【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘要

由于工厂企业中很多磨床年代久远,其工作已远远达不到现代生产的要求。因此有必要对旧式的常规电动机控制系统进行技术改造,以可编程序控制器取代常规的继电器,以达到磨床的自动化控制。本文介绍了用可编程序控制器来对平面磨床控制系统进行现代化改造,简要叙述了老式成型平面磨床的工作原理及用PLC进行改造设计的方法和设计步骤,并给出PLC编程程序梯形图。改造后的磨床工作安全可靠,系统运行情况良好,磨削精度更高;利用PLC控制磨床运行,实现了磨床启动、停止、故障停止、紧急停止的功能,可根据运行要求灵活切换磨床的控制方式;提供过载,轻载,断相和电压不平衡保护;现场显示运行状态,实现智能化监控。并因所吸工件的不同灵活调节电磁吸盘的电流,并且显示数值大小。从而实现了磨床运行的自动化。PLC控制的特点使原机床控制大大的简单化,并且维修方便,易于检查。节省大量的继电器元件,使机床的工作效率更高。该项技术还可推广应用于其他辅机设备或其他领域的自动化控制改造中。

关键词 可编程序控制器;平面磨床;改造

Abstract

Because many grinder ages are remote in the manufacturing division, its work could not achieve the modern production by far the request . So it is necessary to carry on technological transformation to the old-fashioned regular motor control system and replace normal regulations by programmable preface controller of after electric appliances with attain grinding machine of automation control. This text introduced comes with the programmable controller to the surface grinding machine control system to make the modernized transformation, narrated the old style formation surface grinding machine's principle of work briefly and carries on the transformation design with PLC the method and the design procedure, and gives PLC the programming procedure trapezoidal chart . After the reformation of grinding machine work safety credibility, he systems operation situation is good, the grinding precision is higher; Using the PLC control grinder movement, realized the grinder to start, the stop, the breakdown to stop, the emergency stop function, might cut grinder's control mode nimbly according to the movement request; Provides the overload, the underloading, breaks and the voltage is not balanced protects; The scene demonstration running status, realizes the intellectualized monitoring. Because and attracts the work piece the different nimble adjustment magnet chuck electric current, and demonstration value size. Thus has realized the grinder movement automation. The PLC control's characteristic causes the original machine tool control big simplification, and services conveniently, easy to inspect. Saves the massive relay element, causes engine bed's working efficiency to be higher. This technology may also promote applies in other auxiliary engine equipment or in other domain automated control transformation.

