………………………………………………………………………11

2.2.4 驱动装置…………………………………………………………………………15

3. 水平螺旋输送机的工作过程分析…………………………………………17

3.1 物料的运动分析和叶片的设计…………………………………………………17

3.1.1 物料的运动分析…………………………………………………………………17

3.1.2 叶片的设计………………………………………………………………………21

4. 总体设计计算……………………………………………………………………26

4.1 原始资料…………………………………………………………………………26

4.1.1 被输送物料的名称及特性………………………………………………………26

4.1.2 选型要求…………………………………………………………………………26

4.2 螺旋输送机的设计计算…………………………………………………………26

4.2.1 确定螺旋直径……………………………………………………………………26

4.2.2 确定螺旋转速……………………………………………………………………27

4.2.3 功率的计算………………………………………………………………………27

4.2.3 电机的选择………………………………………………………………………28

5. 总体尺寸设计……………………………………………………………………29

5.1 LS螺旋输送机的外形及尺寸……………………………………………………29

5.1.1 长度与组合………………………………………………………………………30

5.2 附件尺寸…………………………………………………………………………30

5.2.1 进料口……………………………………………………………………………30

5.2.2 出料口……………………………………………………………………………32

6. 用solidworks对连接轴进行有限元分析………………………………33

7. 结论…………………………………………………………………………………38

8. 参考文献……………………………………………………………………………39

9. 致谢…………………………………………………………………………………40

附录A 英文资料

附录B 中文翻译

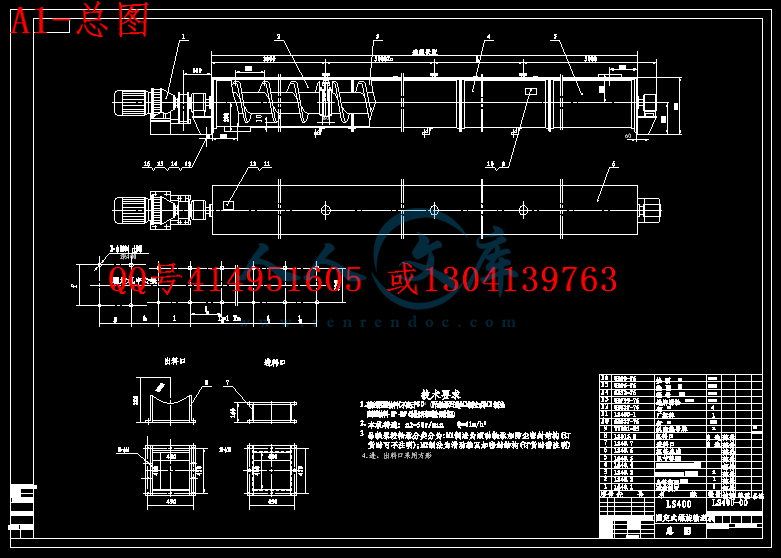

LS螺旋输送机设计

摘要 :LS型螺旋输送机是采用国际标准产品,等效采用ISO1050-75标准,设计制造符合ZBJ1005.1-2-88专业标准。其技术指标先进,结构新颖,是我国九十年代替代GX型螺旋输送机的换代产品。LS型螺旋输送机的应用范围:螺旋机被广泛地使用在各种工业部门,如建材、电力、化工、冶金、煤炭、机械、轻工、粮食及食品行业。

LS螺旋输送机对输送物料的要求,粉状、粒状和小块状物料。如:水泥、煤粉、粮食、化肥、灰渣、砂子等,物料温度不得超过200℃,螺旋机不宜输送易变质的、粘性大的、易结块的物料。因为这些物料在输送时在一螺旋上,并随之旋转而不向前移动,或者在吊轴承处形成物料的积塞而会粘结使螺旋机不能正常工作。LS螺旋机的工作环境应在-20℃~50℃之间,允许稍微倾斜使用,最大倾角不得超过20℃。

本次LS螺旋输送机设计主要分析了粉状物料输送的相关参数。 要求被输送物料的名称及特性来设计,按螺旋输送机驱动方式,我们选择了单端驱动。查阅了相关资料,才完成图纸模型到图纸数据,这都是强有力的效果。

