【温馨提示】 购买原稿文件请充值后自助下载。

[全部文件] 那张截图中的文件为本资料所有内容,下载后即可获得。

预览截图请勿抄袭,原稿文件完整清晰,无水印,可编辑。

有疑问可以咨询QQ:414951605或1304139763

摘要

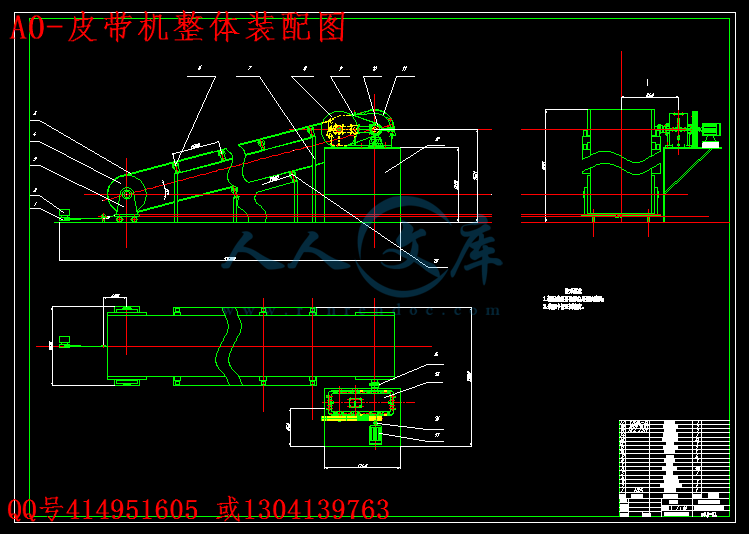

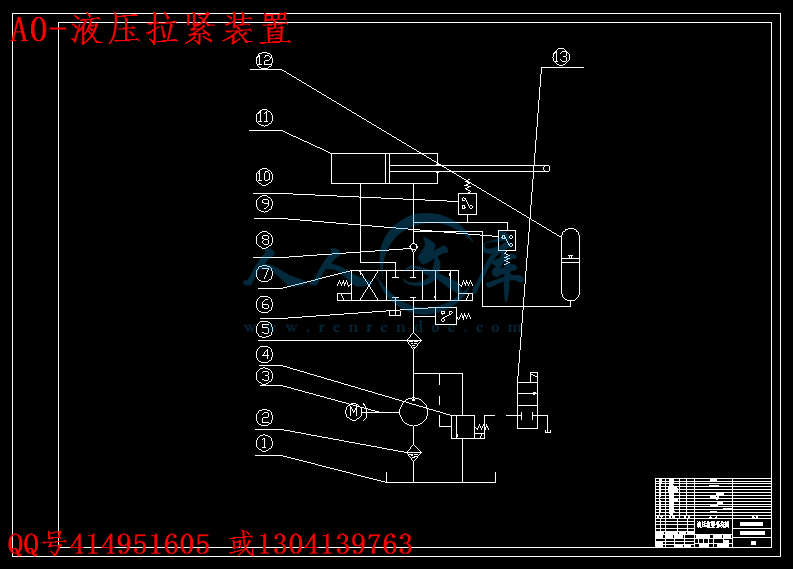

皮带机是一种运送物料的运输机械,它广泛地被用于矿山,码头,工厂等各种场合,但是不同的场合对皮带机的结构的要求是不同的,本设计是以矿山运输为背景,对皮带机的结构进行了设计和计算,本设计先对皮带机传动系统的运动进行了力学分析。对皮带机的保养与维护进行了详细的说明,在拉紧装置的设计中,为了对设备进行优化,弥补其他拉紧装置带来的不足,本设计采用液压拉紧装置对系统进行了拉紧,同时对其他辅助原件也做了必要的计算和选择。

关键词 皮带机;输送带;液压拉紧

Abstract

Belt- machine is a kind of machine which is used to transport the goods ,it is widely used in the place of mine,dock,factory and so on ,but they request different structures in different places. This article is on the ground of mine .and it briefly devises and computes the structure of Belt- machine .first,this article analyses the driving system of Belt- machine .and then gives the brief maintenance and maintain of how to employ the belt-machine .in the design of tense equipment , in order to better the equipment and make up the deficiency of other equipments .here we chose the hydraulic system , and the same time ,this article also gives the compute and chose of others’ assistant elements.

