【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

文档包括:

说明书一份,47页,18500字左右.

任务书一份.

翻译一份.

图纸共5张:

A0-张紧装置装配图.dwg

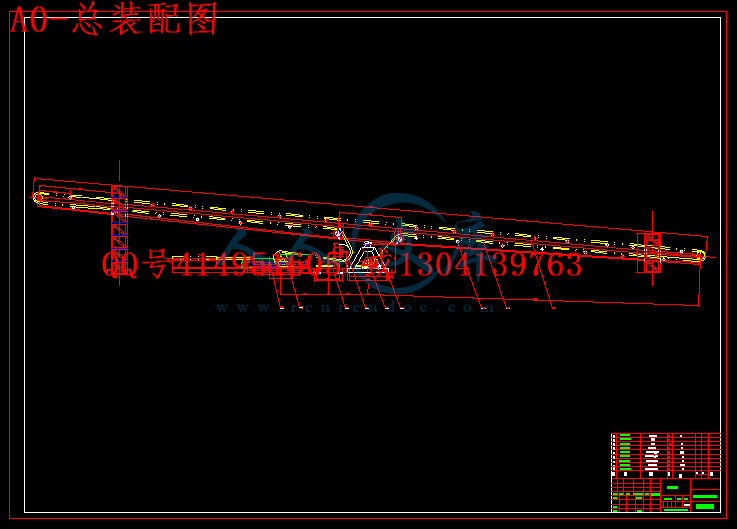

A0-总装配图.dwg

A1-液压缸设计.dwg

A2-车轮子成品.dwg

A3-液压系统原理图.dwg

目 录

摘要 Ⅰ

Abstract Ⅱ

第1章 绪论 1

1.1 输送机自动张紧装置的一般概念 1

1.2 输送机张紧装置的分类 1

1.3 液压自动张紧装置与其它张紧装置的类比 2

第2章 总体设计 3

2.1 设计任务 3

2.2 设计方案的确定 3

2.2.1 液压自动张紧装置的特点 3

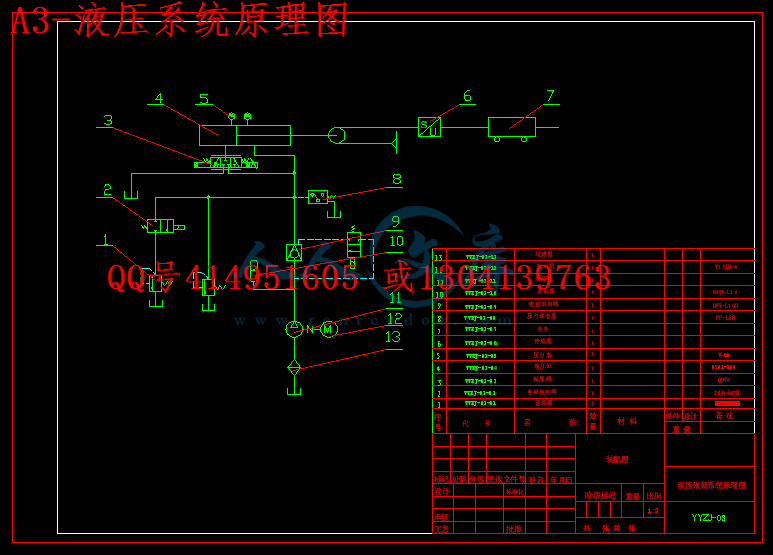

2.2.2 液压张紧系统工作原理 3

2.2.3 总体设计方案的确定 5

第3章 各元件的确定 6

3.1 油缸的选择和计算 6

3.2 液压油液的功能和基本要求 7

3.3 液压泵的选择及计算 9

3.4 电动机的确定 9

3.5 各种阀类的选择 10

3.5.1 电磁换向阀的选择 10

3.5.2 溢流阀的选择 11

3.5.3 压力继电器的选择 12

3.5.4 压力表的选择 13

3.5.5 滤油器的选择 14

3.5.6 蓄能器的选择 15

3.5.7 伺服阀的选择 16

3.5.8 液控单向阀的选择 18

3.6 其它元件的选择 20

3.6.1 滑轮的选择 20

3.6.2 钢丝绳的选取 20

3.6.3 液压泵站的选择与安装 20

第4章 管路的设计 22

4.1 管路的确定 22

4.2 吸油管的设计 22

4.3 压油管的设计 23

4.4 液压系统中的压力损失验算 23

第5章 主要部件的设计计算及强度校核 26

5.1 油缸后的支座的设计及强度校核 26

5.2 液压缸活塞杆上的耳环的设计及强度设计 27

第6章 设计分析 29

结论 31

致谢 32

参考文献 33

专题 34

附录1 42

附录2 49

摘要

输送机时橡胶和纤维织品两者复合而成的制品,在应用中的重锤张进装置,在运行一段时间后,重锤会自动下降一段距离,使输送带变长。这说明输送带发生了蠕变,在启动、制动过程中也会产生蠕变现象。此时张紧装置就必须进一步收缩才不会发生打滑现象。

由此可见,张紧装置是保证带式输送机正常运转必不可少的重要部件。该论文主要介绍了带式输送机的自动张紧装置的设计过程,详细的介绍了各个液压元件的选取。自动张紧装置的设计是张紧装置的设计的一个重大变革。

关键词:自动张紧装置 带式输送机 液压张紧系统

Abstract

This paper mainly introduced based on the PRO—ENGINEERING three dimensional entity design software to the Y0X500 model fluid strength coupler design and the assistance manufacture process; Has in detail given the fluid strength coupler shaping process aswell as utilizes PRO—ENGINEERING to the fluid strength coupler spare part design and the assembly process, utilized the PRO—ENGINEERING grass in the design process to draw, modules fully and so on components, assembly, engineering plat as well as movement simulation, basically has realized the design ingenious, convenient quickly, the efficiency and the reliability higher the merit which could not achieve in the traditional design process. Next, this article also elaborated very much about the fluid strength coupler aspect comprehensive knowledge.

Key word:The fluid strength coupler module limits the moment operational factor assembly constrained motion simulation

川公网安备: 51019002004831号

川公网安备: 51019002004831号