关键词:LS螺旋输送机 物料 应用范围 技术参数。

指导老师签名:

1 引言

螺旋输送机俗称“绞龙”,是一种无挠性牵引构件的连续输送设备,它借助旋转螺旋输送叶片的推力将物料沿着机槽进行输送。螺旋输送机被广泛地使用在各种工业部门,如建材、电力、化工、冶金、煤炭、机械、轻工、粮食及食品行业。螺旋输送机对输 滚动,滑轮轴承互换结构,并设防尘密封装置,密封件用尼龙用塑料,因而其密封性好,耐磨性强,阻力小,寿命长。滑动轴瓦有需加润滑剂的铸铜瓦,合金而磨铸铁瓦和铜基石墨少油润滑瓦,出料端设有清扫装置,整机噪声低,适应性强,操作维修方便,进出料口位置布置灵活。

LS型螺旋输送机的特点及应用范围:

LS型螺旋输送机是采用国际标准产品,等效采用ISO1050-75标准,设计制造符合ZBJ1005.1-2-88专业标准。其技术指标先进,结构新颖,是我国九十年代替代GX型螺旋输送机的换代产品。

LS型螺旋输送机与GX型相比,其头部、尾部轴承移至壳体外,吊轴承采用滚动,滑轮轴承互换结构,并设防尘密封装置,密封件用尼龙用塑料,因而其密封性好,耐磨性强,阻力小,寿命长。滑动轴瓦有需加润滑剂的铸铜瓦,合金而磨铸铁瓦和铜基石墨少油润滑瓦,出料端设有清扫装置,整机噪声低,适应性强,操作维修方便,进出料口位置布置灵活。

LS型螺旋输送机的应用范围:螺旋机被广泛地使用在各种工业部门,如建材、电力、化工、冶金、煤炭、机械、轻工、粮食及食品行业。

LS螺旋输送机对输送物料的要求,粉状、粒状和小块状物料,如:水泥、煤粉、粮食、化肥、灰渣、砂子等,物料温度不得超过200℃,螺旋机不宜输送易变质的、粘性大的、易结块的物料。因为这些物料在输送时会粘结在一螺旋上,并随之旋转而不向前移动,或者在吊轴承处形成物料的积塞而使螺旋机不能正常工作。LS螺旋机的工作环境应在-20℃~50℃之间,允许稍微倾斜使用,最大倾角不得超过20℃。

2 螺旋输送机主要构件的设计和选用

2.1螺旋输送机的一般结构

螺旋输送机的一般结构如图1-1所示。它由料槽、螺旋叶片和转动轴组成的螺旋体、两端轴承、中间悬挂轴承及驱动装置所组成。螺旋体由两端轴承和中间悬挂轴承支承,由驱动装置驱动。螺旋输送机工作时,物料由进料口进入料

- 内容简介:

-

.Automation in Construction 10 2001 477486rlocaterautconSemi-automatic control system for hydraulic shovelHirokazu Araya), Masayuki KagoshimaMechanical Engineering Research Laboratory, Kobe Steel, Ltd., Nishi-ku, Kobe Hyogo 651 2271, JapanAccepted 27 June 2000AbstractA semi-automatic control system for a hydraulic shovel has been developed. Using this system, unskilled operators canoperate a hydraulic shovel easily and accurately. A mathematical control model of a hydraulic shovel with a controller wasconstructed and a control algorithm was developed by simulation. This algorithm was applied to a hydraulic shovel and itseffectiveness was evaluated. High control accuracy and high-stability performance were achieved by feedback plusfeedforward control, nonlinear compensation, state feedback and gain scheduling according to the attitude. q2001 ElsevierScience B.V. All rights reserved.Keywords: Construction machinery; Hydraulic shovel; Feedforward; State feedback; Operation1. IntroductionA hydraulic shovel is a construction machinerythat can be regarded as a large articulated robot.Digging and loading operations using this machinerequire a high level of skill, and cause considerablefatigue even in skilled operators. On the other hand,operators grow older, and the number of skilledoperators has thus decreased. The situation calls forhydraulic shovels, which can be operated easily bywxany person 15 .The reasons why hydraulic shovel requires a highlevel of skill are as follows.1. More than two levers must be operated simulta-neously and adjusted well in such operations.)Corresponding author.E-mail address: arayahrknedo.go.jp H. Araya .2. The direction of lever operations is differentfrom that of a shovels attachment movement.For example, in level crowding by a hydraulicshovel, we must operate three leversarm, boom,.bucket simultaneously to move the top of a bucket.along a level surface Fig. 1 . In this case, the leveroperation indicates the direction of the actuator, butthis direction differs from the working direction.If an operator use only one lever and other free-doms are operated automatically, the operation be-comes very easily. We call this system a semi-auto-matic control system.When we develop this semi-automatic controlsystem, these two technical problems must be solved.1. We must use ordinary control valves for auto-matic control.2. We must compensate dynamic characteristicsof a hydraulic shovel to improve the precisionof control.0926-5805r01r$ - see front matter q2001 Elsevier Science B.V. All rights reserved.PII: S0926-5805 00 00083-2()H. Araya, M. KagoshimarAutomation in Construction 10 2001 477486478Fig. 1. Level crowding of an excavator and frame model of anexcavator.We have developed a control algorithm to solvethese technical problems and confirm the effect ofthis control algorithm by experiments with actualhydraulic shovels. Using this control algorithm, wehave completed a semi-automatic control system forhydraulic shovels. We then report these items.2. Hydraulic shovel modelTo study control algorithms, we have to analyzenumerical models of a hydraulic shovel. The hy-draulic shovel, whose boom, arm, and bucket jointsare hydraulically driven, is modeled as shown in Fig.2. The details of the model are described in thefollowing. 2.1. Dynamic model 6Supposing that each attachment is a solid body,from Lagranges equations of motion, the followingexpressions are obtained:22JuqJ cosuyuuqJ cosuyuuqJ sinuyuuqJ sinuyuuyK sinust.11l1212213133121221313311122J cosuyuuqJuqJ cosuyuuyJ sinuyuuqJ sinuyuuyK sinust.1212122223233121212323322222J cosuyuuqJ cosuyuuqJuyJ sinuyuuqJ sinuyuuyK sinust.131312323233313131232333331 .2.2where,Js m 1q m q m 1 q I ;Js111g1231112m 1 1qm 1 1; Jsm 1 1; Jsm 12q21g231g31331g3222g2m 12qI ; Jsm 1 1; Jsm 12qI ; K s3222332g3333g331.m 1qm 1 qm 1g;K s m 1qm 1g;1g1213122g233K sm 1g; and gsgravitational acceleration.33g3uis the joint angle,tis the supply torque, 1 isiiithe attachment length, 1is the distance betweengithe fulcrum and the center of gravity, m is the massiof the attachment, I is the moment of inertia aroundithe center of gravity subscripts is13, mean boom,.arm, and bucket, respectively .2.2. Hydraulic modelEach joint is driven by a hydraulic cylinder whoseflow is controlled by a spool valve, as shown in Fig.3. We can assume the following:1. The open area of a valve is proportional to thespool displacement.2. There is no oil leak.3. No pressure drop occurs when oil flows throughpiping.