Keywords belt-machine conveyer belt hydraulic tension system

目 录

1 绪论 1

1.1 背景介绍 1

1.2 带式输送机的分类 1

1.3 各种带式输送机的特点 1

1.4 带式输送机的发展状况 2

1.5 带式输送机的结构和布置形式 3

1.5.1 带式输送机的结构 3

1.5.2 布置方式 4

1.6 带式输送机拉紧装置的设计要求 4

1.6.1 设计方案 4

1.6.2 主要技术特点 5

1.6.3 应用效果 5

2 皮带机的设计与计算 6

2.1 胶带运动阻力的计算 6

2.2 胶带张力的计算 7

2.3 牵引力及功率的计算 9

2.4皮带机常见故障的原因及处理方法 9

2.4.1.皮带运输机皮带跑偏的处理 9

2.5皮带机的安全使用及保养 10

2.5.1皮带机的安全使用 10

2.5.2皮带机的保养 11

3 液压拉紧装置的设计和计算 12

3.1拉紧装置的类型 12

3.2液压拉紧装置的特点 12

3.3 液压拉紧装置的设计计算 13

3.3.1 系统的工作原理 13

3.3.2 参数设定及工况分析 14

3.3.3 液压回路设计和工作过程分析 14

3.3.4 各元件的确定 15

3.3.5 液压油的确定 16

3.3.6 液压泵的选择和计算 18

3.3.7 电动机的确定 18

3.3.8 各种阀类的选择 19

3.3.9 管路的确定 19

3.3.10 液压系统中的压力损失验算 20

3.4系统基本回路 23

3.5 主要部件的设计计算及强度校核 25

3.5.1 油缸后支座的设计及强度校核 25

3.5.2 液压缸活塞上的耳环的设计及强度计算 26

3.5.3 销轴类的强度校核及结构设计 27

3.5.4 联轴器键的校核 27

3.5.5 焊缝的强度校核 27

3.6液压缸低速爬行的现象的原因及分析 28

3.6.1液压缸低速爬行的现象 28

3.6.2液压缸爬行现象的分析 28

3.6.3液压缸爬行现象的解决办法 29

3.7管接头处泄漏的预防 29

3.8管路预安装 30

3.8.1管路简介 30

3.8.2管路布置要求 30

3.8.3确定管子长度 30

3.8.4管子切断 31

3.8.5管子弯曲 31

3.8.6管子与接头焊接 31

3.8.7管路安装 31

结论 32

致谢 33

参考文献 34

附录 35

附录1 35

附录2 44

1 绪论

1.1 背景介绍

带式输送机特别是上运机是当代最为得力的输送设备之一,随着国民经济的不断发展,多种类型的工件传送机广泛的运用于冶金、矿山、水泥、码头、化工、粮食等行业的各种场合。同时在各种场合对不同的工况所使用的工件传输机也不尽相同。拉紧装置是煤矿井下用带式输送机不可缺少的重要组成部分。拉紧装置主要有螺旋拉紧,重力式拉紧,钢丝绳绞车式拉紧和液压拉紧。其中液压拉紧装置能克服其他拉紧装置方式的不足之处,它可以直接关系到带式输送机的安全运行及使用寿命。以往煤矿井下带式输送机一般均采用绞车拉紧或重锤拉紧,然而近年来,人们已发现上述两种拉紧装置对带式输送机正常运行均会产生一些技术和经济方面问题。所以本设计采用液压拉紧装置实现对整个设备的优化。

带式输送机是连续运输机的一种,连续运输机是固定式或运移式起重运输机中主要类型之一,其运输特点是形成装载点到装载点之间的连续物料流,靠连续物料流的整体运动来完成物流从装载点到卸载点的输送。在工业、农业、交通等各企业中,连续运输机是生产过程中组成有节奏的流水作业运输线不可缺少的组成部分,连续运输机可分为:

(1)具有挠性牵引物件的输送机,如带式输送机,板式输送机,刮板输送机,斗式输送机、自动扶梯及架空索道等;

(2)不具有挠性牵引物件的输送机,如螺旋输送机、振动输送机等;

(3)管道输送机(流体输送),如气力输送装置和液力输送管道。

其中带输送机是连续运输机中是使用最广泛的,带式输送机运行可靠,输送量大,输送距离长,维护简便,适应于冶金煤炭,机械电力,轻工,建材,粮食等各个部门。

1.2 带式输送机的分类

带式输送机分类方法有多种,按运输物料的输送带结构可分成两类,一类是普通型带式输送机,这类带式输送机在输送带运输物料的过程中,上带呈槽形,下带呈平形,输送带有托辊托起,输送带外表几何形状均为平面;另外一类是特种结构的带式输送机,各有各的输送特点。

