【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘 要

柱塞式往复泵的突出优点是:可获得高的排压,且流量与压力无关,适应输送介质十分广泛,吸入性能好,效率高,泵的性能不随压力和输送介质粘度的变动而变动.在当今世界能源紧缺的形势下,往复泵作为节能产品,在石油开发、管道输煤、煤气化工、电站排渣、矿山开采等方面起着重要作用,而且在压力容器检测和实现现代化石油化工工业全面自动化方面也是不可缺少的品种.近年来,其产量明显增长,证实了它在国民经济发展中的地位.

柱塞泵主要用于国内上有关的国民经济部门,该技术在我国的煤炭工业上也发挥其重要作用.

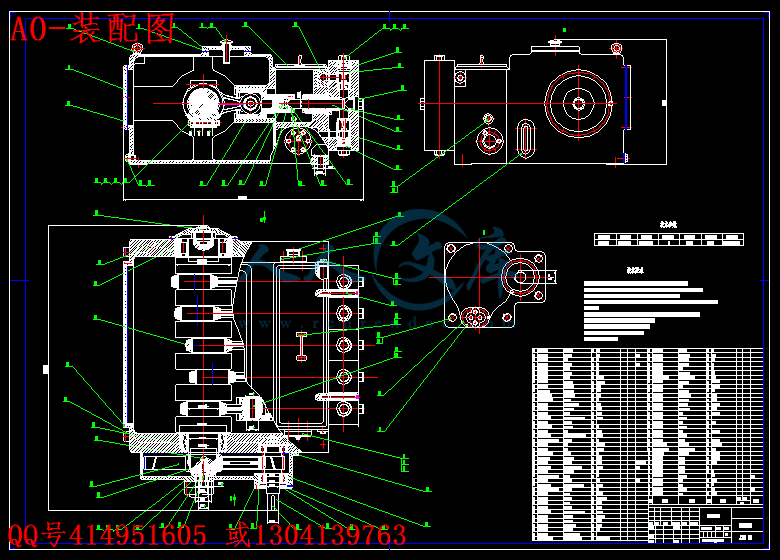

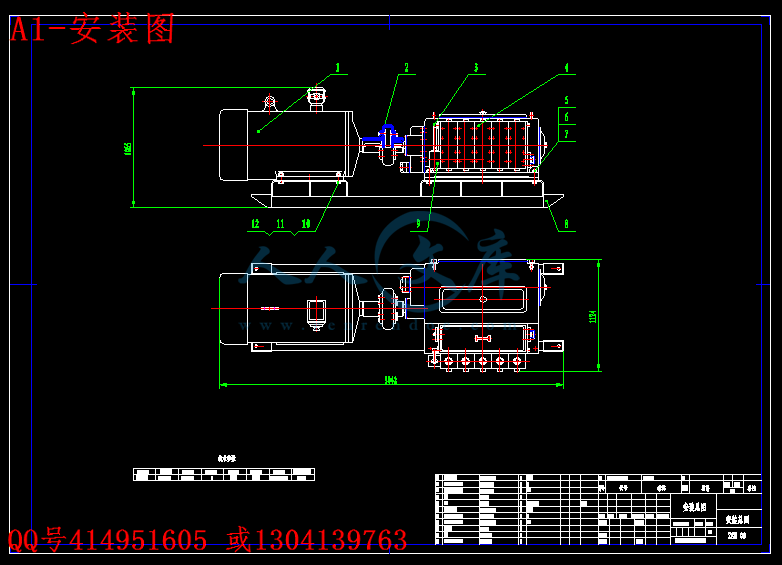

本说明书从以下几个方面介绍了五柱塞泵的设计.

本泵设计时尽可能考虑实现“条例化、通用化、标准化”以利加工、制造、使用和维修.首先搞清楚柱塞泵的分类及其发展历史再说明了柱塞泵的工作原理.