()H. Araya, M. KagoshimarAutomation in Construction 10 2001 477486479Fig. 2. Model of hydraulic shovel.4. The effective sectional area of the cylinder isthe same on both the head and the rod sides.In this problem, for each joint, we have thefollowing equation from the pressure flow character-istics of the cylinder:ViA h sKX P ysgn XPyP2(. .ii0iisii1i1iKwhen,KscB2rgP sP yP0ii1i1i2iwhere, A seffective cross-sectional area of cylin-ider; h scylinder length; X sspool displacement;iiP ssupply pressure; P scylinder head-side pres-si1isure; P scylinder rod-side pressure; V soil vol-2iiume in the cylinder and piping; B sspool width;igsoil density; Ksbulk modulus of oil; and csflow coefficient.2.3. Link relationsIn the model shown in Fig. 1, the relation be-tween the cylinder length change rate and the attach-mentrotationalangularvelocityisgivenas .follows: 1 boomfu.11h1su1OA OC sinuqb.1111sy,22(OA qOC q2OA OC cosuqb.111111 .2 arm.fu,u212h2suyu21.O A O C sinuyuqbqa22222122sy,22(.O A qO C q2O A O C cosuyuqbqa222222222122 .3 bucketwhenO D sO B sB C sC D33333333YhA B B C sinuyuqgyaqu.3333332332fu,ussy.3 .32322Yuyu(A BqB Cq2A B B C cosuyuqgyaqu.323333333332332()H. Araya, M. KagoshimarAutomation in Construction 10 2001 477486480Fig. 3. Model of hydraulic cylinder and valve.2.4. Torque relationsFrom the link relations of Section 2.3, the supplytorquetis given as follows, taking cylinder frictioniinto consideration:tsyfuP1 A qfu,uP1 A.1111121222qfu,uP1 A y Cfuu.32333c1111qsgnuFfu4. ./1111tsyfu,uP1 A y Cfu,uuyu./221222c221221qsgnuyuFfu,u.5/212212tsyfu,uP1 A y Cfu,uuyu./332333c332332qsgnuyuFfu,u.5/323323Where, Cis the viscous friction coefficient andciF is kinetic frictional force of a cylinder.i2.5. Response characteristics of the spoolSpool action has a great effect on control charac-teristics. Thus, we are assuming that the spool hasthe following first-order lag against the referenceinput.1XX sX .5 .iiTSq1spiWhere, XXis the reference input of spool dis-iplacement and Tis a time constant.spi3. Angle control systemAs shown in Fig. 4, the angleuis basicallycontrolled to follow the reference angleuby posi-gtion feedback. In order to obtain more accuratecontrol, nonlinear compensation and state feedbackare added to the position feedback. We will discussdetails of these algorithms as follows.3.1. Nonlinear compensationIn the ordinary automatic control systems, newcontrol devices such as servo valves are used. In oursemi-automatic system, in order to realize the coexis-tence of manual and automatic operations, we mustuse the main control valves, which are used inmanual operation. In these valves, the relation be-tween spool displacement and open area is nonlinear.Then, in automatic operation, using this relation, thespool displacement is inversely calculated from therequired open area, and the nonlinearity is compen-.sated Fig. 5 . .Fig. 4. Block diagram of control systemu.()H. Araya, M. KagoshimarAutomation in Construction 10 2001 477486481Fig. 5. Nonlinear compensation.3.2. State feedbackBased on the model discussed in Section 2, if thedynamic characteristics for boom angle control arelinearized in the vicinity of a certain standard condi-tionspool displacement X, cylinder differential10.pressure P, and boom angleu, the closed-loop11010transfer function can be expressed byKpusug6 .1132a s qa s qa sqK210pwhere, Kis position feedback gain; andpfuACfu.1101c1110a sq02 AP yP.KP yP(1s111001s1110XJqJ cosuXqJ cosuXquX?4.10111221323a s12 A fuP yP.1110s1110CfuV.c11101qA KKP yP(101s1110V JqJ cosuXqJ cosuXquX?4.1111221323a s.2A fuKKP yP.(111001s1110This system has a comparatively small coefficienta , so the response is oscillatory. For instance, if in1our large SK-16 hydraulic shovel, Xis 0, the10coefficients are given as a s2.7=10y2, a s6.001=10y6, a s1.2=10y3. Addingthe acceleration2feedback of gain K , to this the upper loop in Fig.a.4 , the closed loop transfer function is given asKpusu.7 .1r132a s q a qKs qa sqK.21a0pAdding this factor, the coefficient of s2becomeslarger, thus, the system becomes stable. In this way,acceleration feedback is effective in improving theresponse characteristics.However, it is generally difficult to detect acceler-ation accurately. To overcome this difficulty, cylin-der force feedback was applied instead of accelera-.tion feedback the lower loop in Fig. 4 . In this case,cylinder force is calculated from detected cylinderpressure and filtered in its lower-frequency portionwx7,8 . This is called pressure feedback.4. Servo control systemWhen one joint is manually operated and anotherjoint is controlled automatically to follow the manualoperation, a servo control system must be required.For example, as shown in Fig. 6, in the level crowd-ing control, the boom is controlled to keep the arm.end height Z calculated fromuanduto refer-12ence Zr. In order to obtain more accurate control, thefollowing control actions are introduced.