1.3 各种带式输送机的特点

(1)QD80轻型固定式带输送机

QD80轻型固定式带输送机与TDII型相比,其带较薄、载荷也较轻,运距一般不超过100m,电机容量不超过22kw。

(2)

它属于高强度带式输送机,其输送带的带芯中有平行的细钢绳,一台运输机运距可达几公里到几十公里。

(3)U形带式输送机

它又称为槽形带式输送机,其明显特点是将普通带式输送机的槽形托辊角由30°—45°提高到90°使输送带成U形。这样一来输送带与物料间产生挤压,导致物料对胶带的摩擦力增大,从而输送机的运输倾角可达25°。

(4)管形带式输送机

U形带式输送带进一步的成槽,最后形成一个圆管状,即为管形带式输送机,因为输送带被卷成一个圆管,故可以实现闭密输送物料,可明显减轻粉状物料对环境的污染,并且可以实现弯曲运行。

(5)气垫式带输送机

其输送带不是运行在托辊上的,而是在空气膜(气垫)上运行,省去了托辊,用不动的带有气孔的气室盘形槽和气室取代了运行的托辊,运动部件的减少,总的等效质量减少,阻力减小,效率提高,并且运行平稳,可提高带速。但一般其运送物料的块度不超过300mm。增大物流断面的方法除了用托辊把输送带强压成槽形外,也可以改变输送带本身,把输送带的运载面做成垂直边的,并且带有横隔板。一般把垂直侧挡边作成波状,故称为波状带式输送机,这种机型适用于大倾角,倾角在30°以上,最大可达90°。

(6)压带式带输送机

它是用一条辅助带对物料施加压力。这种输送机的主要优点是:输送物料的最大倾角可达90°,运行速度可达6m/s,输送能力不随倾角的变化而变化,可实现松散物料和有毒物料的密闭输送。其主要缺点是结构复杂、输送带的磨损增大和能耗较大。

(7)钢绳牵引带式输送机

它是无际绳运输与带式运输相结合的产物,既具有钢绳的高强度、牵引灵活的特点,又具有带式运输的连续、柔性的优点。

1.4 带式输送机的发展状况

目前带式输送机已广泛应用于国民经经济各个部门,近年来在露天矿和地下矿的联合运输系统中带式输送机又成为重要的组成部分。主要有:钢绳芯带式输送机、钢绳牵引胶带输送机和排弃场的连续输送设施等。

这些输送机的特点是输送能力大(可达30000t/h),适用范围广(可运送矿石,煤炭,岩石和各种粉状物料,特定条件下也可以运人),安全可靠,自动化程度高,设备维护检修容易,爬坡能力大(可达16°),经营费用低,由于缩短运输距离可节省基建投资。

目前,带式输送机的发展趋势是:大运输能力、大带宽、大倾角、增加单机长度和水平转弯,合理使用胶带张力,降低物料输送能耗,清理胶带的最佳方法等。我国已于1978年完成了钢绳芯带式输送机的定型设计。钢绳芯带式输送机的适用范围:

(1)适用于环境温度一般为(°C°C);在寒冷地区驱动站应有采暖设施;

(2)可做水平运输,倾斜向上(16°)和向下(10°12°)运输,也可以转弯运输;运输距离长,单机输送可达15km;

(3)可露天铺设,运输线可设防护罩或设通廊;

(4)输送带伸长率为普通带的1/5左右;其使用寿命比普通胶带长;其成槽性好;运输距离大。

提高传动装置的牵引力可以从以下三个方面考虑:

(1)增大拉紧力。增加初张力可使输送带在传动滚筒分离点的张力增加,此法提高牵引力虽然是可行的。但因增大必须相应地增大输送带断面,这样导致传动装置的结构尺寸加大,是不经济的。故设计时不宜采用。但在运转中由于运输带伸长,张力减小,造成牵引力下降,可以利用拉紧装置适当地增大初张力,从而增大,以提高牵引力。

(2)增加围包角对需要牵引力较大的场合,可采用双滚筒传动,以增大围包角。

(3)增大摩擦系数其具体措施可在传动滚筒上覆盖摩擦系数较大的衬垫,以增大摩擦系数。

通过对上述传动原理的阐述可以看出,增大围包角是增大牵

川公网安备: 51019002004831号

川公网安备: 51019002004831号