Keywords Programmable logic controller Flat surface grinding machine Reformation

目 录

1 绪论 1

2 磨床的概述 3

2.1 磨床的介绍 3

2.2 世界平面磨床发展趋势 3

3 可编程控制器的概况 5

3.1 PLC的产生和特点及其发展动向 5

3.1.1 PLC的产生 5

3.1.2 PLC的定义 5

3.1.3 PLC的特点 6

3.1.4 PLC的发展趋势 7

3.2 PLC的系统结构和基本工作原理 8

3.2.1 PLC的系统结构 8

3.2.2 PLC的系统结构和基本工作原理 9

3.2.3 PLC的主要功能 10

3.2.4 PLC的应用设计步骤 11

3.3 PLC的选型原则 12

4 系统的总体设计 15

4.1 改造平面磨床的步骤 15

4.1.1 改造方案的确定 15

4.1.2 改造的技术准备 15

4.1.3 改造的实施 16

4.1.4 验收及后期工作 17

4.1.5 用PLC改造继电-接触式控制系统的步骤 18

4.2 控制线路控制改造要求 18

4.3 原设备电器的工作原理 19

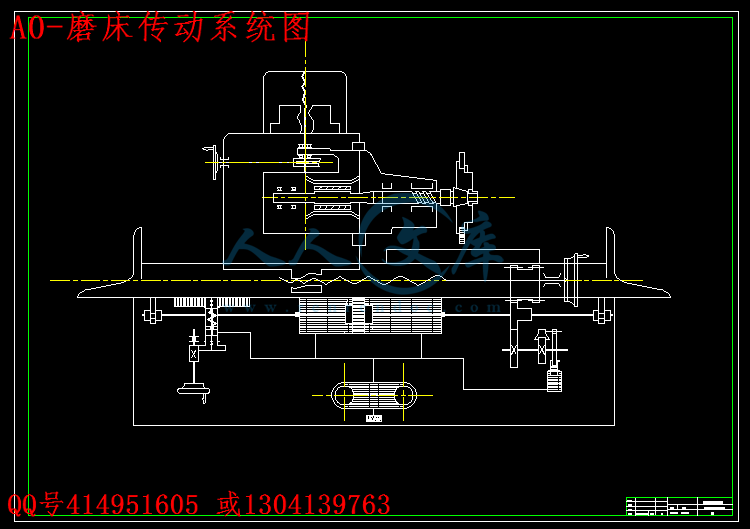

4.3.1 平面磨床主要结构和运动形式 19

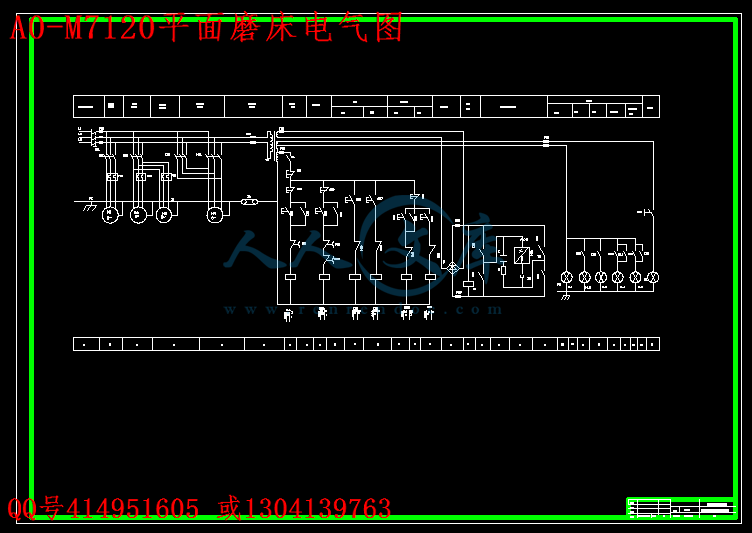

4.3.2 电气控制线路分析 20

4.4 分析控制对象,进行系统的硬件设计 23

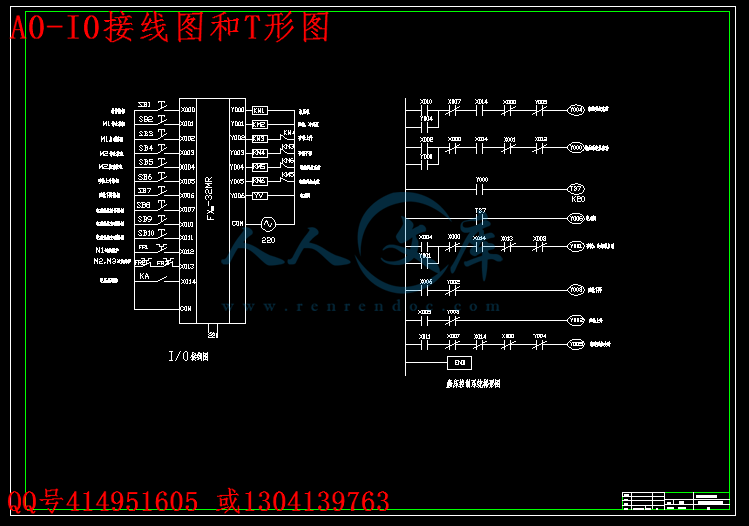

4.5 系统的软件设计 24

5 性能测试与分析 27

结论 28

致谢 29

参考文献 30

附录 31

中文翻译: 31

外文翻译: 38

川公网安备: 51019002004831号

川公网安备: 51019002004831号