()H. Araya, M. KagoshimarAutomation in Construction 10 2001 477486482 .Fig. 6. Block diagram of control system Z .4.1. Feedforward controlCalculating Z from Fig. 1, we obtainZs1 cosuq1 cosu.8 .1122 .Differentiating both sides of Eq. 8 with respectto time, we have the following relation,Z1 sinu22usyyu.9 .121 sinu1 sinu1111The first term of the right-hand side can be taken.as the expression feedback portion to convert Z tou, and the second term of the right-hand side is the1.expressionfeedforward portionto calculate howmuchushould be changed whenuis changed12manually.Actually,uis determined using the difference2value of Du. To optimize the feedforward rate,2feedforward gain Kis tunned.ffThere may be a method to detect and use the arm.operating-lever condition i.e. angle instead of armangular velocity, since the arm is driven at an angu-lar velocity nearly proportional to this lever condi-tion.4.2. Adaptie gain scheduling according to the atti-tudeIn articulated machines like hydraulic shovels,dynamic characteristics are greatly susceptible to theattitude. Therefore, it is difficult to control the ma-chine stably at all attitudes with constant gain. Tosolve this problem, the adaptive gain schedulingaccording to the attitude is multiplied in the feedback.loop Fig. 6 . As shown in Fig. 7, the adaptive gain.KZ or Kuis characterized as a function of twovariables,uXand Z.uXmeans how the arm is22extended, and Z means the height of the bucket.5. Simulation resultsThe level crowding control was simulated byapplying the control algorithm described in Section 4to the hydraulic shovel model discussed in Section 2.In the simulation, our large SK-16 hydraulic shovel.was employed. Fig. 8 shows one of the results. Fiveseconds after the control started, load disturbance()H. Araya, M. KagoshimarAutomation in Construction 10 2001 477486483Fig. 7. Gain scheduling according to the attitude.was applied stepwise. Fig. 9 shows the use of feed-forward control can reduce control error.6. Semi-automatic control systemBased on the simulation, a semi-automatic controlsystem was manufactured for trial, and applied to theSK-16 shovel. Performance was then ascertained byfield tests. This section will discuss the configurationand functions of the control system.6.1. ConfigurationAs illustrated in Fig. 10, the control system con-sists of a controller, sensors, manmachine interface,and hydraulic control system.The controller is based on a 16-bit microcomputerwhich receives angle input signals of the boom, arm,and bucket from the sensor; determines the conditionof each control lever; selects control modes andcalculates actuating variables; and outputs the resultsfrom the amplifier as electrical signals. The hy-Fig. 8. Simulation result of level crowding.draulic control system generates hydraulic pressureproportional to the electrical signals from the electro-magnetic proportional-reducing valve, positions thespool of the main control valve, and controls theflow rate to the hydraulic cylinder.In order to realize high-speed, high-accuracy con-trol, a numeric data processor is employed for theFig. 9. Effect of feedforward control on control error of Z.()H. Araya, M. KagoshimarAutomation in Construction 10 2001 477486484Fig. 10. Schema of control system.controller, and a high-resolution magnetic encoder isused for the sensor. In addition to these, a pressuretransducer is installed in each cylinder to achievepressure feedback.The measured data are stored up to the memory,and can be taken out from the communication port.6.2. Control functionsThis control system has three control modes,which are automatically switched in accordance withlever operation and selector switches. These func-tions are the following .1 Level crowding mode: during the manual armpushing operation with the level crowding switch,the system automatically controls the boom and holdsthe arm end movement level. In this case, the refer-ence position is