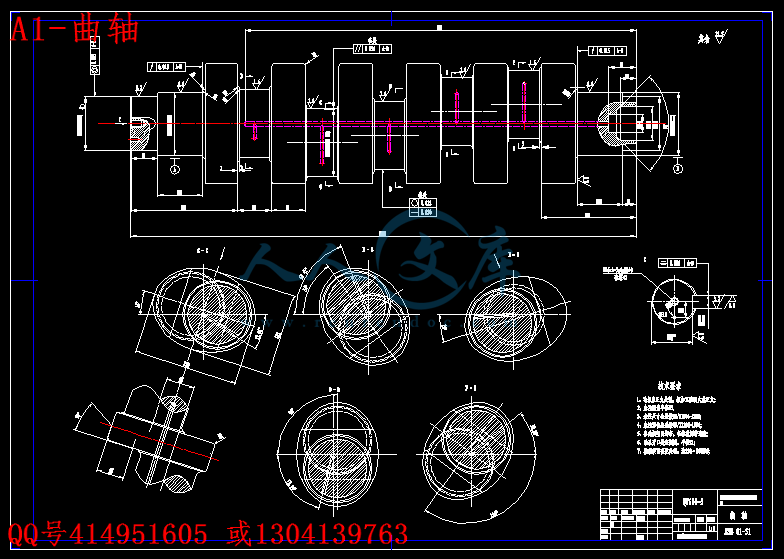

然后选择了电机、减速器等部件,最主要的是五曲轴及连杆液缸体等主要零部件的设计计算,最后是销、阀、箱体等的选择以及泵的保养、维修、安全使用等等.

关键词:柱塞泵 ;五柱塞 ;煤炭 ;分类

ABSTRACT

Reciprocating pump the plunger prominent advantages are: the row will be high pressure, and the flow has nothing to do with the pressure to adapt to a wide range transmission medium, inhalation good performance, high efficiency, not with the performance of pump pressure and transmission medium viscosity change in the movement . In today's world energy shortage situation,reciprocating pump as energy-saving products, in the development of oil, coal handling pipes, gas chemical industry, power plants slag discharge, such as mining plays an important role, and pressure vessels in the detection and modernization Petrochemical Comprehensive industrial automation is also indispensable varieties. In recent years, significant growth in its production, confirmed in the position of national economic development.

Piston pump used on the domestic economic sector, the technology in China's coal industry has also played an important role.

The statement from the following areas on a five-piston pump design.

The pump designed to achieve as much as possible to consider "the, universal, standardized" to facilitate the processing, manufacture, use and maintenance. Piston pump first make clear the historical development of the Classification and again that the principle of the piston pump.

Then select the motor, reducer, and other components, most notably the five-cylinder crankshaft and connecting rod, and other major parts of the design basis, the sale is final, valves, tank and pump, and so the choice of the maintenance, repair, security, use And so on.

Keyword:

Piston pump ;five plunger ;coal ;Category

目 录

一 概述 1

1.1往复泵的发展概况 1

1.2往复泵的原理及特点 1

1.2.1往复泵的原理 2

1.2.2往复泵的特点 2

1.3往复泵的分类 4

1.4往复泵的应用与发展 6

二 方案论证 9

2.1大流量柱塞泵 9

2.1.1柱塞泵的基本原理 9

2.1.2柱塞泵的分类 10

2.1.3方案确定 18

三 主要参数的设计 22

3.1泵内主要参数的计算 22

3.2原动机的选择 23

3.3运动与动力参数计算 24

四 齿轮传动设计 26

4.1齿轮的设计 26

4.1.1按照齿面接触疲劳强度计算 26

4.1.2齿轮的基本几何参数 32

4.2齿轮轴的结构设计及强度计算 33

4.2.1齿轮轴的结构设计 34

4.2.2齿轮轴的强度校核 35

4.2.3齿轮轴轴承寿命计算 40

五 传动端结构设计 41

5.1曲轴连杆机构的运动分析 41

5.2曲轴的结构设计 42

5.2.1主要尺寸的初步确定 45

5.2.2曲轴的静强度校核 47

5.3主轴承寿命计算 67

5.4连杆的结构设计 68

5.4.1确定连杆的主要尺寸 69

5.4.2连杆的强度及稳定性校核 74

5.4.3连杆大头轴瓦的计算 82

5.5十字头的结构设计 84

5.5.1确定十头字主要尺寸 85

5.5.2十字头强度校核 86

六 液力端结构设计 89

6.1液缸体的设计计算 89

6.2柱塞的结构尺寸 89

6.3泵阀(吸、排液阀)的设计计算 90

七 机体的结构设计 94

7.1机体主要尺寸的确定 95

结论 97

参考文献 98

翻译部分 100

英文原文 100

中文译文 107

致谢 112

一 概述

1.1往复泵的发展概况

往复泵是工业泵中不可缺少的一类产品.它的突出优点是:可获得高的排压,且流量与压力无关,适应输送介质十分广泛,吸入性能好,效率高,泵的性能不随压力和输送介质粘度的变动而变动.在当今世界能源紧缺的形势下,往复泵作为节能产品,在石油开发、管道输煤、煤气化工、电站排渣、矿山开采等方面起着重要作用,而且在压力容器检测和实现现代化石油化工工业全面自动化方面也是不可缺少的品种.近年来,其产量明显增长,证实了它在国民经济发展中的地位.

1.2 往复泵的原理及特点

1-泵缸 2-活塞 3-活塞杆

图1-1 往复泵装置简图

1.2.1 往复泵的原理

(一)主要部件:泵缸、活塞,活塞杆及吸人阀、排出阀。

(二)工作原理:活塞自左向右移动时,泵缸内形成负压,则贮槽内液体经吸入阀进入泵缸内。当活塞自右向左移动时,缸内液体受挤压,压力增大,由排出阀排出。

活塞往复一次,各吸入和排出一次液体,称为一个工作循环;这种泵称为单动泵。

活塞往返一次,各吸入和排出两次液体,称为双动泵。

活塞由一端移至另一端,称为一个冲程。

(三)往复泵的流量和压头:

往复泵的流量与压头无关,与泵缸尺寸、活塞冲程及往复次数有关。

单动泵的理论流量为:

QT=Asn

往复泵的实际流量比理论流量小,且随着压头的增高而减小,这是因为漏失所致。

往复泵的压头与泵的流量及泵的几何尺寸无关,而由泵的机械强度、原动机的功率等因素决定。

(四)往复泵的安装高度和流量调节:

往复泵启动时不需灌入液体,因往复泵有自吸能力,但其吸上真空高度亦随泵安装地区的大气压力、液体的性质和温度而变化,故往复泵的安装高度也有一定限制。

往复泵的流量不能用排出管路上的阀门来调节,而应采用旁路管或改变活塞的往复次数、改变活塞的冲程来实现。往复泵启动前必须将排出管路中的阀门打开。

往复泵的活塞由连杆曲轴与原动机相连。原动机可用电机,亦可用蒸汽机。往复泵适用于高压头、小流量、高粘度液体的输送,但不宜于输送腐蚀性液体。有时由蒸汽机直接带动,输送易燃、易爆的液体。

1.2.2 往复泵的特点

在离心式和容积式两大类泵中,往复泵属于容积式泵.亦即它也是借助工作腔里的容积周期性变化来达到输送液体的目的的;原动机的机械能经泵直接转化为输送液体的压力能;泵的流量只取决于工作腔容积变化值及其在单位时间内的变化次数(频率),而(在理论上)与排出压力无关.

往复泵和其它类型容积式泵的区别,仅在于它实现工作腔容积变化的方式和结构特点上;往复泵是借助于活塞(柱塞)在液缸工作腔内的往复运动(或通过隔膜、波纹管等挠性元件在工作腔内的周期性弹性变形)来使工作腔容积产生周期性变化的.在结构上,往复泵的工作腔是借助密封装置与外界隔开,通过泵阀(吸入阀和排出阀)与管路沟通或闭合.

往复泵这一实现工作容积变化的方式和结构特点,构成了这类类型泵性能参数和总体结构的一系列特点.这些特点也正是这类类型泵借以生存、竞争和发展的依据:

川公网安备: 51019002004831号

川公网安备: 51019002004831号