the height of the arm end from theground when the arm lever began to be operated.Operation of the boom lever can interrupt automaticcontrol temporarily, because priority is given to man-ual operation. .2Horizontal bucket lifting mode: during themanual boom raising operation with the horizontalbucket lifting switch, the system automatically con-trols the bucket. Keeping the bucket angle equal tothat at the beginning of operation prevents materialspillage from the bucket. .3Manual operation mode: when neither thelevel crowding switch nor the horizontal bucket lift-ing switch are selected, the boom, arm, and bucketare controlled by manual operation only.The program realizing these functions is primarilywritten in C language, and has well-structured mod-ule to improve maintainability.7. Results and analysis of field testWe put the field test with the system. We con-firmed that the system worked correctly and theeffects of the control algorithm described in Chaps. 3and 4 were ascertained as follows.7.1. Automatic control tests of indiidual attach-mentsFor each attachment of the boom, arm, and bucket,the reference angle was changed 58 stepwise fromthe initial value, and the responses were measured;thus, the effects of the control algorithm described inChap. 3 were ascertained.()H. Araya, M. KagoshimarAutomation in Construction 10 2001 477486485Fig. 11. Effect of nonlinear compensation on boom angle.7.1.1. Effect of nonlinear compensationFig. 11 shows the test results of boom lowering.Because dead zones exist in the electro-hydraulicsystems, steady-state error remains when simple po-sition feedback without compensation is applied OFF.in the figure . Addition of nonlinear compensation.ON in the figure can reduce this error.7.1.2. Effect of state feedback controlFor the arm and bucket, stable response can beobtained by position feedback only, but adding ac-celeration or pressure feedback can improve fast-re-sponse capability. As regards the boom, with onlythe position feedback, the response becomes oscilla-tory. Adding acceleration or pressure feedback madethe response stable without impairing fast-responsecapability. As an example, Fig. 12 shows the testresults when pressure feedback compensation wasapplied during boom lowering.7.2. Leel crowding control testControl tests were conducted under various con-trol and operating conditions to observe the controlFig. 12. Effect of pressure feedback control on boom angle.Fig. 13. Effect of feedforward control on control error of Z.characteristics, and at the same time to determine theoptimal control parameters such as the control gains.shown in Fig. 6 .7.2.1. Effects of feedforward controlIn the case of position feedback only, increasinggain Kto decrease error DZ causes oscillation duepto the time delay in the system, as shown by AOFFBin Fig. 13. That is, Kcannot be increased. Apply-ping the feedforward of the arm lever value describedin Section 4.1 can decrease error without increasingKas shown by AONB in the figure.p7.2.2. Effects of compensation in attitudeLevel crowding is apt to become oscillatory at theraised position or when crowding is almost com-pleted. This oscillation can be prevented by changinggainKaccording to the attitude, as has beenpdiscussed in Section 4.2. The effect is shown in Fig.14. This shows the result when the level crowdingwas done at around 2 m above ground. Compared tothe case without the compensation, denoted by OFFin the figure, the ON case with the compensationprovides stable response.Fig. 14. Effect of adaptive gain control on control error of Z.()H. Araya, M. KagoshimarAutomation in Construction 10 2001 4774864867.2.3. Effects of control interalThe effects of control interval on control perfor-mance were investigated. The results are:1. when the control interval is set to more than100 ms, oscillation becomes greater at attitudeswith large moments of inertia; and2. when the control interval is less tha

- 温馨提示:

1: 本站所有资源如无特殊说明,都需要本地电脑安装OFFICE2007和PDF阅读器。图纸软件为CAD,CAXA,PROE,UG,SolidWorks等.压缩文件请下载最新的WinRAR软件解压。

2: 本站的文档不包含任何第三方提供的附件图纸等,如果需要附件,请联系上传者。文件的所有权益归上传用户所有。

3.本站RAR压缩包中若带图纸,网页内容里面会有图纸预览,若没有图纸预览就没有图纸。

4. 未经权益所有人同意不得将文件中的内容挪作商业或盈利用途。

5. 人人文库网仅提供信息存储空间,仅对用户上传内容的表现方式做保护处理,对用户上传分享的文档内容本身不做任何修改或编辑,并不能对任何下载内容负责。

6. 下载文件中如有侵权或不适当内容,请与我们联系,我们立即纠正。

7. 本站不保证下载资源的准确性、安全性和完整性, 同时也不承担用户因使用这些下载资源对自己和他人造成任何形式的伤害或损失。

人人文库网所有资源均是用户自行上传分享,仅供网友学习交流,未经上传用户书面授权,请勿作他用。

川公网安备: 51019002004831号

川公网安备: 51019002004831号